ASTM F2980-13(2017)

(Test Method)Standard Test Method for Analysis of Heavy Metals in Glass by Field Portable X-Ray Fluorescence (XRF)

Standard Test Method for Analysis of Heavy Metals in Glass by Field Portable X-Ray Fluorescence (XRF)

SIGNIFICANCE AND USE

5.1 Waste glass is currently recycled into various consumer products. This test method has been developed as a tool for evaluation of heavy metals in glass to satisfy reporting requirements for maximum allowable content for some applications.

5.2 The ranges within which this test method is quantitative are given in Table 1.

5.3 For amounts of the analyte elements outside the ranges in Table 1, this test method provides screening results. That is, it provides an unambiguous indication that each element can be described as present in an amount greater than the scope upper limit or that the amount of the element can be described as less than the scope lower limit with a high degree of confidence.

Note 2: In general, when a quantitative result is obtained, the analyst can make a clear decision as to whether a material is suitable for the intended purpose. When the contents of elements of interest are outside the quantitative range, the analyst can still make a decision whether the amount is too high or whether additional analyses are required.

5.4 These methods can be applied to glass beads, plate glass, float glass, fiber glass, or ground glass. This test method has been validated for the ranges of matrix compositions that are summarized in Table 2.

5.5 Detection limits, sensitivity, and element ranges will vary with matrices, detector type, and other instrument conditions and parameters.

5.6 All analytes are determined as the element and reported as such. These include all elements listed in Table 1. This test method may be applicable to other glass matrices, additional elements, and wider concentration ranges provided the laboratory is able to validate the broadened scope of this test method.

SCOPE

1.1 This test method covers field portable X-ray fluorescence (XRF) spectrometric procedures for analyses of arsenic and lead in glass compositions using field portable energy dispersive XRF spectrometers.

1.2 The mass fraction range of arsenic within which this test method is quantitative is given in Table 1. Scope limits were determined from the interlaboratory study results using the approach given in Practice E1601.

1.3 The mass fraction range for which lead was tested is given in Table 1. However, lead results cannot be considered quantitative on the basis of single-sample results because the precision performance is not good enough to allow laboratories to compare results in a quantitative manner.

Note 1: The performance of this test method was evaluated using results based on single-sample determinations from specimens composed of glass beads. One laboratory has determined that performance can be significantly improved by basing reported results on the mean of determinations from multiple samples to overcome inherent heterogeneity of elements in glass beads, especially the element lead. Additional information is provided in Section 17 on Precision and Bias.

1.3.1 To obtain quantitative performance, lead results must consist of the average of four or more determinations.

1.4 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. Some specific hazards statements are given in Section 7 on Hazards.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: F2980 − 13 (Reapproved 2017)

Standard Test Method for

Analysis of Heavy Metals in Glass by Field Portable X-Ray

1

Fluorescence (XRF)

This standard is issued under the fixed designation F2980; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope ization established in the Decision on Principles for the

Development of International Standards, Guides and Recom-

1.1 This test method covers field portable X-ray fluores-

mendations issued by the World Trade Organization Technical

cence (XRF) spectrometric procedures for analyses of arsenic

Barriers to Trade (TBT) Committee.

and lead in glass compositions using field portable energy

dispersive XRF spectrometers.

2. Referenced Documents

1.2 Themassfractionrangeofarsenicwithinwhichthistest

2

2.1 ASTM Standards:

method is quantitative is given in Table 1. Scope limits were

D75/D75M Practice for Sampling Aggregates

determined from the interlaboratory study results using the

D6299 Practice for Applying Statistical Quality Assurance

approach given in Practice E1601.

and Control Charting Techniques to Evaluate Analytical

1.3 The mass fraction range for which lead was tested is

Measurement System Performance

given in Table 1. However, lead results cannot be considered

E29 Practice for Using Significant Digits in Test Data to

quantitative on the basis of single-sample results because the

Determine Conformance with Specifications

precisionperformanceisnotgoodenoughtoallowlaboratories

E135 Terminology Relating to Analytical Chemistry for

to compare results in a quantitative manner.

Metals, Ores, and Related Materials

E177 Practice for Use of the Terms Precision and Bias in

NOTE 1—The performance of this test method was evaluated using

ASTM Test Methods

results based on single-sample determinations from specimens composed

of glass beads. One laboratory has determined that performance can be

E691 Practice for Conducting an Interlaboratory Study to

significantly improved by basing reported results on the mean of deter-

Determine the Precision of a Test Method

minations from multiple samples to overcome inherent heterogeneity of

E1361 Guide for Correction of Interelement Effects in

elements in glass beads, especially the element lead. Additional informa-

X-Ray Spectrometric Analysis

tion is provided in Section 17 on Precision and Bias.

E1601 Practice for Conducting an Interlaboratory Study to

1.3.1 To obtain quantitative performance, lead results must

Evaluate the Performance of an Analytical Method

consist of the average of four or more determinations.

E1621 Guide for ElementalAnalysis by Wavelength Disper-

1.4 The values stated in SI units are to be regarded as

sive X-Ray Fluorescence Spectrometry

standard. No other units of measurement are included in this

F2576 Terminology Relating to Declarable Substances in

standard.

Materials

3

1.5 This standard does not purport to address all of the

2.2 ANSI Standard:

safety concerns, if any, associated with its use. It is the

N43.2 Radiation Safety for X-Ray Diffraction and Fluores-

responsibility of the user of this standard to establish appro-

cence Analysis Equipment

priate safety, health, and environmental practices and deter- 4

2.3 AASHTO Standard:

mine the applicability of regulatory limitations prior to use.

TP-97-11 Test Method for Glass Beads used in Pavement

Some specific hazards statements are given in Section 7 on

Markings

Hazards.

1.6 This international standard was developed in accor-

dance with internationally recognized principles on standard-

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

1

This test method is under the jurisdiction of ASTM Committee F40 on the ASTM website.

3

Declarable Substances in Materials and is the direct responsibility of Subcommittee Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

F40.01 on Test Methods. 4th Floor, New York, NY 10036, http://www.ansi.org.

4

Current edition approved Nov. 1, 2017. Published November 2017. Originally Available from American Association of State Highway and Transportation

approved in 2013. Last previous edition approved in 2013 as F29180-13. DOI: Officials (AASHTO), 444 N. Capitol St., NW, Suite 249, Washington, DC 20001,

10.1520/F2980-13R17. http://www.transportation.org.

Copyright © AS

...

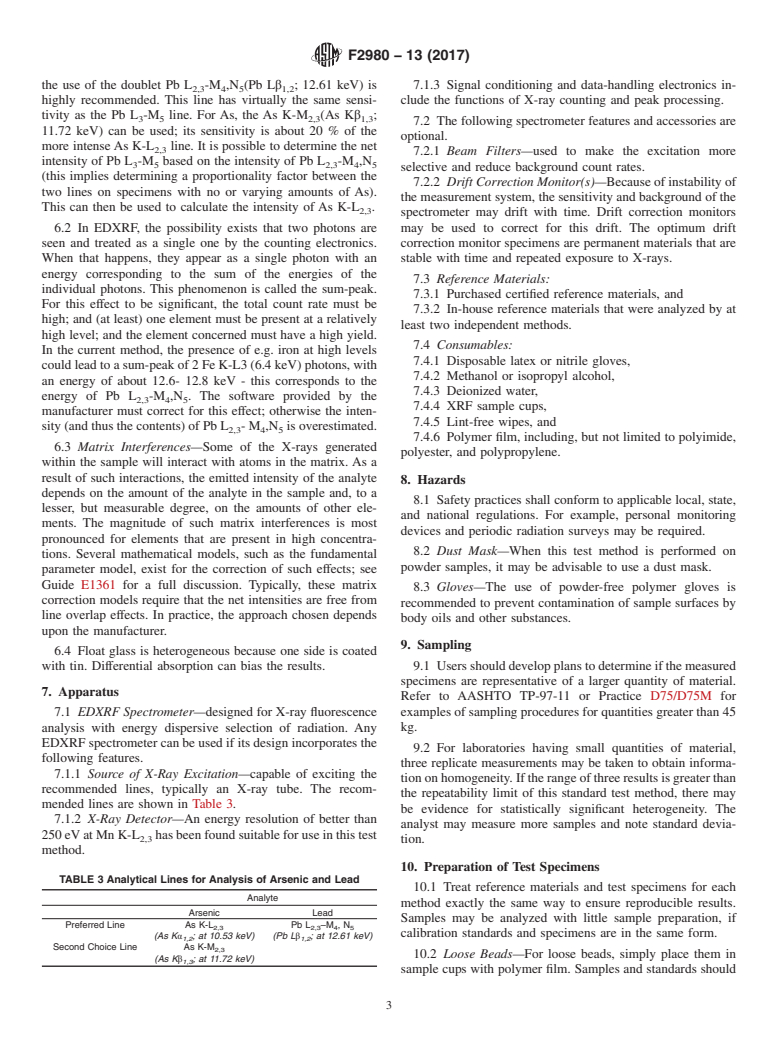

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.