ASTM D2148-02(2008)e1

(Test Method)Standard Test Methods for Bondable Silicone Rubber Tapes Used for Electrical Insulation

Standard Test Methods for Bondable Silicone Rubber Tapes Used for Electrical Insulation

SIGNIFICANCE AND USE

Self-adhesion is a primary initial property since it affects layer-to-layer bonding. The integrity of the bond can significantly affect the electrical and physical performance of the insulation system. Therefore, the degree of self-adhesion is directly related to apparatus performance.

A high degree of self-adhesion is desirable for most electrical applications. In this test, a short unwinding length indicates a high degree of self-adhesion.

This test method has been found useful as a quality control test for lot acceptance.

SCOPE

1.1 These test methods cover tests for bondable silicone rubber tapes which form a sealed structure either with the application of heat (and pressure if needed) or by the process of auto-adhesion (self-fusing).

1.2 The methods appear in the following sections:

Test MethodSection Adhesion3-9 Bond Strength10-17 Dielectric Breakdown Voltage18-25 Hardness 40 Length32 and 33 Thickness 26-31 Width35-39

1.3 The values stated in inch-pound units are to be regarded as standard, except for °C. The values in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For a specific hazard statement see 22.1.1.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation: D2148 − 02(Reapproved 2008) An American National Standard

Standard Test Methods for

Bondable Silicone Rubber Tapes Used for Electrical

Insulation

This standard is issued under the fixed designation D2148; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

´ NOTE—The units statement in subsection 1.3 was corrected editorially in July 2008.

1. Scope D374 Test Methods for Thickness of Solid Electrical Insu-

lation

1.1 These test methods cover tests for bondable silicone

D1000 Test Methods for Pressure-Sensitive Adhesive-

rubber tapes which form a sealed structure either with the

Coated Tapes Used for Electrical and Electronic Applica-

application of heat (and pressure if needed) or by the process

tions

of auto-adhesion (self-fusing).

D1458 Test Methods for Fully Cured Silicone Rubber-

1.2 The methods appear in the following sections:

Coated Glass Fabric and Tapes for Electrical Insulation

Test Method Section

D2240 Test Method for Rubber Property—Durometer Hard-

ness

Adhesion 3-9

D6054 Practice for Conditioning Electrical Insulating Mate-

Bond Strength 10-17

Dielectric Breakdown Voltage 18-25

rials for Testing

Hardness 40

2.2 ASTM Adjuncts:

Length 32 and 33

Thickness 26-31 Tack tester (one drawing)

Width 35-39

ADHESION

1.3 The values stated in inch-pound units are to be regarded

as standard, except for °C. The values in parentheses are

3. Scope

mathematical conversions to SI units that are provided for

information only and are not considered standard.

3.1 This test method covers the determination of the self-

adhesion of unsupported, self-fusing silicone rubber rectangu-

1.4 This standard does not purport to address all of the

lar and taper-edge (Note 1) tape designed for use as electrical

safety concerns, if any, associated with its use. It is the

insulation.

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

NOTE 1—Taper-edge tape includes such cross sections as triangular,

bility of regulatory limitations prior to use. For a specific lens, etc.

hazard statement see 22.1.1.

4. Significance and Use

2. Referenced Documents

4.1 Self-adhesionisaprimaryinitialpropertysinceitaffects

2.1 ASTM Standards:

layer-to-layer bonding. The integrity of the bond can signifi-

D149 Test Method for Dielectric Breakdown Voltage and

cantly affect the electrical and physical performance of the

Dielectric Strength of Solid Electrical Insulating Materials

insulation system. Therefore, the degree of self-adhesion is

at Commercial Power Frequencies

directly related to apparatus performance.

4.2 A high degree of self-adhesion is desirable for most

These methods are under the jurisdiction of ASTM Committee D09 on electrical applications. In this test, a short unwinding length

Electrical and Electronic Insulating Materials and are the direct responsibility of

indicates a high degree of self-adhesion.

Subcommittee D09.07 on Flexible and Rigid Insulating Materials.

CurrenteditionapprovedMay1,2008.PublishedJuly2008.Originallyapproved

4.3 This test method has been found useful as a quality

´1

in 1963. Last previous edition approved in 2002 as D2148 – 02 . DOI: 10.1520/

control test for lot acceptance.

D2148-02R08E01.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on Available from ASTM International Headquarters. Order Adjunct No.

the ASTM website. ADJD2148. Original adjunct produced in 1965.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

D2148 − 02 (2008)

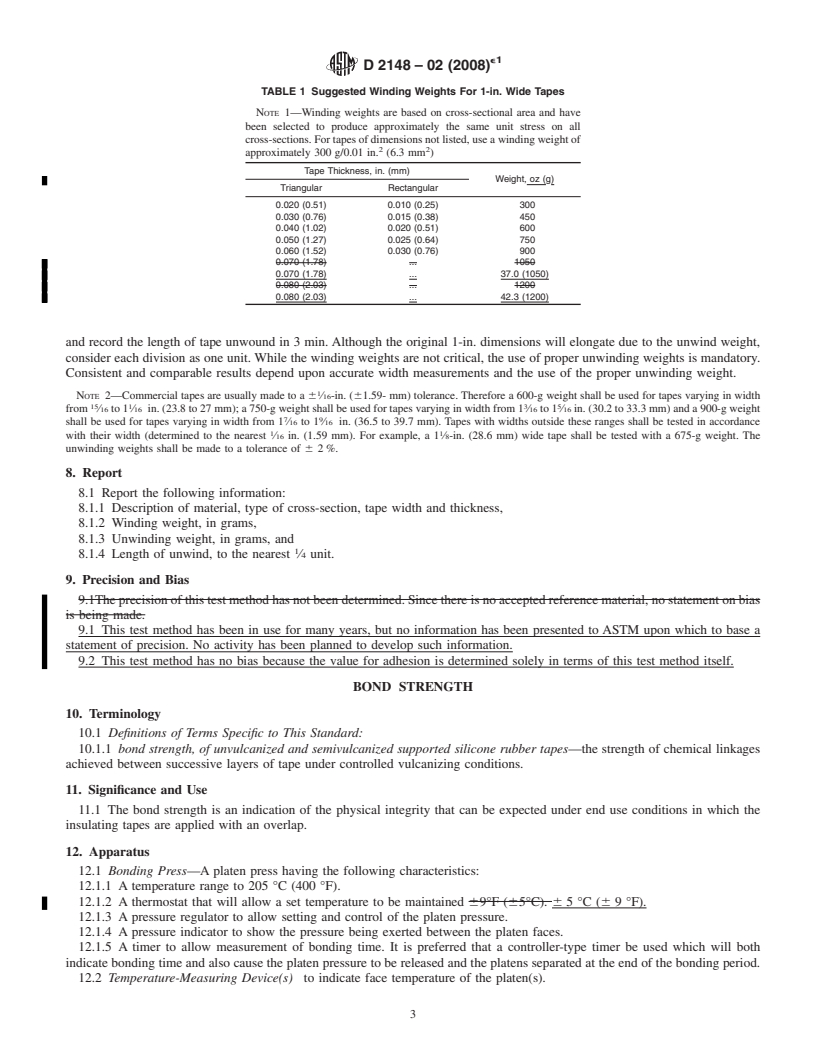

TABLE 1 Suggested Winding Weights For 1-in. Wide Tapes

5. Apparatus

NOTE 1—Winding weights are based on cross-sectional area and have

5.1 Inclined Mandrel Tack Test Fixture— A suggested fix-

been selected to produce approximately the same unit stress on all

ture is shown in Fig. 1. The mandrel shall consist of a ⁄8-in.

cross-sections. For tapes of dimensions not listed, use a winding weight of

(15.9-mm) diameter aluminum rod mounted in low-friction

2 2

approximately 10.5 oz (300 g)/0.01 in. (6.3 mm )

bearings. Good alignment of bearings is necessary for accurate

Tape Thickness, in. (mm)

Weight, oz (g)

results.Whenproperlyassembled,themandrelshallturnfreely

Triangular Rectangular

when loaded with a 1-oz (30-g) weight suspended from a

0.020 (0.51) 0.010 (0.25) 10.5 (300)

cotton thread wound in a single layer at the center of the

0.030 (0.76) 0.015 (0.38) 15.8 (450)

mandrel. 0.040 (1.02) 0.020 (0.51) 21.0 (600)

0.050 (1.27) 0.025 (0.64) 26.4 (750)

5.2 Weights, as specified in Section 7 and means for

0.060 (1.52) 0.030 (0.76) 31.7 (900)

0.070 (1.78) . 37.0 (1050)

attachment.

0.080 (2.03) . 42.3 (1200)

6. Test Specimen

6.1 Atest specimen shall consist of two pieces of tape 12 to

(Note2).Attachtheweighttothefreeendofthetapebymeans

15 in. (300 to 380 mm) long. Divisions spaced 1 in. (25.4 mm)

of a bulldog paper clamp or other suitable device. Release the

apart shall be marked off on one piece of tape. If tapes contain

weight and record the length of tape unwound in 3 min.

an interliner, the interliner shall be removed just prior to

Although the original 1-in. dimensions will elongate due to the

wrapping the mandrel. Dirt and other forms of contamination

unwind weight, consider each division as one unit. While the

shall be avoided.

winding weights are not critical, the use of proper unwinding

7. Procedure

weights is mandatory. Consistent and comparable results de-

pend upon accurate width measurements and the use of the

7.1 Winding—Half lap the unmarked specimen perfectly on

proper unwinding weight.

the mandrel of the test fixture, using the suggested weight as

showninTable1.Theseweightsarenotcritical.However,they 1

NOTE 2—Commercial tapes are usually made to a 6 ⁄16-in. (61.59-

are necessary to get intimate contact and conformability of the

mm) tolerance. Therefore a 600-g weight shall be used for tapes varying

15 1

in width from ⁄16 to 1 ⁄16 in. (23.8 to 27 mm); a 750-g weight shall be

tape. To obtain perfect half lapping, tilt the tack tester at an

3 5

usedfortapesvaryinginwidthfrom1 ⁄16to1 ⁄16in.(30.2to33.3mm)and

appropriate angle as shown in Fig. 1. Wrap the tape on the

7 9

a 900-g weight shall be used for tapes varying in width from 1 ⁄16 to 1 ⁄16

mandrel at a speed of approximately 18 in. (450 mm)/min.

in. (36.5 to 39.7 mm). Tapes with widths outside these ranges shall be

Using the winding procedure and weights just described, half 1

tested in accordance with their width (determined to the nearest ⁄16 in.

lap the marked tape sample on the mandrel over the first piece (1.59 mm). For example, a 1 ⁄8-in. (28.6 mm) wide tape shall be tested

with a 675-g weight. The unwinding weights shall be made to a tolerance

of tape. With the winding weight attached, return the test

of 62%.

fixture to a horizontal position and allow the tape to bond for

1 min. Remove the winding weight from the tape and the

8. Report

handle from the fixture and proceed with the unwinding test.

8.1 Report the following information:

7.2 Unwinding—After the tape has bonded for 1 min, attach

8.1.1 Description of material, type of cross-section, tape

a load of 21 oz (600 g)/in. (25 mm) of the original tape width

width and thickness,

8.1.2 Winding weight, in grams,

8.1.3 Unwinding weight, in grams, and

8.1.4 Length of unwind, to the nearest ⁄4 unit.

9. Precision and Bias

9.1 This test method has been in use for many years, but no

information has been presented to ASTM upon which to base

a statement of precision. No activity has been planned to

develop such information.

9.2 This test method has no bias because the value for

adhesion is determined solely in terms of this test method

itself.

BOND STRENGTH

10. Terminology

10.1 Definitions of Terms Specific to This Standard:

10.1.1 bond strength, of unvulcanized and semivulcanized

supported silicone rubber tapes—the strength of chemical

linkages achieved between successive layers of tape under

FIG. 1 Inclined Mandrel Tack Test Fixture controlled vulcanizing conditions.

´1

D2148 − 02 (2008)

11. Significance and Use 15.3 Superimpose one strip on another, front side to back

side, to form a specimen.

11.1 The bond strength is an indication of the physical

integrity that can be expected under end use conditions in 15.4 Separate the two strips at one end for a distance of

which the insulating tapes are applied with an overlap. about 1 in. (25 mm) and insert a strip of release film.

15.5 Preheat the press to 177 °C (350 °F).

12. Apparatus

15.6 Assemble the test specimens between two sheets of

12.1 Bonding Press—A platen press having the following

release film. Place the assembly on the unheated silicone

characteristics:

rubber pad and insert in the press.

12.1.1 A temperature range to 205 °C (400 °F).

15.7 Close the press and apply 50 psi (345 kPa) pressure to

12.1.2 A thermostat that will allow a set temperature to be

the specimens for 5 min.

maintained 65°C(6 9 °F).

12.1.3 A pressure regulator to allow setting and control of

15.8 Release the pressure, remove the specimens, and allow

the platen pressure.

them to cool for at least 5 min.

12.1.4 A pressure indicator to show the pressure being

15.9 Remove the release film and trim the specimens to a

exerted between the platen faces.

1-in. (25-mm) width.

12.1.5 A timer to allow measurement of bonding time. It is

15.10 Clamp one separated end in the upper jaw of the

preferred that a controller-type timer be used which will both

testing machine; peel the other separated end back 180 deg and

indicate bonding time and also cause the platen pressure to be

clamp it in the lower jaw.

released and the platens separated at the end of the bonding

period.

15.11 Adjustthetestingmachinetoprovideajawseparation

rate of 20 in. (500 mm) per min. If the pendulum-type machine

12.2 Temperature-Measuring Device(s) to indicate face

isused,disengagethepawlsduringthetest.Recordtheaverage

temperature of the platen(s).

observed force for each specimen using the technique de-

12.3 Silicone Rubber Pad, approximately ⁄8 in. (3.20 mm)

scribed for adhesion strength in Test Methods D1000.

thick, 60 to 70 Shore A durometer hardness, larger in dimen-

sion than the specimens to be tested. This is used as a

16. Report

pressure-equalizing device, compensating for irregularities in

16.1 Report the following information:

either the specimen or the platens.

16.1.1 Bond strength of each specimen and the average in

12.4 Polytetrafluoroethylene or suitable release film, three

pounds per inch or newtons per metre of width, and

sheets, approximately 2 to 4 mils (0.05 to 0.10 mm) thick. One

16.1.2 Bonding time, pressure, and temperature used, if

sheet is placed on each side of the specimens as a release sheet,

other than as specified.

the third sheet being used to separate the ends of the two test

specimens.

17. Precision and Bias

12.5 Testing Machine—A power-driven testing machine of

17.1 Thistestmethodhasbeeninuseformanyyears,butno

either the cross head or dead-weight pendulum type. The

information has been presented to ASTM upon which to base

machine shall be equipped with a tension weighing device

a statement of precision. No activity has been planned to

having a maximum capacity of 50 lb (22.7 kg) graduated to

develop such information.

read 0.1 lb (50 g) or less per scale division.

17.2 This test method has no bias because the value for

bond strength is determined solely in terms of this test method

13. Test Specimen

itself.

13.1 The test specimen shall be selected to be representative

DIELECTRIC BREAKDOWN VOLTAGE

of the material to be tested. The size of sample shall be

sufficient to give six strips at least 1.25 to 1.5 in. (32 to 38 mm)

18. Scope

wide and 6 in. (150 mm) long. Care should be taken to prevent

contamination.

18.1 This test method covers determination of the break-

down voltage of unsupported bondable silicone rubber tapes

14. Conditioning

with tapered edges (Note 3) for use as electrical insulation.

14.1 The specimen shall not be exposed to temperatures

18.2 The method to be used for rectangular cross section

above 30 °C (85 °F) before bonding. The tests shall be

tapes is described in Test Methods D1458.

conductedintheStandardLaboratoryAtmosphereasdescribed

NOTE 3—Tapes with tapered edges include such cross sections as

in Practice D6054.

triangular and lens-shaped.

15. Procedure

19. Significance and Use

15.1 Cut the strips of material to 1.25 to 1.5 in. (32 to 38

19.1 The level of dielectric breakdown voltage as deter-

mm) wide and at least 6 in. (150 mm) long, the length being

minedbythistestisonemeasureofthequalityofbothmaterial

measured in the warp or machine direction of the backing.

and fabrication methods used in producing the tape. This

15.2 Remove any interliner material. voltage value should not be compared directly with the results

´1

D2148 − 02 (2008)

of tests made on rectangular cross section tapes. For further Solidly ground all electrically conductive parts which it is

details, refer to Test Method D149. possible for a person to contact during the test. Provide means

for use at the completion of any test to ground any parts which

20. Apparatus

were at high voltage during the test or have the potential for

acquiring an induced charge during the test or retaining a

20.1 Test Fixture, designed to support a removable mandrel

charge even after disconnection of the voltage source. Thor-

⁄8 in. (15.9 mm) in diameter and about (20 in.) (500 mm) in

oughly instruct all operators as to the correct procedures for

length. This fixture may be a modification of the one described

performing tests safely. When making high voltage tests,

in 5.1.

particularly in compressed gas or in oil, it is possible for the

20.2 Voltage Source,capableofapplyingalternatingvoltage

energy released at breakdown to be suffıcient to result in fire,

and increasing it at the rate of 500 V/s. This equipment shall

explosion, or rupture of the test chamber. Design test equip-

conform to the requirements of Test Method D149.

ment, test chambers, and test specimens so as to minimize the

possibility of such occurrences and to eliminate the possibility

21. Test Specimen

of personal injury. If the potential for fire exists, have fire

21.1 The test specimen shall consist of lengths of bond

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

An American National Standard

e1

Designation:D2148–95 Designation: D 2148 – 02 (Reapproved 2008)

Standard Test Methods for

Bondable Silicone Rubber Tapes Used for Electrical

Insulation

This standard is issued under the fixed designation D 2148; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

e NOTE—The units statement in subsection 1.3 was corrected editorially in July 2008.

1. Scope

1.1 These test methods cover tests for bondable silicone rubber tapes which form a sealed structure either with the application

of heat (and pressure if needed) or by the process of auto-adhesion (self-fusing).

1.2 The methods appear in the following sections:

Test Method Section

Adhesion 3-9

Bond Strength 10-17

Dielectric Breakdown Voltage 18-25

Hardness 40

Length 32 and 33

Thickness 26-31

Width 35-39

1.3The values stated in inch-pound units are to be regarded as the standard except for °C.

1.3 The values stated in inch-pound units are to be regarded as standard, except for °C. The values in parentheses are

mathematical conversions to SI units that are provided for information only and are not considered standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use. For a specific hazard statement see 22.1.1.

2. Referenced Documents

2.1 ASTM Standards:

D 149 Test MethodsMethod for Dielectric Breakdown Voltage and Dielectric Strength of Solid Electrical Insulating Materials

at Commercial Power Frequencies

D 374 Test Methods for Thickness of Solid Electrical Insulation

2,

D618Practice for Conditioning Plastics and Electrical Insulating Materials for Testing 1000 Test Methods for Pressure-

Sensitive Adhesive-Coated Tapes Used for Electrical and Electronic Applications

D1000Test Methods for Pressure-SensitiveAdhesive Coated Tapes Used for Electrical and ElectronicApplications 1458 Test

Methods for Fully Cured Silicone Rubber-Coated Glass Fabric and Tapes for Electrical Insulation

D1458Test Methods for Fully Cured Silicone Rubber-Coated Glass Fabric and Tapes for Electrical Insulation 2240 Test

Method for Rubber PropertyDurometer Hardness

D2240Test Method for Rubber Property—Durometer Hardness 6054 Practice for Conditioning Electrical Insulating Materials

for Testing

2.2 ASTM Adjuncts:

Tack tester (one drawing)

These methods are under the jurisdiction ofASTM Committee D-9 on Electrical and Electronic Insulating Materials and are the responsibility of Subcommittee D09.07

on Flexible and Rigid Insulating Materials.

Current edition approved Jan. 15, 1995. Published March 1995. Originally published as D2148–63T. Last previous edition D2148–90.

These methods are under the jurisdiction of ASTM Committee D09 on Electrical and Electronic Insulating Materials and are the direct responsibility of Subcommittee

D09.07 on Flexible and Rigid Insulating Materials.

´1

Current edition approved May 1, 2008. Published July 2008. Originally approved in 1963. Last previous edition approved in 2002 as D 2148 – 02 .

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

, Vol 10.01.volume information, refer to the standard’s Document Summary page on the ASTM website.

Annual Book of ASTM Standards, Vol 08.01.

Available from ASTM International Headquarters. Order Adjunct No. ADJD2148. Original adjunct produced in 1965.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

e1

D 2148 – 02 (2008)

ADHESION

3. Scope

3.1 This test method covers the determination of the self-adhesion of unsupported, self-fusing silicone rubber rectangular and

taper-edge (Note 1) tape designed for use as electrical insulation.

NOTE 1—Taper-edge tape includes such cross sections as triangular, lens, etc.

4. Significance and Use

4.1 Self-adhesion is a primary initial property since it affects layer-to-layer bonding. The integrity of the bond can significantly

affect the electrical and physical performance of the insulation system. Therefore, the degree of self-adhesion is directly related

to apparatus performance.

4.2 A high degree of self-adhesion is desirable for most electrical applications. In this test, a short unwinding length indicates

a high degree of self-adhesion.

4.3 This test method has been found useful as a quality control test for lot acceptance.

5. Apparatus

5.1 Inclined Mandrel Tack Test Fixture—AsuggestedfixtureisshowninFig.1. Themandrelshallconsistofa ⁄8-in.(15.9-mm)

diameter aluminum rod mounted in low-friction bearings. Good alignment of bearings is necessary for accurate results. When

properly assembled, the mandrel shall turn freely when loaded with a 1-oz (30-g) weight suspended from a cotton thread wound

in a single layer at the center of the mandrel.

5.2 Weights, as specified in Section 7 and means for attachment.

6. Test Specimen

6.1 Atest specimen shall consist of two pieces of tape 12 to 15 in. (25(300 to 380 mm) long. Divisions spaced 1 in. (25.4 mm)

apart shall be marked off on one piece of tape. If tapes contain an interliner, the interliner shall be removed just prior to wrapping

the mandrel. Dirt and other forms of contamination shall be avoided.

7. Procedure

7.1 Winding—Half lap the unmarked specimen perfectly on the mandrel of the test fixture, using the suggested weight as shown

in Table 1. These weights are not critical. However, they are necessary to get intimate contact and conformability of the tape. To

obtain perfect half lapping, tilt the tack tester at an appropriate angle as shown in Fig. 1. Wrap the tape on the mandrel at a speed

of approximately 18 in. (450 mm)/min. Using the winding procedure and weights just described, half lap the marked tape sample

on the mandrel over the first piece of tape. With the winding weight attached, return the test fixture to a horizontal position and

allow the tape to bond for 1 min. Remove the winding weight from the tape and the handle from the fixture and proceed with the

unwinding test.

7.2 Unwinding—Afterthetapehasbondedfor1min,attachaloadof21oz(600g)/in.(25mm)oftheoriginaltapewidth(Note

2). Attach the weight to the free end of the tape by means of a bulldog paper clamp or other suitable device. Release the weight

FIG. 1 Inclined Mandrel Tack Test Fixture

e1

D 2148 – 02 (2008)

TABLE 1 Suggested Winding Weights For 1-in. Wide Tapes

NOTE 1—Winding weights are based on cross-sectional area and have

been selected to produce approximately the same unit stress on all

cross-sections. For tapes of dimensions not listed, use a winding weight of

2 2

approximately 300 g/0.01 in. (6.3 mm )

Tape Thickness, in. (mm)

Weight, oz (g)

Triangular Rectangular

0.020 (0.51) 0.010 (0.25) 300

0.030 (0.76) 0.015 (0.38) 450

0.040 (1.02) 0.020 (0.51) 600

0.050 (1.27) 0.025 (0.64) 750

0.060 (1.52) 0.030 (0.76) 900

0.070 (1.78) . 1050

0.070 (1.78) . 37.0 (1050)

0.080 (2.03) . 1200

0.080 (2.03) . 42.3 (1200)

and record the length of tape unwound in 3 min. Although the original 1-in. dimensions will elongate due to the unwind weight,

consider each division as one unit. While the winding weights are not critical, the use of proper unwinding weights is mandatory.

Consistent and comparable results depend upon accurate width measurements and the use of the proper unwinding weight.

NOTE 2—Commercial tapes are usually made to a 6 ⁄16-in. (61.59- mm) tolerance. Therefore a 600-g weight shall be used for tapes varying in width

15 1 3 5

from ⁄16 to 1 ⁄16 in. (23.8 to 27 mm); a 750-g weight shall be used for tapes varying in width from 1 ⁄16 to 1 ⁄16 in. (30.2 to 33.3 mm) and a 900-g weight

7 9

shall be used for tapes varying in width from 1 ⁄16 to 1 ⁄16 in. (36.5 to 39.7 mm). Tapes with widths outside these ranges shall be tested in accordance

1 1

with their width (determined to the nearest ⁄16 in. (1.59 mm). For example, a 1 ⁄8-in. (28.6 mm) wide tape shall be tested with a 675-g weight. The

unwinding weights shall be made to a tolerance of 62%.

8. Report

8.1 Report the following information:

8.1.1 Description of material, type of cross-section, tape width and thickness,

8.1.2 Winding weight, in grams,

8.1.3 Unwinding weight, in grams, and

8.1.4 Length of unwind, to the nearest ⁄4 unit.

9. Precision and Bias

9.1The precision of this test method has not been determined. Since there is no accepted reference material, no statement on bias

is being made.

9.1 This test method has been in use for many years, but no information has been presented to ASTM upon which to base a

statement of precision. No activity has been planned to develop such information.

9.2 This test method has no bias because the value for adhesion is determined solely in terms of this test method itself.

BOND STRENGTH

10. Terminology

10.1 Definitions of Terms Specific to This Standard:

10.1.1 bond strength, of unvulcanized and semivulcanized supported silicone rubber tapes—the strength of chemical linkages

achieved between successive layers of tape under controlled vulcanizing conditions.

11. Significance and Use

11.1 The bond strength is an indication of the physical integrity that can be expected under end use conditions in which the

insulating tapes are applied with an overlap.

12. Apparatus

12.1 Bonding Press—A platen press having the following characteristics:

12.1.1 A temperature range to 205 °C (400 °F).

12.1.2 A thermostat that will allow a set temperature to be maintained 69°F (65°C). 65°C(6 9 °F).

12.1.3 A pressure regulator to allow setting and control of the platen pressure.

12.1.4 A pressure indicator to show the pressure being exerted between the platen faces.

12.1.5 A timer to allow measurement of bonding time. It is preferred that a controller-type timer be used which will both

indicate bonding time and also cause the platen pressure to be released and the platens separated at the end of the bonding period.

12.2 Temperature-Measuring Device(s) to indicate face temperature of the platen(s).

e1

D 2148 – 02 (2008)

12.3 Silicone Rubber Pad, approximately ⁄8 in. (3.20 mm) thick, 60 to 70 ShoreAdurometer hardness, larger in dimension than

the specimens to be tested. This is used as a pressure-equalizing device, compensating for irregularities in either the specimen or

the platens.

12.4 Polytetrafluoroethylene or suitable release film, three sheets, approximately 2 to 4 mils (0.05 to 0.10 mm) thick. One sheet

is placed on each side of the specimens as a release sheet, the third sheet being used to separate the ends of the two test specimens.

12.5 Testing Machine—A power-driven testing machine of either the cross head or dead-weight pendulum type. The machine

shall be equipped with a tension weighing device having a maximum capacity of 50 lb (22.7 kg) graduated to read 0.1 lb (50 g)

or less per scale division.

13. Test Specimen

13.1 The test specimen shall be selected to be representative of the material to be tested. The size of sample shall be sufficient

togivesixstripsatleast1.25to1.5in.(32to38mm)wideand6in.(150mm)long.Careshouldbetakentopreventcontamination.

14. Conditioning

14.1 The specimen shall not be exposed to temperatures above 85°F (30°C) 30 °C (85 °F) before bonding. The tests shall be

conducted in the Standard Laboratory Atmosphere as described in Practice D618D 6054.

15. Procedure

15.1 Cut the strips of material to 1.25 to 1.5 in. (32 to 38 mm) wide and at least 6 in. (150 mm) long, the length being measured

in the warp or machine direction of the backing.

15.2 Remove any interliner material.

15.3 Superimpose one strip on another, front side to back side, to form a specimen.

15.4 Separate the two strips at one end for a distance of about 1 in. (25 mm) and insert a strip of release film.

15.5 Preheat the press to 177 °C (350 °F).

15.6 Assemble the test specimens between two sheets of release film. Place the assembly on the unheated silicone rubber pad

and insert in the press.

15.7 Close the press and apply 50 psi (345 kPa) pressure to the specimens for 5 min.

15.8 Release the pressure, remove the specimens, and allow them to cool for at least 5 min.

15.9 Remove the release film and trim the specimens to a 1-in. (25-mm) width.

15.10 Clamp one separated end in the upper jaw of the testing machine; peel the other separated end back 180 deg and clamp

it in the lower jaw.

15.11 Adjust the testing machine to provide a jaw separation rate of 20 in. (500 mm) per min. If the pendulum-type machine

is used, disengage the pawls during the test. Record the average observed force for each specimen using the technique described

for adhesion strength in Test Methods D 1000.

16. Report

16.1 Report the following information:

16.1.1 Bond strength of each specimen and the average in pounds per inch or newtons per metre of width, and

16.1.2 Bonding time, pressure, and temperature used, if other than as specified.

17. Precision and Bias

17.1The precision of this test method has not been determined. Since there is no accepted reference material, no statement on

bias is being made.

17.1 This test method has been in use for many years, but no information has been presented to ASTM upon which to base a

statement of precision. No activity has been planned to develop such information.

17.2 This test method has no bias because the value for bond strength is determined solely in terms of this test method itself.

DIELECTRIC BREAKDOWN VOLTAGE

18. Scope

18.1 This test method covers determination of the breakdown voltage of unsupported bondable silicone rubber tapes with

tapered edges (Note 3) for use as electrical insulation.

18.2 The method to be used for rectangular cross section tapes is described in Test Methods D 1458.

NOTE 3—Tapes with tapered edges include such cross sections as triangular and lens-shaped.

19. Significance and Use

19.1 The level of dielectric breakdown voltage as determined by this test is one measure of the quality of both material and

fabrication methods used in producing the tape. This voltage va

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.