ASTM D5763-11

(Test Method)Standard Test Method for Oxidation and Thermal Stability Characteristics of Gear Oils Using Universal Glassware

Standard Test Method for Oxidation and Thermal Stability Characteristics of Gear Oils Using Universal Glassware

SIGNIFICANCE AND USE

Degradation of gear oils by oxidation or thermal breakdown, or both, can result in sludge buildup and render the oil unsuitable for further use as a lubricant.

This is the only test method that employs glassware to measure the amount of sludge produced during oxidation and thermal degradation. This test method is a modification of Test Method D2893 which measures the viscosity increase and precipitation number of the oil stressed at 95°C, but does not measure the amount of sludge formed.

This test method can be used to evaluate the oxidation/thermal stability of gear oils. However, the test results may not correlate with the performance of gear oils in field service.

SCOPE

1.1 This test method covers the determination of the oxidation characteristics of extreme pressure and non-extreme pressure gear oils and includes the quantitative determination of total sludge, viscosity change, and oil loss.

Note 1—While the round-robin tests used ISO VG 220 extreme pressure gear oils for developing precision data, the test method can be extended to other viscosity grades and to non-extreme pressure gear oils. Refer to Classification D2422 for viscosity grades.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D5763 − 11

StandardTest Method for

Oxidation and Thermal Stability Characteristics of Gear Oils

1

Using Universal Glassware

This standard is issued under the fixed designation D5763; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 3. Terminology

3.1 Definitions of Terms Specific to This Standard:

1.1 This test method covers the determination of the oxida-

tion characteristics of extreme pressure and non-extreme pres- 3.1.1 adherent sludge, n—sludge that is formed on the walls

sure gear oils and includes the quantitative determination of of a container and is not easily removed.

total sludge, viscosity change, and oil loss.

3.1.2 aliquot, n—portion of sample being tested that is a

representative portion of the whole.

NOTE 1—While the round-robin tests used ISO VG 220 extreme

pressure gear oils for developing precision data, the test method can be

3.1.3 extreme pressure gear oil, n—gear oil that contains

extended to other viscosity grades and to non-extreme pressure gear oils.

chemical additives, such as sulfur and phosphorus compounds,

Refer to Classification D2422 for viscosity grades.

whichproduceaprotectivefilmonthemetalsurfacetoprovide

1.2 The values stated in SI units are to be regarded as

anti-scuffing and anti-scoring properties.

standard. No other units of measurement are included in this

3.1.4 filterable sludge, n—sludge that is formed in the oil.

standard.

3.1.5 non-extreme pressure gear oil, n, n—gear oil that

1.3 This standard does not purport to address all of the

contains no extreme pressure additives.

safety concerns, if any, associated with its use. It is the

3.1.6 oxidation, n—theprocessbywhichoxygenchemically

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica- reacts with materials.

bility of regulatory limitations prior to use.

3.1.7 sludge, n—in gear oils, a precipitate that sometimes

forms as the oil ages or oxidizes.

2. Referenced Documents

3.1.8 universal glassware, n—the glassware that is de-

2

2.1 ASTM Standards:

scribed in the universal oxidation thermal stability test. Refer

D445 Test Method for Kinematic Viscosity of Transparent

to Guide D4871.

and Opaque Liquids (and Calculation of Dynamic Viscos-

ity)

4. Summary of Test Method

D2422 Classification of Industrial Fluid Lubricants by Vis-

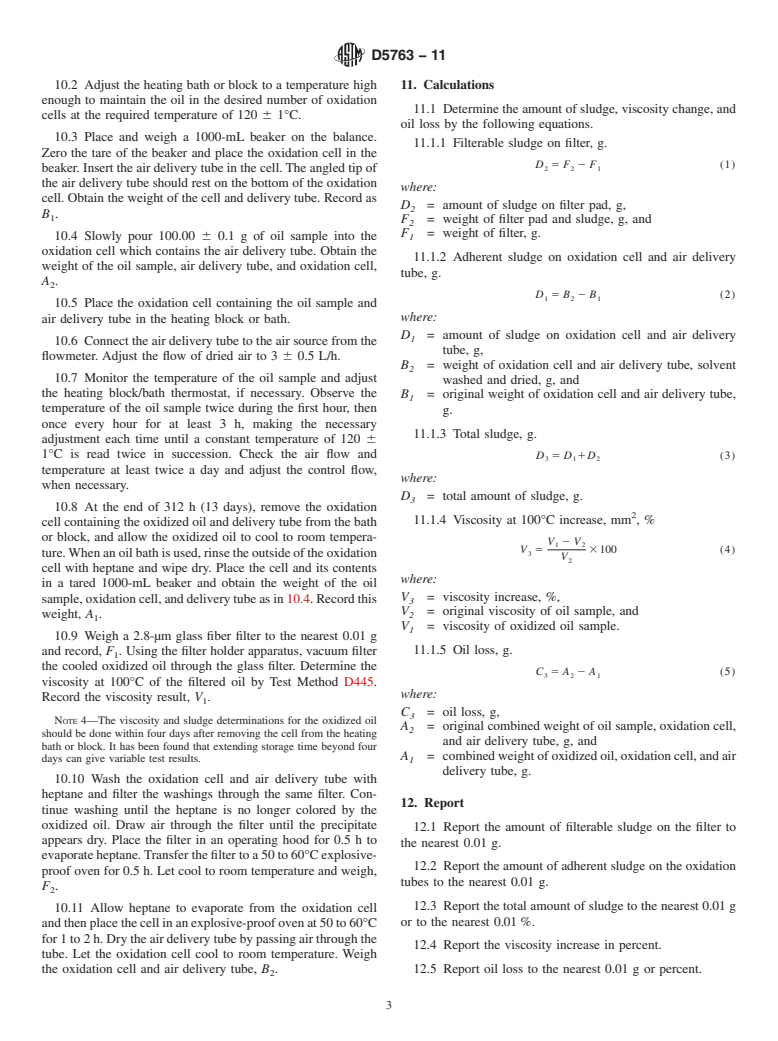

4.1 The viscosity of the gear oil being tested is determined.

cosity System

A 100-g aliquot of the oil in a weighed apparatus is subjected

D2893 Test Methods for Oxidation Characteristics of

to a temperature of 120°C for 312 h while dry air is passed

Extreme-Pressure Lubrication Oils

through the aliquot at 3 L/h.

D4057 Practice for Manual Sampling of Petroleum and

Petroleum Products 4.2 At the end of the stress period, the aliquot is cooled to

D4871 Guide for Universal Oxidation/Thermal Stability room temperature.The apparatus is reweighed to determine oil

Test Apparatus

loss. Filterable sludge is recovered by vacuum filtration using

a 2.8-µm glass fiber filter medium. The viscosity of the filtered

oil is determined. Sludge adhering to the oxidation cell and

associated glassware is rinsed with heptane and the washings

1

This test method is under the jurisdiction of ASTM Committee D02 on

passed through the same filter used to filter the filterable

Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of

Subcommittee D02.09.0D on Oxidation of Lubricants.

sludge. The filter is dried in an oven to a constant weight to

Current edition approved Dec. 1, 2011. Published March 2012. Originally

determine the total filterable sludge.

ε1

approved in 1995. Last previous edition approved in 2006 as D5763–95(2006) .

DOI: 10.1520/D5763-11.

4.3 The apparatus is dried and weighed to determine the

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

amountofadherentsludge.Thesumofthefilterablesludgeand

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

adherent sludge is reported as total sludge. The percentage

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. change in viscosity and percent oil loss are also reported.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D5763 − 11

5. Significance and Use be clamped between the ground glass sealing surfaces of the

funnel and its base by means of a metal clamp.

5.1 Degradation

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation:D5763–95 (Reapproved 2006) Designation:D5763–11

Standard Test Method for

Oxidation and Thermal Stability Characteristics of Gear Oils

1

Using Universal Glassware

This standard is issued under the fixed designation D5763; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1

´ NOTE—Added research report to existing footnote for Section 13 editorially in December 2008.

1. Scope*

1.1 This test method covers the determination of the oxidation characteristics of extreme pressure and non-extreme pressure

gear oils and includes the quantitative determination of total sludge, viscosity change, and oil loss.

NOTE 1—While the round-robin tests used ISO VG 220 extreme pressure gear oils for developing precision data, the test method can be extended to

other viscosity grades and to non-extreme pressure gear oils. Refer to Classification D2422 for viscosity grades.

1.2The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D445 Test Method for Kinematic Viscosity of Transparent and Opaque Liquids (and Calculation of Dynamic Viscosity)

D2422 Classification of Industrial Fluid Lubricants by Viscosity System

D2893 Test Methods for Oxidation Characteristics of Extreme-Pressure Lubrication Oils

D4057 Practice for Manual Sampling of Petroleum and Petroleum Products

D4871 Guide for Universal Oxidation/Thermal Stability Test Apparatus

E1Specification for ASTM Liquid-in-Glass Thermometers Guide for Universal Oxidation/Thermal Stability Test Apparatus

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

3.1.1 adherent sludge, n—sludge that is formed on the walls of a container and is not easily removed.

3.1.2 aliquot, n—portion of sample being tested that is a representative portion of the whole.

3.1.3 extreme pressure gear oil, n—gear oil that contains chemical additives, such as sulfur and phosphorus compounds, which

produce a protective film on the metal surface to provide anti-scuffing and anti-scoring properties.

3.1.4 filterable sludge, n—sludge that is formed in the oil.

3.1.5 non-extreme pressure gear oil, n, n—gear oil that contains no extreme pressure additives.

3.1.6 oxidation, n—the process by which oxygen chemically reacts with materials.

3.1.7 sludge, n—in gear oils, a precipitate that sometimes forms as the oil ages or oxidizes.

3.1.8 universal glassware, n—the glassware that is described in the universal oxidation thermal stability test. Refer to Guide

D4871.

4. Summary of Test Method

4.1 The viscosity of the gear oil being tested is determined. A 100-g aliquot of the oil in a weighed apparatus is subjected to

1

This test method is under the jurisdiction ofASTM Committee D02 on Petroleum Products and Lubricants and is the direct responsibility of Subcommittee D02.09.0D

on Oxidation of Lubricants.

Current edition approved Nov. 1, 2006. Published January 2007. Originally approved in 1995. Last previous edition approved in 2001 as D5763–95 (2001). DOI:

10.1520/D5763-95R06E01.

´1

Current edition approved Dec. 1, 2011. Published March 2012. Originally approved in 1995. Last previous edition approved in 2006 as D5763–95(2006) . DOI:

10.1520/D5763-11.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D5763–11

a temperature of 120°C for 312 h while dry air is passed through the aliquot at 3 L/h.

4.2 At the end of the stress period, the aliquot is cooled to room temperature. The

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.