ASTM E1434-00(2013)

(Guide)Standard Guide for Recording Mechanical Test Data of Fiber-Reinforced Composite Materials in Databases (Withdrawn 2015)

Standard Guide for Recording Mechanical Test Data of Fiber-Reinforced Composite Materials in Databases (Withdrawn 2015)

SIGNIFICANCE AND USE

4.1 This guide provides recommended standard formats for the computerization of mechanical test data for a range of test methods for high-modulus fiber-reinforced composite materials. The types of mechanical tests considered are tension, compression, shear, flexure, open/filled hole, bearing, fracture toughness, and fatigue. The ASTM standards for which this guide was developed are listed in 2.1. The recommended formats are not limited in use to these test methods. There are other test methods for which these recommended formats may be useful.

4.2 Comparison of data from various sources will be most meaningful if all of the elements are available.

4.3 The intent is to provide sufficient detail that values are known for the testing variables that may influence the results. The motivation for this guide is the steadily increasing use of computerized databases. However, this guide is equally appropriate for data stored in a hard-copy form.

4.4 This format is for mechanical test data for high-modulus fiber-reinforced composites only. It does not include the recommended material description or the presentation of other specific types of test data (such as fracture toughness test results). These items are covered by separate formats to be referenced in material specifications or other test standards.

SCOPE

1.1 This guide provides a common format for mechanical test data for composite materials for two purposes: (1) to establish data reporting requirements for test methods and (2) to provide information for the design of material property databases. This guide should be used in combination with Guide E1309 which provides similar information to identify the composite material tested.

1.2 These guidelines are specific to mechanical tests of high-modulus fiber-reinforced composite materials. Types of tests considered in this guide include tension, compression, shear, flexure, open/filled hole,2 bearing, fracture toughness, and fatigue. The ASTM standards for which this guide was developed are listed in 2.1. The guidelines may also be useful for additional tests or materials.

1.3 This guide is the second part of a modular approach for which the first part is Guide E1309. Guide E1309 serves to identify the material, and this guide serves to describe mechanical testing procedures and variables and to record results. The interaction of this guide with Guide E1309 is emphasized by the common numbering of data elements. Data Elements A1 through G13 are included in Guide E1309 and numbering data elements in this guide begins with H1.

1.4 This guide with Guide E1309 may be referenced by the data-reporting section of a test method to provide common data-reporting requirements for the types of tests listed in 1.2.

1.5 From this information and Guide E1309, the database designer should be able to construct the data dictionary preparatory to developing a database schema.

1.6 Data elements in this guide are relevant to test data, data as obtained in the test laboratory and historically recorded in lab notebooks. Property data, data which have been analyzed and reviewed, require a different level of data elements. Data elements for property data are provided in Annex A1.

WITHDRAWN RATIONALE

This guide provides a common format for mechanical test data for composite materials for two purposes: (1) to establish data reporting requirements for test methods and (2) to provide information for the design of material property databases. This guide should be used in combination with Guide E1309 which provides similar information to identify the composite material tested.

Formerly under the jurisdiction of Committee D30 on Composite Materials, this guide was withdrawn in August 2015. This standard is being withdrawn without replacement due to its limited use by industry.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E1434 − 00(Reapproved 2013)

Standard Guide for

Recording Mechanical Test Data of Fiber-Reinforced

Composite Materials in Databases

This standard is issued under the fixed designation E1434; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope and reviewed, require a different level of data elements. Data

elements for property data are provided in Annex A1.

1.1 This guide provides a common format for mechanical

test data for composite materials for two purposes: (1)to

2. Referenced Documents

establish data reporting requirements for test methods and (2)

2.1 ASTM Standards:

to provide information for the design of material property

D790 Test Methods for Flexural Properties of Unreinforced

databases. This guide should be used in combination with

and Reinforced Plastics and Electrical Insulating Materi-

Guide E1309 which provides similar information to identify

als

the composite material tested.

D3039/D3039M Test Method forTensile Properties of Poly-

1.2 These guidelines are specific to mechanical tests of

mer Matrix Composite Materials

high-modulus fiber-reinforced composite materials. Types of

D3410/D3410M Test Method for Compressive Properties of

tests considered in this guide include tension, compression,

Polymer Matrix Composite Materials with Unsupported

shear, flexure, open/filled hole, bearing, fracture toughness,

Gage Section by Shear Loading

and fatigue. The ASTM standards for which this guide was

D3518/D3518M Test Method for In-Plane Shear Response

developed are listed in 2.1. The guidelines may also be useful

ofPolymerMatrixCompositeMaterialsbyTensileTestof

for additional tests or materials.

a 645° Laminate

1.3 This guide is the second part of a modular approach for

D3552 Test Method for Tensile Properties of Fiber Rein-

which the first part is Guide E1309. Guide E1309 serves to forced Metal Matrix Composites

identify the material, and this guide serves to describe me-

D3878 Terminology for Composite Materials

chanical testing procedures and variables and to record results. D5229/D5229M TestMethodforMoistureAbsorptionProp-

The interaction of this guide with Guide E1309 is emphasized

erties and Equilibrium Conditioning of Polymer Matrix

bythecommonnumberingofdataelements.DataElementsA1

Composite Materials

through G13 are included in Guide E1309 and numbering data D5379/D5379M Test Method for Shear Properties of Com-

elements in this guide begins with H1.

posite Materials by the V-Notched Beam Method

D5449/D5449M Test Method for Transverse Compressive

1.4 This guide with Guide E1309 may be referenced by the

Properties of Hoop Wound Polymer Matrix Composite

data-reporting section of a test method to provide common

Cylinders

data-reporting requirements for the types of tests listed in 1.2.

D5528 TestMethodforModeIInterlaminarFractureTough-

1.5 From this information and Guide E1309, the database

ness of Unidirectional Fiber-Reinforced Polymer Matrix

designer should be able to construct the data dictionary

Composites

preparatory to developing a database schema.

D5961/D5961M Test Method for Bearing Response of Poly-

1.6 Dataelementsinthisguidearerelevanttotestdata,data mer Matrix Composite Laminates

as obtained in the test laboratory and historically recorded in D6115 Test Method for Mode I Fatigue Delamination

lab notebooks. Property data, data which have been analyzed Growth Onset of Unidirectional Fiber-Reinforced Poly-

mer Matrix Composites

E6 Terminology Relating to Methods of Mechanical Testing

E111 Test Method for Young’s Modulus, Tangent Modulus,

This guide is under the jurisdiction of ASTM Committee D30 on Composite

and Chord Modulus

Materials and is the direct responsibility of Subcommittee D30.01 on Editorial and

Resource Standards.

Current edition approved May 1, 2013. Published May 2013. Originally

approved in 1991. Last previous edition approved in 2006 as E1434 – 00 (2006). For referenced ASTM standards, visit the ASTM website, www.astm.org, or

DOI: 10.1520/E1434-00R13. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Documentation requirements for filled-hole tests were based on open-hole tests Standards volume information, refer to the standard’s Document Summary page on

with the addition of fastener identification and application information. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E1434 − 00 (2013)

E1309 Guide for Identification of Fiber-Reinforced database for the possible collection of all sentences that are in

Polymer-Matrix Composite Materials in Databases the conceptual schema and in the information base, including

E1013 Terminology Relating to Computerized Systems manipulation aspects of these forms. (ANSI X3.172)

(Withdrawn 2000)

3.2.5 essential data element—adataelementinarecordthat

E1443 Terminology Relating to Building and Accessing

must be completed to make the record meaningful in accor-

Material and Chemical Databases (Withdrawn 2000)

dance with the pertinent guidelines or standard. (E1443)

E1484 Guide for Formatting and Use of Material and

3.2.5.1 Discussion—Data elements are considered essential

Chemical Property Data and Database Quality Indicators

iftheyarerequiredtomakeacomparisonofpropertydatafrom

(Withdrawn 2000)

different sources meaningful. A comparison of data from

IEEE/ASTM SI 10 Standard for Use of the International

different sources may still be possible if essential information

System of Units (SI): The Modern Metric System

is omitted, but the value of the comparison may be greatly

2.2 Other Standards:

reduced.

ANSI X3.172–1996 Information Technology—American

3.2.6 value set—an open listing of representative acceptable

National Standard Dictionary of Information Technology

strings that could be included in a particular field of a record.

(ANSDIT)

(E1443)

CODATA A Glossary of Terms Relating to Data, Data

3.2.6.1 Discussion—Aclosedlistingofsuchstringsiscalled

Capture, Data Manipulation, and Databases, CODATA

a domain or category set.

Bulletin, Vol 23, Nos. 1–2, Jan.-June 1991

3.3 Other relevant terminology can be found in Terminolo-

ISO 8601 Data Elements and Interchange Formats—

gies E6 and E1013.

Information Interchange—Representation of Dates and

Times

4. Significance and Use

Recommended Method SRM 11R-94 SACMA Recom-

4.1 This guide provides recommended standard formats for

mended Method for Environmental Conditioning of Com-

the computerization of mechanical test data for a range of test

posite Test Laminates

methods for high-modulus fiber-reinforced composite materi-

Recommended Method SRM 1–88 SACMA Recommended

als. The types of mechanical tests considered are tension,

Method for Compressive Properties of Oriented Fiber-

compression, shear, flexure, open/filled hole, bearing, fracture

Resin Composites

toughness, and fatigue. The ASTM standards for which this

3. Terminology guide was developed are listed in 2.1. The recommended

formats are not limited in use to these test methods. There are

3.1 Definitions—Terminology in accordance with Termi-

other test methods for which these recommended formats may

nologies D3878 and E1443 shall be used where applicable.

be useful.

3.2 Definitions of Terms Specific to This Standard:

4.2 Comparison of data from various sources will be most

3.2.1 composite material—a substance consisting of two or

meaningful if all of the elements are available.

more materials, insoluble in one another, which are combined

to form a useful engineering material possessing certain 4.3 The intent is to provide sufficient detail that values are

properties not possessed by the constituents. known for the testing variables that may influence the results.

3.2.1.1 Discussion—A composite material is inherently in- The motivation for this guide is the steadily increasing use of

homogeneous on a microscopic scale but can often be assumed computerized databases. However, this guide is equally appro-

to be homogeneous on a macroscopic scale for certain engi- priate for data stored in a hard-copy form.

neering applications. The constituents of a composite retain

4.4 Thisformatisformechanicaltestdataforhigh-modulus

their identities; they do not dissolve or otherwise merge

fiber-reinforced composites only. It does not include the

completely into each other, although they act in concert.

recommended material description or the presentation of other

3.2.2 data dictionary—a collection of the names of all data specific types of test data (such as fracture toughness test

items used in a software system together with relevant prop-

results). These items are covered by separate formats to be

erties of those items; for example, length of data item, mode of

referenced in material specifications or other test standards.

representation, and so forth. (CODATA)

5. Data Reporting

3.2.3 data element—one individual piece of information

5.1 This guide is intended to provide common data-

used in describing a material or to record test results, for

reporting requirements for the documents listed in 1.2. Each

example, a variable name, test parameter, and so forth.

document will reference this guide and identify any usage

3.2.4 database schema—in a conceptual schema language,

specific to that document in the data-reporting section. For

the definition of the representation forms and structure of a

example, Test Method D3410/D3410M requires that the tran-

sition strain be reported as the progressive damage parameter.

These requirements do not mean that the information must be

The last approved version of this historical standard is referenced on

www.astm.org.

reported separately for each specimen. Any data elements that

Available from American National Standards Institute, 25 W. 43rd St., 4th

arethesameforaseriesofspecimensmaybereportedoncefor

Floor, New York, NY 10036.

theentireseries,aslongasitisclearlyindicatedthattheyapply

Suppliers of Advanced Composite Materials, 1600 Wilson Blvd., Suite 901,

Arlington, VA 22209. to all specimens.

E1434 − 00 (2013)

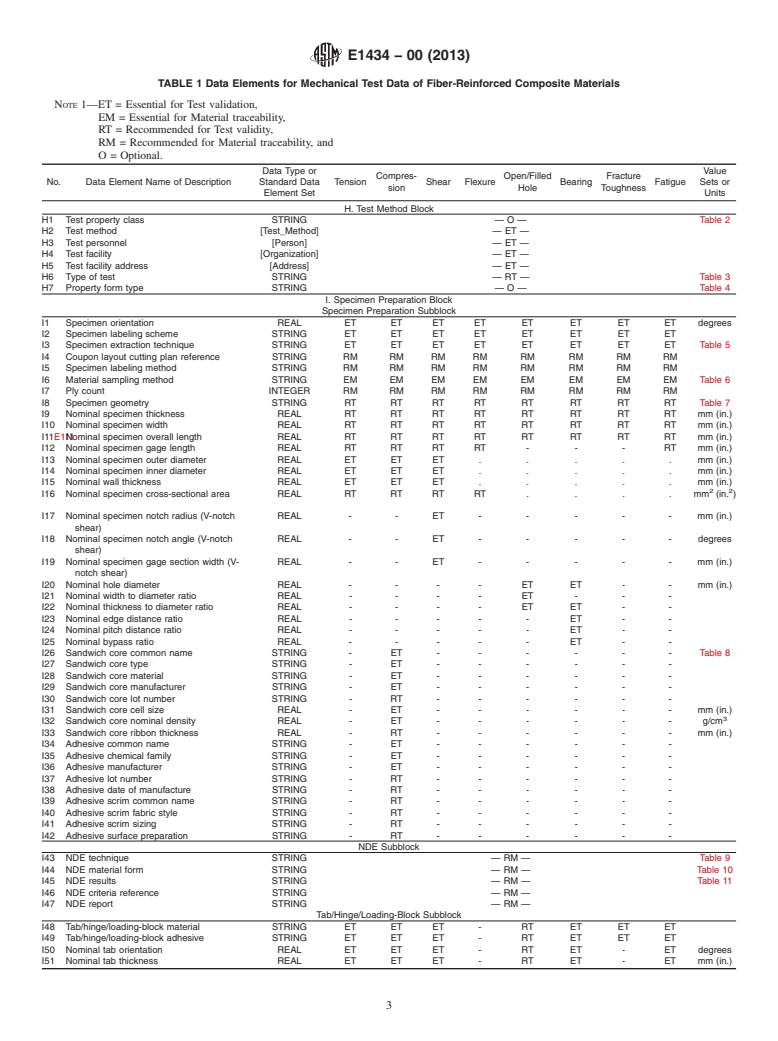

TABLE 1 Data Elements for Mechanical Test Data of Fiber-Reinforced Composite Materials

NOTE 1—ET = Essential for Test validation,

EM = Essential for Material traceability,

RT = Recommended for Test validity,

RM = Recommended for Material traceability, and

O = Optional.

Data Type or Value

Compres- Open/Filled Fracture

No. Data Element Name of Description Standard Data Tension Shear Flexure Bearing Fatigue Sets or

sion Hole Toughness

Element Set Units

H. Test Method Block

H1 Test property class STRING — O — Table 2

H2 Test method [Test_Method] — ET —

H3 Test personnel [Person] — ET —

H4 Test facility [Organization] — ET —

H5 Test facility address [Address] — ET —

H6 Type of test STRING — RT — Table 3

H7 Property form type STRING — O — Table 4

I. Specimen Preparation Block

Specimen Preparation Subblock

I1 Specimen orientation REAL ET ET ET ET ET ET ET ET degrees

I2 Specimen labeling scheme STRING ET ET ET ET ET ET ET ET

I3 Specimen extraction technique STRING ET ET ET ET ET ET ET ET Table 5

I4 Coupon layout cutting plan reference STRING RM RM RM RM RM RM RM RM

I5 Specimen labeling method STRING RM RM RM RM RM RM RM RM

I6 Material sampling method STRING EM EM EM EM EM EM EM EM Table 6

I7 Ply count INTEGER RM RM RM RM RM RM RM RM

I8 Specimen geometry STRING RT RT RT RT RT RT RT RT Table 7

I9 Nominal specimen thickness REAL RT RT RT RT RT RT RT RT mm (in.)

I10 Nominal specimen width REAL RT RT RT RT RT RT RT RT mm (in.)

I11E111Nominal specimen overall length REAL RT RT RT RT RT RT RT RT mm (in.)

I12 Nominal specimen gage length REAL RT RT RT RT - - - RT mm (in.)

I13 Nominal specimen outer diameter REAL ET ET ET . . . . . mm (in.)

I14 Nominal specimen inner diameter REAL ET ET ET . . . . . mm (in.)

I15 Nominal wall thickness REAL ET ET ET . . . . . mm (in.)

2 2

I16 Nominal specimen cross-sectional area REAL RT RT RT RT . . . . mm (in. )

I17 Nominal specimen notch radius (V-notch REAL - - ET - - - - - mm (in.)

shear)

I18 Nominal specimen notch angle (V-notch REAL - - ET - - - - - degrees

shear)

I19 Nominal specimen gage section width (V- REAL - - ET - - - - - mm (in.)

notch shear)

I20 Nominal hole diameter REAL - - - - ET ET - - mm (in.)

I21 Nominal width to diameter ratio REAL - - - - ET - - -

I22 Nominal thickness to diameter ratio REAL - - - - ET ET - -

I23 Nominal edge distance ratio REAL - - - - - ET - -

I24 Nominal pitch distance ratio REAL - - - - - ET - -

I25 Nominal bypass ratio REAL - - - - - ET - -

I26 Sandwich core common name STRING - ET - - - - - - Table 8

I27 Sandwich core type STRING - ET - - - - - -

I28 Sandwich core material STRING - ET - - - - - -

I29 Sandwich core manufacturer STRING - ET - - - - - -

I30 Sandwich core lot number STRING - RT - - - - - -

I31 Sandwich core cell size REAL - ET - - - - - - mm (in.)

I32 Sandwich core nominal density REAL - ET - - - - - - g/cm

I33 Sandwich core ribbon thickness REAL - RT - - - - - - mm (in.)

I34 Adhesive common name STRING - ET - - - - - -

I35 Adhesive chemical family STRING - ET - - - - - -

I36 Adhesive manufacturer STRING - ET - - - - - -

I37 Adhesive lot number STRING - RT - - - - - -

I38 Adhesive date of manufacture STRING - RT - - - - - -

I39 Adhesive scrim common name STRING - RT - - - - - -

I40 Adhesive scrim fabric style STRING - RT - - - - - -

I41 Adhesive scrim sizing STRING - RT - - - - - -

I42 Adhesive surface preparation STRING - RT - - - - - -

NDE Subblock

I43 NDE technique STRING — RM — Table 9

I44 NDE material form STRING — RM — Table 10

I45 NDE results STRING — RM — Table 11

I46 NDE criteria reference STRING — RM —

I47 NDE report STRING — RM —

Tab/Hinge/Loading-Block Subblock

I48 Tab/hinge/loading-block material STRING ET ET ET - RT ET ET ET

I49 Tab/hinge/loading-block adhesive STRING ET ET ET - RT ET ET ET

I50 Nominal tab orientation REAL ET ET ET - RT ET - ET degrees

I51 Nominal tab thickness REAL ET ET ET - RT ET - ET mm (in.)

E1434 − 00 (2013)

TABLE 1 Continued

Data Type or Value

Compres- Open/Filled Fracture

No. Data Element Name of Description Standard Data Tension Shear Flexure Bearing Fatigue Sets or

sion Hole Toughness

Element Set Units

I52 Nominal tab bevel angle REAL ET ET ET - RT ET - ET degrees

I53 Nominal tab length REAL RT RT RT - RT RT - RT mm (in.)

I54 Tab adhesive curing temperature REAL RT RT RT - RT RT - RT C (F)

I55 Tab adhesive curing time REAL RT RT RT - RT RT - RT min

J. Specimen Conditioning Block

J1 Speci

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.