ASTM D7076-10(2015)e1

(Test Method)Standard Test Method for Measurement of Shives in Retted Flax

Standard Test Method for Measurement of Shives in Retted Flax

SIGNIFICANCE AND USE

5.1 Few standards exist to objectively determine flax quality. Shive is the woody core of the stem and has an important effect on quality determination. Shive content will vary depending on the stage of processing and can determine in what products the fiber can be used. Spectroscopic data provide an accurate, precise and rapid determination of the amount of shive in flax fiber.

5.1.1 If there are differences of practical significance between reported test results for two or more laboratories, comparative tests should be performed by those laboratories to determine if there is a statistical bias between them, using competent statistical assistance. As a minimum, test samples that are as homogeneous as possible are drawn from the material from which the disputed test results were obtained, and are randomly assigned in equal numbers to each laboratory. These results from the two laboratories should be compared using a statistical test for unpaired data, a possibility level chosen prior to the testing series. If a bias is found, either its cause must be found and corrected, or future test results for that fiber sample type must be adjusted in consideration of the known bias.

5.2 This test method gives data on shive content of retted flax fiber which can be used as a basis for: (1) estimating the net amount of manufacturing fiber obtainable from retted flax fiber; (2) along with other measurements, predicting the quality of flax products, particularly their aesthetic properties; (3) adjusting processing machinery for maximum efficiency in cleaning; and (4) relating shive content to end-product quality and processing efficiency.

SCOPE

1.1 This test method covers the measurement of shives in retted flax.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation: D7076 − 10 (Reapproved 2015)

Standard Test Method for

Measurement of Shives in Retted Flax

This standard is issued under the fixed designation D7076; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

ε NOTE—The terminology section was added editorially in April 2015.

1. Scope effect on quality determination. Shive content will vary de-

pending on the stage of processing and can determine in what

1.1 This test method covers the measurement of shives in

products the fiber can be used. Spectroscopic data provide an

retted flax.

accurate, precise and rapid determination of the amount of

1.2 The values stated in SI units are to be regarded as

shive in flax fiber.

standard. No other units of measurement are included in this

5.1.1 If there are differences of practical significance be-

standard.

tween reported test results for two or more laboratories,

1.3 This standard does not purport to address all of the

comparative tests should be performed by those laboratories to

safety concerns, if any, associated with its use. It is the

determine if there is a statistical bias between them, using

responsibility of the user of this standard to establish appro- competent statistical assistance. As a minimum, test samples

priate safety and health practices and determine the applica-

that are as homogeneous as possible are drawn from the

bility of regulatory limitations prior to use. material from which the disputed test results were obtained,

and are randomly assigned in equal numbers to each labora-

2. Referenced Documents

tory. These results from the two laboratories should be com-

2.1 ASTM Standards:

pared using a statistical test for unpaired data, a possibility

D123Terminology Relating to Textiles

levelchosenpriortothetestingseries.Ifabiasisfound,either

D6798Terminology Relating to Flax and Linen

its cause must be found and corrected, or future test results for

that fiber sample type must be adjusted in consideration of the

3. Summary of Test Method

known bias.

3.1 The sample to be evaluated is to be ground and the

5.2 This test method gives data on shive content of retted

resulting mixture placed in the appropriate NIR cell and the

flax fiber which can be used as a basis for: (1) estimating the

spectra taken.

net amount of manufacturing fiber obtainable from retted flax

3.2 The data will then be compared to a reference file and

fiber;(2)alongwithothermeasurements,predictingthequality

the value of shive reported as weight percent.

of flax products, particularly their aesthetic properties; (3)

adjusting processing machinery for maximum efficiency in

4. Terminology

cleaning; and (4) relating shive content to end-product quality

4.1 For all terminology related to Flax, see Terminology

and processing efficiency.

D6798.

4.2 For definitions of all other textile terminology, see 6. Apparatus

Terminology D123.

6.1 Grinder—SPEX 8000 mixer mill or equivalent instru-

ment for the initial grinding.

5. Significance and Use

6.2 NIRSystems Model 6500 Monochrometer or equivalent

5.1 Few standards exist to objectively determine flax qual-

instrument—Reference spectra scanned over the range 400 to

ity. Shive is the woody core of the stem and has an important

2498 nm at 2 nm intervals and stored as log (1/R), where R is

reflectance. Standard 50 mm diameter black minicup with a

ThistestmethodisunderthejurisdictionofASTMCommitteeD13onTextiles

and is the direct responsibility of Subcommittee D13.17 on Flax and Linen.

quartz window is used and equipped with a 15 mm i.d. spacer

Current edition approved Feb. 1, 2015. Published April 2015. Originally

ring if sample size is limited.

approved in 2005. Last previous edition approved in 2010 as D7076–10. DOI:

10.1520/D7076-10R15E01.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or 7. Hazards

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

7.1 Whenhandlingorgrindinganyflaxmaterialabreathing

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. mask should be worn.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

D7076 − 10 (2015)

8. Sampling, Test Specimens, and Test Units blended shive/fiber samples of known composition samples of

known weight. A calibration equation will be prepared from

8.1 For acceptable testing, take a lot sample from shipping

these samples through the use of Partial Least Squares (PLS1),

container as directed in an applicable specification, or as

Multiple Linear Regression (MLR) or another suitable statis-

agreed upon between the purchaser and supplier.

tical procedure. These are standard chemometric algorithms

8.2 Take measurements at a minimum of five sites within a

whichwillbepartoftheinstrumentsoftwarepackageobtained

sample, and three measurements at each site. Means of the

from the manufacturer.

three replicates constitute the site reading. For each specimen,

10.2 To verify or to account for a difference in particle size

report means of the five sites.

producedbyasecondgrinder,asecondsetofstandardsamples

8.3 Sample Handling and Preparation:

will be run which has been ground using a grinder to provide

8.3.1 Eachspecimentobeanalyzedshouldbeatleast2gin

a uniform particle size. These data will be plotted and a

weight. Care should be taken not to loose any free shive.

slope/bias correction to the spectral data obtained to account

8.3.2 Each 2-g aliquot is to be ground for 3 min in a SPEX

for differences in particle size produced by the grinder.

8000 mixer mill. If the grinder cannot hold all 2 g, the aliquots

10.3 Alternatively the calibration file from the USDA in-

are to be thoroughly mixed after separate grinding.

strument can be transferred to the host instrument. This is

accomplished by using a set of standardization samples ob-

9. Preparation of Apparatus

tained from the manufacturer (Foss in this case) and scan

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation: D7076 − 10 D7076 − 10 (Reapproved 2015)

Standard Test Method for

Measurement of Shives in Retted Flax

This standard is issued under the fixed designation D7076; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

ε NOTE—The terminology section was added editorially in April 2015.

1. Scope

1.1 This test method covers the measurement of shives in retted flax.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

D123 Terminology Relating to Textiles

D6798 Terminology Relating to Flax and Linen

3. Summary of Test Method

3.1 The sample to be evaluated is to be ground and the resulting mixture placed in the appropriate NIR cell and the spectra

taken.

3.2 The data will then be compared to a reference file and the value of shive reported as weight percent.

4. Terminology

4.1 For all terminology related to Flax, see Terminology D6798.

4.2 For definitions of all other textile terminology, see Terminology D123.

5. Significance and Use

5.1 Few standards exist to objectively determine flax quality. Shive is the woody core of the stem and has an important effect

on quality determination. Shive content will vary depending on the stage of processing and can determine in what products the

fiber can be used. Spectroscopic data provide an accurate, precise and rapid determination of the amount of shive in flax fiber.

5.1.1 If there are differences of practical significance between reported test results for two or more laboratories, comparative

tests should be performed by those laboratories to determine if there is a statistical bias between them, using competent statistical

assistance. As a minimum, test samples that are as homogeneous as possible are drawn from the material from which the disputed

test results were obtained, and are randomly assigned in equal numbers to each laboratory. These results from the two laboratories

should be compared using a statistical test for unpaired data, a possibility level chosen prior to the testing series. If a bias is found,

either its cause must be found and corrected, or future test results for that fiber sample type must be adjusted in consideration of

the known bias.

5.2 This test method gives data on shive content of retted flax fiber which can be used as a basis for: (1) estimating the net

amount of manufacturing fiber obtainable from retted flax fiber; (2) along with other measurements, predicting the quality of flax

products, particularly their aesthetic properties; (3) adjusting processing machinery for maximum efficiency in cleaning; and (4)

relating shive content to end-product quality and processing efficiency.

This test method is under the jurisdiction of ASTM Committee D13 on Textiles and is the direct responsibility of Subcommittee D13.17 on Flax and Linen.

Current edition approved June 1, 2010Feb. 1, 2015. Published July 2010April 2015. Originally approved in 2005. Last previous edition approved in 20092010 as

D7076–09E1.D7076–10. DOI: 10.1520/D7076-10.10.1520/D7076-10R15E01.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

D7076 − 10 (2015)

6. Apparatus

6.1 Grinder—SPEX 8000 mixer mill or equivalent instrument for the initial grinding.

6.2 NIRSystems Model 6500 Monochrometer or equivalent instrument—Reference spectra scanned over the range 400 to 2498

nm at 2 nm intervals and stored as log (1/R), where R is reflectance. Standard 50 mm diameter black minicup with a quartz window

is used and equipped with a 15 mm i.d. spacer ring if sample size is limited.

7. Hazards

7.1 When handling or grinding any flax material a breathing mask should be worn.

8. Sampling, Test Specimens, and Test Units

8.1 For acceptable testing, take a lot sample from shipping container as directed in an applicable specification, or as agreed upon

between the purchaser and supplier.

8.2 Take measurements at a minimum of five sites within a sample, and three measurements at each site. Means of the three

replicates constitute the site reading. For each specimen, report means of the five sites.

8.3 Sample Handling and Preparation:

8.3.1 Each specimen to be analyzed should be at least 2 g in weight. Care should be taken not to loose any free shive.

8.3.2 Each 2-g aliquot is to be ground for 3 min in a SPEX 8000 mixer mill. If the grinder cannot hold all 2 g, the aliquots are

to be thoroughly mixed after separate grinding.

9. Preparation of Apparatus

9.1 Turn on 6500 and computer and allow enough time for warm up that 11.112.1 is satisfied.

9.2 Start software.

9.3 Begin scan program running diagnostics checking of signal to noise ratio and wave length accuracy.

9.4 Enter routine scan mode.

10. Calibration and Standardization

10.1 The NIR instrument should be standardized with a calibration set which contains samples with a shive content ranging

from 0 to 100 %. This set can be prepared by hand separating fiber and shive, grinding each fraction and preparing blended

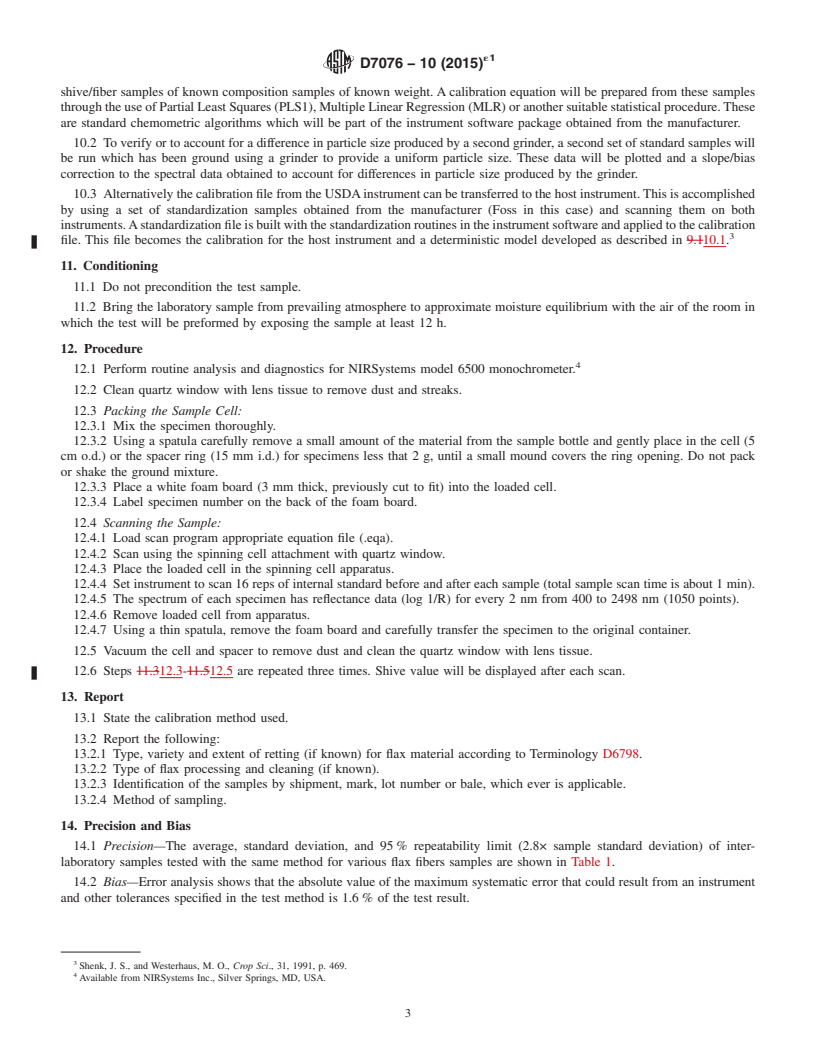

TABLE 1 Summary of Precision and Bias Analysis for

Measurement of Shive Content (%) in Retted Flax

Reproducibility

Repeatability

Repeatability Reproducibility

Standard

Sample Standard

Average Limit Limit

Deviation Deviation x¯

r R

s

r s

R

1 0.15 0.5618 1.3999 1.5731 3.9198

2 10.88 0.7949 1.4153 2.2257 3.9630

3 20.14 0.6897

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.