ASTM D3354-96

(Test Method)Standard Test Method for Blocking Load of Plastic Film by the Parallel Plate Method

Standard Test Method for Blocking Load of Plastic Film by the Parallel Plate Method

SCOPE

1.1 This test method yields quantitative information regarding the degree of blocking (unwanted adhesion) existing between layers of plastic film. It is not intended to measure susceptibility to blocking.

1.2 By this procedure, the film-to-film adhesion is expressed as a blocking load in grams which will cause two layers of polyethylene film to separate with an area of contact of 100 cm (16 in). The test is limited to a maximum load of 200 g. See also Test Method D 1893.

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

Note 1- This test method resembles ISO 11502 in title only. The content is significantly different.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 3354 – 96

Standard Test Method for

Blocking Load of Plastic Film by the Parallel Plate Method

This standard is issued under the fixed designation D 3354; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 4. Summary of Test Method

1.1 This test method yields quantitative information regard- 4.1 The load in grams required to separate a specimen of

ing the degree of blocking (unwanted adhesion) existing blocked film is measured by a balance-beam system similar to

between layers of plastic film. It is not intended to measure an analytical balance. One sheet of a blocked specimen is

susceptibility to blocking. secured to an aluminum block suspended from the end of the

1.2 Bythisprocedure,thefilm-to-filmadhesionisexpressed balance beam and the other sheet is secured to an aluminum

as a blocking load in grams which will cause two layers of block fastened to the balance base. Weight is added equivalent

polyethylene film to separate with an area of contact of 100 to90 610g/mtotheothersideofthebeam,untilthetwofilms

cm . The test method is limited to a maximum load of 200 g. just totally separate, or until they reach 1.905-cm separation.

See also Test Method D 1893.

5. Significance and Use

1.3 The values stated in SI units are to be regarded as the

standard. The values given in parentheses are for information 5.1 Blocking develops in film processing and storage. In

most cases the adhesion occurs when touching layers of

only.

1.4 This standard does not purport to address all of the smooth film are in intimate contact with nearly complete

exclusion of air. Adhesion of the touching surfaces is induced

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro- by temperature or pressure, or both.

5.2 The procedure of this test method closely simulates the

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use. operation of separating film in some end-use applications.

NOTE 1—This test method resembles ISO 11502 in title only. The

6. Apparatus

content is significantly different.

6.1 Balance Modification:

2. Referenced Documents 6.1.1 A system found satisfactory in a round robin was to

modify a heavy-duty, two-pan analytical balance sensitive to

2.1 ASTM Standards:

2 0.1 g by replacing one pan with an aluminum block suspended

D 883 Terminology Relating to Plastics

3 over another aluminum block attached to the balance base.

D 1893 Test Method for Blocking of Plastic Film

TheessentialfeaturesofthemodificationarepicturedinFig.1.

E 691 Practice for Conducting an Interlaboratory Study to

4 The hook, rod, and universal joint suspension have a total

Determine the Precision of a Test Method

length that will allow the aluminum blocks to mate when the

2.2 ISO Standard:

5 balance is unlocked and balanced. The mating faces shall be

ISO 11502 Determination of Blocking Resistance

square and 100 6 0.1 mm on each edge with a flat and slightly

3. Terminology knurled or sand-blasted finish of root mean square 125.

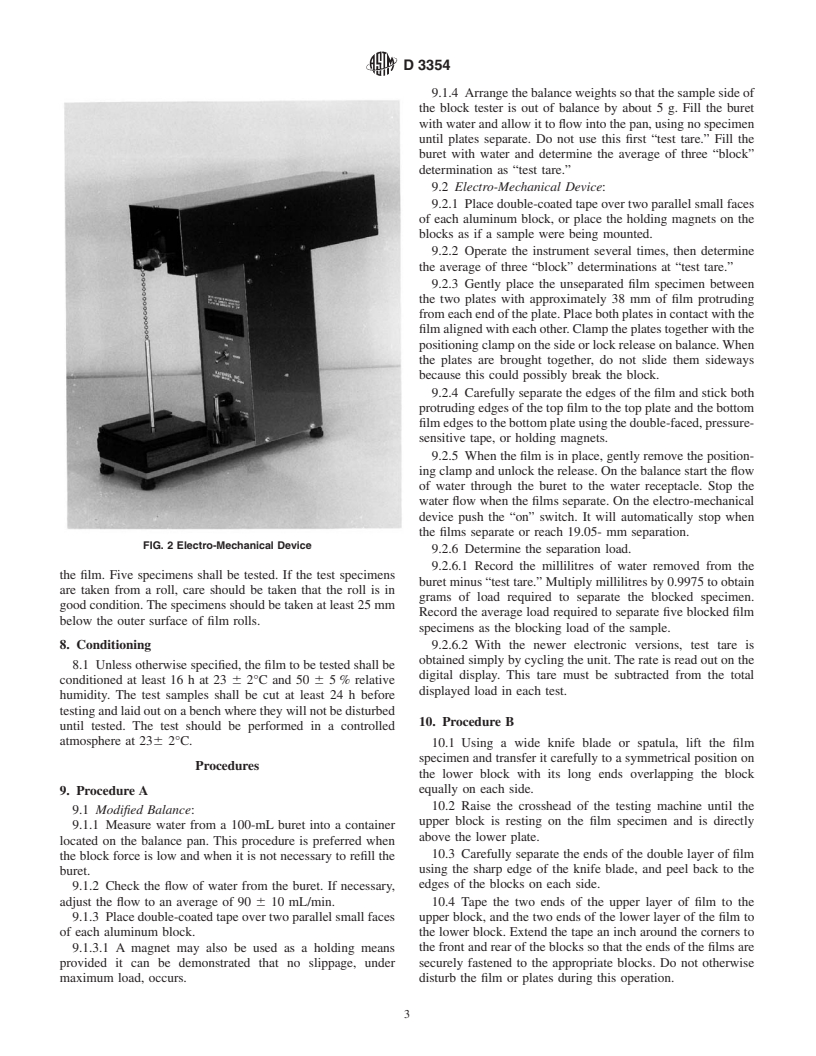

6.2 Electro Mechanical Devices :

3.1 Definitions: For definitions related to plastics, see Ter-

6.2.1 Versions of the same test method have been developed

minology D 883.

which conform to the same test procedure but with different

mechanics.Theunitaddsweightbymovingaweightoutalong

ThistestmethodisunderthejurisdictionofASTMCommitteeD-20onPlastics

a beam at a rate equivalent to the 90-g rate, and instead of

and is the direct responsibility of Subcommittee D20.19 on Film and Sheeting.

weighing the accumulated water, the weight is electronically

Current edition approved Aug. 10, 1996. Published February 1997. Originally

displayed (Fig. 2).

published as D 3354 – 74. Last previous edition D 3354 – 89.

This edition was revised to meet current ASTM format.

Annual Book of ASTM Standards, Vol 08.01.

3 6

Discontinued—See 1990 Annual Book of ASTM Standards, Vol 08.01. TheanalyticbalanceapparatusisavailablefromCustomScientificInstruments,

Annual Book of ASTM Standards, Vol 14.02. Inc., 13 Wing Drive, Cedar Knolls, NJ 07927.

5 7

Available from American National Standards Institute, 11 W. 42nd St., 13th The electro mechanical apparatus is available from Kayeness, Inc., East Main

Floor, New York, NY 10036. St., Honeybrook, PA 19344.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D 3354

FIG. 1 Balance Modification with Buret Assembly

6.2.2 Atypicalstationaryaluminumblockis100 61mm(4 This may be accomplished using a stepper motor with a digital

by 4 in.) and 20 6 0.1 mm thick. If holes are drilled through stepping drive with 60 cycles as its reference control. The

the blocks for mounting they must be countersunk so that the weight-addition rate must be equivalent to the 90 6 10

head of the fastener is below the surface of the block. mL/min.

Back-mounting tapped holes are preferred to leave a smooth 6.4 Constant Rate of Separation Testing Device—A pair of

surface. aluminum blocks 100 by 100 6 1 mm and 75 6 0.1 mm thick

6.2.3 A means must be provided to clamp the two blocks with appropriate adapters for mounting in a universal testing

firmly together. However, the clamp must not close with machine (see Fig. 3).

enough force to cause the films to block. 6.5 Accessory Equipment—Necessary accessories may in-

6.3 Water Supply—Water is measured from a 100-mL buret clude a 100 by 180-mm template, double-faced pressure-

intoacontainerrestingonthebalancepan.Theburetshouldbe sensitive tape, a stopwatch, and a balance sensitive to 0.1 g.

of the bottom-loading, three-way-stopcock type adjusted to

7. Test Specimens

deliver90 610mLofwaterin1min(SeeFig.1).Othermeans

such as constant-volume pumps for adding water to this 7.1 Cut block test specimens with a 100 by 180-mm

container may be used if the rate of flow is 90 6 10 mL/min. template with the longer length being in the machine direction.

6.3.1 An alternate method of adding weight is to move a Due to variations in gage and blocking tendencies, it is

weight axially along the beam with a precision-drive system. desirable to select several sample locations across the width of

D 3354

9.1.4 Arrange the balance weights so that the sample side of

the block tester is out of balance by about 5 g. Fill the buret

with water and allow it to flow into the pan, using no specimen

until plates separate. Do not use this first “test tare.” Fill the

buret with water and determine the average of three “block”

determination as “test tare.”

9.2 Electro-Mechanical Device:

9.2.1 Place double-coated tape over two parallel small faces

of each aluminum block, or place the holding magnets on the

blocks as if a sample were being mounted.

9.2.2 Operate the instrument several times, then determine

the average of three “block” determinations at “test tare.”

9.2.3 Gently place the unseparated film specimen between

the two plates with approximately 38 mm of film protruding

fromeachendoftheplate.Placebothplatesincontactwiththe

filmalignedwitheachother.Clamptheplatestogetherwiththe

positioning clamp on the side or lock release on balance.When

the plates are brought together, do not slide them sideways

because this could possibly break the block.

9.2.4 Carefully separate the edges of the film and stick both

protruding edges of the top film to the top plate and the bottom

filmedgestothebottomplateusingthedouble-faced,pressure-

sensitive tape, or holding magnets.

9.2.5 When the film is in place, gently remove the position-

ing clamp and unlock the release. On the balance start the flow

of water through the buret to the water receptacle. Stop the

water flow when the films separate. On the electro-mechanical

device push the “on” switch. It will automatically stop when

the films separate or reach 19.05- mm separation.

FIG. 2 Electro-Mechanical Device

9.2.6 Determine the separation load.

9.2.6.1 R

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.