ASTM D95-99

(Test Method)Standard Test Method for Water in Petroleum Products and Bituminous Materials by Distillation

Standard Test Method for Water in Petroleum Products and Bituminous Materials by Distillation

SCOPE

1.1 This test method covers the determination of water in petroleum products, tars, and other bituminous materials by the distillation method. The specific products considered during the development of this test method are listed in Table 1. For bituminous emulsions refer to Test Method D244. This test method, along with ASTM Test Method D4006 (API Chapter 10.2 and IP 358), supersedes the previous edition of ASTM Test Method D95 (API Standard 2560, IP74). Note 1-With some types of oil, satisfactory results may be obtained from ASTM Test Method D4007 (API Chapter 10.3, IP 358, and ASTM Method D1796 API Chapter 10.6).

1.2 This standard may involve hazardous materials, operations, and equipment. This standard does not purport to address all of the safety problems associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.> For specific hazard statements, see 5.1.1.2 and 5.1.1.3.

1.3 The values stated in SI units are to be regarded as the standard. The values in parentheses are for information only.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 95 – 99 An American National Standard

American Association State

Highway Transportation Standard

AASHTO No. T55

MPMS Chapter 10.5

Designation: 74/82 (88)

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Test Method for

Water in Petroleum Products and Bituminous Materials by

Distillation

This standard is issued under the fixed designation D 95; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A superscript

epsilon (e) indicates an editorial change since the last revision or reapproval.

This test method has been approved by the sponsoring committees and accepted by the cooperating organizations in accordance with

established procedures.

This standard has been approved for use by agencies of the Department of Defense.

TABLE 1 Type of Solvent-Carrier Liquid Versus Material to Be

1. Scope

Tested

1.1 This test method covers the determination of water in

Type of Solvent-Carrier Liquid Material to be Tested

the range from 0 to 25 % volume in petroleum products, tars,

Aromatic asphalt, tar, coal tar, water gas tar, road

and other bituminous materials by the distillation method.

tar, cut-back bitumin, liquid asphalt, tar

acid

NOTE 1—Volatile water-soluble material, if present, may be measured

Petroleum distillate road oil, fuel oil, lubricating oil, petroleum

as water.

sulfonates

Volatile spirits lubricating grease

1.2 The specific products considered during the develop-

ment of this test method are listed in Table 1. For bituminous

emulsions refer to Test Method D 244. For crude oils, refer to

the Centrifuge Method (Laboratory Procedure)

Test Method D 4006.

D 4006 Test Method for Water in Crude Oil by Distillation

D 4057 Practice for Manual Sampling of Petroleum and

NOTE 2—With some types of oil, satisfactory results may be obtained

Petroleum Products

from Test Method D 1796.

D 4177 Practice for Automatic Sampling of Petroleum and

1.3 The values stated in SI units are to be regarded as the

Petroleum Products

standard. The values in parentheses are for information only.

D 5854 Practice for Mixing and Handling of Liquid

1.4 This standard may involve hazardous materials, opera-

Samples of Petroleum and Petroleum Products

tions, and equipment. This standard does not purport to

E 123 Specification for Apparatus for Determination of

address all of the safety concerns, if any, associated with its

Water by Distillation

use. It is the responsibility of the user of this standard to

2.2 API Manual of Petroleum Measurements Standards:

establish appropriate safety and health practices and deter-

Chapter 8.1 Manual Sampling of Petroleum and Petroleum

mine the applicability of regulatory limitations prior to use.

Products (ASTM Practice D 4057)

For specific hazard statements, see Section 5 .

Chapter 8.2 Automatic Sampling of Petroleum and Petro-

leum Products (ASTM Practice D 4177)

2. Referenced Documents

Chapter 8.3 Mixing and Handling of Liquid Samples of

2.1 ASTM Standards:

Petroleum and Petroleum Products

D 244 Test Methods for Emulsified Asphalts

Chapter 10.2 Determination of Water in Crude Oil by the

D 1796 Test Method for Water and Sediment in Fuel Oils by

Distillation Method (ASTM Test Method D 4006)

This test method is under the jurisdiction of ASTM Committee D-2 on

Petroleum Products and Lubricants and API Committee on Petroleum Measurement Annual Book of ASTM Standards, Vol 05.01.

and is the direct responsibility of Subcommittee D02.02, the Joint ASTM-API Annual Book of ASTM Standards, Vol 05.02.

Committee on Static Petroleum Measurement. Annual Book of ASTM Standards, Vol 05.03.

Current edition approved June 10, 1999. Published August 1999. Originally Annual Book of ASTM Standards, Vol 14.02.

published as D 95.21. Last previous edition D 95 – 83 (90). Available from American Petroleum Institute, 1220 L St., N.W., Washington,

Annual Book of ASTM Standards, Vol 04.03. DC 20005.

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D95

Chapter 10.6 Determination of Water and Sediment in Fuel be determined by distilling an equivalent amount of the same

Oil by the Centrifuge Method (ASTM Test Method solvent used for the test sample in the distillation apparatus and

D 1796) testing as outlined in Section 9. The blank shall be determined

to the nearest scale division and used to correct the volume of

3. Summary of Test Method

water in the trap in Section 10.

3.1 The material to be tested is heated under reflux with a

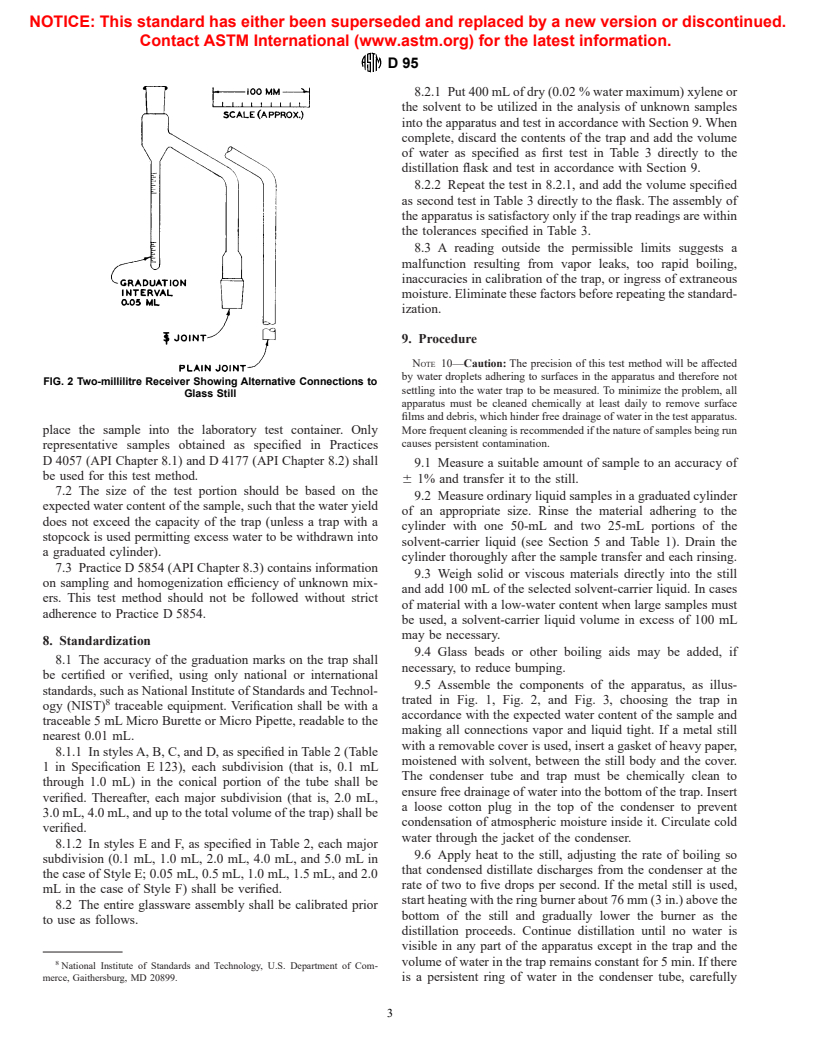

6. Apparatus

water-immiscible solvent, which co-distills with the water in

the sample. Condensed solvent and water are continuously 6.1 General—The apparatus comprises a glass or metal

separated in a trap, the water settling in the graduated section

still, a heater, a reflux condenser, and a graduated glass trap.

of the trap and the solvent returning to the still. The still, trap, and condenser may be connected by any suitable

method that produces a leakproof joint. Preferred connections

4. Significance and Use

are ground joints for glass and O-rings for metal to glass.

4.1 A knowledge of the water content of petroleum products

Typical assemblies are illustrated in Fig. 1, Fig. 2, and Fig. 3.

is important in the refining, purchase, sale, and transfer of

The stills and traps should be chosen to cover the range of

products.

materials and water contents expected. On assembly, care

4.2 The amount of water as determined by this test method

should be taken to prevent the joints from freezing or sticking.

(to the nearest 0.05 volume %) may be used to correct the

This may be prevented by the application of a very thin film of

volume involved in the custody transfer of petroleum products

stopcock grease.

and bituminous materials.

6.2 Still—A glass or metal vessel with a short neck and

4.3 The allowable amount of water may be specified in

suitable joint for accommodating the reflux tube of the trap

contracts.

shall be used. Vessels of 500, 1000, and 2000-mL nominal

capacity have proved satisfactory.

5. Solvent-Carrier Liquid

6.3 Heater—A suitable gas burner or electric heater may be

5.1 A solvent-carrier liquid appropriate to the material being

used with the glass still. A gas ring burner with ports on the

tested (see Table 1) shall be used.

inside circumference shall be used with the metal still. The gas

5.1.1 Aromatic Solvent—The following aromatic solvents

ring burner shall be of such dimensions that it may be moved

are acceptable:

up and down the vessel when testing materials that are likely to

5.1.1.1 Industrial Grade Xylene.

foam or solidify in the still.

6.4 Glassware—Dimensions and descriptions of typical

NOTE 3—Warning: Flammable. Vapor harmful.

glassware for use in this test method are provided in Specifi-

5.1.1.2 A blend of 20 volume % industrial grade toluene and

cation E 123.

80 volume % industrial grade xylene.

NOTE 9—Instead of standardizing on a particular apparatus specifica-

NOTE 4—Warning: Flammable. Vapor harmful.

tion with respect to dimensions and style, a given apparatus will be

deemed satisfactory when accurate results are obtained by the standard

5.1.1.3 Petroleum or Coal Tar Naphtha, free of water,

addition technique described in Section 8.

yielding not more than 5% distillates at 125°C (257°F) and not

less than 20% at 160°C (320°F) and with a relative density

7. Sampling

(specific gravity) not lower than 0.8545 at 15.56/15.56°C

7.1 Sampling is defined as all steps required to obtain an

(60/60°F).

aliquot of the contents of any pipe, tank, or other system and to

NOTE 5—Warning: Extremely flammable. Harmful if inhaled. Vapors

may cause fire.

5.1.2 Petroleum Distillate Solvent—A petroleum distillate

solvent, 5% boiling between 90 and 100°C (194 and 212°F)

and 90% distilling below 210°C (410°F), shall be used. Percent

may be determined by mass or by volume. These solvents are

available from most chemical companies under the name of

stoddard solvent or ligroine.

NOTE 6—Warning: Flammable. Vapor harmful.

5.1.3 Volatile Spirits Solvent—The following volatile spirits

solvents are acceptable:

5.1.3.1 Petroleum Spirit, with a boiling range from 100 to

120°C (212 to 248°F).

NOTE 7—Warning: Flammable. Vapor harmful.

5.1.3.2 Isooctane, of 95% purity or better.

NOTE 8—Warning: Extremely flammable. Harmful if inhaled. Vapors

may cause fire.

5.2 Solvent Blank—The water content of the solvent shall FIG. 1 Typical Assembly with Glass Still

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D95

8.2.1 Put 400 mL of dry (0.02 % water maximum) xylene or

the solvent to be utilized in the analysis of unknown samples

into the apparatus and test in accordance with Section 9. When

complete, discard the contents of the trap and add the volume

of water as specified as first test in Table 3 directly to the

distillation flask and test in accordance with Section 9.

8.2.2 Repeat the test in 8.2.1, and add the volume specified

as second test in Table 3 directly to the flask. The assembly of

the apparatus is satisfactory only if the trap readings are within

the tolerances specified in Ta

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.