ASTM D1856-09

(Test Method)Standard Test Method for Recovery of Asphalt From Solution by Abson Method

Standard Test Method for Recovery of Asphalt From Solution by Abson Method

SIGNIFICANCE AND USE

The asphalt should be extracted from the aggregate-asphalt mixture in accordance with Method A of Test Methods D 2172 (centrifuge method) as there is some experimental evidence that the recovered asphalt may have slightly lower penetration values when recovered from solutions obtained from hot extraction methods.

SCOPE

1.1 This test method covers the recovery by the Abson method of asphalt from a solution from a previously conducted extraction. The asphalt is recovered with properties substantially the same as those it possessed in the bituminous mixture and in quantities sufficient for further testing.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are provided for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D1856 − 09

StandardTest Method for

1

Recovery of Asphalt From Solution by Abson Method

This standard is issued under the fixed designation D1856; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope where most of the solvent has been distilled, at which time

carbon dioxide gas is introduced into the distillation process to

1.1 This test method covers the recovery by the Abson

remove all traces of the extraction solvent. The recovered

methodofasphaltfromasolutionfromapreviouslyconducted

asphalt (distillation residue) can then be subjected to further

extraction. The asphalt is recovered with properties substan-

testing as required.

tially the same as those it possessed in the bituminous mixture

and in quantities sufficient for further testing.

4. Significance and Use

1.2 The values stated in SI units are to be regarded as the

4.1 The asphalt should be extracted from the aggregate-

standard. The values given in parentheses are provided for

asphalt mixture in accordance with MethodAofTest Methods

information only.

D2172 (centrifuge method) as there is some experimental

1.3 This standard does not purport to address all of the

evidence that the recovered asphalt may have slightly lower

safety concerns, if any, associated with its use. It is the

penetration values when recovered from solutions obtained

responsibility of the user of this standard to establish appro-

from hot extraction methods.

priate safety and health practices and determine the applica-

5. Apparatus

bility of regulatory limitations prior to use.

5.1 Centrifuge, batch unit capable of exerting a minimum

2. Referenced Documents

centrifugal force of 770 times gravity or continuous unit

2

2.1 ASTM Standards:

capable of exerting a minimum force of 3000 times gravity.

C670Practice for Preparing Precision and Bias Statements

5.2 Centrifuge Tubes—A supply of wide-mouth bottles or

for Test Methods for Construction Materials

centrifuge tubes may be used for the batch unit. A tube as

D2172TestMethods for Quantitative ExtractionofBitumen

illustrated in Fig. 1 has been found satisfactory for the

From Bituminous Paving Mixtures

continuous unit.

D2939Test Methods for Emulsified Bitumens Used as

3

Protective Coatings (Withdrawn 2012)

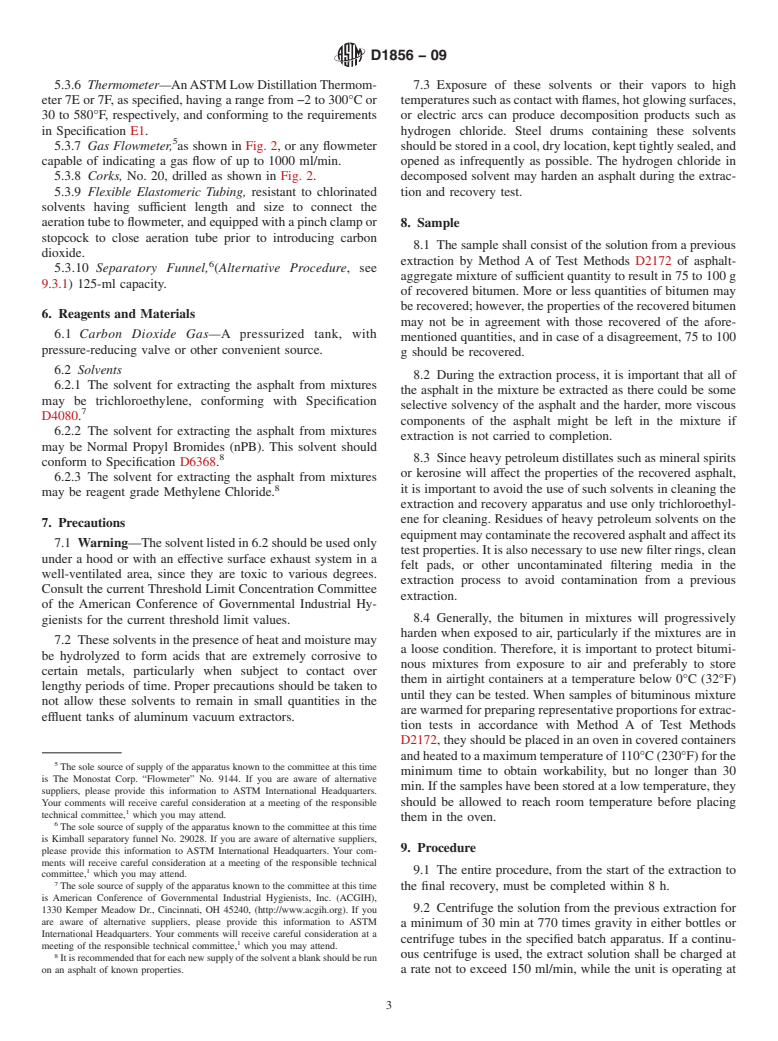

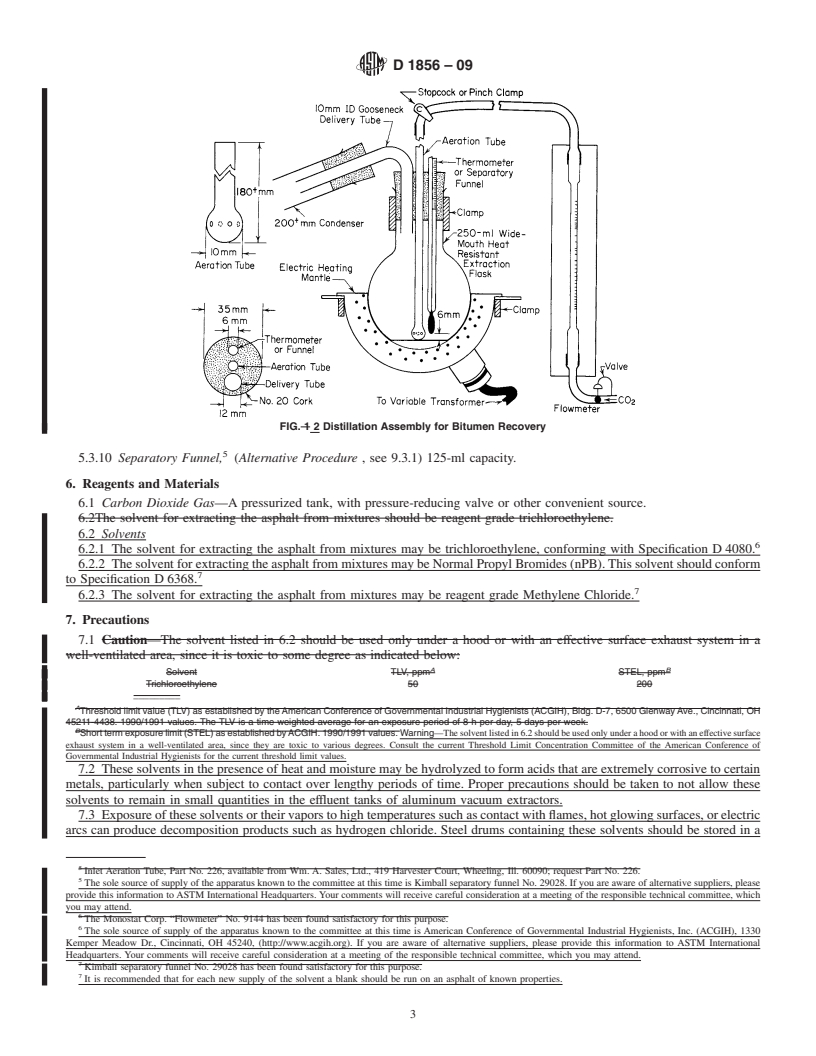

5.3 DistillationAssembly,asshowninFig.2,andconsisting

D4080Specification for Trichloroethylene, Technical and of the following items:

Vapor-Degreasing Grade

5.3.1 Extraction Flasks—Two 250-ml, wide-mouth, heat-

D6368Specification for Vapor-Degreasing Solvents Based resistant flasks, one for distillation and the other for the

on normal-Propyl Bromide and Technical Grade normal-

receiver.

Propyl Bromide

5.3.2 Glass Tubing—Heat-resistant glass tubing, having

E1Specification for ASTM Liquid-in-Glass Thermometers

10-mm inside diameter and gooseneck shaped (as shown in

Fig. 2) for connecting the flask to the condenser.

3. Summary of Test Method

4

5.3.3 InletAerationTube, atleast180mminlength,having

3.1 The solution of solvent and asphalt from an asphalt mix

a 6-mm outside diameter with a 10-mm bulb carrying six

extraction is distilled under prescribed conditions to a point

staggered side holes approximately 1.5 mm in diameter.

5.3.4 ElectricHeatingMantle,withvariabletransformer,oil

1

This method is under the jurisdiction of ASTM Committee D04 on Road and

bath, or fluidized sand bath, to fit a 250-ml flask.

Paving Materials and is the direct responsibility of Subcommittee D04.25 on

5.3.5 Water-Jacketed Condenser, Allihn type, with 200-mm

Analysis of Bituminous Mixtures.

minimum jacket length or equivalent.

Current edition approved July 1, 2009. Published August 2009. Originally

approved in 1961. Last previous edition approved in 2003 as D1856–95a (2003).

DOI: 10.1520/D1856-09.

2 4

For referenced ASTM standards, visit the ASTM website, www.astm.org, or The sole source of supply of the apparatus known to the committee at this time

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM is Inlet Aeration Tube, Part No. 226, available from Wm. A. Sales, Ltd., 419

Standards volume information, refer to the standard’s Document Summary page on Harvester Court, Wheeling, Ill. 60090; request Part No. 226. If you are aware of

the ASTM website. alternative suppliers, please provide this information to ASTM International

3

The last approved version of this historical standard is referenced on Headquarters.Your comments will receive careful consideration at a meeting of the

1

www.astm.org. responsible technical committee, which you may attend.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Consho

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:D1856–95a (Reapproved 2003) Designation:D1856–09

Standard Test Method for

1

Recovery of Asphalt From Solution by Abson Method

This standard is issued under the fixed designation D1856; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers the recovery by the Abson method of asphalt from a solution from a previously conducted

extraction. The asphalt is recovered with properties substantially the same as those it possessed in the bituminous mixture and in

quantities sufficient for further testing.

1.2

1.2 ThevaluesstatedinSIunitsaretoberegardedasthestandard.Thevaluesgiveninparenthesesareprovidedforinformation

only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

C670 Practice for Preparing Precision and Bias Statements for Test Methods for Construction Materials D96Test Methods for

Water and Sedi-

mentinCrudeOil

by Centrifuge

Method (Field

Procedure)

D2172 Test Methods for Quantitative Extraction of Bitumen fromFrom Bituminous Paving Mixtures

D2939 Test Methods for Emulsified Bitumens Used as Protective Coatings

D4080 Specification for Trichloroethylene, Technical and Vapor-Degreasing Grade

D6368 Specification for Vapor-Degreasing Solvents Based on normal-Propyl Bromide and Technical Grade normal-Propyl

Bromide

E1 Specification for ASTM Liquid-in-Glass Thermometers

3. Summary of Test Method

3.1 The solution of solvent and asphalt from a prioran asphalt mix extraction is distilled under prescribed conditions to a point

wheremostofthesolventhasbeendistilled,atwhichtimecarbondioxidegasisintroducedintothedistillationprocesstoremove

all traces of the extraction solvent.The recovered asphalt (distillation residue) can then be subjected to further testing as required.

4. Significance and Use

4.1 The asphalt should be extracted from the aggregate-asphalt mixture in accordance with MethodAof Test Methods D2172

(centrifuge method) as there is some experimental evidence that the recovered asphalt may have slightly lower penetration values

when recovered from solutions obtained from hot extraction methods.

5. Apparatus

5.1 Centrifuge, batch unit capable of exerting a minimum centrifugal force of 770 times gravity, or continuous unit capable of

exerting a minimum force of 3000 times gravity. (The apparatus specified in Test Methods D96 may also be used.) , batch unit

1

This method is under the jurisdiction ofASTM Committee D04 on Road and Paving Materials and is the direct responsibility of Subcommittee D04.25 onAnalysis of

Bituminous Mixtures.

Current edition approved Dec. 1, 2003. Published January 2004. Originally approved in 1961. Last previous edition approved in 1995 as D1852–95a.

Current edition approved July 1, 2009. Published August 2009. Originally approved in 1961. Last previous edition approved in 2003 as D1856–95a (2003).

2

ForreferencedASTMstandards,visittheASTMwebsite,www.astm.org,orcontactASTMCustomerServiceatservice@astm.org.ForAnnualBookofASTMStandards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D1856–09

capable of exerting a minimum centrifugal force of 770 times gravity or continuous unit capable of exerting a minimum force of

3000 times gravity.

5.2 Centrifuge Tubes—Asupply of wide-mouth bottles or centrifuge tubes as shown in Fig. 1 or Fig. 2 of Test Methods D96.

—Asupplyofwide-mouthbottlesorcentrifugetubesmaybeusedforthebatchunit.AtubeasillustratedinFig.1hasbeenfound

satisfactory for the continuous unit.

5.3 Distillation Assembly, as shown in Fig. 1Fig. 2, and consisting of the following items:

5.3.1 Extraction Flasks—Two 250-ml, wide-mouth, heat-resistant flasks, one for distillation and the other for the receiver.

5.3.2 Glass Tubing—Heat-resistantglasstubing,having10-mminsidediameterandgooseneckshaped(asshowninFig.1Fig.

2) for connecting the flask to the condenser.

3

5.3.3 Inlet Aeration Tub

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.