ASTM B230/B230M-99(2004)

(Specification)Standard Specification for Aluminum 1350-H19 Wire for Electrical Purposes

Standard Specification for Aluminum 1350-H19 Wire for Electrical Purposes

SCOPE

1.1 This specification covers aluminum 1350-H19 (extra hard) round wire for electrical purposes.

1.2 The values stated in inch-pound or SI units are to be regarded separately as standard. The values in each system are not exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in nonconformance with the specification.

1.2.1 For density, resistivity, and temperature, the values stated in SI units are to be regarded as standard.

Note 1—lPrior to 1975 aluminum 1350 was designated EC aluminum.

Note 2—The aluminum and temper designations conform to ANSI H35.1/H35.1M. Aluminum 1350 corresponds to UNS A91350 in accordance with Practice E 527.Note 3

For definitions of terms found in this specification relating to uninsulated electrical conductors see Terminology B 354.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B 230/B 230M – 99 (Reapproved 2004)

Standard Specification for

Aluminum 1350–H19 Wire for Electrical Purposes

This standard is issued under the fixed designation B 230/B 230M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope ANSI H35.1 American National Standard for Alloy and

Temper Designations Systems for Aluminum

1.1 This specification covers aluminum 1350–H19 (extra

ANSI H35.1M American National Standard for Alloy and

hard) round wire for electrical purposes.

Temper Systems for Aluminum [Metric]

1.2 The values stated in inch-pound or SI units are to be

2.4 NIST Document:

regarded separately as standard. The values in each system are

NBS Handbook 100–Copper Wire Tables

not exact equivalents; therefore, each system shall be used

independently of the other. Combining values from the two

3. Terminology

systems may result in nonconformance with the specification.

3.1 Definitions of Terms Specific to This Standard:

1.2.1 For density, resistivity, and temperature, the values

3.1.1 lot—a group of production units, up to 30 000 lb

stated in SI units are to be regarded as standard.

[15 000 kg] of mass, of one type and size of wire, which was

NOTE 1—Prior to 1975 aluminum 1350 was designated EC aluminum.

produced during the same time period, under similar produc-

NOTE 2—The aluminum and temper designations conform to ANSI

tion conditions, and is presented for acceptance at the same

H35.1/H35.1M. Aluminum 1350 corresponds to UNS A91350 in accor-

time (Explanatory Note 1 and Note 2).

dance with Practice E 527.

3.1.2 production unit—a coil, reel, spool, or other package

NOTE 3—For definitions of terms found in this specification relating to

of wire that represents a single usable length.

uninsulated electrical conductors see Terminology B 354.

3.1.3 sample—theproductionunitorunitsfromwhichatest

2. Referenced Documents

specimen or specimens has been removed, and which is

2.1 The following documents of the issue in effect on the considered to have properties representative of the lot.

date of material purchase form a part of this specification to the 3.1.4 specimen—alengthofwireremovedfortestpurposes.

extent referenced herein.

2 4. Ordering Information

2.2 ASTM Standards:

4.1 Orders for material under this specification shall include

B 193 Test Method for Resistivity of Electrical Conductor

Materials the following information:

4.1.1 Quantity of each size,

B 233 Specification forAluminum 1350 Drawing Stock for

Electrical Purposes 4.1.2 Wire size (see 11.1 and Table 1 or Table 2),

4.1.3 Special tension test, if required (see 7.2 and 7.3),

B 354 Terminology Relating to Uninsulated Metallic Elec-

trical Conductors 4.1.4 Frequency of bending test (see 8.1 and 14.5),

4.1.5 Special jointing procedures, if permitted (see 12.2),

B 557/B 557M Test Methods of Tension Testing Wrought

and Cast Aluminum- and Magnesium-Alloy Products 4.1.6 Place of inspection (see 15.2),

4.1.7 Package size and type (see 16.1), and

E 527 Practice for Numbering Metals and Alloys (UNS)

2.3 ANSI Standard: 4.1.8 Special package marking, if required (see 16.4).

5. Materials and Manufacture

This specification is under the jurisdiction of ASTM Committee B01 on

5.1 The aluminum wire shall be made from drawing stock

Electrical Conductors and is the direct responsibility of Subcommittee B01.07 on

meeting the requirements of Specification B 233.

Conductors of Light Metals.

Current edition approved April 1, 2004. Published April 2004. Originally

approved in 1948. Last previous edition approved in 1999 as B 230/B 230M – 99.

2 3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Available from American National Standards Institute (ANSI), 25 W. 43rd St.,

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM 4th Floor, New York, NY 10036.

Standards volume information, refer to the standard’s Document Summary page on Available from National Institute of Standards and Technology (NIST), 100

the ASTM website. Bureau Dr., Stop 3460, Gaithersburg, MD 20899-3460.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

B 230/B 230M – 99 (2004)

TABLE 1 Tensile Strength and Elongation Requirements

7.2 When requested by the purchaser, tension tests shall be

Elongation in 10 in., min made of specimens of wire containing joints made in the

Tensile Strength, min ksi

(%)

drawing stock or in the wire prior to final drawing. Such tests

Diameter, in.

Average for Individual Average for Individual

shall indicate tensile strengths not less than 90 % of the values

A

a Lot Tests a Lot Tests

for individual tests shown in Table 1 or Table 2.

0.0105 to 0.0500 25.0 23.0 . . . . . .

7.3 When requested by the purchaser, tension tests of

0.0501 to 0.0600 29.0 27.0 1.4 1.2

specimens containing joints in the finished wire, or in the final

0.0601 to 0.0700 28.5 27.0 1.5 1.3

0.0701 to 0.0800 28.0 26.5 1.6 1.4 drawing, if permitted, shall be made. Such tests shall indicate

0.0801 to 0.0900 27.5 26.0 1.6 1.5

tensile strengths to be not less than 11.0 ksi [145 MPa] for

0.0901 to 0.1000 27.0 25.5 1.6 1.5

electric-butt welded joints, and not less than 21.0 ksi [75 MPa]

0.1001 to 0.1100 26.0 24.5 1.6 1.5

0.1101 to 0.1200 25.5 24.0 1.7 1.6 for cold-pressure welded joints and electric-butt, cold-upset

0.1201 to 0.1400 25.0 23.5 1.8 1.7

welded joints.

0.1401 to 0.1500 24.5 23.5 1.9 1.8

0.1501 to 0.1800 24.0 23.0 2.0 1.9

8. Bending Properties

0.1801 to 0.2100 24.0 23.0 2.1 2.0

0.2101 to 0.2600 23.5 22.5 2.3 2.2

8.1 The wire shall be free of brittleness as evidenced by its

A

For wire diameters within 0.0501 to 0.2600 in., the minimum average tensile

ability to be coiled or looped around its own diameter with or

strength for a lot may be estimated from the following logarithmic equation for

without a mandrel. No fracture shall occur. Slight surface

process control purposes to meet the requirements of this specification: Tensile

strength, ksi = 17.40 – 3.84 3 ln (diameter of wire, in.). Requirements stated in the

checks shall not constitute cause for rejection.

table are to be used for all other purposes.

9. Resistivity

TABLE 2 Tensile Strength and Elongation Requirements

9.1 The electrical resistivity shall not exceed the values

Elongation in 250 mm, min

shown in Table 3 (Explanatory Note 4).

Tensile Strength, min MPa

(%)

Diameter, mm

Average for Individual Average for Individual

10. Density

A

a Lot Tests a Lot Tests

10.1 For the purpose of calculating linear density, cross

0.227 to 1.25 170.0 160.0 . . . . . .

section, and so forth, the density of aluminum 1350 shall be

1.26 to 1.50 200.0 185.0 1.4 1.2

3 3

1.51 to 1.75 195.0 185.0 1.5 1.3

taken as 2705 kg/m [0.0975 lb/in. ] at 20°C [68°F].

1.76 to 2.00 195.0 185.0 1.6 1.4

2.01 to 2.25 190.0 180.0 1.6 1.5

11. Diameter

2.26 to 2.50 185.0 175.0 1.6 1.5

2.51 to 2.75 180.0 170.0 1.6 1.5

11.1 The diameter of the wire shall be specified in inches to

2.76 to 3.00 175.0 165.0 1.7 1.6

the nearest 0.0001 in. or the diameter of the wire shall be

3.01 to 3.50 170.0 160.0 1.8 1.7

3.51 to 3.75 170.0 160.0 1.9 1.8 specified in millimetres to the nearest 0.001 mm for wires less

3.76 to 4.50 165.0 160.0 2.0 1.9

than 1.000 mm in diameter, and to the nearest 0.01 mm for

4.51 to 5.25 165.0 160.0 2.1 2.0

wires1.00mmindiameterandlarger.Theactualwirediameter

5.26 to 6.50 160.0 155.0 2.3 2.2

A shall not vary from the specified diameter by more than the

For wire diameters within 1.26 to 6.50 mm the minimum average tensile

strength for a lot may be estimated from the following logarithmic equation for values shown in Table 4.

process control purposes to meet the requirements of this specification: Tensile

Strength, MPa = 205.88 – 27.14 3 ln (diameter of wire, mm). Requirements stated

12. Joints

in the table are to be used for all other purposes.

12.1 No joints shall be made in the finished wire except as

6. Workmanship, Finish andAppearance provided in 12.2. Joints may be made in the drawing stock and

in the wire prior to final drawing and shall be in accordance

6.1 The wire shall be free of imperfections not consistent

with good commercial practice.

with good commercial practice.

12.2 If agreed upon between the manufacturer and the

7. Tensile Properties

purchaser, joints may be made during the final drawing or in

7.1 Tensile Strength and Elongation—The wire shall con- the finished wire by electric-butt welding, cold-pressure weld-

form to the tensile strength and elongation requirements set ing, or electric-butt, cold-upset welding, subject to the follow-

forth in Table 1 or Table 2 (Explanatory Note 3). ing limitations.

A

TABLE 3 Electrical Resistivity Requirements at 20°C (68°F) and Equivalent Copper Resistivity

NOTE 1—The values in boldface are standard; other values are for information only.

Volume

Electrical Resistivity

Conductivity

Volume Mass

%IACS

2 2 2

V·mm /m µVin. µV·cm V·cmil/ft V·lb/mile V·g/m

Average for lot 61.2 0.028172 1.1091 2.8172 16.946 434.81 0.076149

Individual tests 61.0 0.028265 1.1128 2.8265 17.002 436.23 0.076399

Copper equivalent 100.0 0.017241 0.67879 1.7241 10.371 875.20 0.15328

A 2

The equivalent resistivity values for 100 % IACS conductivity were each computed from the fundamental IEC value ( ⁄58 V·mm /m) using conversion factors each

accurate to at least seven significant figures. Corresponding values for aluminum conductivities were derived from these by multiplying by the reciprocal of the conductivity

ratios and, where applicable, also by the density ratios, both accurate to at least seven significant figures.

B 230/B 230M – 99 (2004)

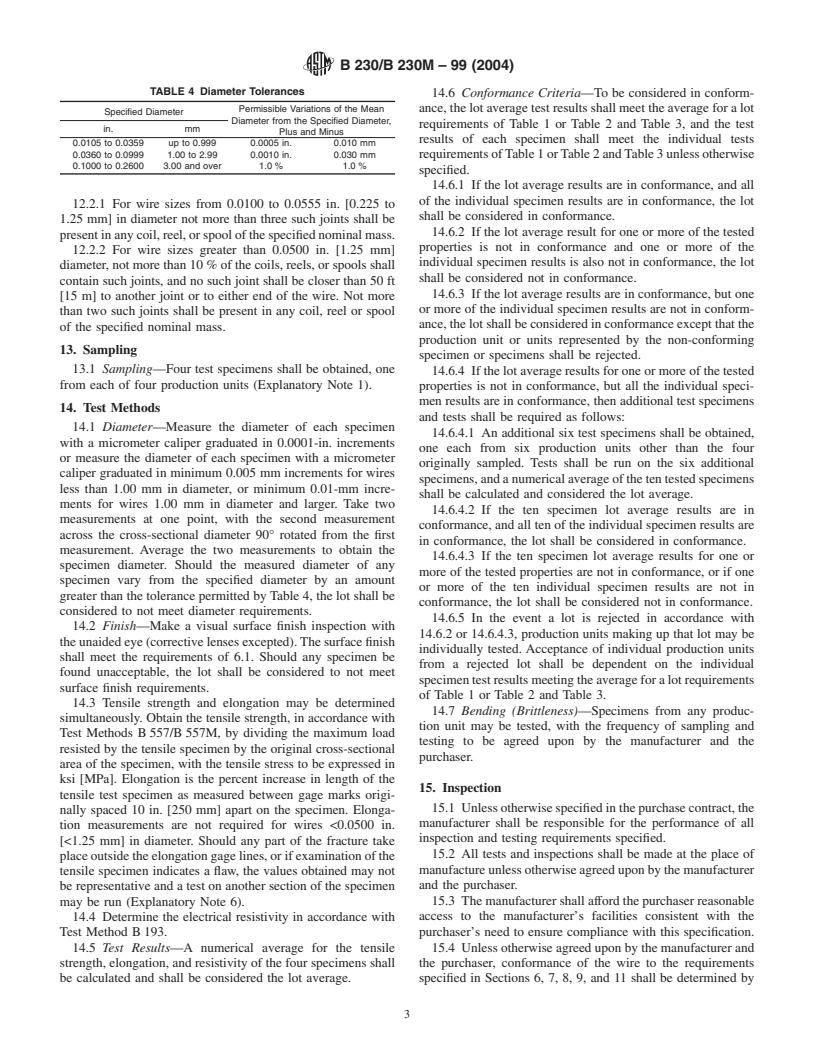

TABLE 4 Diameter Tolerances

14.6 Conformance Criteria—To be considered in conform-

Permissible Variations of the Mean ance, the lot average test results shall meet the average for a lot

Specified Diameter

Diameter from the Specified Diameter,

requirements of Table 1 or Table 2 and Table 3, and the test

in. mm

Plus and Minus

results of each specimen shall meet the individual tests

0.0105 to 0.0359 up to 0.999 0.0005 in. 0.010 mm

0.0360 to 0.0999 1.00 to 2.99 0.0010 in. 0.030 mm requirementsofTable1orTable2andTable3unlessotherwise

0.1000 to 0.2600 3.00 and over 1.0 % 1.0 %

specified.

14.6.1 If the lot average results are in conformance, and all

of t

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.