ASTM B985-12(2016)

(Practice)Standard Practice for Sampling Aluminum Ingots, Billets, Castings and Finished or Semi-Finished Wrought Aluminum Products for Compositional Analysis

Standard Practice for Sampling Aluminum Ingots, Billets, Castings and Finished or Semi-Finished Wrought Aluminum Products for Compositional Analysis

SIGNIFICANCE AND USE

5.1 Products covered by this practice are unwrought aluminum ingots, billets, and castings and unclad wrought aluminum sheet, plate, rolled or cold finished extrusions, extruded profiles, wire, rod and bar. Machined wrought products (finished or semi-finished) are excluded (see Note 3). These practices, used in conjunction with the appropriate sample preparation techniques in Practices E716 and the Test Methods E34, E607, E1251, and EN 14242, are suitable to determine if the piece sampled meets the chemical composition limits registered with the Aluminum Association Inc.5 or other specified chemical composition limits for the alloy. Analysis of such samples shall not supersede the analysis of samples taken during pouring of castings or ingots in accordance with Practices E716 and analyzed in accordance with Test Methods E34, E607, E1251, or EN 14242 and shall not be used for determining compliance with chemical composition requirements for an entire cast lot or part thereof.

Note 3: Sampling machined pieces of products pose a particular problem because the piece itself may not be a representative sample of the original cast chemical composition. Larger differences may be expected between an analysis obtained from samples taken in accordance with this practice and the original cast analysis of samples taken during pouring of castings or ingot.

Note 4: Portable Spark-AES and hand held XRF instruments should not be used to determine if the piece sampled meets chemical composition limits registered with Aluminum Association Inc or other specified chemical composition limits for the alloy.

5.2 Users should be aware that chemical compositions determined using samples taken from unwrought aluminum ingots, billets, and castings and finished or semi-finished products might differ from the bulk chemical composition determined using samples taken when ingots or castings are poured. This difference can be due to elemental segregation upon solidification, sampling a non-h...

SCOPE

1.1 This practice describes procedures for sampling unwrought aluminum ingots, billets, castings and finished or semi-finished wrought aluminum products to obtain a representative sample for determining chemical composition.

1.1.1 Chemical compositions determined from samples obtained in accordance with this standard practice may differ from the bulk chemical composition determined from samples taken when ingots or castings are poured. These differences can be due to elemental segregation that occurs during solidification, procedures that remove enriched material (for example, ingot scalping), or procedures that remove depleted areas (for example, removal of the riser from a casting).

1.1.2 Analysis of samples obtained from unwrought aluminum ingots, billets, and castings and finished or semi-finished wrought aluminum products can be used to determine if the piece sampled meets The Aluminum Association, Inc. registered chemical composition limits or other specified chemical composition limits for the alloy. Analysis of such samples shall not supersede the analysis of samples taken during pouring of castings or ingots in accordance with Practices E716 and analyzed in accordance with Test Methods E34, E607, E1251, or EN 14242 and shall not be used for determining compliance with chemical composition requirements for an entire cast lot or part thereof.

Note 1: Pieces may include ingots, forgings, coils, sheets, extrusions, castings, and so forth. A single unwrought ingot or billet may produce multiple finished or semi-finished pieces.

Note 2: Certification of entire cast lots should be determined using samples taken during pouring of castings or ingots in accordance with Practices E716 and analyzed in accordance with Test Methods E34, E607, E1251, or EN 14242.

1.2 Units—The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be...

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: B985 − 12 (Reapproved 2016)

Standard Practice for

Sampling Aluminum Ingots, Billets, Castings and Finished

or Semi-Finished Wrought Aluminum Products for

Compositional Analysis

This standard is issued under the fixed designation B985; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope therefore,eachsystemshallbeusedindependentlyoftheother.

Combining values from the two systems may result in non-

1.1 This practice describes procedures for sampling un-

conformance with the standard.

wrought aluminum ingots, billets, castings and finished or

1.3 This standard does not purport to address all of the

semi-finished wrought aluminum products to obtain a repre-

safety concerns, if any, associated with its use. It is the

sentative sample for determining chemical composition.

responsibility of the user of this standard to establish appro-

1.1.1 Chemical compositions determined from samples ob-

priate safety and health practices and determine the applica-

tained in accordance with this standard practice may differ

bility of regulatory limitations prior to use.

from the bulk chemical composition determined from samples

takenwheningotsorcastingsarepoured.Thesedifferencescan

2. Referenced Documents

be due to elemental segregation that occurs during

2.1 ASTM Standards:

solidification, procedures that remove enriched material (for

B881 Terminology Relating toAluminum- and Magnesium-

example, ingot scalping), or procedures that remove depleted

Alloy Products

areas (for example, removal of the riser from a casting).

E34 Test Methods for Chemical Analysis of Aluminum and

1.1.2 Analysis of samples obtained from unwrought alumi-

Aluminum-Base Alloys

num ingots, billets, and castings and finished or semi-finished

E135 Terminology Relating to Analytical Chemistry for

wrought aluminum products can be used to determine if the

Metals, Ores, and Related Materials

piece sampled meets The Aluminum Association, Inc. regis-

E607 Test Method for Atomic Emission Spectrometric

tered chemical composition limits or other specified chemical

Analysis Aluminum Alloys by the Point to Plane Tech-

composition limits for the alloy.Analysis of such samples shall

nique Nitrogen Atmosphere (Withdrawn 2011)

not supersede the analysis of samples taken during pouring of

E716 Practices for Sampling and Sample Preparation of

castings or ingots in accordance with Practices E716 and

Aluminum and Aluminum Alloys for Determination of

analyzed in accordance with Test Methods E34, E607, E1251,

Chemical Composition by Spark Atomic Emission Spec-

or EN 14242 and shall not be used for determining compliance

trometry

with chemical composition requirements for an entire cast lot

E1251 Test Method for Analysis of Aluminum and Alumi-

or part thereof.

num Alloys by Spark Atomic Emission Spectrometry

NOTE 1—Pieces may include ingots, forgings, coils, sheets, extrusions, 4

2.2 Other Standards:

castings, and so forth. A single unwrought ingot or billet may produce

EN 14242 Aluminum and Aluminum Alloys–chemical

multiple finished or semi-finished pieces.

Analysis—inductively Coupled Plasma Optical Emission

NOTE 2—Certification of entire cast lots should be determined using

samples taken during pouring of castings or ingots in accordance with Spectral Analysis

Practices E716 and analyzed in accordance with Test Methods E34, E607,

3. Terminology

E1251, or EN 14242.

1.2 Units—The values stated in either SI units or inch-

3.1 For definitions of terms used in this Standard, refer to

pound units are to be regarded separately as standard. The Terminologies B881 and E135.

values stated in each system may not be exact equivalents;

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

This practice is under the jurisdiction of ASTM Committee B07 on Light Standards volume information, refer to the standard’s Document Summary page on

Metals and Alloys and is the direct responsibility of Subcommittee B07.05 on the ASTM website.

Testing. The last approved version of this historical standard is referenced on

Current edition approved Nov. 1, 2016. Published November 2016. Originally www.astm.org.

approved in 2012. Last previous edition approved in 2012 as B985 – 12. DOI: Available from European Committee for Standardization, Central Secretariat

10.1520/B0985-12R16. (CEN), rue de Stassart 36, B1050 Brussels, Belgium. http://www.cen.eu/esearch.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

B985 − 12 (2016)

4. Summary of Practice 6.1.1 Chips that will be prepared as described in Test

MethodE34orEN14242canbeobtainedbydrillingorcutting

4.1 The procedures described in this practice involve the

and drilling at the locations specified in Section 7 for each type

cuttinganddrillingofaluminumproductstoobtainsamplesfor

of product. The chips should be uniformly small in size and

subsequent chemical analysis in accordance withTest Methods

free from scale, dirt, oil, grease, and so forth.

E34, E607, E1251, or EN 14242.

6.1.1.1 Cleaning—Oil and grease may be removed from the

5. Significance and Use

chips by rinsing with alcohol then drying before taking the

laboratory sample. Scale and dirt may be removed by washing

5.1 Products covered by this practice are unwrought alumi-

num ingots, billets, and castings and unclad wrought aluminum with a detergent and water then rinsing with distilled de-

ionized water and drying before taking the laboratory sample.

sheet, plate, rolled or cold finished extrusions, extruded

profiles, wire, rod and bar. Machined wrought products (fin- Additional chemical cleaning such as soaking the chips in 1%

ished or semi-finished) are excluded (see Note 3). These

(by volume) nitric acid may be necessary to remove embedded

practices, used in conjunction with the appropriate sample contaminants. Other cleaning procedures may be used pro-

preparation techniques in Practices E716 and the Test Methods

vided they do not alter the chemical composition in any way.

E34, E607, E1251, and EN 14242, are suitable to determine if

6.1.2 Use of a carbide or diamond tipped drill bit should

the piece sampled meets the chemical composition limits

provide satisfactory samples. To obtain chips, use a drill bit

registered with the Aluminum Association Inc. or other

between 10 mm [0.4 in.] and 13 mm [0.5 in.] in diameter. A

specified chemical composition limits for the alloy.Analysis of

25 mm [1 in.] deep hole with a 10 mm [0.4 in.] bit typically

such samples shall not supersede the analysis of samples taken

produces about 5 g [0.18 oz] of sample. Drill enough holes to

during pouring of castings or ingots in accordance with

collect at least 20 g [0.71 oz] of chips.The initial chips from an

Practices E716 and analyzed in accordance with Test Methods

external surface shall be discarded for any surface that is

E34, E607, E1251, or EN 14242 and shall not be used for

contaminated; in other words, lubricants, surface conditioning

determining compliance with chemical composition require-

materials, dirt, scale, and so forth. The chips from all locations

ments for an entire cast lot or part thereof.

shallbethoroughlymixedpriortotakingthelaboratorysample

NOTE 3—Sampling machined pieces of products pose a particular

for analysis.

problem because the piece itself may not be a representative sample of the

original cast chemical composition. Larger differences may be expected

NOTE 6—Using a drill bit made from bare HSS (high speed steel) may

between an analysis obtained from samples taken in accordance with this

contaminate the sample with iron.

practice and the original cast analysis of samples taken during pouring of

castings or ingot.

6.1.2.1 Othermachiningmethodsmaybeusedprovidedthat

NOTE 4—Portable Spark-AES and hand held XRF instruments should

contamination-free chips are obtained from the specified area

not be used to determine if the piece sampled meets chemical composition

of the product being sampled. Products that are too thin to drill

limits registered with Aluminum Association Inc or other specified

may be sampled by clipping off small samples.

chemical composition limits for the alloy.

5.2 Users should be aware that chemical compositions

6.2 Sampling for Remelt Analysis using Practices E716 in

determined using samples taken from unwrought aluminum

Combination with Test Method E1251:

ingots, billets, and castings and finished or semi-finished

6.2.1 Samples that will be re-melted (see Notes 8 and 9)in

products might differ from the bulk chemical composition

accordance with Practices E716 for subsequent elemental

determined using samples taken when ingots or castings are

analysis using Test Method E1251 should be obtained by

poured. This difference can be due to elemental segregation

cutting, (in other words, sawing, snipping, or shearing) at the

upon solidification, sampling a non-homogenous section of the

locations specified in Section 7 for each type of product.

ingot or billet, removal of enriched material, or depleted areas

6.2.1.1 If it is not possible to obtain laboratory samples by

of solidified material by subsequent procedures such as ingot

cutting, laboratory samples may be obtained by drilling and

scalping, the removal of risers from castings, or machining.

re-melting the chips. Due to the high surface area of chips, it

NOTE 5—When aluminum solidifies, macro-segregation may cause the

may be necessary to press the chips into solid pellets with

chemical composition to vary throughout the ingot or casting. Certain

sufficient pressure to compact the chips to reduce dross

areas may have enhanced or depleted concentrations of some elements

formation. Pressure of 140 MPa [20,000 psi] has been shown

relative to the average bulk chemical composition. Remnants of the

macro-segregationmayberetainedinfinishedandsemi-finishedproducts.

to be adequate for compressing chips.

Thesamplingproceduresdescribedinthispracticearedesignedtoprovide

6.2.2 The amount of laboratory sample required depends on

a laboratory sample for analysis which represents the chemical composi-

the sampler type in use and the method used to preheat the

tion of the piece by taking samples in a way that symmetrically includes

the various enhanced and depleted zones for example, sampling across the sampler as required by E716. Preheating the sampler by taking

radius of a round ingot, and so forth.

and discarding a laboratory sample requires enough material

fortwolaboratorysamples.Preheatingbyothermeansrequires

6. Sampling and Handling Requirements Specific to Each

enough material for one laboratory sample. The type B book

Analysis Method

molds and Alcoa vacuum samplers require approximately

6.1 Sampling for the Analysis of Chips by Test Method E34

150 g [6 oz] and 60 g [2.5 oz] of metal per laboratory sample

or EN 14242:

respectively to completely fill the mold and sprue.

Available from TheAluminumAssociation, Inc., 1400 Crystal Drive Suite 430 NOTE7—A25mm[1in.]cubeofaluminumweighsapproximately45 g

Arlington, VA 22202, http://www.aluminum.org. [1.5 oz].

B985 − 12 (2016)

6.2.3 If possible, combine all cut samples into a single 7.1.1 Sampling a Round Ingot by Drilling—Prior to drilling,

laboratory sample in the remelt furnace. If the cut samples are metal must be removed or cropped from the head and butt of

too big for the remelt crucible, they may be cut into smaller round ingots. For ingots 250 mm [10 in.] or less in diameter,

size samples or multiple laboratory samples may be analyzed remove or crop at least 1.5 times the diameter from the head

separately. When analyzed separately, the chemical composi- and butt of the ingot. For ingots greater than 250 mm [10 in.]

tion reported should be the average analysis determined from in diameter, remove or crop at least 380 mm [15 in.] from the

multiple remelt and cast laboratory samples for each element head and butt of the ingot.

analyzed.

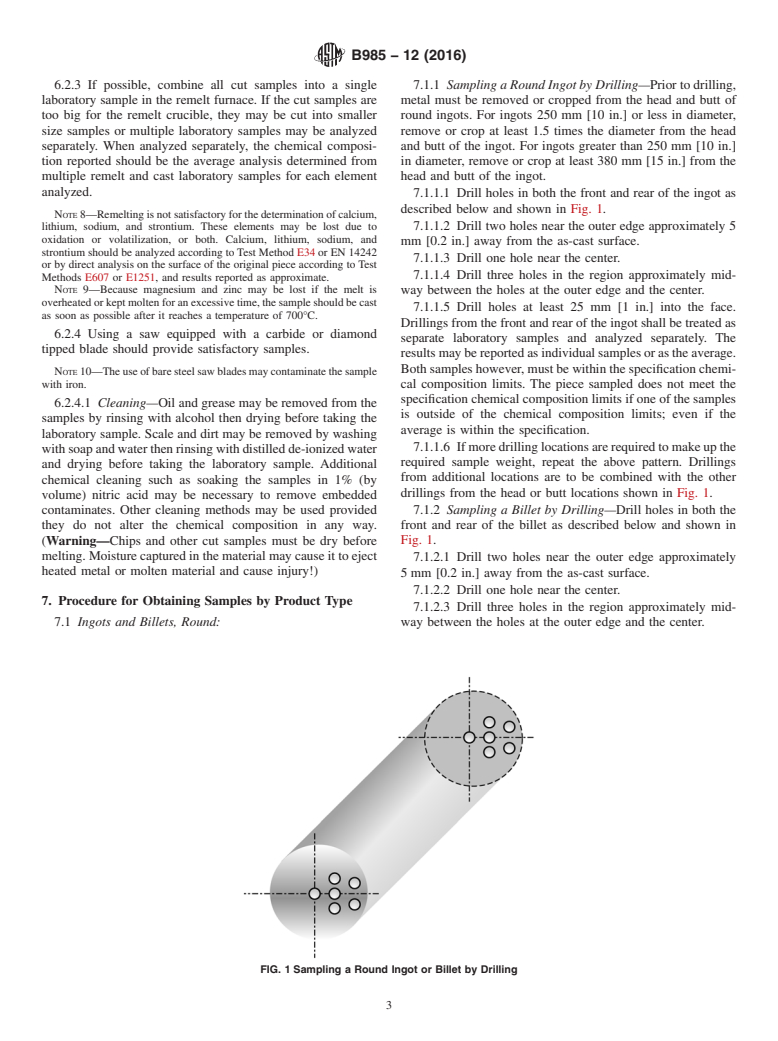

7.1.1.1 Drill holes in both the front and rear of the ingot as

described below and shown in Fig. 1.

NOTE8—Remeltingisnotsatisfactoryforthedeterminationofcalcium,

7.1.1.2 Drill two holes near the outer edge approximately 5

lithium, sodium, and strontium. These elements may be lost due to

oxidation or volatilization, or both. Calcium, lithium, sodium, and

mm [0.2 in.] away from the as-cast surface.

strontium should be analyzed according to Test Method E34 or EN 14242

7.1.1.3 Drill one hole near the center.

or by direct analysis on the surface of the original piece according to Test

7.1.1.4 Drill three holes in the region approximately mid-

Methods E607 or E1251, and results reported as approximate.

NOTE 9—Because magnesium and zinc may be lost if the melt is

way between the holes at the outer edge and the center.

overheatedorkeptmoltenforanexcessivetime,thesampleshouldbecast

7.1.1.5 Drill holes at least 25 mm [1 in.] into the face.

as soon as possible after it reaches a temperature of 700°C.

Drillings from the front and rear of the ingot shall be treated as

6.2.4 Using a saw equipped with a carbide or diamond

separate laboratory samples and analyzed separately. The

tipped blade should provide satisfactory samples.

resultsmaybereportedasindividualsamplesorastheaverage.

Both samples however, must be within the specification chemi-

NOTE10—Theuseofbaresteelsawbladesmaycontaminatethesample

with iron. cal composition limits. The piece sampled does not meet the

specification chemical composition limits if one of the samples

6.2.4.1 Cleaning—Oil and grease may be removed from the

is outside of the chemical composition limits; even if the

samples by rinsing with alcohol then drying before taking the

average is within the specification.

laboratory sample. Scale and dirt may be removed by washing

7.1.1.6 Ifmoredrillinglocationsarerequiredtomakeupthe

withsoapandwaterthenrinsingwithdistilledde-ionizedwater

required sample weight, repeat the above pattern. Drillings

and drying before taking the laboratory sample. Additional

from additional locations are to be combined with the other

chemical cleaning such as soaking the samples in 1% (by

drillings from the head or butt locations shown in Fig. 1.

volume) nitric acid may be necessary to remove embedded

7.1.2 Sampling a Billet by Drilling—Drill holes in both the

contaminates. Other cleaning m

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.