ASTM E716-10

(Practice)Standard Practices for Sampling and Sample Preparation of Aluminum and Aluminum Alloys for Determination of Chemical Composition by Spectrochemical Analysis

Standard Practices for Sampling and Sample Preparation of Aluminum and Aluminum Alloys for Determination of Chemical Composition by Spectrochemical Analysis

SIGNIFICANCE AND USE

The practice for taking a sample of molten metal during production and producing a chill cast disk, used in conjunction with the following appropriate quantitative spark atomic emission spectrochemical methods, Test Methods E607 and E1251, is suitable for use in manufacturing control or certifying, or both, that the entire lot of alloy sampled meets established composition limits.

The practice for melting a piece of a product to produce a chill cast disk analyzed in conjunction with the following appropriate quantitative spark atomic emission spectrochemical methods, Test Methods E607 and E1251, is suitable, if a representative sample is taken, for determining if the piece sampled meets Aluminum Association composition limits.

The practice for direct analysis of product is suitable for determining an approximate composition of the piece analyzed

SCOPE

1.1 These practices describe procedures for producing a chill cast disk sample from molten aluminum during the production process, and from molten metal produced by melting pieces cut from products.

1.2 These practices describe a procedure for obtaining qualitative results by direct analysis of product using spark atomic emission spectroscopy.

1.3 These practices describe procedures for preparation of samples and products prior to analysis.

1.4 The values stated in SI units are to be regarded as standard. The values given in parentheses are mathematical conversions to inch-pound units that are provided for information only and are not considered standard.

1.5 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific precautionary statements are given in 6.1 and 7.2.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E716 − 10

StandardPractices for

Sampling and Sample Preparation of Aluminum and

Aluminum Alloys for Determination of Chemical

1

Composition by Spectrochemical Analysis

This standard is issued under the fixed designation E716; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope E607 Test Method for Atomic Emission Spectrometric

Analysis Aluminum Alloys by the Point to Plane Tech-

1.1 These practices describe procedures for producing a

3

nique Nitrogen Atmosphere (Withdrawn 2011)

chill cast disk sample from molten aluminum during the

E1251Test Method for Analysis of Aluminum and Alumi-

production process, and from molten metal produced by

num Alloys by Spark Atomic Emission Spectrometry

melting pieces cut from products.

1.2 These practices describe a procedure for obtaining

3. Terminology

qualitative results by direct analysis of product using spark

3.1 For definitions of terms used in this practice, refer to

atomic emission spectroscopy.

Terminology E135.

1.3 These practices describe procedures for preparation of

samples and products prior to analysis.

4. Summary of Practices

1.4 The values stated in SI units are to be regarded as

4.1 Molten metal representative of the furnace melt is

standard. The values given in parentheses are mathematical

poured or drawn by vacuum into a specified mold to produce

conversions to inch-pound units that are provided for informa-

a chill-cast disk.The disk is machined to a specified depth that

tion only and are not considered standard.

representstheaveragecompositionandproducesanacceptable

1.5 This standard does not purport to address all of the

surface for analysis by spark atomic emission spectroscopy.

safety problems, if any, associated with its use. It is the

4.2 Pieces of solid aluminum fabricated, cast, or wrought

responsibility of the user of this standard to establish appro-

products are remelted and cast into molds or briquetted then

priate safety and health practices and determine the applica-

remelted and cast into molds.

bility of regulatory limitations prior to use. Specific precau-

4.3 Product can be qualitatively analyzed directly without

tionary statements are given in 6.1 and 7.2.

remelting after suitable surface preparation. Product with

insufficient mass for direct analysis may be bonded to more

2. Referenced Documents

massive material prior to analysis.

2

2.1 ASTM Standards:

4.4 Special practices are included for the sampling and

E135Terminology Relating to Analytical Chemistry for

analysis of aluminum-silicon alloys, containing greater than

Metals, Ores, and Related Materials

14% silicon.

E401Practice for Bonding Thin Spectrochemical Samples

and Standards to aGreater Mass of Material (Withdrawn

3

5. Significance and Use

1995)

5.1 The practice for taking a sample of molten metal during

production and producing a chill cast disk, used in conjunction

1

These practices are under the jurisdiction of ASTM Committee E01 on

with the following appropriate quantitative spark atomic emis-

Analytical Chemistry for Metals, Ores, and Related Materials and are the direct

sion spectrochemical methods,Test Methods E607 and E1251,

responsibility of Subcommittee E01.04 on Aluminum and Magnesium.

is suitable for use in manufacturing control or certifying, or

Current edition approved Sept. 1, 2010. Published December 2010. Originally

approved in 1980. Last previous edition approved in 2002 as E716–94(2002).

both, that the entire lot of alloy sampled meets established

DOI: 10.1520/E0716-10.

composition limits.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

5.2 The practice for melting a piece of a product to produce

Standards volume information, refer to the standard’s Document Summary page on

a chill cast disk analyzed in conjunction with the following

the ASTM website.

3

appropriate quantitative spark atomic emission spectrochemi-

The last approved version of this historical standard is referenced on

www.astm.org. cal methods, Test Methods E607 and E1251, is suitable, if a

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

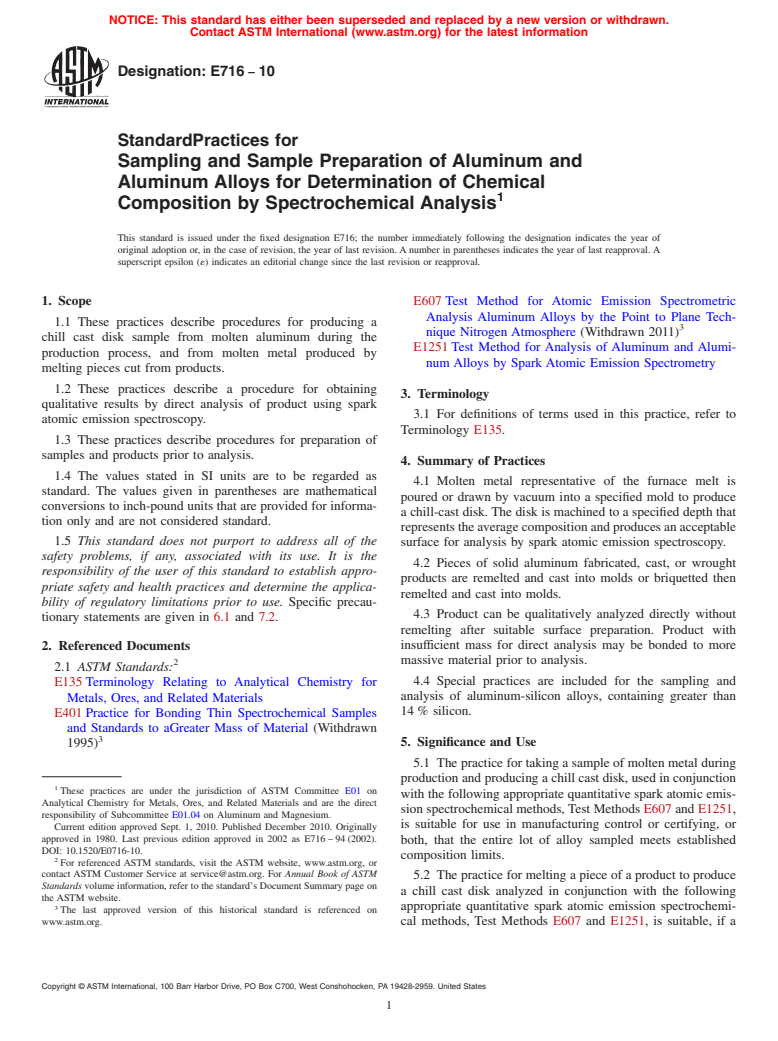

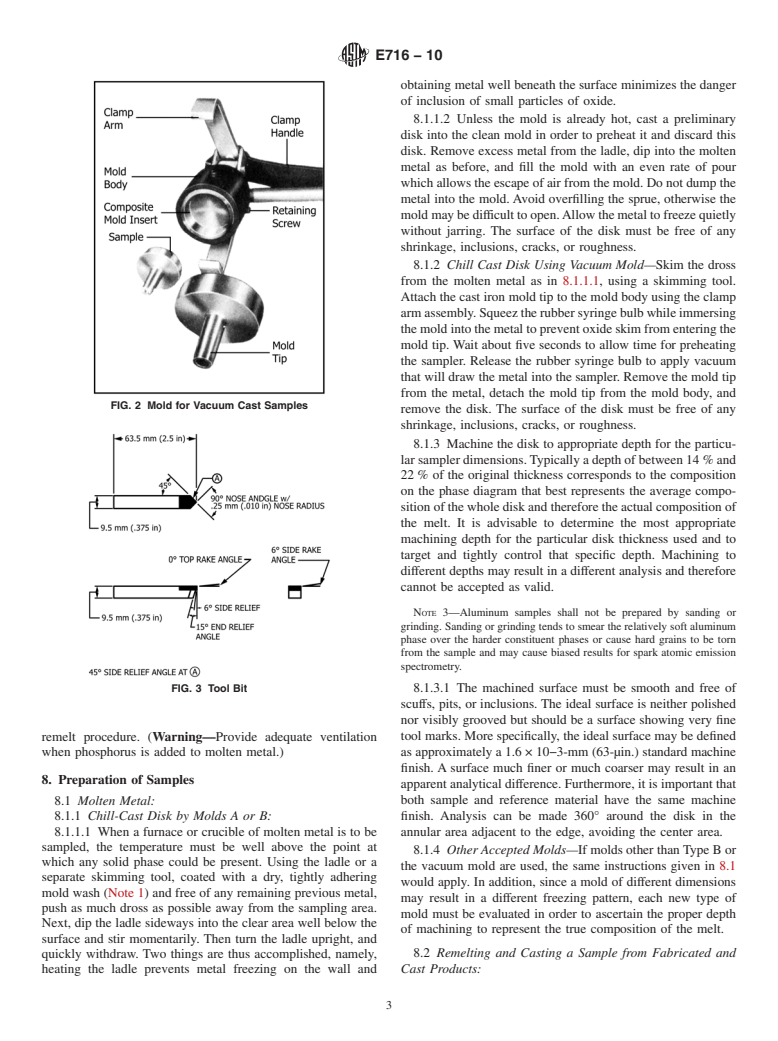

---------------------- Page: 1 ----------------------

E716 − 10

representative sample is taken, for determining if the piece throat for the sprue. A slight taper, 1° to 2°, on the hinged

sampled meets Aluminum Association composition limits. portion of the mold facilitates opening when a disk has been

cast.The mold material should be steel or cast iron and should

5.3

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:E716–94(Reapproved2002) Designation:E716–10

Standard Practices for

Sampling Aluminum and Aluminum Alloys for

Spectrochemical AnalysisSampling and Sample Preparation

of Aluminum and Aluminum Alloys for Determination of

1

Chemical Composition by Spectrochemical Analysis

This standard is issued under the fixed designation E716; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1These practices describe the sampling of aluminum and aluminum-base alloys to obtain a chill-cast disk suitable for

quantitativeopticalemissionspectrochemicalanalysis.Thediskintheregiontobeexcitedisrepresentativeofthemeltorproduct

and gives a repeatability of results which approaches that of the reference materials used.

1.2These practices describe procedures for representative sampling of molten metal, from fabricated or cast products which can

be melted, and from other forms which cannot be melted.

1.3

1.1 These practices describe procedures for producing a chill cast disk sample from molten aluminum during the production

process, and from molten metal produced by melting pieces cut from products.

1.2 These practices describe a procedure for obtaining qualitative results by direct analysis of product using spark atomic

emission spectroscopy.

1.3 These practices describe procedures for preparation of samples and products prior to analysis.

1.4 The values stated in SI units are to be regarded as standard. The values given in parentheses are mathematical conversions

to inch-pound units that are provided for information only and are not considered standard.

1.5 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use. Specific precautionary statements are given in 5.1 6.1 and 6.27.2.

2. Referenced Documents

2

2.1 ASTM Standards:

E101Test Method for Spectrographic Analysis of Aluminum and Aluminum Alloys by the Point-to-Plane Technique

135 Terminology Relating to Analytical Chemistry for Metals, Ores, and Related Materials

E227Test Method for Optical Emission Spectrometric Analysis of Aluminum and Aluminum Alloys by the Point-to-Plane

Technique

3

E401 Practice for Bonding Thin Spectrochemical Samples and Standards to a Greater Mass of Material

E607 Test Method for Atomic Emission Spectrometric Analysis Aluminum Alloys by the Point to Plane Technique Nitrogen

Atmosphere

E1251 Test Method for Analysis of Aluminum and Aluminum Alloys by Atomic Emission Spectrometry

3. Summary of Practices

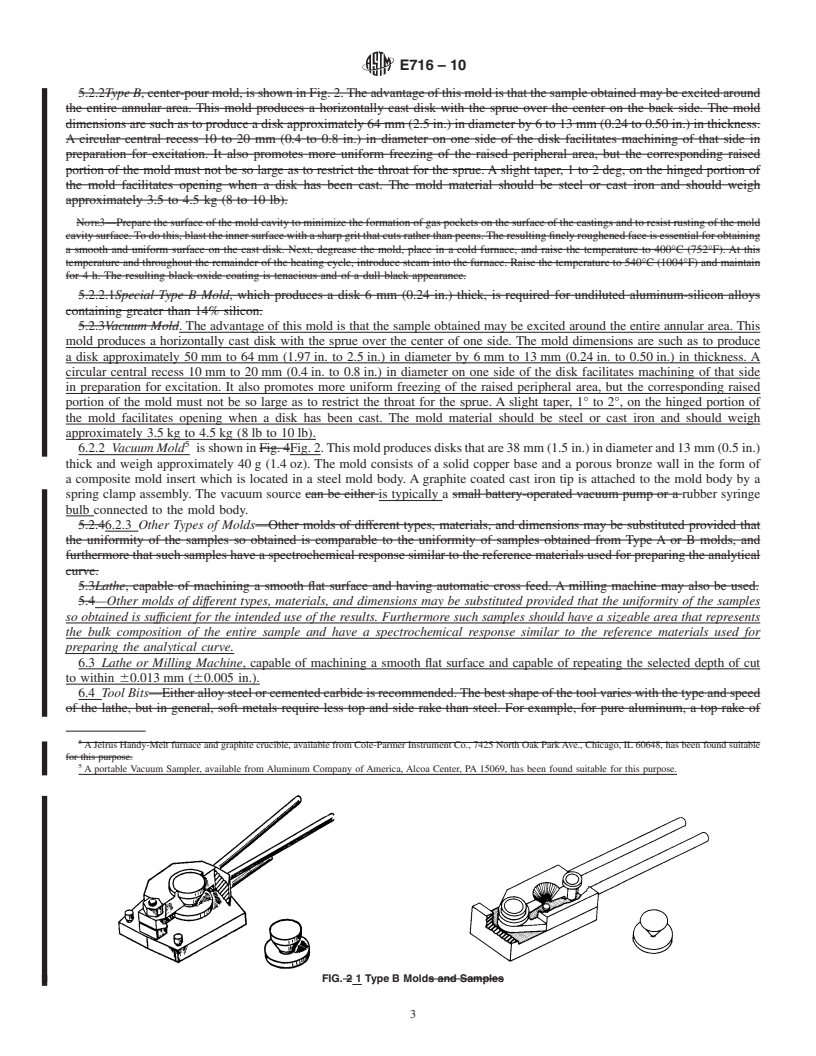

3.1Molten metal representative of the furnace melt is poured into a specified mold to produce a chill-cast disk. The disk is

machined to a specified depth that represents the average composition and produces an acceptable surface for excitation.

3.2Fabricated, cast, or wrought products are remelted and cast into molds, briquetted and remelted, bonded to more massive

material, or excited directly without remelting.

1

These practices are under the jurisdiction of ASTM Committee E01 on Analytical Chemistry for Metals, Ores, and Related Materials and are the direct responsibility

of Subcommittee E01.04 on Aluminum and Magnesium.

Current edition approved Oct. 10, 2002.Sept. 1, 2010. Published December 2002.2010. Originally approved in 1980. Last previous edition approved in 19942002 as

E716–94(2002). DOI: 10.1520/E0716-94R02.10.1520/E0716-10.

2

ForreferencedASTMstandards,visittheASTMwebsite,www.astm.org,orcontactASTMCustomerServiceatservice@astm.org.For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Withdrawn. The last approved version of this historical standard is referenced on www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

E716–10

3.3Specialpracticesareincludedforthesamplingandanalysisofaluminum-siliconalloys,containinggreaterthan14%silicon.

Terminology

3.1 For definitions of terms used in this practice, refer to Terminology E135.

4. Summary of Practices

4.1 Molten metal representative of the furnace melt is poured or drawn by vacuum

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.