ASTM D6560-00(2005)

(Test Method)Standard Test Method for Determination of Asphaltenes (Heptane Insolubles) in Crude Petroleum and Petroleum Products

Standard Test Method for Determination of Asphaltenes (Heptane Insolubles) in Crude Petroleum and Petroleum Products

SIGNIFICANCE AND USE

Asphaltenes are the organic molecules of highest molecular mass and carbon-hydrogen ratio normally occurring in crude petroleum and petroleum products containing residual material. They may give problems during storage and handling if the suspension of asphaltene molecules is disturbed through excess stress or incompatibility. They are also the last molecules in a product to combust completely, and thus may be one indicator of black smoke propensity. Their composition normally includes a disproportionately high quantity of the sulfur, nitrogen, and metals present in the crude petroleum or petroleum product.

SCOPE

1.1 This test method covers a procedure for the determination of the heptane insoluble asphaltene content of gas oil, diesel fuel, residual fuel oils, lubricating oil, bitumen, and crude petroleum that has been topped to an oil temperature of 260°C (see A1.2.1.1).

1.2 The precision is applicable to values between 0.50 and 30.0 % m/m. Values outside this range may still be valid but may not give the same precision values.

1.3 Oils containing additives may give erroneous results.

1.4 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

A1.1.1 This annex covers a procedure for the preparation of a crude petroleum residue (topped to an oil temperature of 260°C) suitable for the determination of asphaltene content (see 9.4).

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D6560–00 (Reapproved 2005)

Designation: IP143/01

Standard Test Method for

Determination of Asphaltenes (Heptane Insolubles) in Crude

,

1 2

Petroleum and Petroleum Products

This standard is issued under the fixed designation D6560; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D4052 Test Method for Density and Relative Density of

Liquids by Digital Density Meter

1.1 This test method covers a procedure for the determina-

D4057 Practice for Manual Sampling of Petroleum and

tion of the heptane insoluble asphaltene content of gas oil,

Petroleum Products

diesel fuel, residual fuel oils, lubricating oil, bitumen, and

D4177 Practice for Automatic Sampling of Petroleum and

crude petroleum that has been topped to an oil temperature of

Petroleum Products

260°C (see A1.2.1.1).

2.2 IP Standard:

1.2 The precision is applicable to values between 0.50 and

Specifications for IP Standard Thermometers

30.0% m/m. Values outside this range may still be valid but

may not give the same precision values.

3. Terminology

1.3 Oils containing additives may give erroneous results.

3.1 Definitions:

1.4 The values stated in SI units are to be regarded as

3.1.1 asphaltenes, n—wax-free organic material insoluble

standard. No other units of measurement are included in this

in heptane, but soluble in hot toluene (benzene).

standard.

1.5 This standard does not purport to address all of the

NOTE 1—Benzeneisincludedinthisdefinitionsolelyonthebasisofits

safety concerns, if any, associated with its use. It is the classical references in the definition of asphaltenes. The precision of this

test method when using toluene has been found to be the same as when

responsibility of the user of this standard to establish appro-

using benzene.

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

4. Summary of Test Method

2. Referenced Documents 4.1 A test portion of the sample is mixed with heptane and

3 the mixture heated under reflux, and the precipitated as-

2.1 ASTM Standards:

phaltenes, waxy substances, and inorganic material are col-

D86 Test Method for Distillation of Petroleum Products at

lected on a filter paper. The waxy substances are removed by

Atmospheric Pressure

washing with hot heptane in an extractor.

D1298 Test Method for Density, Relative Density (Specific

4.2 After removal of the waxy substances, the asphaltenes

Gravity), or API Gravity of Crude Petroleum and Liquid

are separated from the inorganic material by dissolution in hot

Petroleum Products by Hydrometer Method

toluene, the extraction solvent is evaporated, and the as-

phaltenes weighed.

5. Significance and Use

This test method is under the jurisdiction of ASTM Committee D02 on

PetroleumProductsandLubricantsandisthedirectresponsibilityofSubcommittee

5.1 Asphaltenes are the organic molecules of highest mo-

D02.14 on Stability and Cleanliness of Liquid Fuels.

lecular mass and carbon-hydrogen ratio normally occurring in

Current edition approved Nov. 1, 2005. Published November 2005. Originally

approved in 2000. Last previous edition approved in 2000 as D6560–00. DOI: crude petroleum and petroleum products containing residual

10.1520/D6560-00R05.

material.Theymaygiveproblemsduringstorageandhandling

This standard is based on material published in the IP Standard methods for

if the suspension of asphaltene molecules is disturbed through

Analysis and Testing of Petroleum and Related Products and British Standard 2000

excess stress or incompatibility. They are also the last mol-

Parts, copyright Energy Institute, 61 New Cavendish Street, London, W1M 8AR.

Adapted with permission of Energy Institute.

ecules in a product to combust completely, and thus may be

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on Available from Energy Institute, 61 New Cavendish St., London, WIM 8AR,

the ASTM website. UK.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D6560–00 (2005)

TABLE 1 Test Portion Size, Flask, and Heptane Volumes

one indicator of black smoke propensity. Their composition

normally includes a disproportionately high quantity of the Estimated Asphaltene Test Portion Heptane Volume

Content Size Flask Volume

sulfur, nitrogen, and metals present in the crude petroleum or

%m/m g mL mL

petroleum product.

Less than 0.5 10 6 2 1000 300 6 60

0.5to2.0 8 6 2 500 240 6 60

6. Apparatus

Over 2.0 to 5.0 4 6 1 250 120 6 30

Over 5.0 to 10.0 2 6 1 150 60 6 15

6.1 General—Ground-glass joints from different sources

Over 10.0 to 25.0 0.8 6 0.2 100 25 to 30

may have one of two diameter to length ratios. For the

Over 25.0 0.5 6 0.2 100 25 6 1

purposes of this test method, either is suitable, and for some

applications, the diameter itself can be one of two . However,

it is critical that the male and female parts of each joint are

NOTE 3—A rotovapor in conjunction with a nitrogen atmosphere

from the same series to avoid recession or protuberance.

reduces the hazard of toluene evaporation (see 11.7).

6.2 Condenser, with a coil or double surface, fitted with a

34/45or34/35ground-glassjointatthebottomtofitthetopof 6.7 Filter Funnel, of borosilicate glass, approximately

the extractor. Minimum length is 300 mm. 100mm diameter.

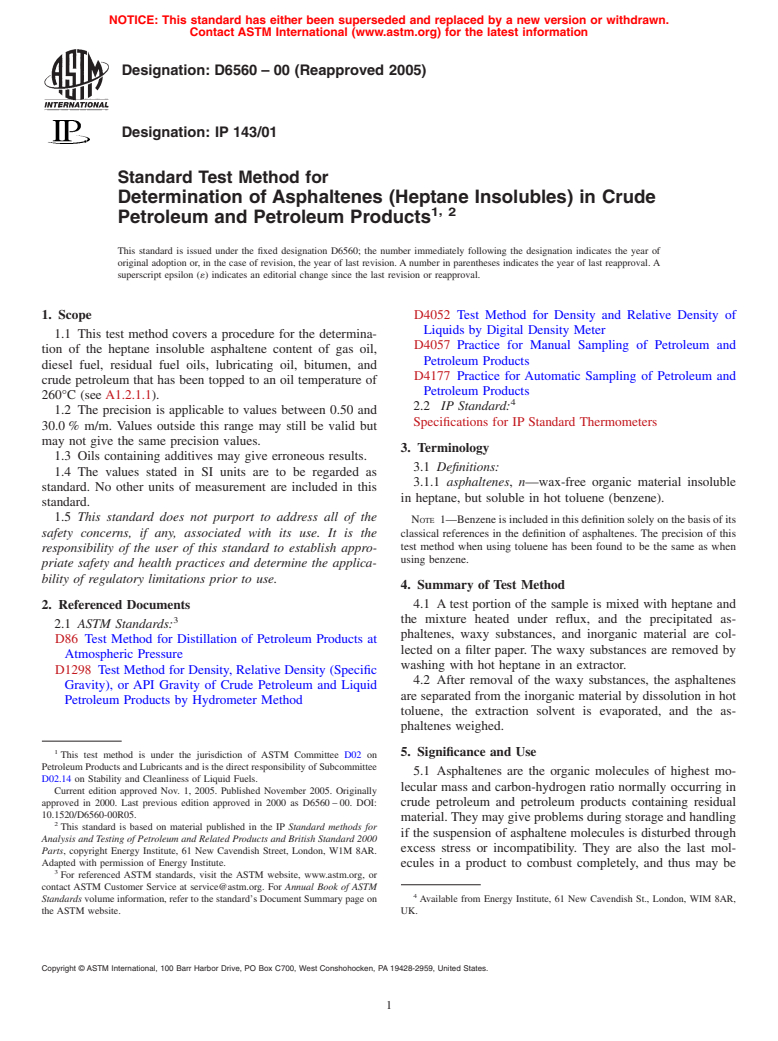

6.3 Reflux Extractor,conformingtothedimensionsgivenin 6.8 Filter Papers, Whatman Grade 42, 110 or 125-mm

Fig.1.Tolerancesare 61mmontheheightandouterdiameter diameter.

(OD) of the extractor body and 60.5 mm on all other 6.9 Analytical Balance, capable of weighing with an accu-

dimensions. The female ground-glass joint at the top shall racy of 0.1 mg.

match the male at the bottom of the condenser, and the male 6.10 Forceps, of stainless steel, spade ended.

ground-glass joint at the bottom shall match the female of the 6.11 Timing Device, electronic or manual, accurate to 1.0 s.

conical flask. 6.12 Oven, capable of maintaining a temperature from 100

6.4 Conical Flasks, of borosilicate glass of appropriate to 110°C.

capacity (see 11.2 and Table 1), with ground-glass joints to fit 6.13 Graduated Cylinders, of 50 and 100 mL capacity.

the bottom of the extractor. 6.14 Stirring Rods, of glass or polytetrafluoroethylene

(PTFE), 150 by 3-mm diameter.

NOTE 2—Sizes 24/39, 24/29, 29/43, or 29/32 are suitable.

6.15 Cooling Vessel, consisting of either a dessicator with-

6.5 Stopper, of borosilicate glass of a size to fit the conical

out desiccant, or another suitable tightly-stoppered vessel.

flask.

6.16 Mixer, high-speed, nonaerating.

6.6 Evaporating Vessel, of borosilicate glass. Either a hemi-

spherical dish of approximately 90 mm diameter, or another

7. Reagents

suitable vessel used in conjunction with a rotovapor.

7.1 Toluene (methylbenzene) [C H CH ],analyticalreagent

6 5 3

or nitration grade.

7.2 Heptane [C H ], analytical reagent grade.

7 16

8. Sampling

8.1 Unless otherwise specified, take samples by the proce-

dures described in Practice D4057 or D4177.

9. Test Portion Preparation

9.1 Test portions from the laboratory samples shall be

drawn after thorough mixing and subdivision. Heat viscous

samples of residual fuels to a temperature that renders the

sample liquid, but not above 80°C, and homogenize, using the

mixer (see 6.16) as necessary.

9.2 Heat samples of penetration grade bitumens to a tem-

perature not exceeding 120°C, and stir well before taking an

aliquot.

9.3 Samples of hard bitumens shall be ground to a powder

before an aliquot is taken.

9.4 Samples of crude petroleum shall be prepared in accor-

dance with the procedure described in theAnnexA1, unless it

The sole source of supply of the filter papers known to the committee at this

timeisWhatmanInt.Ltd.,Maidstone,UK.Ifyouareawareofalternativesuppliers,

please provide this information to ASTM International Headquarters. Your com-

ments will receive careful consideration at a meeting of the responsible technical

FIG. 1 Extractor committee, which you may attend.

D6560–00 (2005)

is known that the crude petroleum contains negligible quanti-

ties of material boiling below 80°C.

10. Apparatus Preparation

10.1 Clean all glass flasks (see 6.4) and dishes (see 6.6)by

a means that matches the cleanliness obtained by the use of a

strongly oxidizing agent, such as chromosulfuric acid, ammo-

nium peroxydisulfate in concentrated sulfuric acid at approxi-

mately 8 g/L, or sulfuric acid itself, soaking for at least 12 h,

followed by rinses in tap water, distilled water, and then

acetone, using forceps only for handling. (Warning—

Chromosulfuricacidisahealthhazard.Itistoxic,arecognized

FIG. 2 Filter Paper

carcinogenasitcontainsCr(VI)compounds,whicharehighly

corrosive and potentially hazardous in contact with organic

11.5 Remove the filter paper and contents from the funnel,

materials. When using chromosulfuric acid cleaning solution,

and place in the reflux extractor (see 6.3). Using a flask

eye protection and protective clothing are essential. Never

different from that used initially, reflux with heptane (see 7.2)

pipette the cleaning solution by mouth.After use, do not pour

atarateof2drops/sto4drops/sfromtheendofthecondenser

cleaning solution down the drain, but neutralize it with great

for an extraction period of not less than 60 min, or until a few

care, owing to the concentrated sulfuric acid present, and

drops of heptane from the bottom of the extractor leave no

dispose of it in accordance with standard procedures for toxic

residue on evaporation on a glass slide.

laboratory waste (chromium is highly dangerous to the envi-

11.6 Replacetheflaskbytheoneusedinitially,andtowhich

ronment). Nonchromium containing, strongly oxidizing acid

has been added 30 to 60 mLof toluene (see 7.1), and continue

cleaning solutions are also highly corrosive and potentially

refluxinguntilalltheasphalteneshavebeendissolvedfromthe

hazardousincontactwithorganicmaterials,butdonotcontain

paper.

chromium, which has its own special disposal problems.)

11.7 Transferthecontentsoftheflasktoacleananddry(see

10.2 For routine analysis, use a proprietary laboratory

Section10)evaporatingvessel(see6.6),weighedtothenearest

detergent to clean the glassware, followed by the rinses

0.2 mg by tare against a similar dish. Wash out the flask with

described in 10.1. When the detergent cleaning no longer

successive small quantities of toluene to a total not exceeding

matches the cleanliness required based on visual appearance,

30 mL. Remove the toluene by evaporation on a boiling water

use a strong oxidizing agent.

bath, or by evaporation in a rotovapor under an atmosphere of

10.3 After rinsing, place the glassware in the oven (see

nitrogen. (Warning—Perform the evaporation in a fume

6.12) for 30 min, and cool in the cooling vessel (see 6.15) for

hood.)

30 min before weighing.

11.8 Dry the dish and contents in the oven (see 6.12)at100

11. Procedure

to 110°C for 30 min. Cool in the cooling vessel (see 6.15) for

30 to 60 min and reweigh by tare against the dish used

11.1 Estimate the asphaltene content of the sample, or

previously for this purpose, and which has been subjected to

residue obtained from the procedure in Annex A1, and weigh

the same heating and cooling procedure as was the dish

the quantity, to the nearest 1 mg for masses above 1 g and to

containing asphaltenes.

the nearest 0.1 mg for masses of 1 g and below (see Table 1),

into a flask (see 6.4) of appropriate capacity (see Table 1).

NOTE 4—Asphaltenes are very susceptible to oxidation, and it is

11.2 Add heptane (see 7.2) to the test portion in the flask at

important that the procedure specified in the final drying stage is adhered

a ratio of 30 mL to each1gof sample if the expected to exactly as regards to temperature and time 61 min.

asphaltene content is below 25% m/m. For samples with an

12. Calculation

expected asphaltene content of above 25% m/m, a minimum

12.1 Calculate the asphaltene content, A, in % m/m, of

heptane volume of 25 mL shall be used (see Table 1).

petroleum products as follows:

11.3 Boil the mixture under reflux for 60 6 5 min. Remove

theflaskandcontentsattheendofthisperiod,cool,closewith

A 5100 ~M/G! (1)

a stopper (see 6.5), and store in a dark cupboard for 90 to

where:

150min, calculated from the time of removal from reflux.

M = is the mass of asphaltenes, in grams, and

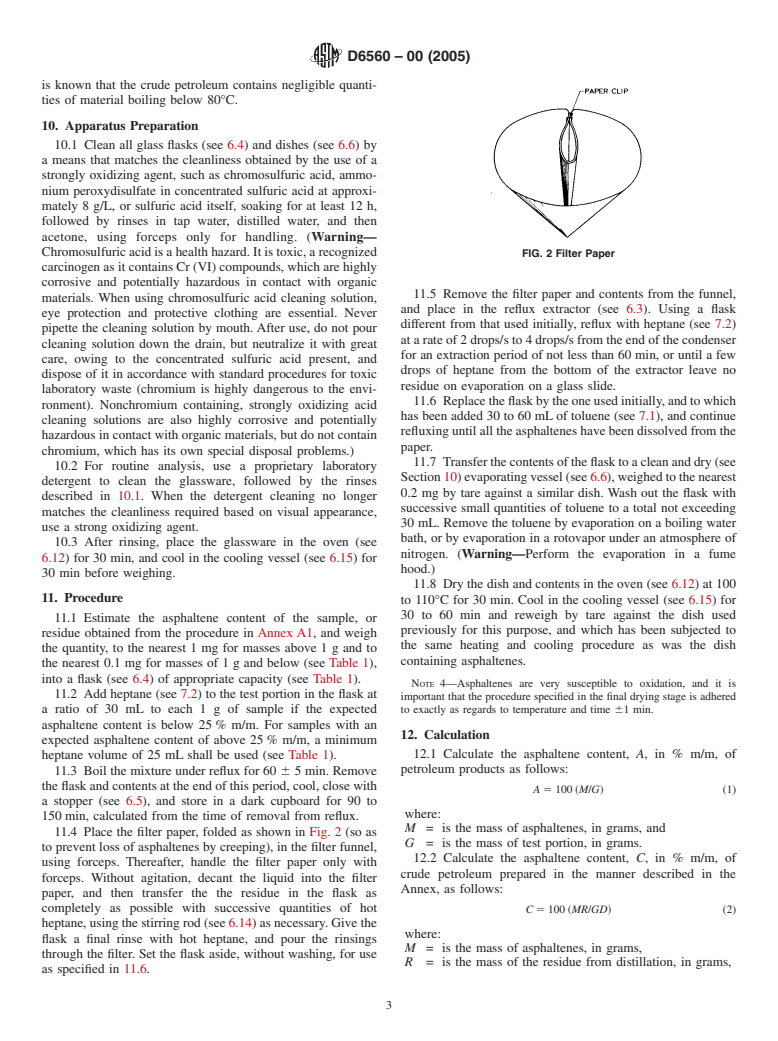

11.4 Place the filter paper, folded as shown in Fig. 2 (so as

G = is the mass of test portion, in grams.

to prevent loss of asphaltenes by creeping), in the filter funnel,

12.2 Calculate the asphaltene content, C, in % m/m, of

using forceps. Thereafter, handle the filter paper only with

crude petroleum prepared in the manner described in the

forceps. Without agitation, decant the liquid into the filter

Annex, as follows:

paper, and then transfer the the residue in the flask as

completely as possible with successive quantities of hot

C 5100 ~MR/GD! (2)

heptane,usingthestirringrod(see6.14)asnecessary.Givethe

where:

flask a final rinse with hot heptane, and pour the rinsings

M = is the mass of asphaltenes, in grams,

through the filter. Set the flask aside, without washing, for use

R = is the mass of the residue from distillation, in grams,

as specified in 11.6.

D6560–00 (2005)

apparatus under constant operating conditions on identical test

G = is the mass of the residue aliquot, in grams, and

material would, in the normal and correct operation of the test

D = is the mass of crude petroleum sample distilled, in

method, exceed the value below in only 1 case in 20.

grams.

r 50.1 A (3)

13. Report

where A is the average result, in % m/m.

13.1 Report the following information:

14.3 Reproducibility—The difference between two single

13.1.1 The heptane insoluble asphaltene content of values

and independent results obtained by different operators work-

less than 1.00% m/m, to the nearest 0.05% m/m, by Test

ingindifferentlaboratoriesonnominallyidenticaltestmaterial

Method D6560.

would, in the normal and correct operation of the test method,

13.1.2 The heptane insoluble asphaltene content of values

exceed the value below in only 1 case in 20.

of 1.0% m/m and greater, to the nearest 0.1% m/m, by Test

Method D6560. R 50.2 A (4)

14. Precision and Bias where A is the average result, in % m/m.

14.4 Bias—Since heptane insoluble asphaltenes are defined

14.1 Precision—The precision values were determined

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.