ASTM D256-00e1

(Test Method)Standard Test Methods for Determining the Izod Pendulum Impact Resistance of Plastics

Standard Test Methods for Determining the Izod Pendulum Impact Resistance of Plastics

SCOPE

1.1 These test methods cover the determination of the resistance of plastics to "standardized" (see Note 1) pendulum-type hammers, mounted in "standardized" machines, in breaking standard specimens with one pendulum swing (see Note 2). The standard tests for these test methods require specimens made with a milled notch (see Note 3). In Test Methods A, C, and D, the notch produces a stress concentration that increases the probability of a brittle, rather than a ductile, fracture. In Test Method E, the impact resistance is obtained breakage by flexural shock as indicated by the energy extracted from by reversing the notched specimen 180° in the clamping vise. The results of all test methods are reported in terms of energy absorbed per unit of specimen width or per unit of cross-sectional area under the notch. (See Note 4.)

Note 1—The machines with their pendulum-type hammers have been "standardized" in that they must comply with certain requirements, including a fixed height of hammer fall that results in a substantially fixed velocity of the hammer at the moment of impact. However, hammers of different initial energies (produced by varying their effective weights) are recommended for use with specimens of different impact resistance. Moreover, manufacturers of the equipment are permitted to use different lengths and constructions of pendulums with possible differences in pendulum rigidities resulting. (See Section 5.) Be aware that other differences in machine design may exist. The specimens are "standardized" in that they are required to have one fixed length, one fixed depth, and one particular design of milled notch. The width of the specimens is permitted to vary between limits.

Note 2—Results generated using pendulums that utilize a load cell to record the impact force and thus impact energy, may not be equivalent to results that are generated using manually or digitally encoded testers that measure the energy remaining in the pendulum after impact.

Note 3—The notch in the Izod specimen serves to concentrate the stress, minimize plastic deformation, and direct the fracture to the part of the specimen behind the notch. Scatter in energy-to-break is thus reduced. However, because of differences in the elastic and viscoelastic properties of plastics, response to a given notch varies among materials. A measure of a plastic's "notch sensitivity" may be obtained with Test Method D by comparing the energies to break specimens having different radii at the base of the notch.

Note 4—Caution must be exercised in interpreting the results of these standard test methods. The following testing parameters may affect test results significantly:Method of fabrication, including but not limited to processingtechnology, molding conditions, mold design, and thermaltreatments;Method of notching;Speed of notching tool;Design of notching apparatus;Quality of the notch;Time between notching and test;Test specimen thickness,Test specimen width under notch, andEnvironmental conditioning.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Note 5—These test methods resemble ISO 180:1993 in regard to title only. The contents are significantly different.

General Information

Relations

Standards Content (Sample)

e1

Designation:D256–00

Standard Test Methods for

Determining the Izod Pendulum Impact Resistance of

Plastics

This standard is issued under the fixed designation D256; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

e NOTE—Note 2 was editorially added in April 2002. Title of Table 1 was editorially corrected in April 2002.

of a plastic’s “notch sensitivity” may be obtained with Test Method D by

1. Scope*

comparing the energies to break specimens having different radii at the

1.1 These test methods cover the determination of the

base of the notch.

resistanceofplasticsto“standardized”(seeNote1)pendulum-

NOTE 4—Caution must be exercised in interpreting the results of these

type hammers, mounted in “standardized” machines, in break-

standard test methods. The following testing parameters may affect test

ingstandardspecimenswithonependulumswing(seeNote2). results significantly:

The standard tests for these test methods require specimens

Method of fabrication, including but not limited to processing

technology, molding conditions, mold design, and thermal

made with a milled notch (see Note 3). In Test MethodsA, C,

treatments;

and D, the notch produces a stress concentration that increases

Method of notching;

the probability of a brittle, rather than a ductile, fracture. In Speed of notching tool;

Design of notching apparatus;

Test Method E, the impact resistance is obtained breakage by

Quality of the notch;

flexural shock as indicated by the energy extracted from by

Time between notching and test;

reversingthenotchedspecimen180°intheclampingvise.The Test specimen thickness,

Test specimen width under notch, and

results of all test methods are reported in terms of energy

Environmental conditioning.

absorbed per unit of specimen width or per unit of cross-

1.2 The values stated in SI units are to be regarded as the

sectional area under the notch. (See Note 4.)

standard. The values given in parentheses are for information

NOTE 1—The machines with their pendulum-type hammers have been

only.

“standardized” in that they must comply with certain requirements,

1.3 This standard does not purport to address all of the

including a fixed height of hammer fall that results in a substantially fixed

safety concerns, if any, associated with its use. It is the

velocity of the hammer at the moment of impact. However, hammers of

responsibility of the user of this standard to establish appro-

different initial energies (produced by varying their effective weights) are

priate safety and health practices and determine the applica-

recommended for use with specimens of different impact resistance.

Moreover, manufacturers of the equipment are permitted to use different

bility of regulatory limitations prior to use.

lengths and constructions of pendulums with possible differences in

NOTE 5—These test methods resemble ISO 180:1993 in regard to title

pendulum rigidities resulting. (See Section 5.) Be aware that other

only. The contents are significantly different.

differences in machine design may exist. The specimens are “standard-

ized” in that they are required to have one fixed length, one fixed depth,

2. Referenced Documents

and one particular design of milled notch. The width of the specimens is

permitted to vary between limits. 2.1 ASTM Standards:

NOTE 2—Results generated using pendulums that utilize a load cell to

D618 Practice for Conditioning Plastics for Testing

record the impact force and thus impact energy, may not be equivalent to 2

D883 Terminology Relating to Plastics

results that are generated using manually or digitally encoded testers that

D3641 Practice for Injection Molding Test Specimens of

measure the energy remaining in the pendulum after impact.

Thermoplastics Molding Extrusion Materials

NOTE 3—The notch in the Izod specimen serves to concentrate the

D4000 Classification System for Specifying Plastic Mate-

stress, minimize plastic deformation, and direct the fracture to the part of

rials

the specimen behind the notch. Scatter in energy-to-break is thus reduced.

However, because of differences in the elastic and viscoelastic properties

D4066 Specification for Nylon Injection and Extrusion

of plastics, response to a given notch varies among materials. A measure

Materials

D4812 Test Methods for Unnoticed Cantilever Beam Im-

pact Strength of Plastics

These test methods are under the jurisdiction of ASTM Committee D20 on

Plastics and are the direct responsibility of Subcommittee D20.10 on Mechanical

Properties. Annual Book of ASTM Standards, Vol 08.01.

Current edition approved Nov. 10, 2000. Published January 2001. Originally Annual Book of ASTM Standards, Vol 08.02.

published as D256–26T. Last previous edition D256–97. Annual Book of ASTM Standards, Vol 08.03.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

e1

D256–00

TABLE 1 Precision Data, Test Method A—Reversed Notch Izod

NOTE 1—Values in ft·lbf/in. of width (J/m of width).

NOTE 2—See Footnote 10.

Number of

A B C D

Material Average S S I I

r R r R

Laboratories

Phenolic 0.57 (30.4) 0.024 (1.3) 0.076 (4.1) 0.06 (3.2) 0.21 (11.2) 19

Acetal 1.45 (77.4) 0.075 (4.0) 0.604 (32.3) 0.21 (11.2) 1.70 (90.8) 9

Reinforced nylon 1.98 (105.7) 0.083 (4.4) 0.245 (13.1) 0.23 (12.3) 0.69 (36.8) 15

Polypropylene 2.66 (142.0) 0.154 (8.2) 0.573 (30.6) 0.43 (23.0) 1.62 (86.5) 24

ABS 10.80 (576.7) 0.136 (7.3) 0.585 (31.2) 0.38 (20.3) 1.65 (88.1) 25

Polycarbonate 16.40 (875.8) 0.295 (15.8) 1.056 (56.4) 0.83 (44.3) 2.98 (159.1) 25

A

S = within-laboratory standard deviation of the average.

r

B

S = between-laboratories standard deviation of the average.

R

C

I = 2.83 S .

r r

D

I = 2.83 S .

R R

E691 Practice for Conducting an Interlaboratory Test Pro- 4.1.3 Test Method D provides a measure of the notch

gram to Determine the Precision of Test Methods sensitivity of a material. The stress-concentration at the notch

2.2 ISO Standard: increases with decreasing notch radius.

ISO 180:1993 Plastics—Determination of Izod Impact 4.1.3.1 For a given system, greater stress concentration

Strength of Rigid Materials results in higher localized rates-of-strain. Since the effect of

strain-rate on energy-to-break varies among materials, a mea-

3. Terminology sure of this effect may be obtained by testing specimens with

different notch radii. In the Izod-type test it has been demon-

3.1 Definitions— For definitions related to plastics see

strated that the function, energy-to-break versus notch radius,

Terminology D883.

is reasonably linear from a radius of 0.03 to 2.5 mm (0.001 to

3.2 Definitions of Terms Specific to This Standard:

0.100 in.), provided that all specimens have the same type of

3.2.1 cantilever—a projecting beam clamped at only one

break. (See 5.8 and 22.1.)

end.

4.1.3.2 For the purpose of this test, the slope, b (see 22.1),

3.2.2 notch sensitivity—ameasureofthevariationofimpact

of the line between radii of 0.25 and 1.0 mm (0.010 and 0.040

energy as a function of notch radius.

in.) is used, unless tests with the 1.0-mm radius give “non-

break” results. In that case, 0.25 and 0.50-mm (0.010 and

4. Types of Tests

0.020-in.) radii may be used. The effect of notch radius on the

4.1 Four similar methods are presented in these test meth-

impact energy to break a specimen under the conditions of this

ods. (See Note 6.) All test methods use the same testing

testismeasuredbythevalue b.Materialswithlowvaluesof b,

machine and specimen dimensions. There is no known means

whether high or low energy-to-break with the standard notch,

for correlating the results from the different test methods.

are relatively insensitive to differences in notch radius; while

NOTE 6—Test Method B for Charpy has been removed and is being the energy-to-break materials with high values of b is highly

revised under a new standard.

dependent on notch radius. The parameter b cannot be used in

design calculations but may serve as a guide to the designer

4.1.1 In Test Method A, the specimen is held as a vertical

and in selection of materials.

cantilever beam and is broken by a single swing of the

4.2 Test Method E is similar to Test Method A, except that

pendulum.Thelineofinitialcontactisatafixeddistancefrom

the specimen is reversed in the vise of the machine 180° to the

thespecimenclampandfromthecenterlineofthenotchandon

usual striking position, such that the striker of the apparatus

the same face as the notch.

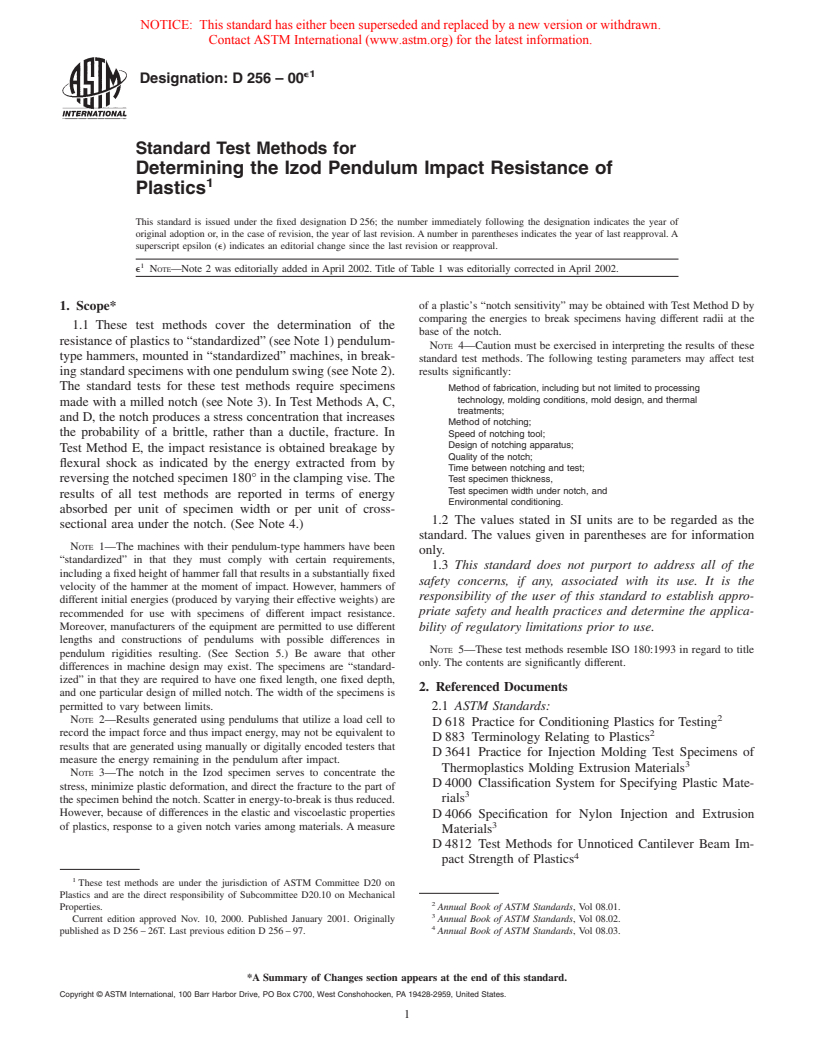

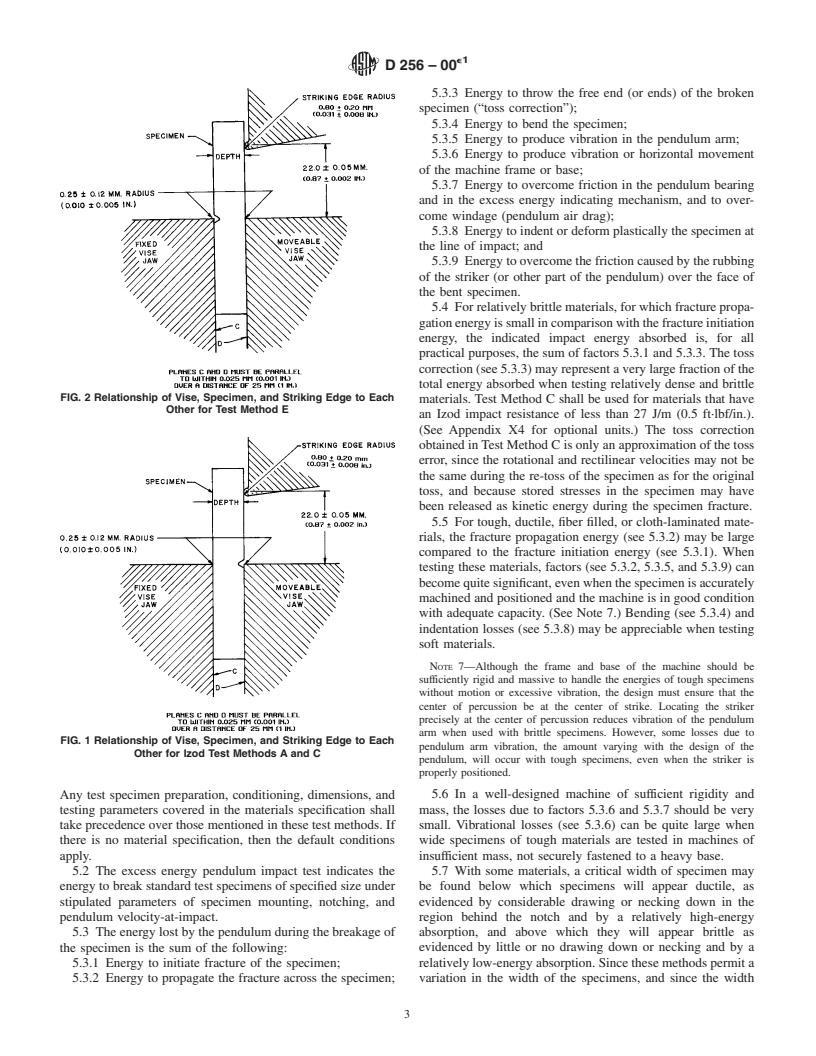

impacts the specimen on the face opposite the notch. (See Fig.

4.1.2 Test Method C is similar toTest MethodA, except for

1, Fig. 2.) Test Method E is used to give an indication of the

the addition of a procedure for determining the energy ex-

unnotched impact resistance of plastics; however, results ob-

pendedintossingaportionofthespecimen.Thevaluereported

tainedbythereversednotchmethodmaynotalwaysagreewith

is called the “estimated net Izod impact resistance.” Test

those obtained on a completely unnotched specimen. (See

Method C is preferred over Test Method A for materials that

,

28.1.)

have an Izod impact resistance of less than 27 J/m (0.5

ft·lbf/in.) under notch. (See Appendix X4 for optional units.)

5. Significance and Use

The differences between Test Methods A and C become

5.1 Before proceeding with these test methods, reference

unimportant for materials that have an Izod impact resistance

shouldbemadetothespecificationofthematerialbeingtested.

higher than this value.

Supporting data giving results of the interlaboratory tests are available from

Annual Book of ASTM Standards, Vol 14.02. ASTM Headquarters. Request RR: D20-1021.

6 8

Available from American National Standards Institute, 11 W. 42nd St., 13th Supporting data giving results of the interlaboratory tests are available from

Floor, New York, NY 10036. ASTM Headquarters. Request RR: D20-1026.

e1

D256–00

5.3.3 Energy to throw the free end (or ends) of the broken

specimen (“toss correction”);

5.3.4 Energy to bend the specimen;

5.3.5 Energy to produce vibration in the pendulum arm;

5.3.6 Energy to produce vibration or horizontal movement

of the machine frame or base;

5.3.7 Energy to overcome friction in the pendulum bearing

and in the excess energy indicating mechanism, and to over-

come windage (pendulum air drag);

5.3.8 Energy to indent or deform plastically the specimen at

the line of impact; and

5.3.9 Energytoovercomethefrictioncausedbytherubbing

of the striker (or other part of the pendulum) over the face of

the bent specimen.

5.4 Forrelativelybrittlematerials,forwhichfracturepropa-

gationenergyissmallincomparisonwiththefractureinitiation

energy, the indicated impact energy absorbed is, for all

practical purposes, the sum of factors 5.3.1 and 5.3.3.The toss

correction(see5.3.3)mayrepresentaverylargefractionofthe

total energy absorbed when testing relatively dense and brittle

FIG. 2 Relationship of Vise, Specimen, and Striking Edge to Each

materials. Test Method C shall be used for materials that have

Other for Test Method E

an Izod impact resistance of less than 27 J/m (0.5 ft·lbf/in.).

(See Appendix X4 for optional units.) The toss correction

obtainedinTestMethodCisonlyanapproximationofthetoss

error, since the rotational and rectilinear velocities may not be

the same during the re-toss of the specimen as for the original

toss, and because stored stresses in the specimen may have

been released as kinetic energy during the specimen fracture.

5.5 For tough, ductile, fiber filled, or cloth-laminated mate-

rials, the fracture propagation energy (see 5.3.2) may be large

compared to the fracture initiation energy (see 5.3.1). When

testing these materials, factors (see 5.3.2, 5.3.5, and 5.3.9) can

becomequitesignificant,evenwhenthespecimenisaccurately

machined and positioned and the machine is in good condition

with adequate capacity. (See Note 7.) Bending (see 5.3.4) and

indentation losses (see 5.3.8) may be appreciable when testing

soft materials.

NOTE 7—Although the frame and base of the machine should be

sufficiently rigid and massive to handle the energies of tough specimens

without motion or excessive vibration, the design must ensure that the

center of percussion be at the center of strike. Locating the striker

precisely at the center of percussion reduces vibration of the pendulum

arm when used with brittle specimens. However, some losses due to

FIG. 1 Relationship of Vise, Specimen, and Striking Edge to Each

pendulum arm vibration, the amount varying with the design of the

Other for Izod Test Methods A and C

pendulum, will occur with tough specimens, even when the striker is

properly positioned.

Any test specimen preparation, conditioning, dimensions, and 5.6 In a well-designed machine of sufficient rigidity and

testing parameters covered in the materials specification shall mass, the losses due to factors 5.3.6 and 5.3.7 should be very

take precedence over those mentioned in these test methods. If small. Vibrational losses (see 5.3.6) can be quite large when

there is no material specification, then the default conditions wide specimens of tough materials are tested in machines of

apply. insufficient mass, not securely fastened to a heavy base.

5.2 The excess energy pendulum impact test indicates the 5.7 With some materials, a critical width of specimen may

energy to break standard test specimens of specified size under be found below which specimens will appear ductile, as

stipulated parameters of specimen mounting, notching, and evidenced by considerable drawing or necking down in the

pendulum velocity-at-impact. region behind the notch and by a relatively high-energy

5.3 The energy lost by the pendulum during the breakage of absorption, and above which they will appear brittle as

the specimen is the sum of the following: evidenced by little or no drawing down or necking and by a

5.3.1 Energy to initiate fracture of the specimen; relativelylow-energyabsorption.Sincethesemethodspermita

5.3.2 Energy to propagate the fracture across the specimen; variation in the width of the specimens, and since the width

e1

D256–00

dictates, for many materials, whether a brittle, low-energy connected, through a rigid frame and bearings, a pendulum-

break or a ductile, high energy break will occur, it is necessary type hammer. (See 6.2.) The machine must also have a

that the width be stated in the specification covering that pendulum holding and releasing mechanism and a pointer and

material and that the width be reported along with the impact dial mechanism for indicating the excess energy remaining in

resistance. In vi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.