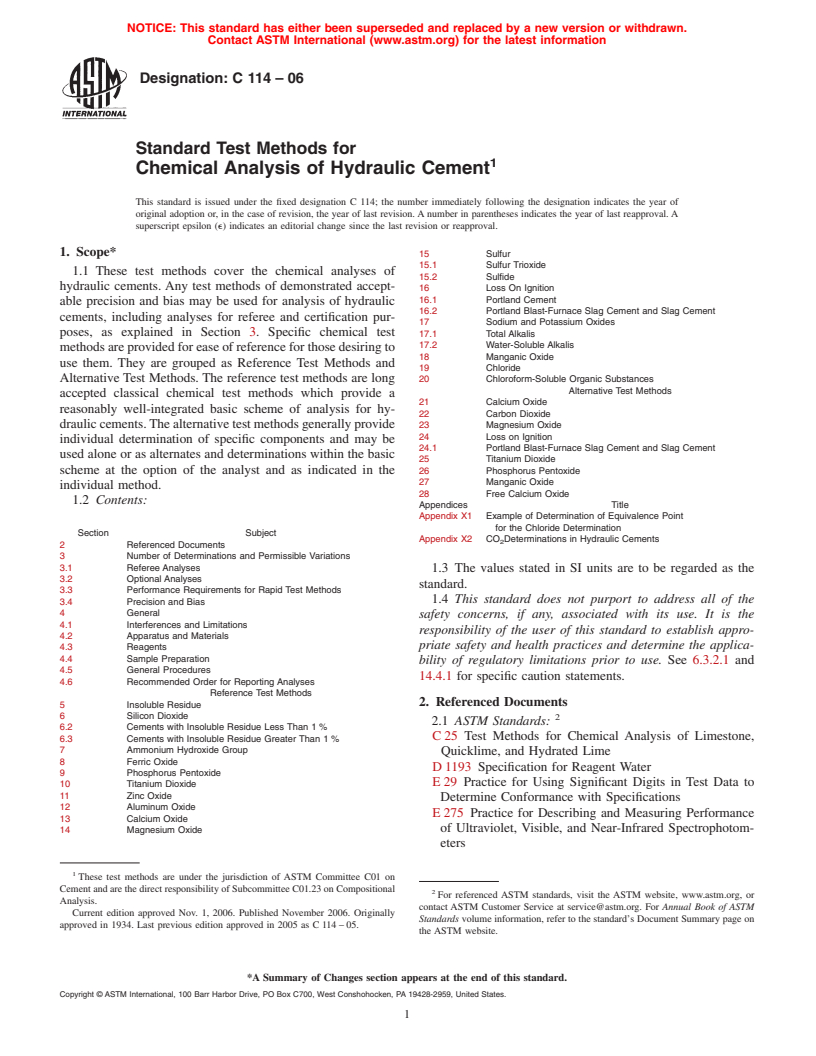

ASTM C114-06

(Test Method)Standard Test Methods for Chemical Analysis of Hydraulic Cement

Standard Test Methods for Chemical Analysis of Hydraulic Cement

SCOPE

1.1 These test methods cover the chemical analyses of hydraulic cements. Any test methods of demonstrated acceptable precision and bias may be used for analysis of hydraulic cements, including analyses for referee and certification purposes, as explained in Section 3. Specific chemical test methods are provided for ease of reference for those desiring to use them. They are grouped as Reference Test Methods and Alternative Test Methods. The reference test methods are long accepted classical chemical test methods which provide a reasonably well-integrated basic scheme of analysis for hydraulic cements. The alternative test methods generally provide individual determination of specific components and may be used alone or as alternates and determinations within the basic scheme at the option of the analyst and as indicated in the individual method.

1.2 Contents:

1.3 The values stated in SI units are to be regarded as the standard.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. See and for specific caution statements.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C 114 – 06

Standard Test Methods for

1

Chemical Analysis of Hydraulic Cement

This standard is issued under the fixed designation C 114; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope*

15 Sulfur

15.1 Sulfur Trioxide

1.1 These test methods cover the chemical analyses of

15.2 Sulfide

hydraulic cements. Any test methods of demonstrated accept-

16 Loss On Ignition

16.1 Portland Cement

able precision and bias may be used for analysis of hydraulic

16.2 Portland Blast-Furnace Slag Cement and Slag Cement

cements, including analyses for referee and certification pur-

17 Sodium and Potassium Oxides

poses, as explained in Section 3. Specific chemical test 17.1 Total Alkalis

17.2 Water-Soluble Alkalis

methodsareprovidedforeaseofreferenceforthosedesiringto

18 Manganic Oxide

use them. They are grouped as Reference Test Methods and

19 Chloride

Alternative Test Methods. The reference test methods are long 20 Chloroform-Soluble Organic Substances

Alternative Test Methods

accepted classical chemical test methods which provide a

21 Calcium Oxide

reasonably well-integrated basic scheme of analysis for hy-

22 Carbon Dioxide

drauliccements.Thealternativetestmethodsgenerallyprovide

23 Magnesium Oxide

24 Loss on Ignition

individual determination of specific components and may be

24.1 Portland Blast-Furnace Slag Cement and Slag Cement

used alone or as alternates and determinations within the basic

25 Titanium Dioxide

scheme at the option of the analyst and as indicated in the 26 Phosphorus Pentoxide

27 Manganic Oxide

individual method.

28 Free Calcium Oxide

1.2 Contents:

Appendices Title

Appendix X1 Example of Determination of Equivalence Point

for the Chloride Determination

Section Subject

Appendix X2 CO Determinations in Hydraulic Cements

2

2 Referenced Documents

3 Number of Determinations and Permissible Variations

3.1 Referee Analyses

1.3 The values stated in SI units are to be regarded as the

3.2 Optional Analyses

standard.

3.3 Performance Requirements for Rapid Test Methods

1.4 This standard does not purport to address all of the

3.4 Precision and Bias

4 General

safety concerns, if any, associated with its use. It is the

4.1 Interferences and Limitations

responsibility of the user of this standard to establish appro-

4.2 Apparatus and Materials

priate safety and health practices and determine the applica-

4.3 Reagents

4.4 Sample Preparation

bility of regulatory limitations prior to use. See 6.3.2.1 and

4.5 General Procedures

14.4.1 for specific caution statements.

4.6 Recommended Order for Reporting Analyses

Reference Test Methods

2. Referenced Documents

5 Insoluble Residue

6 Silicon Dioxide 2

2.1 ASTM Standards:

6.2 Cements with Insoluble Residue Less Than 1 %

C25 Test Methods for Chemical Analysis of Limestone,

6.3 Cements with Insoluble Residue Greater Than 1 %

7 Ammonium Hydroxide Group

Quicklime, and Hydrated Lime

8 Ferric Oxide

D1193 Specification for Reagent Water

9 Phosphorus Pentoxide

E29 Practice for Using Significant Digits in Test Data to

10 Titanium Dioxide

11 Zinc Oxide

Determine Conformance with Specifications

12 Aluminum Oxide

E275 Practice for Describing and Measuring Performance

13 Calcium Oxide

of Ultraviolet, Visible, and Near-Infrared Spectrophotom-

14 Magnesium Oxide

eters

1

These test methods are under the jurisdiction of ASTM Committee C01 on

CementandarethedirectresponsibilityofSubcommitteeC01.23onCompositional

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Analysis.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Current edition approved Nov. 1, 2006. Published November 2006. Originally

Standards volume information, refer to the standard’s Document Summary page on

approved in 1934. Last previous edition approved in 2005 as C114–05.

the ASTM website.

*ASummary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

C 114–06

E350 TestMethodsforChemicalAnalysisofCarbonSteel, E617 Specification for Laboratory Weights and Precision

Low-Alloy Steel, Silicon Electrical Steel, Ingot Iron, and Mass Standards

Wrought Iron E832 Specification for Laboratory Filter Papers

A

TABLE 1 Maximum Permissible Variations in Results

(Column 3)

(Column 2) Maximum

Maximum Difference of the

(Column 1)

Difference Average of

Component

Between Duplicates from

B

Duplicates SRM Certificate

C,D,B

Values

SiO (silicon dioxide) 0.16 60.2

2

Al O (aluminum oxide) 0.20 60.2

2 3

Fe O (ferric oxi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.