ASTM F1704-99

(Test Method)Standard Test Method for Performance of Commercial Kitchen Ventilation Systems

Standard Test Method for Performance of Commercial Kitchen Ventilation Systems

SCOPE

1.1 This test method, also known as the Commercial Kitchen Ventilation (CKV) Energy Balance Protocol (EBP), covers the overall performance evaluation of exhaust hoods with commercial cooking appliances and associated replacement air configuration. This test method addresses exhaust-only hoods positioned adjacent to a wall and appliances that supply air distribution as an integrated system. In particular, it includes the following:

1.1.1 Measurement and calculation of appliance energy inputs, energy exhausted, energy to food, and heat gain to the space adjacent to the hood based on a system energy balance;

1.1.2 Characterization of capture and containment performance of tested hood, appliance, and replacement air under cooking and non-cooking conditions;

1.1.4 Parametric evaluation of operational or design variations in appliances, hoods, or supply air system, that is, varying one factor while holding all other factors constant.

1.2 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation: F 1704 – 99

Standard Test Methods for

Performance of Commercial Kitchen Ventilation Systems

This standard is issued under the fixed designation F 1704; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope F 1521 Test Method for the Performance of Range Tops

F 1605 Test Method for Performance of Double-Sided

1.1 These test methods cover the performance evaluation of

Griddles

exhaust hoods with commercial cooking appliances and asso-

F 1639 Test Method for Performance of Combination Ov-

ciated replacement air configurations. The scope of these test

ens

methods include:

F 1695 Test Method for Performance of Underfired Broil-

1.1.1 Characterization of capture and containment perfor-

ers

mance of hood, appliance(s), and replacement air system

F 1785 Test Method for Performance of Steam Kettles

during cooking and non-cooking conditions;

F 1787 Test Method for Performance of Rotisserie

1.1.2 Determination of appliance heat gain to space derived

F 1817 Test Method for the Performance of Conveyor

from the measurement and calculation of appliance energy

Ovens

consumption, energy exhausted, and energy to food, based on

2.2 NFPA Standard:

a system energy balance;

NFPA 96 Standard for Ventilation Control and Fire Protec-

1.1.3 Parametric evaluation of operational or design varia-

tion of Commercial Cooking Operations

tions in appliances, hoods, or supply air.

2.3 ASHRAE Standards:

1.2 These test methods are contained in the sections indi-

“A Field Test Method for Determining Exhaust Rates in

cated as follows:

Grease Hoods for Commercial Kitchens,” ASHRAE

Sections

Transactions, Vol 100, Part 2, 1994

Test Method to Determine Threshold of Capture and Contain- 8

ment

ASHRAE Guideline 2-1986 (RA90) Engineering Analysis

Test Method to Determine Heat Gain to Space 16

of Experimental Data

1.3 The values stated in inch-pound units are to be regarded

2.4 ANSI Standards:

as the standard. The values given in parentheses are for

ANSI/ASHRAE 51 and ANSI/AMCA 210 Laboratory

information only. Method of Testing Fans for Rating

1.4 This standard does not purport to address all of the

2.5 ICC Standards:

safety concerns, if any, associated with its use. It is the International Mechanical Code

responsibility of the user of this standard to establish appro-

NOTE 1—The replacement air and exhaust system terms and their

priate safety and health practices and determine the applica-

definitions are consistent with terminology used by theAmerican Society

bility of regulatory limitations prior to use. 7

of Heating, Refrigeration, and Air Conditioning Engineers, see Ref (1).

Where there are references to cooking appliances, an attempt has been

2. Referenced Documents

made to be consistent with terminology used in the test methods for

commercial cooking appliances. For each energy rate defined as follows,

2.1 ASTM Standards:

there is a corresponding energy consumption that is equal to the average

F 1275 Test Method for the Performance of Griddles

energy rate multiplied by elapsed time. Electric energy and rates are

F 1361 Test Method for the Performance of Open Deep Fat

expressed in W, kW, and kWh. Gas Energy consumption quantities and

Fryers

F 1484 TestMethodforthePerformanceofSteamCookers

F 1496 Test Method for the Performance of Convection

Available from National Fire Protection Association, 1 Batterymarch Park,

Ovens

Quincy, MA 02269–9101.

Available from American Society of Heating, Refrigerating, and Air Condi-

tioning Engineers, Inc., 1791 Tullie Circle, NE, Atlanta, GA 30329.

1 5

These test methods are under the jurisdiction of ASTM Committee F-26 on Available from American National Standards Institute, 11 W. 42nd St., 13th

Food Service Equipment and are the direct responsibility of Subcommittee F26.06 Floor, New York, NY 10036.

on Productivity and Energy Protocol. Available from International Code Council, 5203 Leesburg Pike, Suite 708,

Current edition approved Oct. 10, 1999. Published January 2000. Originally Falls Church, VA 22041.

published as F 1704 – 96. Last previous edition F 1704 – 96. The boldface numbers in parentheses refer to the list of references at the end of

Annual Book of ASTM Standards, Vol 15.07. these test methods.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F 1704

rates are expressed in Btu, kBtu, and kBtu/h. Energy rates for natural

3.1.12 latent heat gain, n—the energy added to the test

gas-fueled appliances are based on the higher heating value of natural gas.

system by the vaporization of liquids that remain in the vapor

phase prior to being exhausted, for example, by vapor emitted

3. Terminology

by products of combustion and cooking processes.

3.1 Definitions of Terms Specific to This Standard:

3.1.13 makeup air handling hardware:

3.1.1 energyrate,n—the average rate at which an appliance

3.1.13.1 diffuser, n—an outlet discharging supply air in

consumes energy during a specified condition (for example,

various directions and planes.

idle or cooking).

3.1.13.2 grille, n—a covering for any opening through

3.1.2 appliance/hood energy balance, n—mathematical ex-

which air passes.

pression of appliance, exhaust system, and food energy rela-

3.1.13.3 register, n—a grille equipped with a damper.

tionship.

3.1.13.4 throw, n—the horizontal or vertical axial distance

[actual appliance energy consumption]

anairstreamtravelsafterleavinganairoutletbeforemaximum

= [heat gain to space from appliance(s)] + [energy exhausted] +

stream velocity is reduced to a specified terminal velocity, for

[energy-to-food, if any]

example, 100, 150, or 200 ft/min (0.51, 0.76, or 1.02 m/s).

3.1.3 cold start, n—the condition in which appliances are

3.1.14 measured energy input rate, n—the maximum or

energizedwithallcomponentsbeingatnominalroomtempera-

peak rate at which an appliance consumes energy measured

ture.

duringappliancepreheat,thatis,measuredduringtheperiodof

3.1.4 cooking energy consumption rate, n—the average rate

operation when all gas burners or electric heating elements are

of energy consumed by the appliance(s) during heavy-load

set to the highest setting.

cooking specified in appliance test methods in 2.1.

3.1.15 radiant heat gain, n—the fraction of the space

3.1.4.1 Discussion—In this test method, this rate is mea-

energy gain provided by radiation.

suredforheavy-loadcookinginaccordancewiththeapplicable

3.1.15.1 Discussion—Radiant heat gain is not immediately

test method.

converted into cooling load. Radiant energy must first be

3.1.5 exhaust energy rate, n—the average rate at which

absorbed by surfaces that enclose the space and objects in the

energy is removed from the test system.

space. As soon as these surfaces and objects become warmer

3.1.6 exhaust flow rate, n—the volumetric flow of air (plus

than the space air, some of their heat is transferred to the air in

other gases and particulates) through the exhaust hood, mea-

the space by convection. The composite heat storage capacity

suredinstandardcubicfeetperminute,scfm(standardlitreper

of these surfaces and objects determines the rate at which their

second, sL/s). This also shall be expressed as scfm per linear

respective surface temperatures increase for a given radiant

foot (sL/s per linear metre) of active exhaust hood length.

input and thus governs the relationship between the radiant

3.1.7 energy-to-food rate, n—the average rate at which

portion of heat gain and its corresponding part of the cooling

energy is transferred from the appliance to the food being

load. The thermal storage effect is critically important in

cooked, using the cooking conditions specified in the appli-

differentiating between instantaneous heat gain for a given

cable test methods.

space and its cooling load for that moment.

3.1.8 fan and control energy rate, n—the average rate of

3.1.16 rated energy input rate, n—the maximum or peak

energy consumed by fans, controls, or other accessories asso-

rate at which an appliance consumes energy as rated by the

ciated with cooking appliance(s). This energy rate is measured

manufacturer and specified on the appliance nameplate.

during preheat, idle, and cooking tests.

3.1.17 replacementair,n—air deliberately supplied into the

3.1.9 heat gain energy rate from appliance(s), n—the aver-

space (test room), and to the exhaust hood to compensate for

age rate at which energy is transferred from appliance(s) to the

the air, vapor, and contaminants being expelled (typically

test space around the appliance(s), exclusive of the energy

referred to as makeup air).

exhausted from the hood and the energy consumed by the food

3.1.18 supply flow rate, n—the volumetric flow of air

if any.

supplied to the exhaust hood in an airtight room, measured in

3.1.9.1 Discussion—This gain includes conductive, convec-

standard cubic feet per minute, scfm (standard litre per second,

tive, and radiant components. In conditions of complete

sL/s). This also shall be expressed as scfm per linear foot (sL/s

capture, the predominant mechanism of heat gain consists of

per linear metre) of active exhaust hood length.

radiationfromtheappliance(s),andradiationfromhood.Inthe

3.1.19 threshold of capture and containment, n—the condi-

condition of hood spillage, heat is gained additionally by

tions of hood operation in which minimum flow rates are just

convection.

sufficient to capture and contain the products generated by the

3.1.10 hood capture and containment, n—the ability of the

appliance(s). In this context, two minimum capture and con-

hood to capture and contain grease-laden cooking vapors,

tainment points are determined, one for appliance idle condi-

convective heat, and other products of cooking processes.

tion, and the other for heavy-load cooking condition.

Hood capture refers to the products getting into the hood

3.1.20 uncertainty, n—a measure of the precision errors in

reservoir from the area under the hood while containment

refers to the products staying in the hood reservoir. specified instrumentation or the measure of the repeatability of

a reported result.

3.1.11 idle energy consumption rate, n—the average rate at

whichanapplianceconsumesenergywhileitisidling,holding, 3.1.21 ventilation, n—that portion of supply air that is

or ready-to-cook, at a temperature specified in the applicable outdoor air plus any recirculated air that has been treated for

test method from 2.1. the purpose of maintaining acceptable indoor air quality.

F 1704

4. Significance and Use 5. Apparatus

5.1 Specialized apparatus requirements are listed in the

4.1 Threshold of Capture and Containment—This test

Apparatus Section in each method.

method describes flow visualization techniques that are used to

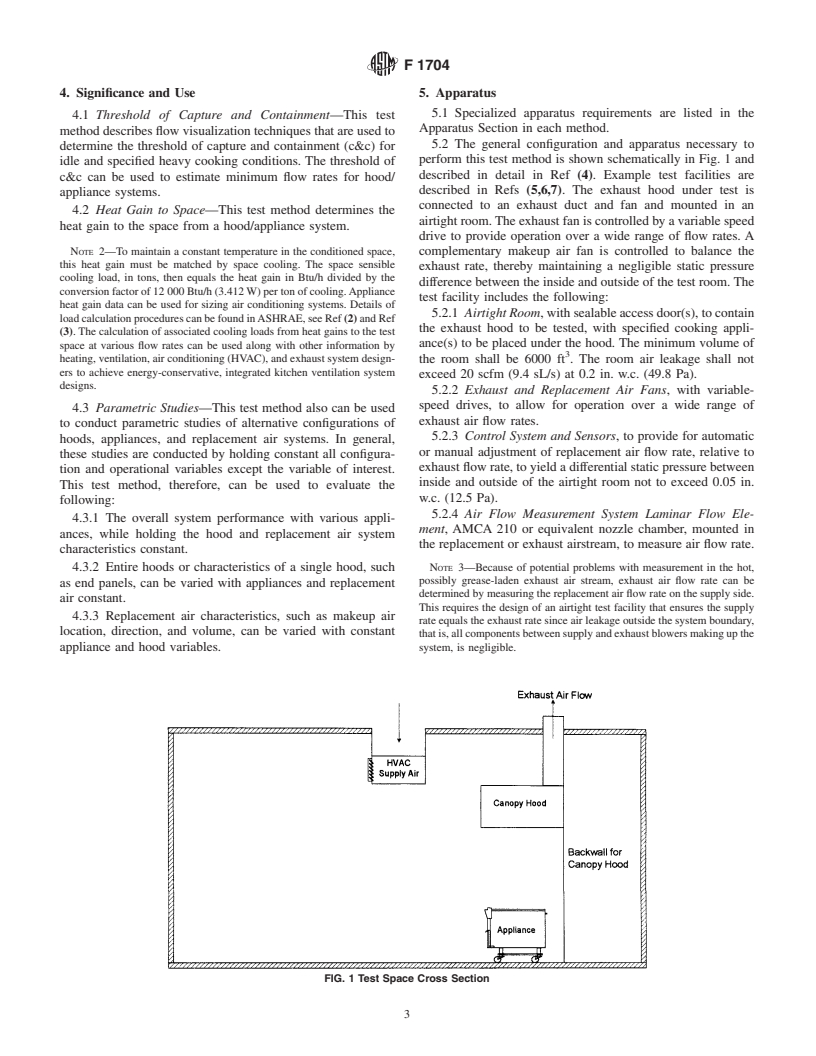

5.2 The general configuration and apparatus necessary to

determine the threshold of capture and containment (c&c) for

perform this test method is shown schematically in Fig. 1 and

idle and specified heavy cooking conditions. The threshold of

described in detail in Ref (4). Example test facilities are

c&c can be used to estimate minimum flow rates for hood/

described in Refs (5,6,7). The exhaust hood under test is

appliance systems.

connected to an exhaust duct and fan and mounted in an

4.2 Heat Gain to Space—This test method determines the

airtight room.The exhaust fan is controlled by a variable speed

heat gain to the space from a hood/appliance system.

drive to provide operation over a wide range of flow rates. A

NOTE 2—To maintain a constant temperature in the conditioned space,

complementary makeup air fan is controlled to balance the

this heat gain must be matched by space cooling. The space sensible

exhaust rate, thereby maintaining a negligible static pressure

cooling load, in tons, then equals the heat gain in Btu/h divided by the

difference between the inside and outside of the test room. The

conversionfactorof12 000Btu/h(3.412W)pertonofcooling.Appliance

test facility includes the following:

heat gain data can be used for sizing air conditioning systems. Details of

5.2.1 AirtightRoom,withsealableaccessdoor(s),tocontain

loadcalculationprocedurescanbefoundinASHRAE,seeRef(2)andRef

the exhaust hood to be tested, with specified cooking appli-

(3). The calculation of associated cooling loads from heat gains to the test

ance(s) to be placed under the hood. The minimum volume of

space at various flow rates can be used along with other information by

heating, ventilation, air conditioning (HVAC), and exhaust system design-

the room shall be 6000 ft . The room air leakage shall not

ers to achieve energy-conservative, integrated kitchen ventilation system

exceed 20 scfm (9.4 sL/s) at 0.2 in. w.c. (49.8 Pa).

designs.

5.2.2 Exhaust and Replacement Air Fans, with variable-

speed drives, to allow for operation over a wide range of

4.3 Parametric Studies—This test method also can be used

exhaust air flow rates.

to conduct parametric studies of alternative configurations of

5.2.3 Control System and Sensors, to provide for automatic

hoods, appliances, and replacement air systems. In general,

or manual adjustment of replacement air flow rate, relative to

these studies are conducted by holding constant all configura-

exhaust flow rate, to yield a differential static pressure between

tion and operational variables except the variable of interest.

inside and outside of the airtight room not to exceed 0.05 in.

This test method, therefore, can be used to evaluate the

w.c. (12.5 Pa).

following:

5.2.4 Air Flow Measurement System Laminar Flow Ele-

4.3.1 The overall system performance with various appli-

ment, AMCA 210 or equivalent nozzle chamber, mounted in

ances, while holding the hood and replacement air system

the replacement or exhaust airstream, to measure air flow rate.

characteristics constant.

4.3.2 Entire hoods or characteristics of a single hood, such NOTE 3—Because of potential problems with measurement in the hot,

possibly grease-laden exhaust air stream, exhaust air flow rate can be

as end panels, can be varied with appliances and replacement

determined by measuring the replacement air flow rate on the supply side.

air constant.

This requires the design of an airtight test facility that ensures the supply

4.3.3 Replacement air characteristics, such as makeup air

rate equals the exhaust rate since air leakage outside the system boundary,

location, direction, and volume, can be varied with constant

thatis,allcomponentsbetweensupplyandexhaustblowersmakingupthe

appliance and h

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.