ASTM D2444-99(2005)

(Test Method)Standard Test Method for Determination of the Impact Resistance of Thermoplastic Pipe and Fittings by Means of a Tup (Falling Weight)

Standard Test Method for Determination of the Impact Resistance of Thermoplastic Pipe and Fittings by Means of a Tup (Falling Weight)

SIGNIFICANCE AND USE

The impact resistance of thermoplastic pipe and fittings relates to suitability for service and to quality of processing. Impact resistance may also provide a relative measure of a material’resistance to breakage during handling and installation and, for non-buried applications, to in-service breakage. See Appendix X4 for guidelines for selecting testing combinations.

Results obtained by use of this test method can be used in three ways:

3.2.1 As the basis for establishing impact test requirements in product standards,

3.2.2 To measure the effect of changes in materials or processing, and

3.2.3 To measure the effect of the environment.

SCOPE

1.1 This test method covers the determination of the impact resistance of thermoplastic pipe and fittings under specified conditions of impact by means of a tup (falling weight). Three interchangeable striking noses are used on the tup, differing in geometrical configuration. Two specimen holders are described.

1.2 The values stated in inch-pound units are to be regarded as the standard. The values in parentheses are provided for information purposes only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation: D2444 – 99 (Reapproved 2005)

Standard Test Method for

Determination of the Impact Resistance of Thermoplastic

1

Pipe and Fittings by Means of a Tup (Falling Weight)

This standard is issued under the fixed designation D2444; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 3.2.1 As the basis for establishing impact test requirements

in product standards,

1.1 This test method covers the determination of the impact

3.2.2 To measure the effect of changes in materials or

resistance of thermoplastic pipe and fittings under specified

processing, and

conditions of impact by means of a tup (falling weight). Three

3.2.3 To measure the effect of the environment.

interchangeable striking noses are used on the tup, differing in

geometrical configuration. Two specimen holders are de-

4. Apparatus

scribed.

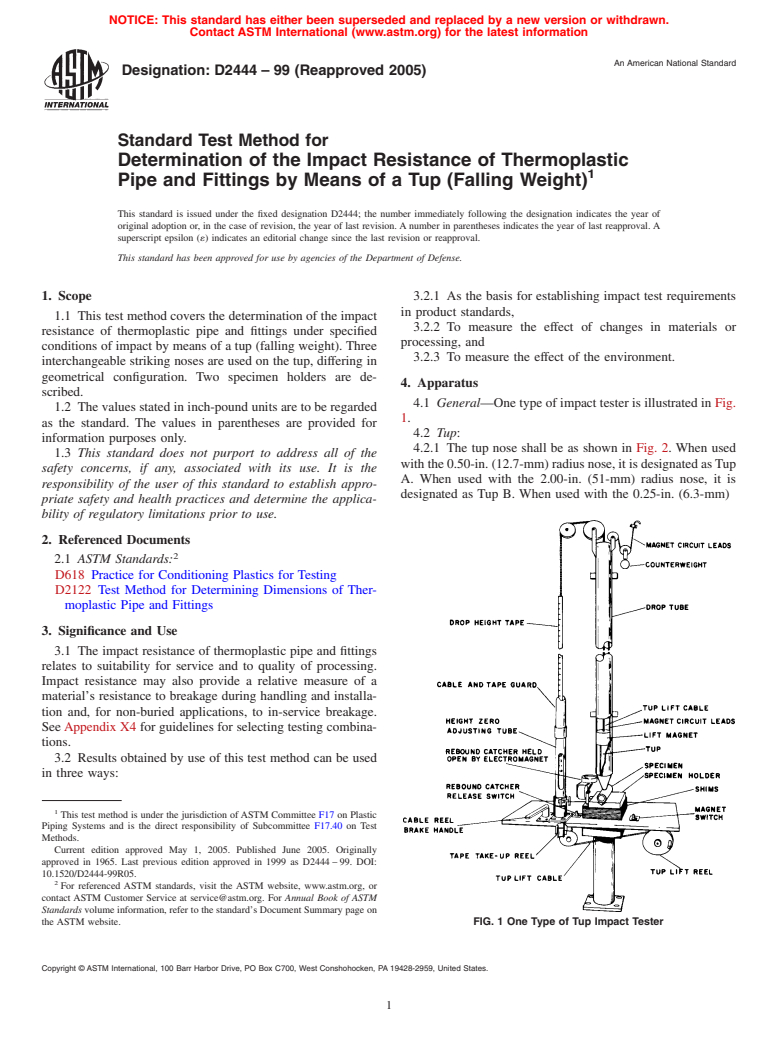

4.1 General—One type of impact tester is illustrated in Fig.

1.2 The values stated in inch-pound units are to be regarded

1.

as the standard. The values in parentheses are provided for

4.2 Tup:

information purposes only.

4.2.1 The tup nose shall be as shown in Fig. 2. When used

1.3 This standard does not purport to address all of the

with the 0.50-in. (12.7-mm) radius nose, it is designated asTup

safety concerns, if any, associated with its use. It is the

A. When used with the 2.00-in. (51-mm) radius nose, it is

responsibility of the user of this standard to establish appro-

designated as Tup B. When used with the 0.25-in. (6.3-mm)

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D618 Practice for Conditioning Plastics for Testing

D2122 Test Method for Determining Dimensions of Ther-

moplastic Pipe and Fittings

3. Significance and Use

3.1 The impact resistance of thermoplastic pipe and fittings

relates to suitability for service and to quality of processing.

Impact resistance may also provide a relative measure of a

material’s resistance to breakage during handling and installa-

tion and, for non-buried applications, to in-service breakage.

SeeAppendix X4 for guidelines for selecting testing combina-

tions.

3.2 Results obtained by use of this test method can be used

in three ways:

1

This test method is under the jurisdiction of ASTM Committee F17 on Plastic

Piping Systems and is the direct responsibility of Subcommittee F17.40 on Test

Methods.

Current edition approved May 1, 2005. Published June 2005. Originally

approved in 1965. Last previous edition approved in 1999 as D2444 – 99. DOI:

10.1520/D2444-99R05.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. FIG. 1 One Type of Tup Impact Tester

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D2444 – 99 (2005)

4.3.3 Means shall be provided (1) to hold the tup at steps of

2 in. (50.8 mm) for a distance of 2 to 10 ft (610 mm to 3.0 m)

above the specimen holder, (2) to release the tup in a

reproducible manner, (3) to allow the tup to fall freely, and (4)

to catch the tup on the first rebound. Refer to Fig. 1.

4.4 Specimen Holder—Two specimen holders are de-

scribed. The V-block (Holder A) is usually used with Tups A

and C; the flat plate (Holder B) is often used with Tup B or for

testing fittings.

4.4.1 The V-block holder shall be at least as long as the

specimen being tested and shall have a 90-deg included angle.

It may be fabricated or of solid construction. The side supports

shallbeofsufficientdepthtosupportthespecimenintheVand

not on the top edges of the V-block.

NOTE 5—Both aluminum and steel have been found suitable for the

holders.

4.4.2 The flat-plate holder shall consist of a plate approxi-

mately 8 by 12 by 1 in. (203 by 305 by 25.4 mm) in which a

groove to position the pipe specimen shall be cut. This groove

shall be about 0.12 in. (3 mm) in depth with the edges rounded

to a radius of about 0.06 in. (1.5 mm). Fittings that do not

contact the plate directly under the point of impact shall be

supported at this point by a flat steel plate or shim. The

specimen holder shall be mounted on a rigid base fastened to

a concrete slab. Means shall be provided to center the speci-

mens under the drop tube. A bar or rod pla

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.