ASTM B947-14(2020)e1

(Practice)Standard Practice for Hot Rolling Mill Solution Heat Treatment for Aluminum Alloy Plate

Standard Practice for Hot Rolling Mill Solution Heat Treatment for Aluminum Alloy Plate

ABSTRACT

This practice covers hot rolling solution heat treatment for aluminum alloy plate. Aluminum alloy ingots or rolling slabs are preheated prior to being hot rolled. Controls shall be adequate to ensure that the equipment is operated in a manner which precludes overheating of the ingot or rolling slab or deleterious contamination by the furnace environment. Metal temperature shall be monitored and controlled to not exceed the maximum temperature prescribed. Non-contact sensors shall be calibrated prior to initial use by an ISO 17025 or A2LA. Noncontact sensors must be compared weekly under operating conditions and temperature to the SAT test instrument/sensor. The accuracy of temperature measuring system(s) shall be tested under operating conditions at least once during each week that the facility is used. For continuous or batch furnaces, the type of survey and procedures for performing the survey shall be established and documented for each particular furnace or furnace type involved. The hot rolling mill solution heat treatment procedures are presented in details. The mechanical properties shall be determined in accordance with test method B557 or B557M. Tensile tests shall be representative of the thinnest and the thickest material to be heat treated; intermediate thickness samples shall be included when necessary to ensure proper production hot rolling mill solution heat treatment. Whenever any qualified equipment is changed or reworked, it shall be requalified unless it is known that the change or rework will not have a detrimental effect upon the properties of products.

SCOPE

1.1 This practice establishes the controls required for hot rolling mill solution heat treatment of the 6xxx series aluminum alloy plate in Table 1 when ASTM material specifications allow use of this process instead of furnace solution heat treatment. For the alloys listed in Table 1, this practice is an alternate process to solution heat treatment in a furnace, such as specified in Practice B918/B918M as the preliminary step for the attainment of T651-type tempers (see ANSI H35.1/H35.1M).

1.2 This practice applies only to hot rolling mill solution heat treatment of plate for the listed aluminum alloys. Precipitation hardening (aging), processing, and equipment calibration for aging shall meet the practice and requirements of Practice B918/B918M.

1.3 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system are not necessarily exact equivalents; therefore, to ensure conformance with the standard, each system shall be used independently of the other, and values from the two systems shall not be combined.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

´1

Designation: B947 − 14 (Reapproved 2020)

Standard Practice for

Hot Rolling Mill Solution Heat Treatment for Aluminum Alloy

Plate

This standard is issued under the fixed designation B947; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

ε NOTE—Warning moved from previous Note 2 to 5.3 editorially in September 2020.

1. Scope 2. Referenced Documents

2.1 The following documents of the issue in effect on the

1.1 This practice establishes the controls required for hot

date of material purchase form a part of this specification to the

rolling mill solution heat treatment of the 6xxx series alumi-

extent referenced herein:

num alloy plate in Table 1 whenASTM material specifications

allow use of this process instead of furnace solution heat

2.2 ASTM Standards:

treatment. For the alloys listed in Table 1, this practice is an

B209 Specification for Aluminum and Aluminum-Alloy

alternate process to solution heat treatment in a furnace, such

Sheet and Plate

as specified in Practice B918/B918M as the preliminary step

B209M Specification for Aluminum and Aluminum-Alloy

for the attainment of T651-type tempers (see ANSI H35.1/

Sheet and Plate (Metric)

H35.1M).

B557 Test Methods for Tension Testing Wrought and Cast

Aluminum- and Magnesium-Alloy Products

1.2 This practice applies only to hot rolling mill solution

B557M Test Methods for Tension Testing Wrought and Cast

heat treatment of plate for the listed aluminum alloys. Precipi-

Aluminum- and Magnesium-Alloy Products (Metric)

tationhardening(aging),processing,andequipmentcalibration

B881 Terminology Relating toAluminum- and Magnesium-

for aging shall meet the practice and requirements of Practice

Alloy Products

B918/B918M.

B918/B918M Practice for Heat Treatment of Wrought Alu-

1.3 The values stated in either SI units or inch-pound units

minum Alloys

are to be regarded separately as standard. The values stated in

E2281 Practice for Process Capability and Performance

each system are not necessarily exact equivalents; therefore, to

Measurement

ensure conformance with the standard, each system shall be 2

2.3 ASTM Manual:

used independently of the other, and values from the two

ASTM MNL7 Manual on Presentation of Data and Control

systems shall not be combined.

Chart Analysis

1.4 This standard does not purport to address all of the

2.4 ANSI Standard:

safety concerns, if any, associated with its use. It is the

H35.1/H35.1M Alloy and Temper Designation Systems for

responsibility of the user of this standard to establish appro-

Aluminum

priate safety, health, and environmental practices and deter-

2.5 European Standard:

mine the applicability of regulatory limitations prior to use.

EN 485-2 Aluminium and Aluminium Alloys—Sheet, Strip

1.5 This international standard was developed in accor-

And Plate—Part 2: Mechanical Properties

dance with internationally recognized principles on standard-

ization established in the Decision on Principles for the

3. Terminology

Development of International Standards, Guides and Recom-

3.1 Definitions:

mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

This practice is under the jurisdiction of ASTM Committee B07 on Light Standards volume information, refer to the standard’s Document Summary page on

Metals and Alloys and is the direct responsibility of Subcommittee B07.03 on the ASTM website.

Aluminum Alloy Wrought Products. Available from American National Standards Institute (ANSI), 25 W. 43rd St.,

Current edition approved Dec. 1, 2014. Published September 2020. Originally 4th Floor, New York, NY 10036, http://www.ansi.org.

approved in 2006. Last previous edition approved in 2014 as B947 – 14. DOI: Available from European Committee for Standardization (CEN), Avenue

10.1520/B0947-14R20. Marnix 17, B-1000, Brussels, Belgium, http://www.cen.eu.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

B947 − 14 (2020)

A

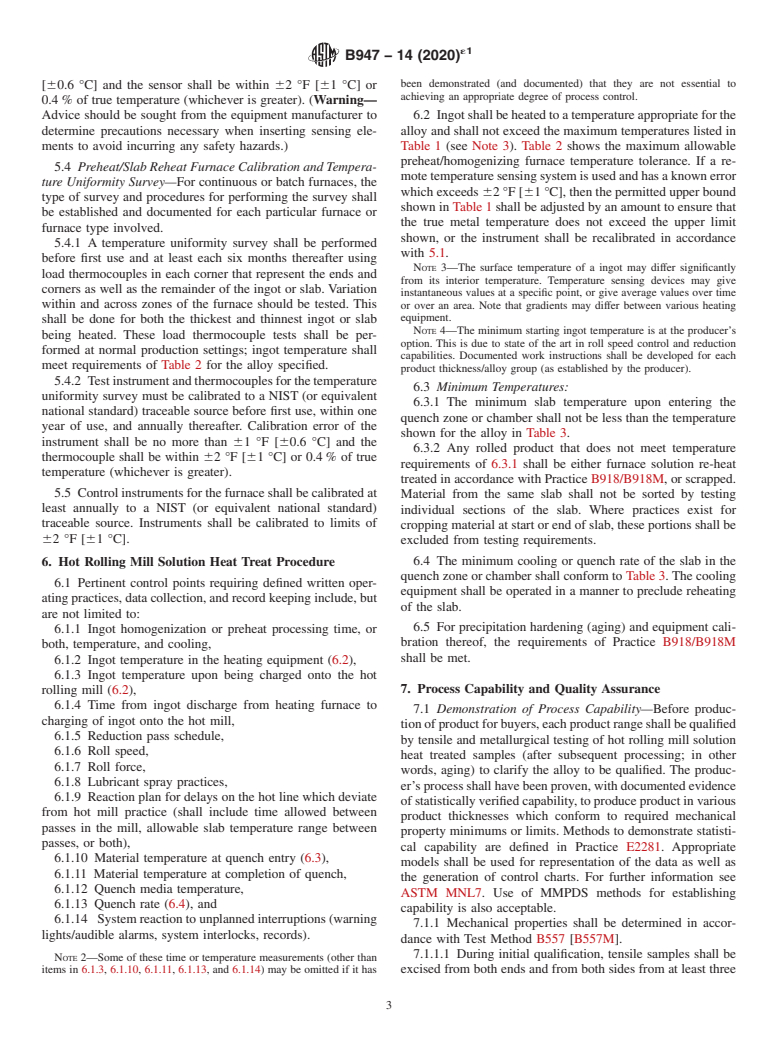

TABLE 1 Ingot High Limit Temperature TABLE 3 Minimum Temperature Entering Quench and Cooling

A,B

Rate in Quench Zone

Ingot Upper Limit Temperature

Alloy

°F [°C]

Min Temp Entering Quench Min Cooling Rate

Alloy

°F [°C] °F/min [°C/min]

6061 1067 [575]

A 6061 870 [466] 600 [316]

These upper limit temperatures avoid the possibility of eutectic melting due to

A

overheating, and include a safety margin of approximately 13 °F [7 °C].

The cooling rate is defined as the average temperature drop per unit of time

when subjected to a constant cooling system from initial slab temperature, down to

400 °F [205 °C], forced cooling allowed at a reduced rate down to 350 °F [175 °C],

and cooling continuing to ambient.

B

These minimum temperatures and cooling rates may be altered when statistical

analysis of mechanical property test data substantiates that the material will meet

3.1.1 For definitions of terms used in this practice, refer to

the tensile property requirements of 7.1 and other required material characteristics

Terminology B881.

such as corrosion resistance.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 load sensor or load thermocouple, n—sensors that are

attached to the production material or a representation of

5. Equipment Calibration and System Accuracy Tests

production material, that supply temperature data of the pro-

(SAT)

duction material to process or test instrumentation.

5.1 Non-contact Sensor System (Remote Sensing System)

3.2.2 rolling slab, n—semi-finished or intermediate product

Calibration and SAT:

produced by hot rolling which is between ingot and plate form.

5.1.1 Initial Calibration—Non-contact sensors shall be cali-

brated prior to initial use by an ISO 17025 orA2LA(American

4. Equipment

Association for Laboratory Accreditation) certified laboratory.

4.1 Aluminum alloy ingots or rolling slabs are preheated It may also be certified by the manufacturer if their calibration

prior to being hot rolled as prescribed in 6.2. Controls shall be process is traceable to NIST or national equivalent. Initial

adequate to ensure that the equipment is operated in a manner calibration shall be within 66°F[63 °C].

which precludes overheating of the ingot or rolling slab or 5.1.2 SAT—Noncontact sensors must be compared weekly

deleterious contamination by the furnace environment. Metal under operating conditions and temperature to the SAT test

temperature shall be monitored and controlled to not exceed

instrument/sensor (5.3); test sensor must be in contact with the

the maximum temperature shown in Table 1 prior to hot ingot, hot rolled slab, or plate within 3 in. [75 mm] of the focus

rolling.

point of the noncontact sensor (see 5.3).The noncontact sensor

must read within 62°F[61 °C] of the contact pyrometry

NOTE 1—Some aspects of the metallurgical structure of the alloy after

system; if not, the noncontact sensor system must be adjusted

solution heat treatment are influenced by the thermal characteristics of the

toreadwithinthestatedtoleranceoranoffsetinoperationmust

heatingequipmentused,andthestartingmicrostructureoftheingot.Some

heating equipment achieves very rapid temperature rise and may require

be used to account for the variation and may then be used for

the metal to be soaked for a period to ensure that sufficient applicable

production.

alloying elements are taken into solid solution. This soaking stage may be

minimized if the alloying elements are substantially in solid solution prior 5.2 Temperature Measuring System Accuracy Test (SAT) for

to charging the metal to the heating equipment (this being accomplished

Contact Systems:

by sufficient prior homogenization/cooling practices).

5.2.1 SAT—The accuracy of temperature measuring sys-

4.1.1 Automatic or manual control and recording devices

tem(s) shall be tested under operating conditions at least once

used to measure temperature at pertinent points in the heating

during each week that the facility is used. The test should be

equipment shall be calibrated as specified in 5.1 and 5.2. Table

made by placing a calibrated test temperature sensing element

2 shows preheat/homogenizing furnace temperature tolerance.

(5.3) to make contact with the surface (ingot, hot rolled slab, or

plate) being measured within 3 in. [75 mm] of the system’s

4.2 The hot rolling and quench equipment and controls shall

sensing element and reading the test temperature sensing

beadequatetoensurethatingotsarecapableofbeinghotrolled

element with a calibrated test potentiometer (see 5.3). The

in accordance with the process requirements for the products

contact system must read within 62°F[61 °C] of the test

being produced, as prescribed in 6.3 and 6.4.

instrument.Ifnot,thecontactsystemshallbecalibratedtoread

4.3 Equipmentforquenchingthehotrolledslabmayconsist

within the stated tolerance or an offset in operation shall be

of, but is not limited to, water or water/glycol mixture in a

used to account for the variation. Once the adjustment or offset

standingwave,quenchtank,spray,orpressurizedwaterdevice.

is in use, the system may then be used for production. When

Controls shall be adequate to assure that the equipment is

the system is equipped with dual potentiometer measuring

operated in a manner which achieves the required quench

systems which are checked daily against each other and agree

conditions in Table 3.

within 62°F[61 °C], the above checks and corrections shall

be conducted at least once every three months.

5.3 Test Instrument/Sensor for SAT—The contact pyrometer

TABLE 2 Homogenization and Pre-heat Furnace

thermocouple(sensor)andtestinstrumentmustbecalibratedto

Temperature Tolerance

a NIST (or equivalent national standard) traceable source

Pre-heat Oven Temperature Range

Alloy

before first use and calibrated within three months of use and

°F [°C]

recalibrated every three months thereafter when used. Calibra-

6061 ±15 [±8]

tion error of the instrument shall be no more than 61°F

´1

B947 − 14 (2020)

been demonstrated (and documented) that they are not essential to

[60.6 °C] and the sensor shall be within 62°F[61 °C] or

achieving an appropriate degree of process control.

0.4 % of true temperature (whichever is greater). (Warning—

Advice should be sought from the equipment manufacturer to 6.2 Ingotshallbeheatedtoatemperatureappropriateforthe

determine precautions necessary when inserting sensing ele- alloy and shall not exceed the maximum temperatures listed in

ments to avoid incurring any safety hazards.) Table 1 (see Note 3). Table 2 shows the maximum allowable

preheat/homogenizing furnace temperature tolerance. If a re-

5.4 Preheat/Slab Reheat Furnace Calibration and Tempera-

motetemperaturesensingsystemisusedandhasaknownerror

ture Uniformity Survey—For continuous or batch furnaces, the

which exceeds 62°F[61 °C], then the permitted upper bound

type of survey and procedures for performing the survey shall

shown in Table 1 shall be adjusted by an amount to ensure that

be established and documented for each particular furnace or

the true metal temperature does not exceed the upper limit

furnace type involved.

shown, or the instrument shall be recalibrated in accordance

5.4.1 A temperature uniformity survey shall be performed

with 5.1.

before first use and at least each six months thereafter using

NOTE 3—The surface temperature of a ingot may differ significantly

load thermocouples in each corner that represent the ends and

from its interior temperature. Temperature sensing devices may give

corners as well as the remainder of the ingot or slab. Variation

instantaneous values at a specific point, or give average values over time

within and across zones of the furnace should be tested. This or over an area. Note that gradients may differ between various heating

equipment.

shall be done for both the thickest and thinnest ingot or slab

NOTE 4—The minimum starting ingot temperature is at the producer’s

being heated. These load thermocouple tests shall be per-

option. This is due to state of the art in roll speed control and reduction

formed at normal production settings; ingot temperature shall

capabilities. Documented work instructions shall be developed for each

meet requirements of Table 2 for the alloy specified.

product thickness/alloy group (as established by the producer).

5.4.2 Testinstrumentandthermocouplesforthetemperature

6.3 Minimum Temperatures:

uniformity survey must be calibrated to a NIST (or equivalent

6.3.1 The minimum slab temperature upon entering the

national standard) traceable source before first use, within one

quench zone or chamber shall not be less than the temperature

year of use, and annually thereafter. Calibration error of the

shown for the alloy in Table 3.

instrument shall be no more than 61°F[60.6 °C] and the

6.3.2 Any rolled product that does not meet temperature

thermocouple shall be within 62°F[61 °C] or 0.4 % of true

requirements of 6.3.1 shall be either furnace solution re-heat

temperature (whichever is greater).

treated in accordance with Practice B918/B918M, or scrapped.

5.5 Control instruments for the furnace shall be calibrated at

Material from the same slab shall not be sorted by testing

least annually to a NIST (or equivalent national standard)

individual sections of the slab. Where practices exist for

traceable source. Instruments shall be calibrated to limits of

cropping material at start or end of slab, these portions shall be

62°F[61 °C].

excluded from testing requirements.

6.4 The minimum cooling or quench rate of the slab in the

6. Hot Rolling Mill Solution Heat Treat Procedure

quench zone or chamber shall conform to Table 3. The cooling

6.1 Pertinent control points requiring defined written oper-

equipment shall be operated in a manner to preclude reheating

ating practices, data collection, and record keeping include, but

of the slab.

are not limited to:

6.5 For precipitation hardening (aging) and equipment cali-

6.1.1 Ingot homogenization or preheat processing time, or

bration thereof, the requirements of Practice B918/B918M

both, temperature, and cooling,

shall be met.

6.1.2 Ingot temperature in the heating equipment (6.2),

6.1.3 Ingot temperature upon being charged onto the hot

7. Process Capability and Quality Assurance

rolling mill

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.