ASTM A536-84(2019)e1

(Specification)Standard Specification for Ductile Iron Castings

Standard Specification for Ductile Iron Castings

ABSTRACT

This specification covers ductile iron castings, also known as spheroidal or nodular iron, that is described as cast iron with the graphite substantially spheroidal in shape and essentially free of other forms of graphite. Appropriate heat treatment shall be identified according to grades, as follows: a full ferritizing anneal for 60-40-18; a quench and temper, or normalize and temper, or isothermal heat treatment for 100-70-03 and 120-90-02; and as-cast for 65-45-12 and 80-55-06. Castings shall be tested and conform to specified tensile requirements such as tensile strength, yield strength, and elongation. When indicated in the contract or purchase order, castings shall also adhere to special requirements like hardness, chemical composition, microstructure, pressure tightness, radiographic soundness, magnetic particle inspection dimensions, and surface finish.

SCOPE

1.1 This specification covers castings made of ductile iron, also known as spheroidal or nodular iron, which is described as cast iron with the graphite substantially spheroidal in shape and essentially free of other forms of graphite, as defined in Terminology A644.

1.2 No precise quantitative relationship can be stated between the properties of the iron in various locations of the same casting or between the properties of castings and those of a test specimen cast from the same iron (see Appendix X1).

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

´1

Designation: A536 −84 (Reapproved 2019)

Standard Specification for

Ductile Iron Castings

This standard is issued under the fixed designation A536; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

ε NOTE—Footnote 3 was editorially corrected in May 2019.

1. Scope 2.2 Military Standard:

MIL-STD-129 Marking for Shipment and Storage

1.1 This specification covers castings made of ductile iron,

alsoknownasspheroidalornodulariron,whichisdescribedas

3. Ordering Information

castironwiththegraphitesubstantiallyspheroidalinshapeand

essentially free of other forms of graphite, as defined in 3.1 Orders for material to this specification shall include the

Terminology A644. following information:

3.1.1 ASTM designation,

1.2 No precise quantitative relationship can be stated be-

3.1.2 Grade of ductile iron required (see Table 1, and

tweenthepropertiesoftheironinvariouslocationsofthesame

Sections 4 and 9),

casting or between the properties of castings and those of a test

3.1.3 Special properties, if required (see Section 7),

specimen cast from the same iron (see Appendix X1).

3.1.4 If a different number of samples is required (see

1.3 The values stated in inch-pound units are to be regarded

Section 10),

as standard. The values given in parentheses are mathematical

3.1.5 Certification, if required (see Section 14), and

conversions to SI units that are provided for information only

3.1.6 Special preparation for delivery, if required (see Sec-

and are not considered standard.

tion 15).

1.4 This international standard was developed in accor-

dance with internationally recognized principles on standard- 4. Tensile Requirements

ization established in the Decision on Principles for the

4.1 The iron represented by the test specimens shall con-

Development of International Standards, Guides and Recom-

form to the requirements as to tensile properties presented in

mendations issued by the World Trade Organization Technical

Tables 1 and 2. The irons listed in Table 1 cover those in

Barriers to Trade (TBT) Committee.

general use, while those listed in Table 2 are used for special

applications (such as pipes, fittings, etc.).

2. Referenced Documents

4.2 Theyieldstrengthshallbedeterminedat0.2 %offsetby

2.1 ASTM Standards:

the offset method (see Test Methods E8/E8M). Other methods

A370 Test Methods and Definitions for Mechanical Testing

may be used by mutual consent of the manufacturer and

of Steel Products

purchaser.

A644 Terminology Relating to Iron Castings

A732/A732M Specification for Castings, Investment, Car-

5. Heat Treatment

bon and Low Alloy Steel for General Application, and

Cobalt Alloy for High Strength at Elevated Temperatures

5.1 The 60-40-18 grade will normally require a full ferritiz-

E8/E8M Test Methods for Tension Testing of Metallic Ma-

ing anneal. The 120-90-02 and the 100-70-03 grades generally

terials

require a quench and temper or a normalize and temper, or an

isothermal heat treatment. The other two grades can be met

This specification is under the jurisdiction of the ASTM Committee A04 on

either as-cast or by heat treatment. Ductile iron, which is heat

Iron Castings and is the direct responsibility of Subcommittee A04.02 on Malleable

treated by quenching to martensite and tempering, may have

and Ductile Iron Castings.

substantially lower fatigue strength than as-cast material of the

Current edition approved May 1, 2019. Published May 2019. Originally

approved in 1965. Last previous edition approved in 2014 as A536 – 84 (2014). same hardness.

DOI: 10.1520/A0536-84R19E01.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on Available from General Services Administration – Vendor Support Center,

the ASTM website. https://vsc.gsa.gov/administration/files/MIL-STD-129R.pdf.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

A536 − 84 (2019)

TABLE 1 Tensile Requirements

Grade Grade Grade Grade Grade

60-40-18 65-45-12 80-55-06 100-70-03 120-90-02

Tensile strength, min, psi 60 000 65 000 80 000 100 000 120 000

Tensile strength, min, MPa 414 448 552 689 827

Yield strength, min, psi 40 000 45 000 55 000 70 000 90 000

Yield strength, min, MPa 276 310 379 483 621

Elongation in 2 in. or 50 mm, min, % 18 12 6.0 3.0 2.0

TABLE 2 Tensile Requirements for Special Applications

Grade Grade Grade

60-42-10 70-50-05 80-60-03

Tensile strength, min, psi 60 000 70 000 80 000

Tensile strength, min, MPa 415 485 555

Yield strength, min, psi 42 000 50 000 60 000

Yield strength, min, MPa 290 345 415

Elongation in 2 in. or 50 mm, 10 5 3

min, %

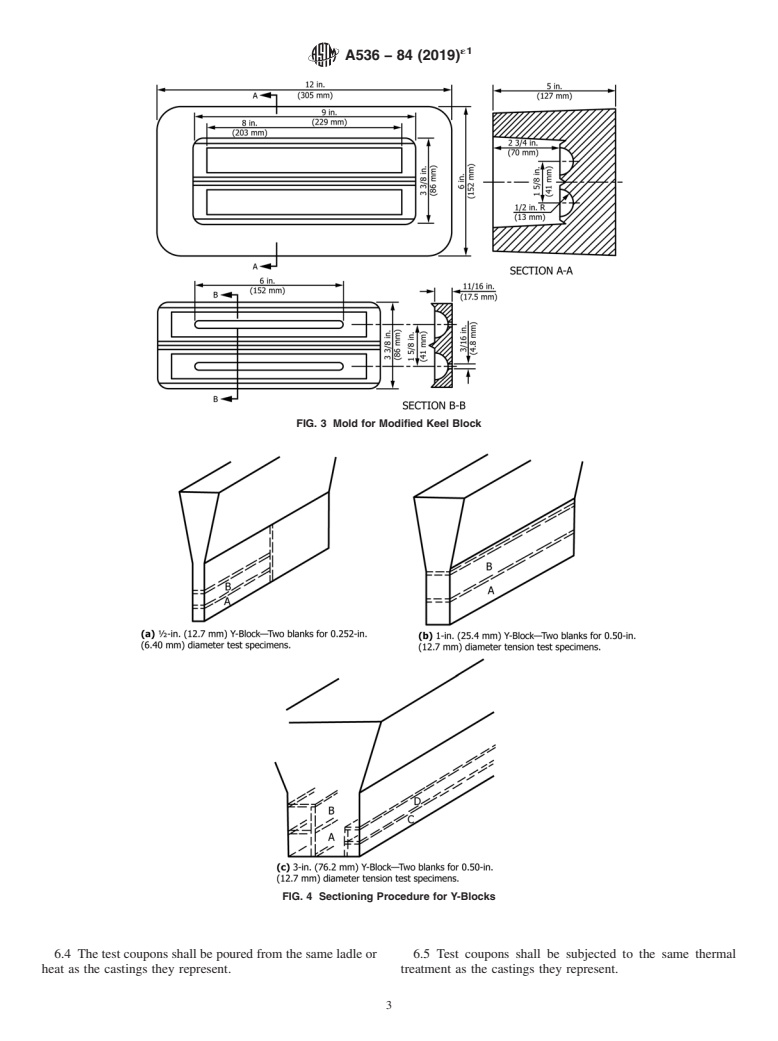

Y-Block Size

6. Test Coupons

For Castings

For Castings For Castings

of Thickness

of Thickness of Thickness

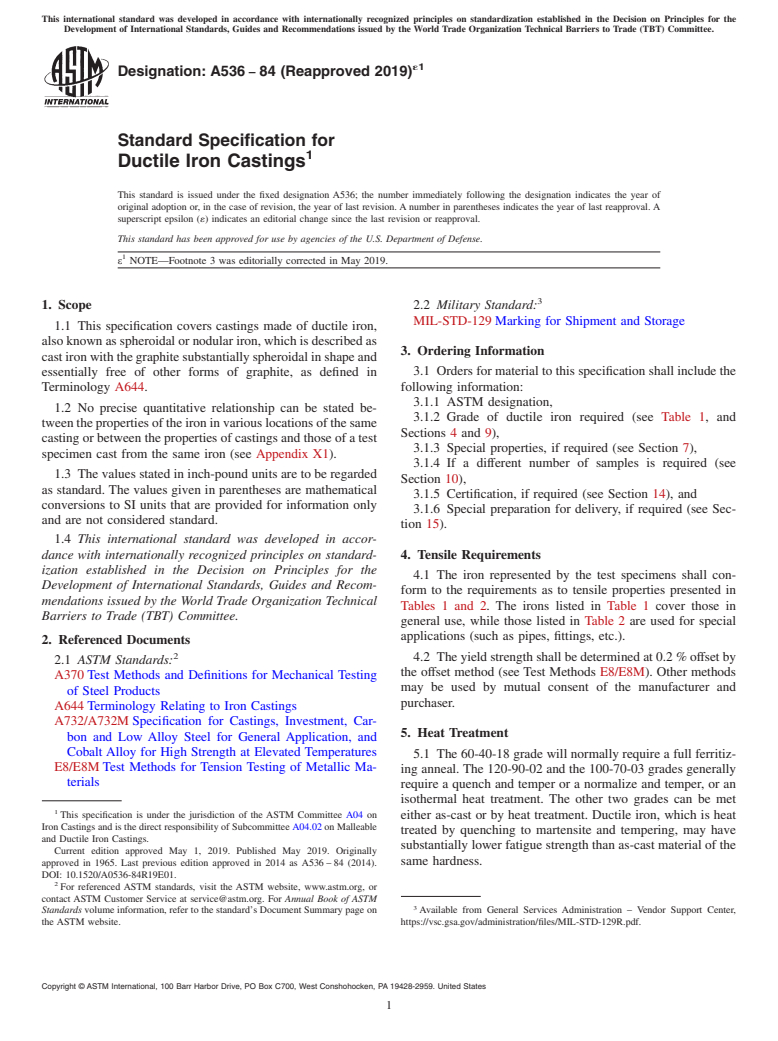

6.1 The separately cast test coupons from which the tension

Dimen- ⁄2 in.

Less Than of 1 ⁄2 in.

test specimens are machined shall be cast to the size and shape

sions (13 mm) to

⁄2 in. (38 mm)

1 ⁄2 in.

shown in Fig. 1 or Fig. 2.Amodified keel block cast from the

(13 mm) and Over

(38 mm)

mold shown in Fig. 3 may be substituted for the 1-in. Y-block

in. mm in. mm in. mm

or the 1-in. keel block. The test coupons shall be cast in open

A ⁄2 13 1 25 3 75

molds made of suitable core sand having a minimum wall

5 1

B1 ⁄8 40 2 ⁄8 54 5 125

1 1

thickness of 1 ⁄2 in. (38 mm) for the ⁄2-in. (12.5-mm) and 1-in. C 2 50 3 75 4 100

D 4 100 6 150 8 200

(25-mm) sizes and 3 in. (75 mm) for the 3-in. size. The

E 7 175 7 175 7 175

coupons shall be left in the mold until they have cooled to a

approx approx approx approx approx approx

black color (approximately 900 °F (482 °C) or less). The size

of coupon cast to represent the casting shall be at the option of FIG. 2 Y-Blocks for Test Coupons

the purchaser. In case no option is expressed, the manufacturer

shall make the choice.

6.2 Wheninvestmentcastingsaremadetothisspecification,

the manufacturer may use test specimens cast to size incorpo-

rated in the mold with the castings, or separately cast to size

using the same type of mold and the same thermal conditions

that are used to produce the castings. These test specimens

shall be made to the dimensions shown in Fig. 1 of Specifica-

tion A732/A732M or Figs. 5 and 6 of Test Methods and

Definitions A370.

6.3 The manufacturer may use separately cast test coupons

or test specimens cut from castings when castings made to this

specification are nodularized or inoculated in the mold. Sepa-

rately cast test coupons shall have a chemistry that is repre-

sentative of castings produced from the ladle poured and a

cooling rate equivalent to that obtained with the test molds

shown in Figs. 1 and 2, Figs. 4-6,or Appendix X2. The size

(cooling rate) of the coupon chosen to represent the casting

should be decided by the purchaser. If test coupon size is not

specified, the manufacturer shall make the choice. When test

Metric Equivalents

bars will be cut from castings, test bar location shall be agreed

in. mm in. mm

1 1

⁄2 12.7 1 ⁄2 38.1

on by the purchaser and manufacturer and indicated on the

1 25.4 2 ⁄2 63.5

casting drawing. The manufacturer shall maintain sufficient

controlsandcontroldocumentationtoassurethepurchaserthat

NOTE 1—The length of the keel block shall be 6 in. (152 mm).

properties determined from test coupons or test bars are

FIG. 1 Keel Block for Test Coupons representative of castings shipped.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.