ASTM E1248-90(1997)

(Practice)Standard Practice for Shredder Explosion Protection

Standard Practice for Shredder Explosion Protection

SCOPE

1.1 This practice covers general recommended design features and operating practices for shredder explosion protection in resource recovery plants and other refuse processing facilities.

1.2 Hammermills and other types of size reduction equipment (collectively termed shredders) are employed at many facilities that mechanically process solid wastes for resource recovery. Flammable or explosive materials (for example, gases, vapors, powders, and commercial and military explosives) may be present in the as-received waste stream. There is potential for these materials to be released, dispersed, and ignited within or near a shredder. Therefore, explosion prevention and damage amelioration provisions are required.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E 1248 – 90 (Reapproved 1997)

Standard Practice for

Shredder Explosion Protection

This standard is issued under the fixed designation E 1248; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.4 explosion venting—the provision of an opening(s) in

the shredder enclosure and contiguous enclosed areas to allow

1.1 This practice covers general recommended design fea-

gases to escape during a deflagration and thus prevent pres-

tures and operating practices for shredder explosion protection

sures from reaching the damage threshold.

in resource recovery plants and other refuse processing facili-

3.1.5 explosion suppression—the technique of detecting and

ties.

extinguishing incipient explosions in the shredder enclosure

1.2 Hammermills and other types of size reduction equip-

and contiguous enclosed areas before pressures exceed the

ment (collectively termed shredders) are employed at many

damage threshold.

facilities that mechanically process solid wastes for resource

3.1.6 inerting—the technique by which a combustible mix-

recovery. Flammable or explosive materials (for example,

ture is rendered nonflammable by addition of a gas incapable of

gases, vapors, powders, and commercial and military explo-

supporting combustion.

sives) may be present in the as-received waste stream. There is

3.1.7 shredder—a size-reduction machine that tears or

potential for these materials to be released, dispersed, and

grinds materials to a smaller and more uniform particle size.

ignited within or near a shredder. Therefore, explosion preven-

tion and damage amelioration provisions are required.

4. Significance and Use

2. Referenced Documents 4.1 Shredder explosions have occurred in most refuse pro-

cessing plants with shredding facilities. Lessons learned in

2.1 National Fire Protection Association Standards:

these incidents have been incorporated into this practice along

National Electrical Code

with results of relevant test programs and general industrial

NFPA 13 Sprinkler Systems

explosion protection recommended practices. Recommenda-

NFPA 68 Guide for Explosion Venting

tions in this practice cover explosion protection aspects of the

NFPA 69 Explosion Prevention Systems

design and operation of shredding facilities and equipment

NFPA 497A Classification of Class I Hazardous (Classified)

used therein.

Locations for Electrical Installations in Chemical Process

4.2 This practice is not intended to be a substitute for an

Areas

operating manual or a detailed set of design specifications.

3. Terminology Rather, it represents general principles and guidelines to be

addressed in detail in generating the operating manual and

3.1 Definitions:

design specifications.

3.1.1 deflagration—an explosion in which the flame or

reaction front propagates at a speed well below the speed of

5. Design Practices

sound in the unburned medium, such that the pressure is

5.1 Design Rationale:

virtually uniform throughout the enclosure (shredder) at any

5.1.1 Each of the following design features is better suited

time during the explosion.

for some types of combustible/explosive materials and shred-

3.1.2 detonation—an explosion in which the flame or reac-

ders than for others. The selection of a particular combination

tion front propagates at a supersonic speed into the unburned

of explosion prevention features or damage control features, or

medium, such that pressure increases occur in the form of

both, should be made with an understanding of the types of

shock waves.

refuse entering the shredder, shredder operating conditions, the

3.1.3 explosion—a rapid release of energy (usually by

inherent strength of the shredder and surrounding structures,

means of combustion) with a corresponding pressure buildup

and the operating controls for screening input materials and

capable of damaging equipment and building structures.

restricting personnel access during shredding operations.

5.1.2 Several of the following explosion protection design

This practice is under the jurisdiction of ASTM Committee D-34 on Waste

practices are effective for deflagrations but not for detonations.

Management and is the direct responsibility of Subcommittee D34.16 on Processing

Deflagrations usually result from accumulations of flammable

Equipment and Unit Operations.

gas-air, vapor-air, or powder(dust) air mixtures in or around the

Current edition approved Dec. 28, 1990. Published February 1991.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E 1248

shredder. However, commercial explosives and military ord- oxygen concentrations for nitrogen and carbon dioxide inerting

nance usually generate detonations. A few flammable gases are as listed in Appendix C of NFPA 69.

(for example, acetylene and hydrogen) are also prone to 5.2.6 Reliable oxygen concentration monitors should be

detonate when dispersed in highly turbulent, strong ignition installed, calibrated, and maintained to verify that the maxi-

source environments such as exist inside a shredder. Because mum oxygen concentration is not being exceeded in the

many explosion protection design practices are not applicable shredder and contiguous enclosures. This will require multiple

to detonations, rigorous visual detection and removal of monitors and sampling points depending on the extent and

detonable material before it enters the shredder is particularly uniformity of flow in the enclosed volume. Provision for

important (6.1). cleaning and clearing sample lines, as recommended in 5.4.5

are needed.

5.1.3 In view of the difficulties in preventing and controlling

5.2.7 The inert gas distribution system should be designed

all types of shredder explosions, it is important to isolate the

in accordance with the provisions of Chapter 2 of NFPA 69.

shredder and surrounding enclosure from vulnerable equip-

5.3 Explosion Venting:

ment and occupied areas in the plant. This is best achieved by

5.3.1 Explosion venting is intended to limit structural dam-

locating the shredder outdoors or, if indoors, in a location

age incurred during deflagrations by allowing unburned gas

suitable for explosion venting directly outside. Locations in or

and combustion products to be discharged from the shredder or

near the center of a processing building are not desirable. If the

contiguous enclosures, or both, before combustion and the

shredder is situated in an isolated, explosion resistant structure,

associated potentially destructive pressure rise is completed.

the structure should be designed to withstand the explosion

The effectiveness of explosion venting for a particular explo-

pressures specified in NFPA 68.

sion depends on the rate of combustion versus the rate of

5.1.4 The shredder and all contiguous enclosures should be

discharge of gases through the explosion vents. The rate of

equipped with an explosion protection system consisting of one

combustion in the shredder or adjacent enclosure depends upon

or more of the following: inerting system (5.2); explosion vents

the composition of the combustible gas-air, vapor-air, or

(5.3); explosion suppression system (5.4). Water spray systems

dust-air mixture, the size of the shredder/enclosure, and the

(5.5), combustible gas detectors (5.6), and industrial fire

turbulence level as determined by air flow rates and hammer tip

protection systems (5.7) should also be installed for additional

speed.

protection. Adjacent structures and personnel should be pro-

5.3.2 In general, explosion venting is most effective with

tected (5.8).

large vent areas, low vent deployment pressures, low vent

5.2 Inerting Systems:

panel weight, and vent locations near the expected ignition

5.2.1 An inerting system is intended to prevent combustion

source (which is often hammer impact sparks within the

explosions within a shredder (and contiguous enclosures) by

shredder). The following quantitative guidelines for these

maintaining oxygen concentrations below the level required to

factors are intended to protect against near worst-case flam-

support combustion.

mable gas-air mixtures occupying the entire shredder internal

5.2.2 The following factors must be accounted for in de-

volume.

signing a shredder inerting system: inert gas source and

5.3.3 Explosion vent areas should be sufficiently large to

distribution; operating controls and associated instrumentation;

maintain explosion pressures under the damage threshold value

leakage of inert gas from and entry of air into enclosures;

for the particular shredder installation. Previously published

maintenance and inspection constraints in an oxygen deficient

guidelines relating peak pressure to vent area are not directly

atmosphere during normal operations; effect of inert gas on

applicable to Municipal Solid Waste (MSW) shredders because

shredder materials and waste throughput; and contingency

shredder hammer velocities can increase the combustion rate

plans for inert gas source supply interruption.

well above that considered in establishing previous guidelines.

5.2.3 Flue gas from an on-site furnace or boiler can be a

The following recommended relationship is based on propane-

suitable inert gas providing there is a reliable means to prevent

air explosion tests conducted in a full-scale large shredder

flame propagation into the shredding system and providing flue

mock-up, including rotating hammers (1).

gas conditioning is installed to maintain suitable temperature

5.3.3.1 The vent area, A , required to maintain explosion

v

(to prevent steam condensation or spontaneous ignition) and

pressures under the shredder damage threshold (in units of

flue gas composition (including dew point, oxygen, carbon

psig), P , is given by the equation:

M

monoxide, soot, and contaminant concentrations).

2/3 20.435

A 5 0.13V P ~5 1 0.034v !

v M H

5.2.4 Steam from an on-site boiler can be a suitable inert gas

(1)

providing the temperatures of the shredder and contiguous

enclosures are sufficiently high (at least 180°F (82°C)) to

where:

prevent steam condensation and the associated increase in

V 5 shredder internal volume, and

oxygen and flammable gas concentrations.

v 5 hammer tip velocity, ft/s.

H

2/3

5.2.5 Oxygen concentrations in the shredder and all contig The calculated vent area will be in the same units as V .

uous enclosures should be no higher than 10 % by volume, The metric equivalent, if P is in bar, and v is in m/s, is

M H

unless test data for the particular inert gas employed and the

variety of combustibles expected in the shredder demonstrate

that a higher oxygen concentration can be tolerated without

The boldface numbers in parentheses refer to the list of references at the end of

generating a flammable mixture. Test data for maximum this practice.

E 1248

2/3 20.435

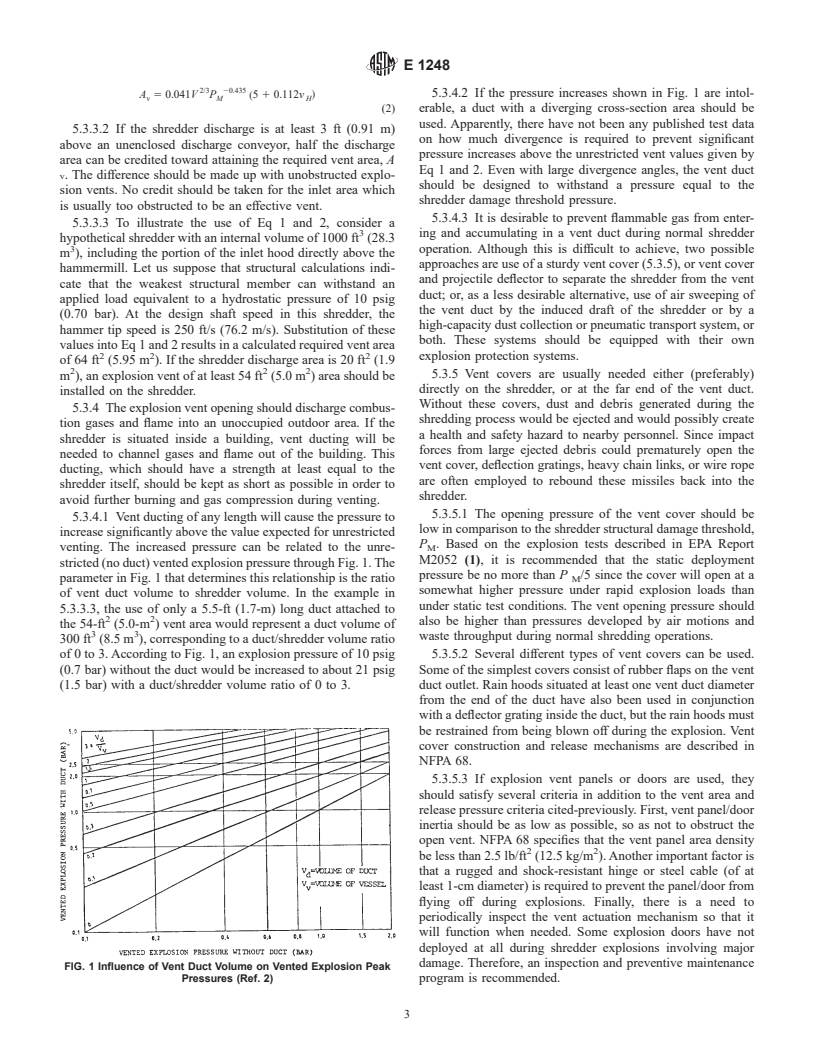

5.3.4.2 If the pressure increases shown in Fig. 1 are intol-

A 5 0.041V P ~5 1 0.112v !

v M H

(2)

erable, a duct with a diverging cross-section area should be

used. Apparently, there have not been any published test data

5.3.3.2 If the shredder discharge is at least 3 ft (0.91 m)

on how much divergence is required to prevent significant

above an unenclosed discharge conveyor, half the discharge

pressure increases above the unrestricted vent values given by

area can be credited toward attaining the required vent area, A

Eq 1 and 2. Even with large divergence angles, the vent duct

v. The difference should be made up with unobstructed explo-

should be designed to withstand a pressure equal to the

sion vents. No credit should be taken for the inlet area which

shredder damage threshold pressure.

is usually too obstructed to be an effective vent.

5.3.4.3 It is desirable to prevent flammable gas from enter-

5.3.3.3 To illustrate the use of Eq 1 and 2, consider a

3 ing and accumulating in a vent duct during normal shredder

hypothetical shredder with an internal volume of 1000 ft (28.3

operation. Although this is difficult to achieve, two possible

m ), including the portion of the inlet hood directly above the

approaches are use of a sturdy vent cover (5.3.5), or vent cover

hammermill. Let us suppose that structural calculations indi-

and projectile deflector to separate the shredder from the vent

cate that the weakest structural member can withstand an

duct; or, as a less desirable alternative, use of air sweeping of

applied load equivalent to a hydrostatic pressure of 10 psig

the vent duct by the induced draft of the shredder or by a

(0.70 bar). At the design shaft speed in this shredder, the

high-capacity dust collection or pneumatic transport system, or

hammer tip speed is 250 ft/s (76.2 m/s). Substitution of these

both. These systems should be equipped with their own

values into Eq 1 and 2 results in a calculated required vent area

2 2 2

explosion protection systems.

of 64 ft (5.95 m ). If the shredder discharge area is 20 ft (1.9

2 2 2

5.3.5 Vent covers are usually needed either (preferably)

m ), an explosion vent of at least 54 ft (5.0 m ) area should be

directly on the shredder, or at the far end of the vent duct.

installed on the shredder.

Without these covers, dust and debris generated during the

5.3.4 The explosion vent opening should discharge combus-

shredding process would be ejected and would possibly create

tion gases and flame into an unoccupied outdoor area. If the

a health and safety hazard to nearby personnel. Since impact

shredder is situated inside a building, vent ducting will be

forces from large ejected debris could prematurely open the

needed to channel gases and flame out of the building. This

vent cover, deflection gratings, heavy chain links, or wire rope

ducting, which should have a strength at least equal to the

are often employed to rebound these missiles back into the

shredder itself, should be kept as short as possible in order to

shredder.

avoid further burning and gas compression during venting.

5.3.5.1 The opening pressure of the vent cover should be

5.3.4.1 Vent ducting of any length will cause the pressure to

low in comparison to the shredder structural damage threshold,

increase significantly above the value expected for unrestricted

P . Based on the explosion tests described in EPA Report

venting. The increased pressure can be related to the unre- M

M2052 (1), it is recommended that the static deployment

stricted (no duct) vented explosion pressure through Fig. 1. The

pressure be no more than P /5 since the cover will open at a

parameter in Fig. 1 that determines this relationship is the ratio M

somewhat higher press

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.