ASTM D5420-04

(Test Method)Standard Test Method for Impact Resistance of Flat, Rigid Plastic Specimen by Means of a Striker Impacted by a Falling Weight (Gardner Impact)

Standard Test Method for Impact Resistance of Flat, Rigid Plastic Specimen by Means of a Striker Impacted by a Falling Weight (Gardner Impact)

SCOPE

1.1 This test method covers the determination of the relative ranking of materials according to the energy required to crack or break flat, rigid plastic specimens under various specified conditions of impact of a striker impacted by a falling weight.

1.2 The values stated in SI units are to be regarded as the standard. The values given in brackets are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

Note 1—There is no similar or equivalent ISO standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D5420 – 04

Standard Test Method for

Impact Resistance of Flat, Rigid Plastic Specimen by Means

1

of a Striker Impacted by a Falling Weight (Gardner Impact)

This standard is issued under the fixed designation D5420; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* E171 Specification for Atmospheres for Conditioning and

Testing Flexible Barrier Materials

1.1 Thistestmethodcoversthedeterminationoftherelative

E691 Practice for Conducting an Interlaboratory Study to

ranking of materials according to the energy required to crack

Determine the Precision of a Test Method

or break flat, rigid plastic specimens under various specified

conditions of impact of a striker impacted by a falling weight.

3. Terminology

1.2 The values stated in SI units are to be regarded as the

3.1 Definitions—For definitions of plastics terms used in

standard.Thevaluesgiveninbracketsareforinformationonly.

this test method, see Terminologies D883 and D1600.

1.3 This standard does not purport to address all of the

3.2 Definitions of Terms Specific to This Standard:

safety concerns, if any, associated with its use. It is the

3.2.1 failure (of test specimen)—the presence of any crack

responsibility of the user of this standard to establish appro-

or split created by the impact of the falling weight that can be

priate safety and health practices and determine the applica-

seen by the naked eye under normal laboratory lighting

bility of regulatory limitations prior to use.

conditions.

NOTE 1—There is no similar or equivalent ISO standard.

3.2.1.1 Discussion—Failure shall include the following:

(1) complete shattering of the plaque; (2) any crack radiating

2. Referenced Documents

out toward the edges of the plaque on either surface of the

2

2.1 ASTM Standards:

plaque; (3) any radial crack within or just outside the impact

D618 Practice for Conditioning Plastics for Testing

area of the striker; (4) any hole in the plaque, whether due to

D883 Terminology Relating to Plastics

brittle or ductile puncture, where unobstructed light or water

D1600 Terminology for Abbreviated Terms Relating to

could pass through; (5) any brittle splitting of the bottom

Plastics

surface of the plaque; and (6) any glassy-type chip dislodged

D2794 Test Method for Resistance of Organic Coatings to

from or loosened from the plaque.

the Effects of Rapid Deformation (Impact)

3.2.1.2 Discussion—Since the interpretation of failure may

D3763 Test Method for High Speed Puncture Properties of

be slightly different between material types, refer to the

Plastics Using Load and Displacement Sensors

appropriate material specification for guidance.

D4066 Classification System for Nylon Injection and Ex-

3.2.1.3 Discussion—Cracks usually start at the surface op-

trusion Materials (PA)

posite the one that is struck. For example, in some cases

D4226 Test Methods for Impact Resistance of Rigid Poly-

incipient cracking in glass-reinforced polymers is difficult to

(Vinyl Chloride) (PVC) Building Products

differentiate from the reinforcing fibers. In such cases, apply a

D5628 Test Method for Impact Resistance of Flat, Rigid

penetratingdyesuchasgentianviolettothestressedsurfaceto

Plastic Specimens by Means of a Falling Dart (Tup or

determine the onset of crack formation.

Falling Mass)

3.2.2 mean-failure energy (mean impact resistance)—the

D5947 Test Methods for Physical Dimensions of Solid

energy required to produce 50% failures, equal to the product

Plastics Specimens

of the constant mass and mean failure height.

3.2.3 mean-failure height (impact-failure height)—the

1

ThistestmethodisunderthejurisdictionofASTMCommitteeD20onPlastics

height at which a standard mass, when dropped on test

and is the direct responsibility of Subcommittee D20.10 on Mechanical Properties.

specimens, will cause 50% failures.

Current edition approved Feb. 1, 2004. Published March 2004. Originally

approved in 1993. Last previous edition approved in 1998 as D5420-98. DOI:

4. Summary of Test Method

10.1520/D5420-04.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

4.1 In this test method, a weight falls through a guide tube

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

and impacts a striker resting on top of a supported specimen.

Standards volume information, refer to the standard’s Document Summary page on

The fixed weight is dropped from various heights (see Fig. 1).

the ASTM website.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, U

...

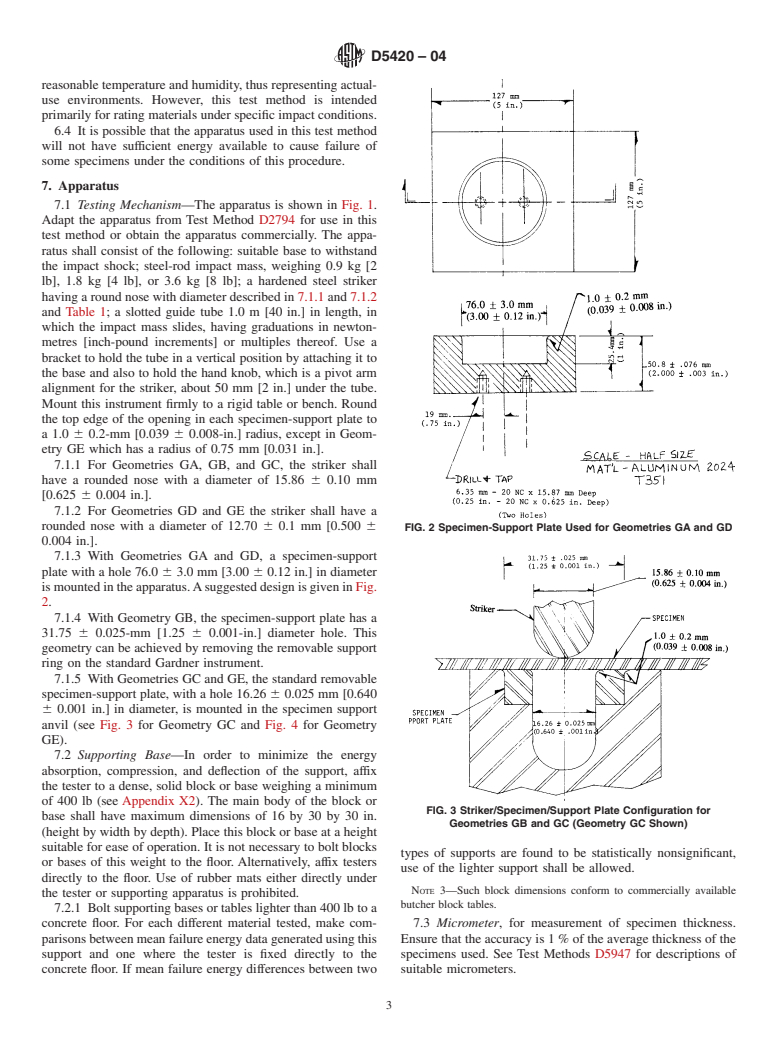

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.