ASTM A437/A437M-10a

(Specification)Standard Specification for Stainless and Alloy-Steel Turbine-Type Bolting Specially Heat Treated for High-Temperature Service

Standard Specification for Stainless and Alloy-Steel Turbine-Type Bolting Specially Heat Treated for High-Temperature Service

ABSTRACT

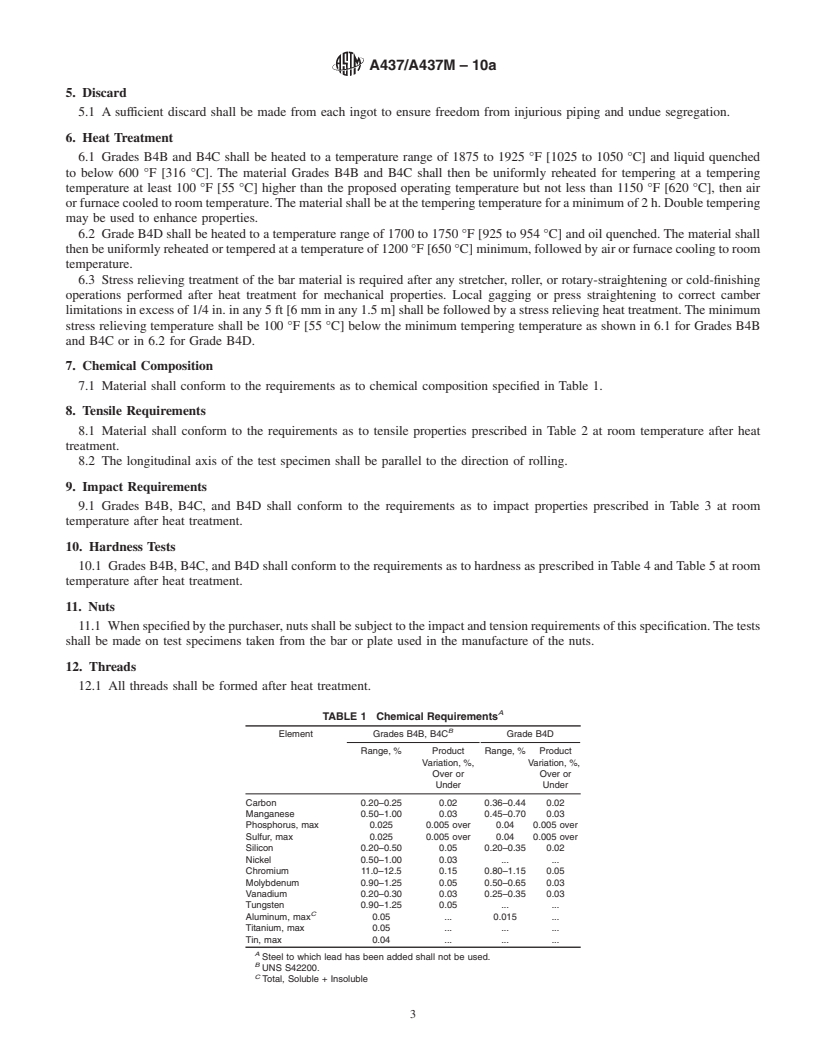

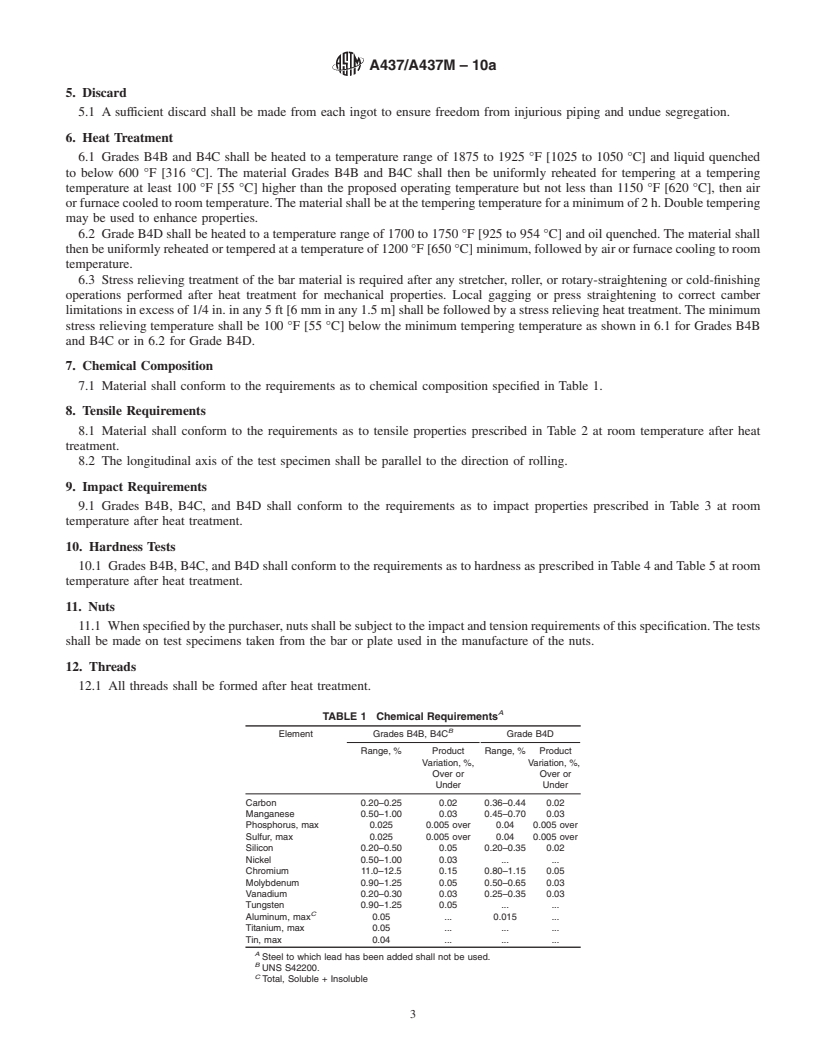

This specifications covers alloy-steel bolting material specially heat treated for high-temperature service, such as steam turbine, gas turbine, and similar uses. The grades of steels covered here are: Grade B4B, Grade B4C, and Grade B4D. Steels of Grades B4B and B4C shall undergo heating, liquid quenching, reheating, tempering, and air or furnace cooling, respectively. Steels of Grade B4D shall undergo heating, oil quenching, reheating or tempering, and air of furnace cooling, respectively. Heat and product analyses shall be performed wherein specimens shall conform to required chemical composition of carbon, manganese, phosphorus, sulfur, silicon, nickel, chromium, molybdenum, vanadium, tungsten, aluminum, titanium, and tin. The steels shall undergo tensile, impact, and hardness tests, and shall conform to the following mechanical requirements: tensile strength, yield strength, elongation, impact value, Brinell hardness number, and Rockwell hardness number. All bars or forged blanks of starting material shall be subjected to nondestructive inspection using any of the following methods: Eddy current, Magnetic particle inspection (wet or dry), Liquid penetrant inspection, Ultrasonic testing, or Visual testing.

SCOPE

1.1 This specification covers stainless and alloy-steel bolting specially heat treated for high-temperature service, such as steam turbine, gas turbine, and similar uses. See Specification for the definition of bolting. This material requires special processing and should not be used in general-purpose applications. Bolting furnished as bars shall be hot wrought and may be further processed by centerless grinding or by cold drawing.

1.2 The high-temperature properties of the bolting covered by this specification are dependent upon special heat treatment, which is required. Although the high-temperature properties are not specified, they are implied by control of the chemistry, heat treatment, and room-temperature properties of the material.

1.3 Three levels of bolting strength are covered, designated Grades B4B, B4C, and B4D.

1.4 The following referenced general requirements are indispensable for application of this specification: Specification .

1.5 Supplementary requirements are provided for use at the option of the purchaser. The supplementary requirements shall apply only when specified individually by the purchaser in the purchase order or contract.

1.6 This specification is expressed in both inch-pound units and in SI units; however, unless the purchase order or contract specifies the applicable M specification designation (SI units), the inch-pound units shall apply.

1.7 The values stated in either SI units or inch-pound units are to be regarded separately as standard. Within the text, the SI units are shown in brackets. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: A437/A437M – 10a

Standard Specification for

Stainless and Alloy-Steel Turbine-Type Bolting Specially

1

Heat Treated for High-Temperature Service

This standard is issued under the fixed designationA437/A437M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* shall be used independently of the other. Combining values

2 from the two systems may result in non-conformance with the

1.1 This specification covers stainless and alloy-steel bolt-

standard.

ing specially heat treated for high-temperature service, such as

steam turbine, gas turbine, and similar uses. See Specification

2. Referenced Documents

A962/A962M for the definition of bolting. This material

3

2.1 ASTM Standards:

requires special processing and should not be used in general-

A962/A962M Specification for Common Requirements for

purpose applications. Bolting furnished as bars shall be hot

Bolting Intended for Use at Any Temperature from Cryo-

wrought and may be further processed by centerless grinding

genic to the Creep Range

or by cold drawing.

E292 Test Methods for Conducting Time-for-Rupture

1.2 The high-temperature properties of the bolting covered

Notch Tension Tests of Materials

by this specification are dependent upon special heat treatment,

E112 Test Methods for Determining Average Grain Size

which is required. Although the high-temperature properties

are not specified, they are implied by control of the chemistry,

3. Ordering Information

heat treatment, and room-temperature properties of the mate-

3.1 It shall be the responsibility of the purchaser to specify

rial.

all requirements necessary for product under this specification.

1.3 Three levels of bolting strength are covered, designated

Such requirements to be considered include, but are not limited

Grades B4B, B4C, and B4D.

to, the following:

1.4 The following referenced general requirements are in-

3.1.1 Specification designation, grade, issue date, and revi-

dispensable for application of this specification: Specification

sion letter,

A962/A962M.

3.1.2 Quantity (weight or number of pieces),

1.5 Supplementary requirements are provided for use at the

3.1.3 Description (bars, bolts, nuts, etc.),

option of the purchaser. The supplementary requirements shall

3.1.4 Dimensions,

apply only when specified individually by the purchaser in the

3.1.5 Finish, and

purchase order or contract.

3.1.6 Impact testing of nuts, if required (see Section 9).

1.6 This specification is expressed in both inch-pound units

and in SI units; however, unless the purchase order or contract

4. Common Requirements

specifies the applicable M specification designation (SI units),

4.1 Bolting supplied to this specification shall conform to

the inch-pound units shall apply.

therequirementsofSpecificationA962/A962M.Theserequire-

1.7 The values stated in either SI units or inch-pound units

ments include test methods, finish, thread dimensions, mac-

are to be regarded separately as standard. Within the text, the

roetch (Grade B4D only), marking, certification, optional

SI units are shown in brackets. The values stated in each

supplementary requirements, and others. Failure to comply

system may not be exact equivalents; therefore, each system

with the requirements of Specification A962/A962M consti-

tutes nonconformance with this specification. In case of con-

1

This specification is under the jurisdiction of ASTM Committee A01 on Steel,

flictbetweenthisspecificationandSpecificationA962/A962M,

Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee

this specification shall prevail.

A01.22 on Steel Forgings and Wrought Fittings for PipingApplications and Bolting

Materials for Piping and Special Purpose Applications.

Current edition approved May 1, 2010. Published June 2010. Originally

3

approved in 1959. Last previous edition approved in 2010 as A437/A437M–10. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

DOI: 10.1520/A0437_A0437M-10a. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

2

For ASME Boiler and Pressure Vessel Code applications see related Specifi- Standards volume information, refer to the standard’s Document Summary page on

cation SA-437 in Section II of that code. the ASTM website.

*ASummary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

A437/A437M – 10a

TABLE 2 Tensile Requirements

5. Discard

5.1 A sufficient discard shall be made from each ingot to

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:A437/A437M–10 Designation: A437/A437M – 10a

Standard Specification for

Stainless and Alloy-Steel Turbine-Type Bolting Specially

1

Heat Treated for High-Temperature Service

This standard is issued under the fixed designationA437/A437M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (ϵ) indicates an editorial change since the last revision or reapproval.

1. Scope*

2

1.1 This specification covers stainless and alloy-steel bolting specially heat treated for high-temperature service, such as steam

turbine, gas turbine, and similar uses. See Specification A962/A962M for the definition of bolting. This material requires special

processing and should not be used in general-purpose applications. Bolting furnished as bars shall be hot wrought and may be

further processed by centerless grinding or by cold drawing.

1.2 The high-temperature properties of the bolting covered by this specification are dependent upon special heat treatment,

which is required. Although the high-temperature properties are not specified, they are implied by control of the chemistry, heat

treatment, and room-temperature properties of the material.

1.3 Three levels of bolting strength are covered, designated Grades B4B, B4C, and B4D.

1.4 The following referenced general requirements are indispensable for application of this specification: Specification

A962/A962M.

1.5 Supplementaryrequirementsareprovidedforuseattheoptionofthepurchaser.Thesupplementaryrequirementsshallapply

only when specified individually by the purchaser in the purchase order or contract.

1.6 This specification is expressed in both inch-pound units and in SI units; however, unless the purchase order or contract

specifies the applicable M specification designation (SI units), the inch-pound units shall apply.

1.7 The values stated in either SI units or inch-pound units are to be regarded separately as standard.Within the text, the SI units

are shown in brackets. The values stated in each system may not be exact equivalents; therefore, each system shall be used

independently of the other. Combining values from the two systems may result in non-conformance with the standard.

2. Referenced Documents

3

2.1 ASTM Standards:

A962/A962M Specification for Common Requirements for Bolting Intended for Use atAnyTemperature from Cryogenic to the

Creep Range Specification for Common Requirements for Bolting Intended for Use at Any Temperature from Cryogenic to

the Creep Range

E292 Test Methods for Conducting Time-for-Rupture Notch Tension Tests of Materials

E112 Test Methods for Determining Average Grain Size

3. Ordering Information

3.1 It shall be the responsibility of the purchaser to specify all requirements necessary for product under this specification. Such

requirements to be considered include, but are not limited to, the following:

3.1.1 Specification designation, grade, issue date, and revision letter,

3.1.2 Quantity (weight or number of pieces),

3.1.3 Description (bars, bolts, nuts, etc.),

3.1.4 Dimensions,

3.1.5 Finish, and

3.1.6 Impact testing of nuts, if required (see Section 9).

1

This specification is under the jurisdiction ofASTM CommitteeA01 on Steel, Stainless Steel and RelatedAlloys and is the direct responsibility of SubcommitteeA01.22

on Steel Forgings and Wrought Fittings for Piping Applications and Bolting Materials for Piping and Special Purpose Applications.

Current edition approved AprilMay 1, 2010. Published MayJune 2010. Originally approved in 1959. Last previous edition approved in 20062010 as A437/A437M–106.

DOI: 10.1520/A0437_A0437M-10a.

2

For ASME Boiler and Pressure Vessel Code applications see related Specification SA-437 in Section II of that code.

3

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book ofASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*ASummary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

A437/A437M – 10a

4. Common Requirements

4.1 Bolting supplied to this specification shall conform to the requirements of SpecificationA962/A962M. These requirements

include test methods, finish, thread dimensions, macroetch (Grade B4D

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:A437/A437M–10 Designation: A437/A437M – 10a

Standard Specification for

Stainless and Alloy-Steel Turbine-Type Bolting Specially

1

Heat Treated for High-Temperature Service

This standard is issued under the fixed designationA437/A437M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

2

1.1 This specification covers stainless and alloy-steel bolting specially heat treated for high-temperature service, such as steam

turbine, gas turbine, and similar uses. See Specification A962/A962M for the definition of bolting. This material requires special

processing and should not be used in general-purpose applications. Bolting furnished as bars shall be hot wrought and may be

further processed by centerless grinding or by cold drawing.

1.2 The high-temperature properties of the bolting covered by this specification are dependent upon special heat treatment,

which is required. Although the high-temperature properties are not specified, they are implied by control of the chemistry, heat

treatment, and room-temperature properties of the material.

1.3 Three levels of bolting strength are covered, designated Grades B4B, B4C, and B4D.

1.4 The following referenced general requirements are indispensable for application of this specification: Specification

A962/A962M.

1.5 Supplementaryrequirementsareprovidedforuseattheoptionofthepurchaser.Thesupplementaryrequirementsshallapply

only when specified individually by the purchaser in the purchase order or contract.

1.6 This specification is expressed in both inch-pound units and in SI units; however, unless the purchase order or contract

specifies the applicable M specification designation (SI units), the inch-pound units shall apply.

1.7 The values stated in either SI units or inch-pound units are to be regarded separately as standard.Within the text, the SI units

are shown in brackets. The values stated in each system may not be exact equivalents; therefore, each system shall be used

independently of the other. Combining values from the two systems may result in non-conformance with the standard.

2. Referenced Documents

3

2.1 ASTM Standards:

A962/A962M Specification for Common Requirements for Bolting Intended for Use atAnyTemperature from Cryogenic to the

Creep Range Specification for Common Requirements for Bolting Intended for Use at Any Temperature from Cryogenic to

the Creep Range

E292 Test Methods for Conducting Time-for-Rupture Notch Tension Tests of Materials

E112 Test Methods for Determining Average Grain Size

3. Ordering Information

3.1 It shall be the responsibility of the purchaser to specify all requirements necessary for product under this specification. Such

requirements to be considered include, but are not limited to, the following:

3.1.1 Specification designation, grade, issue date, and revision letter,

3.1.2 Quantity (weight or number of pieces),

3.1.3 Description (bars, bolts, nuts, etc.),

3.1.4 Dimensions,

3.1.5 Finish, and

3.1.6 Impact testing of nuts, if required (see Section 9).

1

This specification is under the jurisdiction ofASTM CommitteeA01 on Steel, Stainless Steel and RelatedAlloys and is the direct responsibility of SubcommitteeA01.22

on Steel Forgings and Wrought Fittings for Piping Applications and Bolting Materials for Piping and Special Purpose Applications.

Current edition approved AprilMay 1, 2010. Published MayJune 2010. Originally approved in 1959. Last previous edition approved in 20062010 as A437/A437M–106.

DOI: 10.1520/A0437_A0437M-10a.

2

For ASME Boiler and Pressure Vessel Code applications see related Specification SA-437 in Section II of that code.

3

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book ofASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*ASummary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

A437/A437M – 10a

4. Common Requirements

4.1 Bolting supplied to this specification shall conform to the requirements of SpecificationA962/A962M. These requirements

include test methods, finish, thread dimensions, macroetch (Grade B4D

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.