ASTM D1838-91(1996)e2

(Test Method)Standard Test Method for Copper Strip Corrosion by Liquefied Petroleum (LP) Gases

Standard Test Method for Copper Strip Corrosion by Liquefied Petroleum (LP) Gases

SCOPE

1.1 This test method detects the presence of components in liquefied petroleum gases which may be corrosive to copper.

Note 1-For an equivalent copper strip test applicable to less volatile petroleum products, see Test Method D130.

1.2 The values stated in acceptable metric units are to be regarded as the standard. The values in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific hazard statements, see 6.1, 8.3.1, and Annex A1.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

e2

Designation: D 1838 – 91 (Reapproved 1996) An American National Standard

Standard Test Method for

Copper Strip Corrosion by Liquefied Petroleum (LP) Gases

This standard is issued under the fixed designation D 1838; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

e NOTE—Editorial changes were made throughout in January 1996.

e NOTE—This designation was corrected in November 1996.

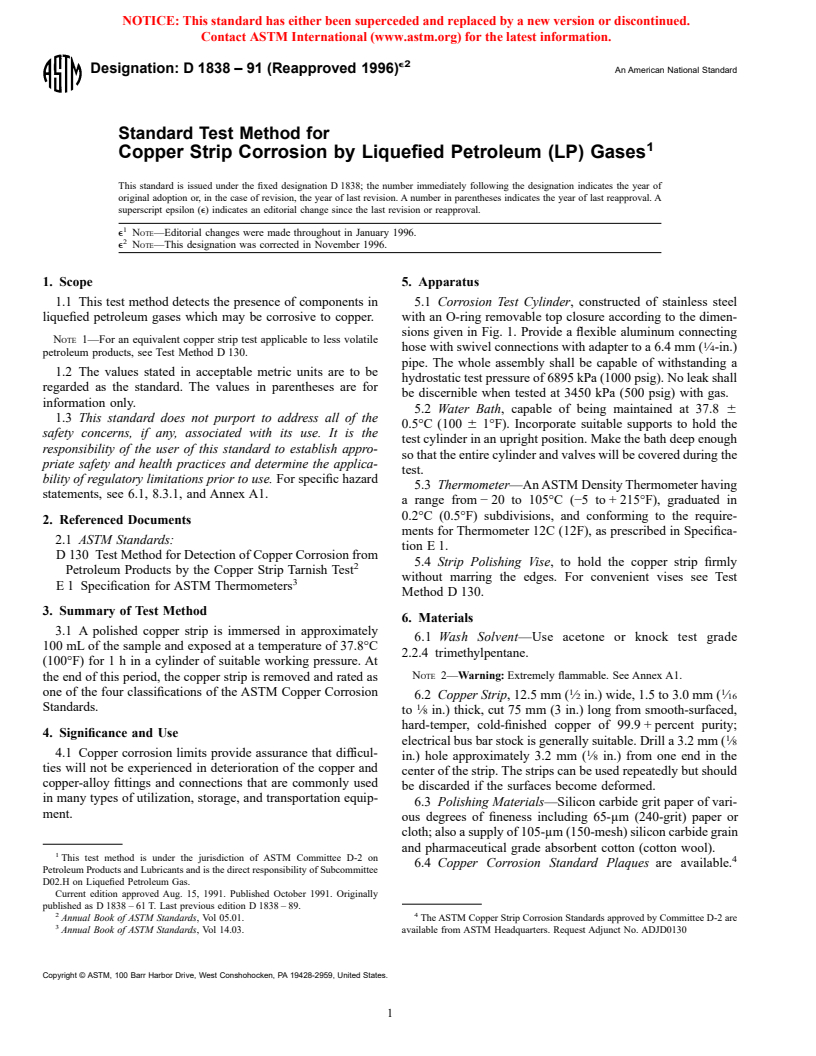

1. Scope 5. Apparatus

1.1 This test method detects the presence of components in 5.1 Corrosion Test Cylinder, constructed of stainless steel

liquefied petroleum gases which may be corrosive to copper. with an O-ring removable top closure according to the dimen-

sions given in Fig. 1. Provide a flexible aluminum connecting

NOTE 1—For an equivalent copper strip test applicable to less volatile

hose with swivel connections with adapter to a 6.4 mm ( ⁄4-in.)

petroleum products, see Test Method D 130.

pipe. The whole assembly shall be capable of withstanding a

1.2 The values stated in acceptable metric units are to be

hydrostatic test pressure of 6895 kPa (1000 psig). No leak shall

regarded as the standard. The values in parentheses are for

be discernible when tested at 3450 kPa (500 psig) with gas.

information only.

5.2 Water Bath, capable of being maintained at 37.8 6

1.3 This standard does not purport to address all of the

0.5°C (100 6 1°F). Incorporate suitable supports to hold the

safety concerns, if any, associated with its use. It is the

test cylinder in an upright position. Make the bath deep enough

responsibility of the user of this standard to establish appro-

so that the entire cylinder and valves will be covered during the

priate safety and health practices and determine the applica-

test.

bility of regulatory limitations prior to use. For specific hazard

5.3 Thermometer—An ASTM Density Thermometer having

statements, see 6.1, 8.3.1, and Annex A1.

a range from − 20 to 105°C (−5 to + 215°F), graduated in

0.2°C (0.5°F) subdivisions, and conforming to the require-

2. Referenced Documents

ments for Thermometer 12C (12F), as prescribed in Specifica-

2.1 ASTM Standards:

tion E 1.

D 130 Test Method for Detection of Copper Corrosion from

5.4 Strip Polishing Vise, to hold the copper strip firmly

Petroleum Products by the Copper Strip Tarnish Test

without marring the edges. For convenient vises see Test

E 1 Specification for ASTM Thermometers

Method D 130.

3. Summary of Test Method

6. Materials

3.1 A polished copper strip is immersed in approximately

6.1 Wash Solvent—Use acetone or knock test grade

100 mL of the sample and exposed at a temperature of 37.8°C

2.2.4 trimethylpentane.

(100°F) for1hina cylinder of suitable working pressure. At

NOTE 2—Warning: Extremely flammable. See Annex A1.

the end of this period, the copper strip is removed and rated as

one of the four classifications of the ASTM Copper Corrosion 1 1

6.2 Copper Strip, 12.5 mm ( ⁄2 in.) wide, 1.5 to 3.0 mm ( ⁄16

Standards.

to ⁄8 in.) thick, cut 75 mm (3 in.) long from smooth-surfaced,

hard-temper, cold-finished copper of 99.9 + percent purity;

4. Significance and Use

electrical bus bar stock is generally suitable. Drill a 3.2 mm ( ⁄8

4.1 Copper corrosion limits provide assurance that difficul- 1

in.) hole approximately 3.2 mm ( ⁄8 in.) from one end in the

ties will not be experienced in deterioration of the copper and

center of the strip. The strips can be used repeatedly but should

copper-alloy fittings and connections that are commonly used

be discarded if the surfaces become deformed.

in many types of utilization, storage, and transportation equip-

6.3 Polishing Materials—Silicon carbide grit paper of vari-

ment.

ous degrees of fineness including 65-μm (240-grit) paper or

cloth; also a supply of 105-μm (150-mesh) silicon carbide grain

and pharmaceutical grade absorbent cotton (cotton wool).

This test method is under the jurisdiction of ASTM Committee D-2 on

6.4 Copper Corrosion Standard Plaques are available.

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

D02.H on Liquefied Petroleum Gas.

Current edition approved Aug. 15, 1991. Published October 1991. Originally

published as D 1838 – 61 T. Last previous edition D 1838 – 89.

2 4

Annual Book of ASTM Standards, Vol 05.01. The ASTM Copper Strip Corrosion Standards approved by Committee D-2 are

Annual Book of ASTM Standards, Vol 14.03. available from ASTM Headquarters. Request Adjunct No. ADJD0130

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D 1838

bent cotton. Rub in the direction of the long axis of the strip,

carrying the stroke beyond the end of the strip before reversing

the direction. Clean all metal dust from the strip by rubbing

vigorously with clean pads of absorbent cotton until a fresh pad

remains unsoiled. When the strip is clean immediately attach to

the dip tube and immerse it in the prepared test bomb.

7.2.1 It is important to polish the whole surface of the strip

uniformly to obtain a uniformly stained strip. If the edges show

wear (surface elliptical) they will likely show more corrosion

than the center. The use of a vise will facilitate uniform

polishing.

8. Procedure

8.1 With valve B (Fig. 1), open, place approximately 1 mL

of distilled water into a clean test cylinder and swirl to moisten

the walls; allow the remainder to drain from the cylinder, insert

the freshly polished copper strip suspended from the hook on

the dip tube making sure that the bottom of the strip is at least

6.4 mm ( ⁄4 in.) from the bottom of the cylinder when

assembled. After assembly of the apparatus, close both valve A

(Fig. 1), on closure assembly with outage tube, and valve B.

8.2 Holding the test cylinder upright so as not to wet the

copper strip with water, attach the sample source to the test

cylinder valve A (Fig. 1) by means of a short length of flexible

aluminum tubing that has been purged with the sample. Admit

Metric Equivalents

in. mm in. mm some sample to the cylinder by opening the valve at the sample

⁄8 3.2 3 76

source and then valve A.

⁄4 6.4

8.3 Close valve A without disconnecting the test cylinder

1 ⁄2 38.1 6 152

from the sample source. Invert the test cylinder and open valve

FIG. 1 Copper Strip Corrosion Test Cylinder

B to purge the air from the test cylinder. Return the test

cylinder to the upright position and drain any residual liquid

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.