ASTM D2570-96(2002)

(Test Method)Standard Test Method for Simulated Service Corrosion Testing of Engine Coolants

Standard Test Method for Simulated Service Corrosion Testing of Engine Coolants

SCOPE

1.1 This test method evaluates the effect of a circulating engine coolant on metal test specimens and automotive cooling system components under controlled, essentially isothermal laboratory conditions.

1.2 This test method specifies test material, cooling system components, type of coolant, and coolant flow conditions that are considered typical of current automotive use.

1.3 The values stated in either SI or inch-pound units are to be regarded as the standard. The values given in parentheses are approximate equivalents for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific precautionary statements are given in Section 6.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D2570–96 (Reapproved 2002)

Standard Test Method for

1

Simulated Service Corrosion Testing of Engine Coolants

This standard is issued under the fixed designation D2570; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope D3306 Specification for Ethylene Glycol Base Engine

2

Coolant for Automobile and Light Duty Service

1.1 This test method evaluates the effect of a circulating

D4985 Specification for Low Silicate Ethylene Glycol

enginecoolantonmetaltestspecimensandautomotivecooling

Base Engine Coolant for Heavy Duty Engines Requiring

system components under controlled, essentially isothermal

an Initial Charge of Supplemental Coolant Additive

laboratory conditions.

2

(SCA)

1.2 This test method specifies test material, cooling system

4

2.2 SAE Standard:

components, type of coolant, and coolant flow conditions that

SAE J20e Standard for Coolant System Hoses

are considered typical of current automotive use.

1.3 The values stated in either SI or inch-pound units are to

3. Summary of Test Method

be regarded as the standard. The values given in parentheses

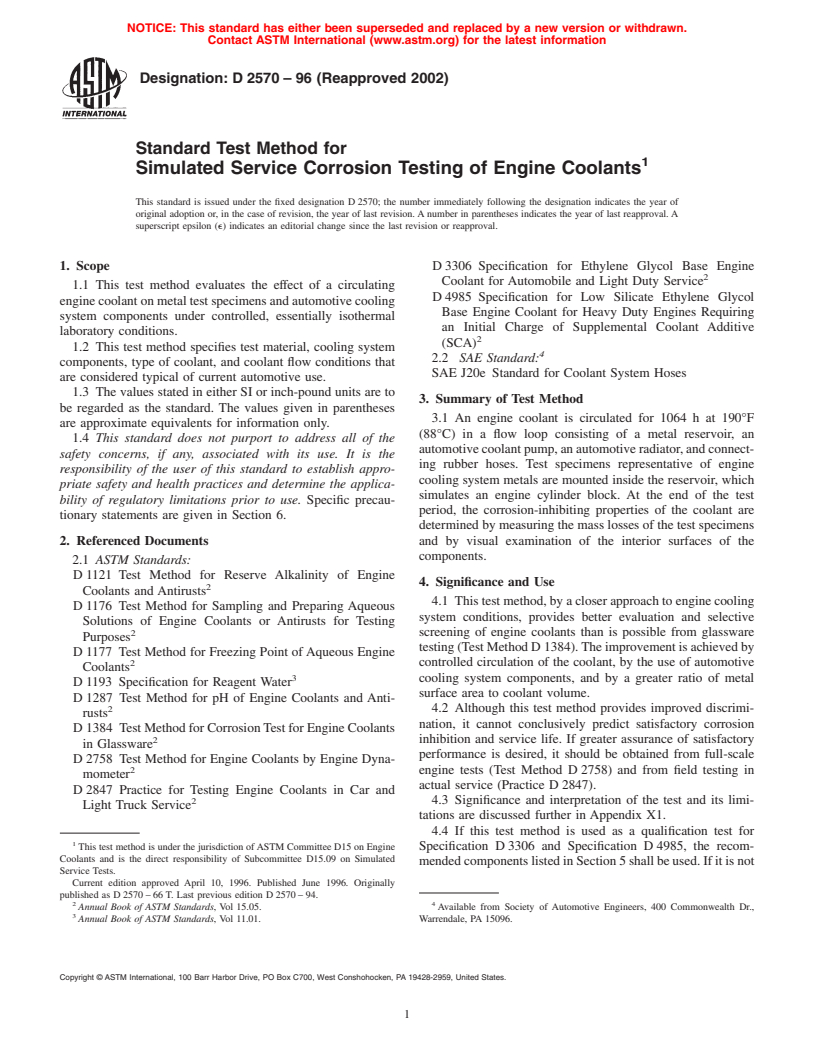

3.1 An engine coolant is circulated for 1064 h at 190°F

are approximate equivalents for information only.

(88°C) in a flow loop consisting of a metal reservoir, an

1.4 This standard does not purport to address all of the

automotivecoolantpump,anautomotiveradiator,andconnect-

safety concerns, if any, associated with its use. It is the

ing rubber hoses. Test specimens representative of engine

responsibility of the user of this standard to establish appro-

cooling system metals are mounted inside the reservoir, which

priate safety and health practices and determine the applica-

simulates an engine cylinder block. At the end of the test

bility of regulatory limitations prior to use. Specific precau-

period, the corrosion-inhibiting properties of the coolant are

tionary statements are given in Section 6.

determinedbymeasuringthemasslossesofthetestspecimens

2. Referenced Documents and by visual examination of the interior surfaces of the

components.

2.1 ASTM Standards:

D1121 Test Method for Reserve Alkalinity of Engine

4. Significance and Use

2

Coolants and Antirusts

4.1 Thistestmethod,byacloserapproachtoenginecooling

D1176 Test Method for Sampling and Preparing Aqueous

system conditions, provides better evaluation and selective

Solutions of Engine Coolants or Antirusts for Testing

2 screening of engine coolants than is possible from glassware

Purposes

testing(TestMethodD1384).Theimprovementisachievedby

D1177 Test Method for Freezing Point ofAqueous Engine

2 controlled circulation of the coolant, by the use of automotive

Coolants

3 cooling system components, and by a greater ratio of metal

D1193 Specification for Reagent Water

surface area to coolant volume.

D1287 Test Method for pH of Engine Coolants and Anti-

2 4.2 Although this test method provides improved discrimi-

rusts

nation, it cannot conclusively predict satisfactory corrosion

D1384 TestMethodforCorrosionTestforEngineCoolants

2 inhibition and service life. If greater assurance of satisfactory

in Glassware

performance is desired, it should be obtained from full-scale

D2758 Test Method for Engine Coolants by Engine Dyna-

2

engine tests (Test Method D2758) and from field testing in

mometer

actual service (Practice D2847).

D2847 Practice for Testing Engine Coolants in Car and

2

4.3 Significance and interpretation of the test and its limi-

Light Truck Service

tations are discussed further in Appendix X1.

4.4 If this test method is used as a qualification test for

1

This test method is under the jurisdiction ofASTM Committee D15 on Engine Specification D3306 and Specification D4985, the recom-

Coolants and is the direct responsibility of Subcommittee D15.09 on Simulated

mendedcomponentslistedinSection5shallbeused.Ifitisnot

Service Tests.

Current edition approved April 10, 1996. Published June 1996. Originally

published as D2570–66T. Last previous edition D2570–94.

2 4

Annual Book of ASTM Standards, Vol 15.05. Available from Society of Automotive Engineers, 400 Commonwealth Dr.,

3

Annual Book of ASTM Standards, Vol 11.01. Warrendale, PA 15096.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D2570

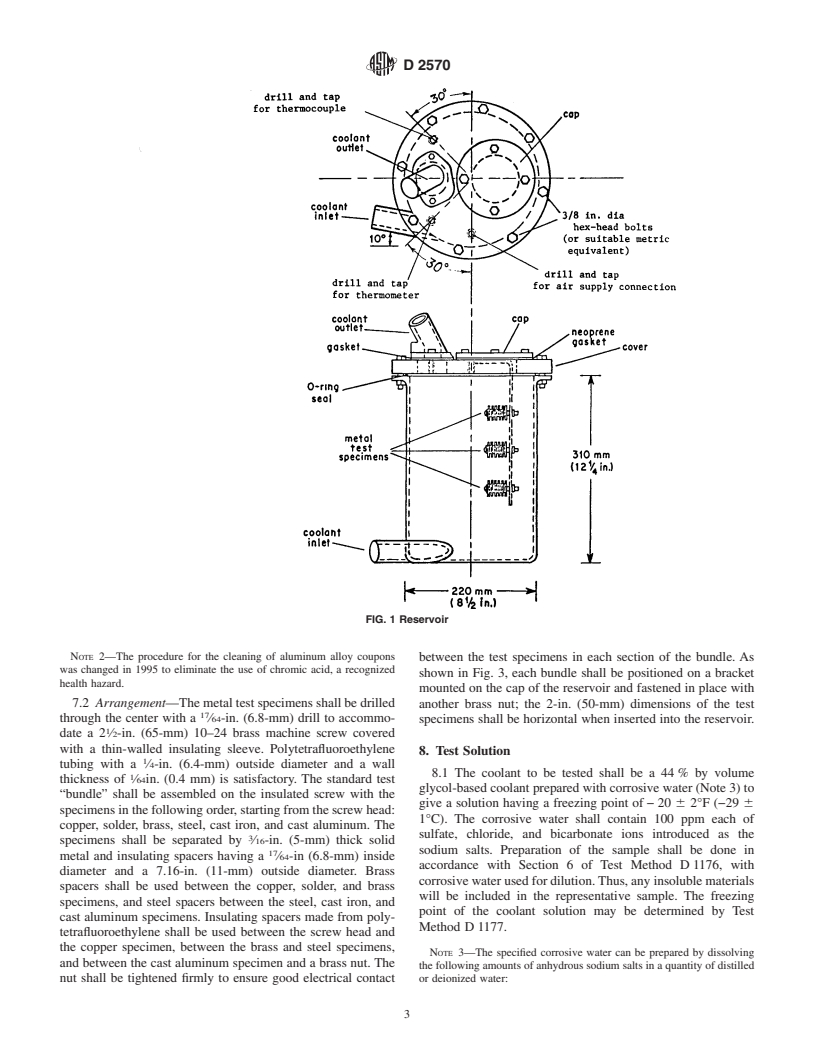

being used for such qualification purposes, then suitable indicatedinFig.2.Thepressuredropbetweenpumpdischarge

substitution components may be used, if agreed upon between and reservoir inlet, measured by the pressure gages shown in

the contracting parties. Fig. 2, must be maintained when

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.