ASTM F1348/F1348M-91(1997)

(Specification)Standard Specification for Pneumatic Rotary Descaling Machines

Standard Specification for Pneumatic Rotary Descaling Machines

SCOPE

1.1 This specification covers requirements for pneumatic rotary descaling machines for removal of paint, rust, scale, nonskid deck covering, and other coatings from steel and aluminum structures. These portable machines are intended for use in a marine environment, subject to salt air and spray during use and high humidity during storage.

1.2 The values stated in either inch-pound units or SI units are to be regarded separately as standard. The values stated in each system are not exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in nonconformance with the specification.

1.3 The following precautionary statement pertains to the test method portion only, Section 12, of this specification: This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific precautionary statements are given in 17.2.1.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: F 1348/F1348M – 91 (Reapproved 1997) An American National Standard

Standard Specification for

Pneumatic Rotary Descaling Machines

This standard is issued under the fixed designation F 1348/F1348M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope PPP-B-640 Boxes, Fiberboard, Corrugated, Triple Wall

PPP-B-676 Boxes, Setup

1.1 This specification covers requirements for pneumatic

2.4 Military Standards:

rotary descaling machines for removal of paint, rust, scale,

MIL-STD-129 Marking for Shipment and Storage

nonskid deck covering, and other coatings from steel and

MIL-STD-147 Palletized Unit Loads

aluminum structures. These portable machines are intended for

2.5 Military Specifications:

use in a marine environment, subject to salt air and spray

MIL-B-117 Bags, Sleeves and Tubing

during use and high humidity during storage.

MIL-H-775 Hose, Hose Assemblies; Rubber, Plastic, Fabric

1.2 The values stated in either inch-pound units or SI units

or Metal (Including Tubing); and Associated Hardware:

are to be regarded separately as standard. The values stated in

Packaging of

each system are not exact equivalents; therefore, each system

MIL-L-17331 Lubricating Oil, Steam Turbine, Noncorro-

shall be used independently of the other. Combining values

sive

from the two systems may result in nonconformance with the

DOD-G-24508 Grease, High Performance, Ball Roller

specification.

Bearing, Continuous Run to 300°F

1.3 The following precautionary statement pertains to the

2.6 ABS Publication:

test method portion only, Section 12, of this specification: This

ABS Rules for Building and Classing Steel Vessels

standard does not purport to address all of the safety concerns,

if any, associated with its use. It is the responsibility of the user

3. Classification

of this standard to establish appropriate safety and health

3.1 Descaling machines are available in two types and two

practices and determine the applicability of regulatory limita-

classes, as follows:

tions prior to use. Specific precautionary statements are given

3.1.1 Type 1, Hand-Held:

in 17.2.1.

3.1.1.1 Class A—Inch-pound design, and

2. Referenced Documents 3.1.1.2 Class B—SI metric design.

3.1.2 Type 2, Deck-Supported:

2.1 ASTM Standards:

3.1.2.1 Class A—Inch-pound design, and

B 209 Specification for Aluminum and Aluminum-Alloy

3.1.2.2 Class B—SI metric design.

Sheet and Plate

3.2 Hubs for use with descaling machines are available in

D 4417 Test Method for Field Measurement of Surface

four classes, as follows:

Profile of Blast Cleaned Steel

3.2.1 Class A—Nonmetallic, nonwoven, noncontaminating,

F 1166 Practice for Human Engineering Design for Marine

4 3.2.2 Class B—Peening hub for aluminum surfaces,

Systems, Equipment, and Facilities

3.2.3 Class C—Metallic hammer type for steel surfaces, and

2.2 Federal Standard:

5 3.2.4 Class D—Metallic cutter type for steel surfaces.

Fed. Std. No. 123 Marking for Shipment (Civil Agencies)

2.3 Federal Specifications:

4. Ordering Information

PPP-B-566 Boxes, Folding, Paperboard

5 4.1 Orders for material under this specification shall include

PPP-B-601 Boxes, Wood, Cleated-Plywood

5 the following:

PPP-B-621 Boxes, Wood, Nailed and Lock-Corner

5 4.1.1 Title, number, and date of this specification,

PPP-B-636 Boxes, Shipping, Fiberboard

4.1.2 Quantity,

4.1.3 Type and class required (see Section 3),

This specification is under the jurisdiction of ASTM Committee F-25 on Ships

4.1.4 Test and inspection certification requirements, if ap-

and Marine Technology and is the direct responsibility of Subcommittee F25.07 on

plicable (see Section 15),

General Requirements.

Current edition approved July 15, 1991. Published September 1991.

Annual Book of ASTM Standards, Vol 02.02.

3 6

Annual Book of ASTM Standards, Vol 06.02. Available from American Bureau of Shipping, ABS Plaza, 16855 Northchase

Annual Book of ASTM Standards, Vol 01.07. Dr., Houston, TX 77060.

5 7

Available from Standardization Documents Order Desk, Bldg 4 Section D, 700 Available from Uniform Classification Committee Agent, Tariff Publication

Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS. Officer, Room 1106, 222 S. Riverside Plaza, Chicago, IL 60606.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

F 1348/F1348M

4.1.5 Test report requirements (see Section 15), percentile male, as defined in Practice F 1166. Clearance shall

4.1.6 Technical manual requirements (see Section 16), be provided around each component, part or control so that an

4.1.7 Special marking required (see 18.3), individual with aforementioned percentile body dimensions

4.1.8 Level of preservation, packaging, packing, and mark- and physical capabilities can safely operate, maintain, remove,

ing required (see Section 17 and Supplementary Require- or replace any item using normally available tools and test

ments), and equipment. The controls required for operation and mainte-

4.1.9 Lubrication requirements of Supplementary Require- nance shall be in accordance with Practice F 1166 and shall not

ments, if applicable (see Section S3). require operator forces to exceed the strength limitations listed

therein.

5. Materials and Manufacture

6.3 Interchangeability—Component parts and assemblies

5.1 Asbestos and Cadmium:

peculiar to each type and class of machine from any one

5.1.1 Material used in the machines, or in any components,

manufacturer shall be fully interchangeable. Such interchange-

accessories, repair parts, tools, and packing and packaging

ability shall not require any alterations or modifications.

shall be free of asbestos and cadmium.

6.4 Dimensions and Weight—The machines, fully as-

5.2 Metal Parts—Metal parts shall be corrosion resistant or

sembled with guards; debris collector attachment (less hoses

treated to resist corrosion.

and collection container); and with operating handles (Type 2)

locked in its operating position; fully lubricated and ready in all

6. Mechanical Properties

aspects for operation (less air hose and filter, evaporator and

6.1 The machines shall be powered by an air motor and

lubricator attachments) shall not exceed the maximum dimen-

shall accept each of the rotary hubs (see 6.9).

sions and weight shown in Table 1.

6.1.1 Type 1—The Type 1 machine shall be a hand-held unit

6.5 Air Motor—The machines shall be driven by air motors

having a minimum of two handles, one of which shall house

that operate on the minimum air supplies as shown in Table 2.

the trigger mechanism. The trigger mechanism shall be of the

6.6 Guards—Machines of both Type 1 and Type 2 shall be

spring-loaded “dead man” type and shall immediately shut off

provided with guards that protect the operator from inadvertent

air flow to the motor when released. The arrangement of the

contact with moving parts and prevent uncontrolled scattering

handles and trigger mechanism shall permit right- or left-

of chips or scale removed by the machine. These guards shall

handed operation with equal ease. The direction of rotation of

not interfere with the performance of the machine throughout

the hubs shall tend to propel the machine in the forward

the machine’s useful life, unduly decrease any of the hub’s

direction, away from the operator. The Type 1 machine shall

physical dimensions or wear, or interfere with changing of the

remove coatings to within ⁄4 in. [6 mm] of bulkheads,

hubs. The guards/rotary hub containment shall be constructed

coamings, decks, and other immovable objects.

to accommodate a debris collection system.

6.1.2 Type 2—The Type 2 machine shall be a deck sup-

6.7 Air Connections—Air connections for both Type 1 and

ported unit with a T-shaped operating handle. The operating

Type 2 machines shall be of the quick disconnect type. The

handle shall be adjustable for height, rigid and strong enough

locations of the air connection shall be such that the hose does

to operate the machine without bending, and long enough to

not interfere with operation of the machine or the operator. The

allow any operator with the percentile body dimensions speci-

inside diameter of the connections shall be in accordance with

fied herein (see 6.2) to operate the machine while walking

Table 3.

behind it in a natural walking position. The air hose connection

6.8 Lubrication—Lubrication fittings shall be installed so

and trigger mechanism shall be located on the T-handle. The

that lubrication can be accomplished without disassembly of

trigger mechanism shall be of the spring-loaded “dead man”

the machine (see 6.2). Lubrication materials shall be high-

type and shall immediately shut off air flow to the motor when

temperature lubricating oil or high-performance grease.

released. The handle shall detach or be adjustable to and

6.9 Hubs:

lockable in the vertical position for storage. The machine shall

6.9.1 Hubs for each type and class of machine shall clean a

be provided with at least two wheels used to move the

path of width not less than that shown in Table 4. Hubs for each

machine. With the handle, air hose and each of the abrasive

type, class, and manufacture of machine shall be interchange-

hubs attached, the machine shall sit level on the deck with the

able with hubs of any other machine of the same type, class,

abrasive hubs in contact with the deck and not interfere with

and manufacture, using only the normally available tools (see

deck coating removal process. The machine shall easily propel

8.1.2) for the interchange.

itself or be propelled by the operator across the deck without

6.9.2 Hubs shall be of the following classes, classified by

overstressing the operator (see 6.2). The Type 2 machine shall

intended composition, function, and service life, as follows:

remove deck coating to within 1 ⁄2 in. [40 mm] of the

bulkheads, coamings, and other immovable objects.

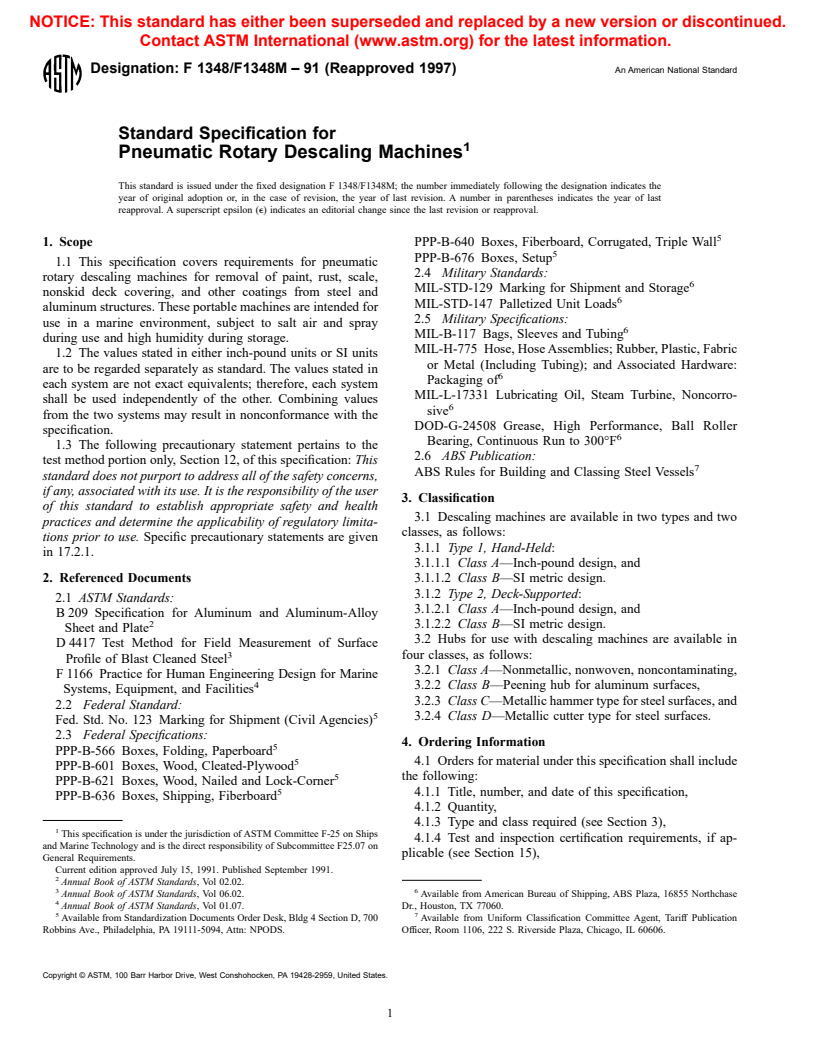

TABLE 1 Maximum Dimensions and Weights

6.2 Human Engineering—The machines shall be in accor-

dance with the human engineering criteria of Practice F 1166

Type 1 Type 1 Type 2 Type 2

Class A Class B Class A Class B

except where such requirements conflict with the requirements

of this specification. The machines shall incorporate the Length 16 in. 410 mm 36 in. 915 mm

Width 6 in. 155 mm 16 in. 410 mm

maintainability requirements of Practice F 1166 and shall

Height 12 in. 306 mm 48 in. 1220 mm

permit safe and efficient performance of operation and main-

Weight 5 lb 2.3 kg 110 lb 50 kg

tenance by the fifth percentile female to the ninety-fifth

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

F 1348/F1348M

2 2

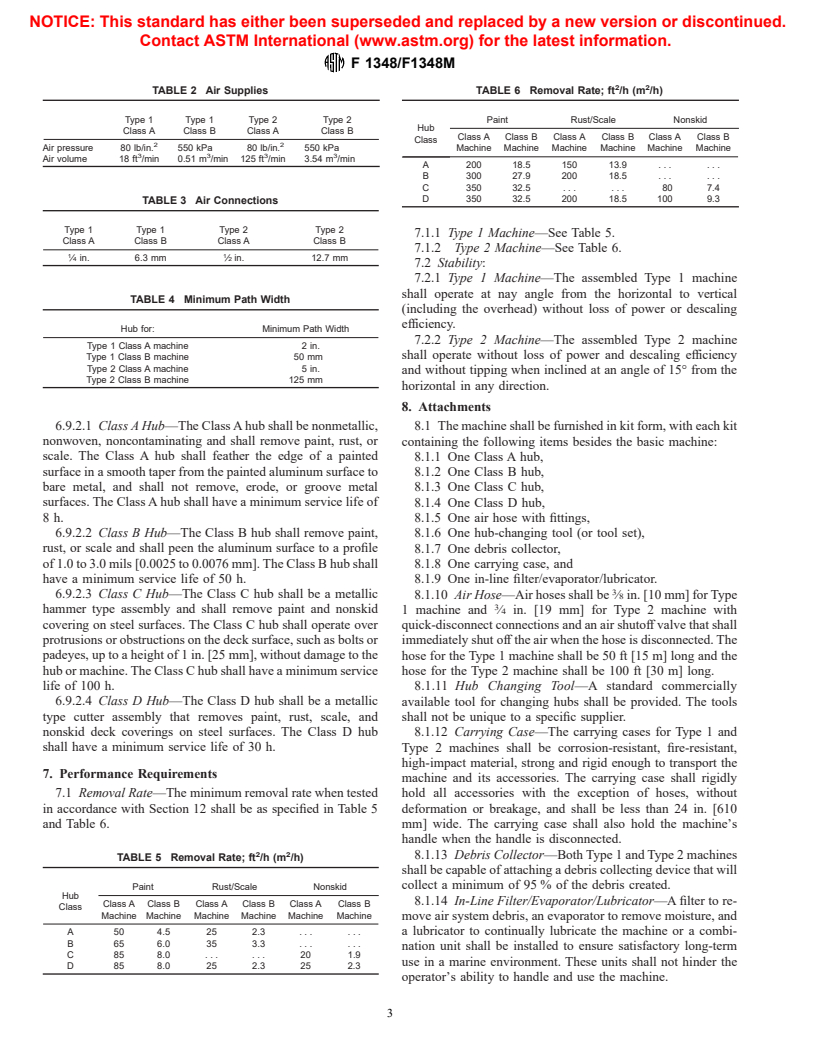

TABLE 2 Air Supplies TABLE 6 Removal Rate; ft /h (m /h)

Type 1 Type 1 Type 2 Type 2 Paint Rust/Scale Nonskid

Hub

Class A Class B Class A Class B

Class A Class B Class A Class B Class A Class B

Class

2 2

Air pressure 80 lb/in. 550 kPa 80 lb/in. 550 kPa

Machine Machine Machine Machine Machine Machine

3 3 3 3

Air volume 18 ft /min 0.51 m /min 125 ft /min 3.54 m /min

A 200 18.5 150 13.9 . . . . . .

B 300 27.9 200 18.5 . . . . . .

C 350 32.5 . . . . . . 80 7.4

D 350 32.5 200 18.5 100 9.3

TABLE 3 Air Connections

Type 1 Type 1 Type 2 Type 2

7.1.1 Type 1 Machine—See Table 5.

Class A Class B Class A Class B

7.1.2 Type 2 Machine—See Table 6.

1 1

⁄4 in. 6.3 mm ⁄2 in. 12.7 mm

7.2 Stability:

7.2.1 Type 1 Machine—The assembled Type 1 machine

shall operate at nay angle from the horizontal to vertical

TABLE 4 Minimum Path Width

(including the overhead) without loss of power or descaling

efficiency.

Hub for: Minimum Path Width

7.2.2 Type 2 Machine—The assembled Type 2 machine

Type 1 Class A machine 2 in.

shall operate without loss of power and descaling efficiency

Type 1 Class B machine 50 mm

Type 2 Class A machine 5 in.

and without tipping when inclined at an angle of 15° from the

Type 2 Class B machine 125 mm

horizontal in any direction.

8. Attachments

6.9.2.1 Class A Hub—The Class A hub shall be nonmetallic, 8.1 The machine shall be furnished in kit form, with each kit

nonwoven, noncontaminating and shall remove paint, rust, or

containing the following items besides the basic machine:

scale. The Class A hub shall feather the edge of a painted 8.1.1 One Class A hub,

surface in a smooth taper from the painted aluminum surface to

8.1.2 One Class B hub,

bare metal, and shall not remove, erode, or groove metal 8.1.3 One Class C hub,

surfaces. The Class A hub shall have a minimum service life of

8.1.4 One Class D hub,

8h. 8.1.5 One air hose with fittings,

6.9.2.2 Class B Hub—The Class B hub shall remove paint,

8.1.6 One hub-changing tool (or tool set),

rust, or scale and shall peen the aluminum surface to a profile 8.1.7 One debris collector,

of 1.0 to 3.0 mils [0.0025 to 0.0076 mm]. The Class B hub shall 8.1.8 One carrying case, and

have a minimum service life of 50 h. 8.1.9 One in-line filter/evaporator/lubricator.

6.9.2.3 Class C Hub—The Class C hub shall be a metallic 8.1.10 Air Hose—Air hoses shall be ⁄8 in. [10 mm] for Type

hammer type assembly and shall remove paint and nonskid 1 machine and ⁄4 in. [19 mm] for Type 2 machine with

covering on steel surfaces. The Class C hub shall operate over quick-disconnect connections and an air shutoff valve that shall

protrusions or obstructions on the deck surface, such as bolts or immediately shut off the air when the hose is disconnected. The

padeyes, up to a height of 1 in. [25 mm], without damage to the hose for the Type 1 machine shall be 50 ft [15 m] long and the

hub or machine. The Class C hub shall have a minimum service hose for the Type 2 machine shall be 100 ft [30 m] long.

life of 100 h. 8.1.11 Hub Changing Tool—A standard commercially

6.9.2.4 Class D Hub—The Class D hub shall be a metallic

available tool for changing hubs shall be provided. The tools

type cutter assembly that removes paint, rust, scale, and shall not be unique to a specific supplier.

nonskid deck coverings on steel surfaces. The Class D hub

8.1.12 Carrying Case—The carrying cases for Type 1 and

shall have a minimum service life of 30 h. Type 2 machines shall be corrosion-resistant, fire-resistant,

high-impact material, strong and rigid enough to transport the

7. Performance Requirements

machine and its accessories. The carrying case shall rigidly

7.1 Removal Rate—The minimum removal rate when

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.