ASTM G118-02(2015)

(Guide)Standard Guide for Recommended Format of Wear Test Data Suitable for Databases (Withdrawn 2016)

Standard Guide for Recommended Format of Wear Test Data Suitable for Databases (Withdrawn 2016)

SIGNIFICANCE AND USE

5.1 This guide can be used to facilitate categorizing wear data for insertion into a computerized database. This guide identifies a set of essential data fields which should be provided for all records, and also identifies additional optional data fields. This guide does not require the use of any particular database format, nor does it endorse any particular computer database software.

5.2 Because of increased activity in building computerized databases and the desire to encourage their uniformity and therefore the ease of data comparison and data interchange, it is appropriate to provide a guide for the inclusion of wear test data in databases. Availability of a guide also encourages the builders of databases to include sufficiently complete information so that comparisons among individual sources may be made with assurance that similarities or differences, or both, in the wear test procedures and conditions are covered.

5.3 The set of data fields described in this guide will usually be expanded and customized by the user for specific purposes. It should be possible to arrange the additional fields within the logical structure that is presented in this guide.

5.4 This guide does not apply to data from rolling contact wear tests, galling tests, or erosion or cavitation tests. Data that are included should apply to standard tests or to steady-state wear.

5.5 This guide has no implication on data required for materials production or purchase. Reporting of actual test results should be as described in the actual material specification or as agreed upon between the purchaser and the manufacturer, as shown on the purchase order and acknowledgement.

SCOPE

1.1 This guide covers and is intended to assist in the organization of wear test data for the purpose of data storage in computerized databases. It is meant to assist the user in developing databases for the purpose of data comparison and utilization. Data elements (fields) are described covering both materials and wear test issues.

WITHDRAWN RATIONALE

This guide covered and was intended to assist in the organization of wear test data for the purpose of data storage in computerized databases. It was meant to assist the user in developing databases for the purpose of data comparison and utilization. Data elements (fields) were described covering both materials and wear test issues.

Formerly under the jurisdiction of Committee G02 on Wear and Erosion, this guide was withdrawn in November 2016. This standard is being withdrawn without replacement due to its limited use by industry.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: G118 − 02(Reapproved 2015)

Standard Guide for

Recommended Format of Wear Test Data Suitable for

Databases

This standard is issued under the fixed designation G118; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope G115 Guide for Measuring and Reporting Friction Coeffi-

cients

1.1 This guide covers and is intended to assist in the

G132 Test Method for Pin Abrasion Testing

organization of wear test data for the purpose of data storage in

computerized databases. It is meant to assist the user in 2.2 ANSI Standard:

developing databases for the purpose of data comparison and B46.1.85 Surface Texture, Surface Roughness, Waviness

utilization. Data elements (fields) are described covering both

materials and wear test issues. 3. Terminology

3.1 Definitions—For definitions of some terms applicable to

2. Referenced Documents

this guide, see Practice E1314 and Terminology G40.

2.1 ASTM Standards:

3.2 Definitions of Terms Specific to This Standard:

E527 Practice for Numbering Metals and Alloys in the

3.2.1 class—major material class, for example, metal,

Unified Numbering System (UNS)

ceramic, polymer, etc.

E1314 Practice for Structuring Terminological Records Re-

3.2.2 common name—name frequently given to a particular

lating to Computerized Test Reporting and Materials

material, for example, nylon.

Designation Formats (Withdrawn 2000)

E1338 Guide for Identification of Metals and Alloys in

3.2.3 contact environment—terms describing the environ-

Computerized Material Property Databases

ment at the contact, for example, atmosphere, humidity, gases

G40 Terminology Relating to Wear and Erosion

present, and so forth.

G65 Test Method for Measuring Abrasion Using the Dry

3.2.4 form—materialform,forexample,rod,sheet,andcast.

Sand/Rubber Wheel Apparatus

3.2.5 grade—designation given a material by a manufac-

G75 Test Method for Determination of Slurry Abrasivity

turer.

(Miller Number) and Slurry Abrasion Response of Mate-

3.2.6 hardness—usual methods for hardness determinations

rials (SAR Number)

include Rockwell C, Vickers, etc. Load should be specified.

G77 Test Method for Ranking Resistance of Materials to

Sliding Wear Using Block-on-Ring Wear Test

3.2.7 processing treatment—descriptive phrase on the pro-

G83 Test Method for Wear Testing with a Crossed-Cylinder

cess method, for example, casting, hardening, and conditions,

Apparatus (Withdrawn 2005)

for example, time, temperature.

G99 Test Method for Wear Testing with a Pin-on-Disk

3.2.8 specification—precise statement of a set of require-

Apparatus

ments to be satisfied by a material, promulgated by an

G105 Test Method for Conducting Wet Sand/Rubber Wheel

organization, for example, ASTM, SAE, etc.

Abrasion Tests

3.2.9 specimen shape—shape of the test specimen, for

example, block, pin.

This guide is under the jurisdiction of ASTM Committee G02 on Wear and

3.2.10 standard test specification—test designation, that is,

Erosion and is the direct responsibility of Subcommittee G02.20 on Data Acquisi-

ASTM, SAE, etc. (Note that the test must conform to the

tion in Tribosystems.

standard if so designated.)

Current edition approved May 1, 2015. Published May 2015. Originally

approved in 1993. Last previous edition approved in 2007 as G118–02 (2007). DOI:

3.2.11 subclass—subdivisions of a class, for example,

10.1520/G0118-02R15.

ferrous, boride, etc.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

3 4

The last approved version of this historical standard is referenced on Available from American National Standards Institute (ANSI), 25 W. 43rd St.,

www.astm.org. 4th Floor, New York, NY 10036, http://www.ansi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

G118 − 02 (2015)

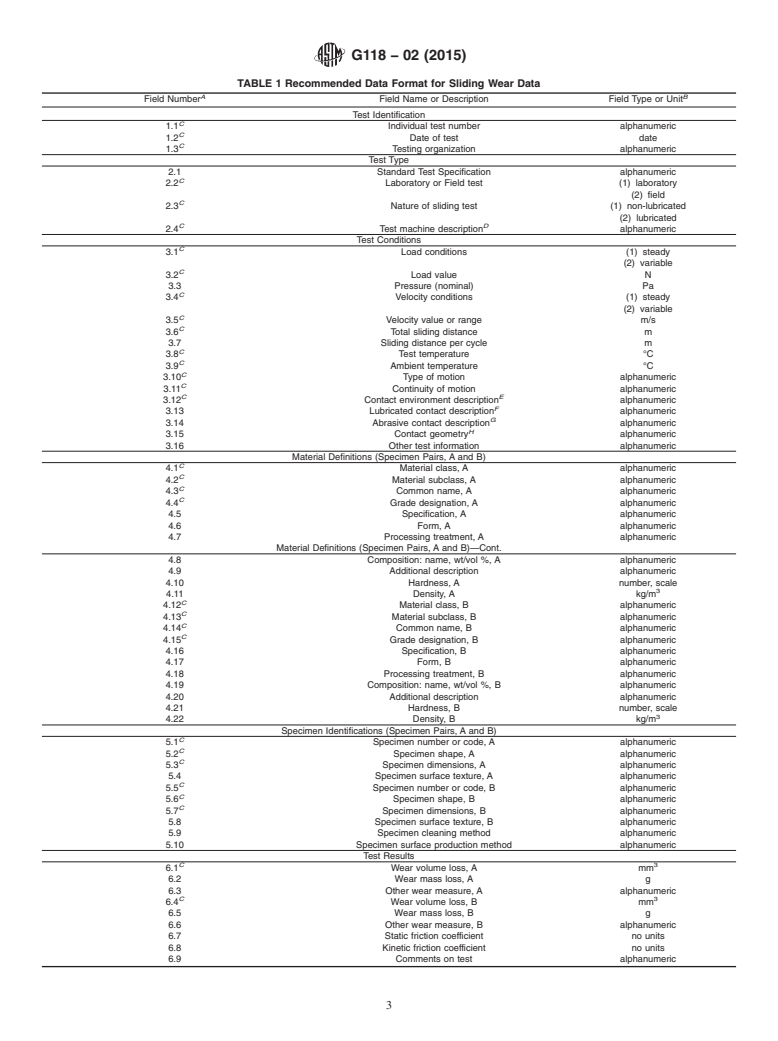

4. Summary of Guide 6.1.5 Specimen Identification—Detailed information on the

test specimens, for example, size, surface texture (ANSI

4.1 This guide specifies a set of fields that form the basis of

B46.1.85).

a format for organizing wear data for use in computerized

6.1.6 Test Results—Listing of the numeric results of the test,

databases. Sufficient information is provided in this guide to

for example, amount of wear, friction coefficient (see Guide

enable the user to construct a database structure suitable for an

G115 for details of friction measurements).

intended application involving wear.Aset of essential fields in

6.1.7 Documentation—Identification of the location and

the database are identified. The user may also add or delete

type of documentation concerning the test data, for example,

fields to customize the database format for any particular

place of publication.

application.

5. Significance and Use 7. Data Format

5.1 This guide can be used to facilitate categorizing wear 7.1 A recommended format for wear test data is shown in

data for insertion into a computerized database. This guide Table 1. An example of the use of this format is shown in

identifiesasetofessentialdatafieldswhichshouldbeprovided Appendix X1. There are three columns of information for each

for all records, and also identifies additional optional data item, that is, each field name, as follows:

fields. This guide does not require the use of any particular 7.1.1 Field Reference Number—A number for each indi-

database format, nor does it endorse any particular computer vidual field within this format guideline. This number has no

database software. permanent value and does not become part of the database

itself.The number is keyed to the set of categories presented in

5.2 Because of increased activity in building computerized

Section 6 of this guide.

databases and the desire to encourage their uniformity and

7.1.2 Field Name or Description—The complete name of

therefore the ease of data comparison and data interchange, it

the field, descriptive of the information to be entered in this

is appropriate to provide a guide for the inclusion of wear test

field of the database.

data in databases. Availability of a guide also encourages the

7.1.3 Field Type—There are three types of fields as de-

builders of databases to include sufficiently complete informa-

scribed in the following:

tion so that comparisons among individual sources may be

7.1.3.1 Category Sets—Closed (complete) sets containing

made with assurance that similarities or differences, or both, in

all possible (acceptable) inputs to the field.

the wear test procedures and conditions are covered.

7.1.3.2 Alphanumeric—Representative inputs to the field.

5.3 The set of data fields described in this guide will usually

7.1.3.3 Numeric—The numeric value in the units listed.

be expanded and customized by the user for specific purposes.

7.2 The fields included in this format are those recom-

It should be possible to arrange the additional fields within the

mended to provide sufficiently complete information that users

logical structure that is presented in this guide.

may be confident of their ability to compare sets of data from

5.4 This guide does not apply to data from rolling contact

individual databases. This set of fields should make the

wear tests, galling tests, or erosion or cavitation tests. Data that

database useful to a relatively broad range of users.

are included should apply to standard tests or to steady-state

7.3 It is recognized that many databases are prepared for

wear.

very specific applications, and individual database builders

5.5 This guide has no implication on data required for

may elect to omit certain pieces of information considered to

materials production or purchase. Reporting of actual test

be of no value for that specific application. However, there are

results should be as described in the actual material specifica-

certain minimum number of fields considered essential to any

tion or as agreed upon between the purchaser and the

database without which the user will not have sufficient

manufacturer, as shown on the purchase order and acknowl-

information to reasonably interpret or compare the data. In the

edgement.

recommended format (Table 1), these fields are marked.

6. Data Categorization

7.4 The presentation of this format does not represent a

requirement that all of the elements included in the recommen-

6.1 Seven general categories of data are identified for use

dation be appropriate for every database. Rather it is a guide to

with wear databases, as follows:

those elements that are likely to be useful to at least some users

6.1.1 Test Identification—Coded information that describes

of most databases. It is understood that not all of the elements

the test, for example, test number.

of information recommended for inclusion will be available in

6.1.2 Test Type—Identification of the type of sliding wear

alldatabases.Thatfactshouldnotdiscouragedatabasebuilders

test, for example, standardized (examples include Test Meth-

and users from proceeding so long as the minimum essential

ods G77, G83, and G99).

information is included (the items marked). Blank fields are

6.1.3 Test Conditions—Description of the exposure

acceptable where the required information is not available.

conditions, for example, test load.

6.1.4 Material Definition—Informationonthematerialpairs

8. Keywords

used in the test, for example, common names (background

information is provided in Practice E527 and Guide E1338). 8.1 computer; data; database; format; wear

G118 − 02 (2015)

TABLE 1 Recommended Data Format for Sliding Wear Data

A B

Field Number Field Name or Description Field Type or Unit

Test Identification

C

1.1 Individual test number alphanumeric

C

1.2 Date of test date

C

1.3 Testing organization alphanumeric

Test Type

2.1 Standard Test Specification alphanumeric

C

2.2 Laboratory or Field test (1) laboratory

(2) field

C

2.3 Nature of sliding test (1) non-lubricated

(2) lubricated

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.