ASTM E2218-02

(Test Method)Standard Test Method for Determining Forming Limit Curves

Standard Test Method for Determining Forming Limit Curves

SCOPE

1.1 This method gives the procedure for constructing a forming limit curve (FLC) for a metallic sheet material by using a hemispherical deformation punch test and a uniaxial tension test to quantitatively simulate biaxial stretch and deep drawing processes.

1.2 FLCs are useful in evaluating press performance by metal fabrication strain analysis.

1.3 The method applies to metallic sheet from 0.5 mm (0.020 in.) to 3.3 mm (0.130 in.).

1.4 The values stated in SI units are to be regarded as the standard. The inch-pound equivalents are approximate.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:E2218–02

Standard Test Method for

Determining Forming Limit Curves

This standard is issued under the fixed designation E2218; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

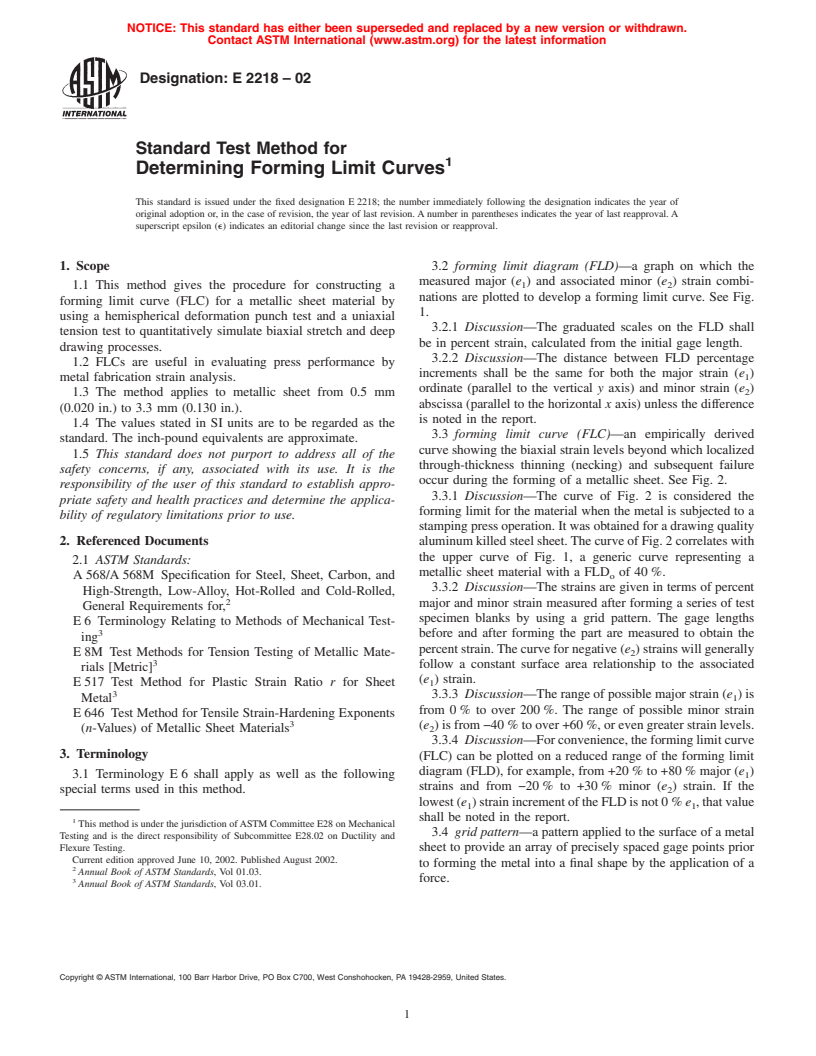

1. Scope 3.2 forming limit diagram (FLD)—a graph on which the

measured major (e ) and associated minor (e ) strain combi-

1.1 This method gives the procedure for constructing a 1 2

nations are plotted to develop a forming limit curve. See Fig.

forming limit curve (FLC) for a metallic sheet material by

1.

using a hemispherical deformation punch test and a uniaxial

3.2.1 Discussion—The graduated scales on the FLD shall

tension test to quantitatively simulate biaxial stretch and deep

be in percent strain, calculated from the initial gage length.

drawing processes.

3.2.2 Discussion—The distance between FLD percentage

1.2 FLCs are useful in evaluating press performance by

increments shall be the same for both the major strain (e )

metal fabrication strain analysis. 1

ordinate (parallel to the vertical y axis) and minor strain (e )

1.3 The method applies to metallic sheet from 0.5 mm

abscissa (parallel to the horizontal x axis) unless the difference

(0.020 in.) to 3.3 mm (0.130 in.).

is noted in the report.

1.4 The values stated in SI units are to be regarded as the

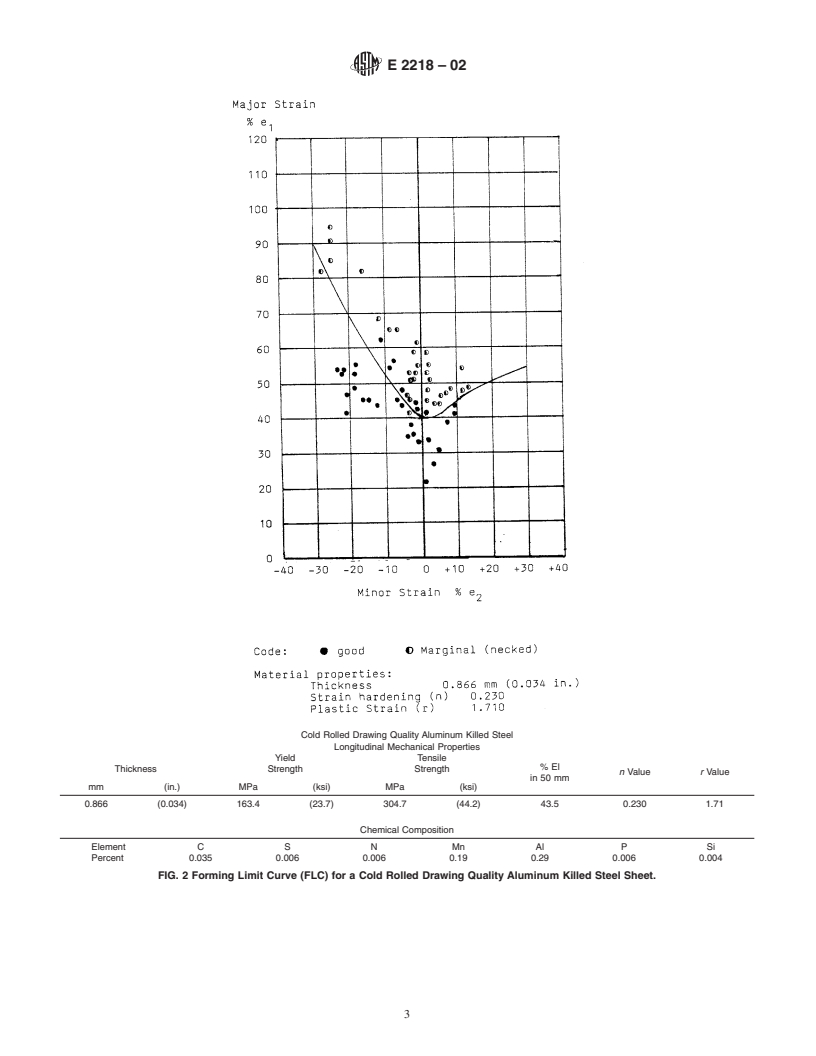

3.3 forming limit curve (FLC)—an empirically derived

standard. The inch-pound equivalents are approximate.

curve showing the biaxial strain levels beyond which localized

1.5 This standard does not purport to address all of the

through-thickness thinning (necking) and subsequent failure

safety concerns, if any, associated with its use. It is the

occur during the forming of a metallic sheet. See Fig. 2.

responsibility of the user of this standard to establish appro-

3.3.1 Discussion—The curve of Fig. 2 is considered the

priate safety and health practices and determine the applica-

forming limit for the material when the metal is subjected to a

bility of regulatory limitations prior to use.

stampingpressoperation.Itwasobtainedforadrawingquality

2. Referenced Documents

aluminumkilledsteelsheet.ThecurveofFig.2correlateswith

the upper curve of Fig. 1, a generic curve representing a

2.1 ASTM Standards:

metallic sheet material with a FLD of 40%.

A568/A568M Specification for Steel, Sheet, Carbon, and o

3.3.2 Discussion—The strains are given in terms of percent

High-Strength, Low-Alloy, Hot-Rolled and Cold-Rolled,

major and minor strain measured after forming a series of test

General Requirements for,

specimen blanks by using a grid pattern. The gage lengths

E6 Terminology Relating to Methods of Mechanical Test-

before and after forming the part are measured to obtain the

ing

percentstrain.Thecurvefornegative(e )strainswillgenerally

E8M Test Methods for Tension Testing of Metallic Mate- 2

follow a constant surface area relationship to the associated

rials [Metric]

(e ) strain.

E517 Test Method for Plastic Strain Ratio r for Sheet 1

3.3.3 Discussion—Therangeofpossiblemajorstrain(e)is

Metal 1

from 0% to over 200%. The range of possible minor strain

E646 Test Method for Tensile Strain-Hardening Exponents

(e )isfrom−40%toover+60%,orevengreaterstrainlevels.

(n-Values) of Metallic Sheet Materials 2

3.3.4 Discussion—Forconvenience,theforminglimitcurve

3. Terminology

(FLC) can be plotted on a reduced range of the forming limit

diagram (FLD), for example, from +20% to +80% major (e )

3.1 Terminology E6 shall apply as well as the following 1

strains and from −20% to +30% minor (e ) strain. If the

special terms used in this method. 2

lowest(e )strainincrementoftheFLDisnot0%e ,thatvalue

1 1

shall be noted in the report.

This method is under the jurisdiction ofASTM Committee E28 on Mechanical

3.4 grid pattern—a pattern applied to the surface of a metal

Testing and is the direct responsibility of Subcommittee E28.02 on Ductility and

Flexure Testing. sheet to provide an array of precisely spaced gage points prior

Current edition approved June 10, 2002. Published August 2002.

to forming the metal into a final shape by the application of a

Annual Book of ASTM Standards, Vol 01.03.

force.

Annual Book of ASTM Standards, Vol 03.01.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E2218–02

NOTE—The upper curve is representative of the forming limit. Strains below the lower curve do not occur during forming metallic sheet products in

the most stamping press operations. Curves to the left of % e = 0 are for constant area of the sheet surface.

FIG. 1 Forming Limit Diagram

3.4.1 Discussion—Anarrayofsquares,orcircles,orboth,is or diameter of a circle pattern.After the part has been formed,

printed on the surface of the specimen. Suggested patterns are

critical areas are measured for the resulting gage length

shown in Fig. 3.The pattern shall adhere to the metal so that it

changes in the long dimension from (L)to(L) of the pattern,

o f

will not be moved on the surface or rubbed off by the forming

and in the width dimension (W)to(W) at 90° to the long

o f

operation. Refer to Specification A568/A568M, Appendix

dimension as shown in Fig. 4. The major strain (e ) and

X4–Procedures for Determining the Extent of Plastic Defor-

associated minor strain (e ) at 90° to (e ) are calculated from

2 1

mation Encountered in Forming or Drawing, for procedures to

these gage length changes. The strains can be either engineer-

applyphotographicandelectrochemicallyprintedgridpatterns

ing strain based on the original gage length, or true strain.

and a review of strain analysis.

3.4.2 Discussion—Suggested dimensions for the gage

lengthsare2.5mm(0.100in.)forthesidesofasquarepattern,

E2218–02

Cold Rolled Drawing Quality Aluminum Killed Steel

Longitudinal Mechanical Properties

Yield Tensile

%El

Thickness Strength Strength

n Value r Value

in 50 mm

mm (in.) MPa (ksi) MPa (ksi)

0.866 (0.034) 163.4 (23.7) 304.7 (44.2) 43.5 0.230 1.71

Chemical Composition

Element C S N Mn Al P Si

Percent 0.035 0.006 0.006 0.19 0.29 0.006 0.004

FIG. 2 Forming Limit Curve (FLC) for a Cold Rolled Drawing Quality Aluminum Killed Steel Sheet.

E2218–02

NOTE—The basic pattern is reapeated over the area of the part to be studied on a flat specimen blank.

FIG. 3 Examples of patterns for Gage Length measurement units used in Determining Forming Limit Curves (FLC)

FIG. 4 Possible Changes in Shape of the Grid Pattern Caused by Forming Operations on Metallic Sheet Products

3.5.1 Discussion—Deep drawing occurs in the walls of a

3.4.3 Discussion—Larger patterns, of 6 mm (0.25 in.) up to drawn cylinder or the corner walls of a deep drawn part when

125 mm (5 in.), can be used to measure low strain levels on the flange clamping force is sufficient to restrain metal move-

formed parts, but are not used in determining the FLC. ment and wrinkling, while permitting the punch to push the

3.4.4 Discussion—Circles are suggested for deformations center area of the blank into the cavity of the die. Strain

where the major strain (e ) does not align with the lines of a conditions that can cause wrinkling or thickening are shown in

square pattern. This condition is less likely in the process of Fig. 1.

determining the FLC than in production stamping evaluations. 3.5.2 Discussion—In forming a square pan shape, metal

These circles commonly have diameters of 2.5 mm (0.100 in.) from an area of the flange under a reduced clamping force is

and can be spaced up to 2.5 mm (0.100 in.) apart. They are pulled into the die to form the side wall of the part.

measured across the diameter of the circle when the line width 3.6 major strain—the largest strain (e ) developed at a

is minimal. For wider lines, the enclosed area of the etched given location in the sheet specimen surface.

circle should be consistent from one circle to another and the 3.6.1 Discussion—The major strain (e ) is measured along

measurement made across the inside diameter. This is more thestretchedlineofasquarepattern,oralongthemajoraxisof

critical with wider line width patterns and at high e strains theellipseresultingfromdeformationofacirculargridpattern.

when the line spreads as the metal surface stretches. 3.7 minor strain—the strain (e ) in the sheet surface in a

3.4.5 Discussion—An alternate to circles is a pattern of direction perpendicular to the major strain.

solid dots of precise diameter, which are measured across the 3.7.1 Discussion—The minor strain (e ) is measured at 90°

diameter of the dot. to the major strain, along the shorter dimension of the final

3.5 deep drawing—a metal sheet forming operation in rectangular shape of a part formed using a square pattern, or

which strains on the sheet surface are positive in the direction the shorter axis of the ellipse resulting from deformation of a

of the punch travel (e ) and negative at 90° to that direction. circular grid pattern. f a square pattern becomes skewed into a

See Fig. 4. parallelogram shape, it shall not be used to measure strain.

E2218–02

3.8 plane strain—the condition in metal sheet forming that 4.1.3.3 Kerosene is not a good lubricant, as it cleans the

maintains a near zero (0 to +5%) minor strain (e ) while the surfaces under pressure and the metal sheet will not slide over

major strain (e ) is positive (in tension). It is sometimes the punch.

referred to as FLD . See Fig. 1 and Fig. 4. 4.1.4 Securely clamping the flanges of a blank in the

o

3.8.1 Discussion—Plane strain is the most severe deforma- serrated, or lock bead, blank-holder dies of the hemispherical

tion mode and causes a low point in the forming limit curve punch test.

(FLC). For convenience, many FLCs are shown with the low 4.1.4.1 For a tension test specimen, the standard procedure

pointat0%(e ),however,suchanabruptreversalof(e )strain for testing sheet type specimens, as shown in Fig. 1 of E8M,

2 1

does not occur. See Fig. 2 and Figs. X2.1-X2.3. shall be followed.

3.9 biaxial stretching—a mode of metal sheet forming in 4.1.5 Stretching the central area of the blank biaxially over

which positive strains are observed in all directions at a given the nose of the hemispherical punch, or pulling in the tension

location. See Fig. 4. test, without interrupting the force.

3.10 limiting dome height (LDH)—an evaluative test for 4.1.5.1 Negative (e ) strains can be obtained using sheared

metalsheetdeformationcapabilityemployinga200mm(4in.) narrow strips stretched over the punch of the LDH tester.

hemispherical punch and a circumferential clamping force 4.1.6 Stopping the punch advance or the force when a

sufficient to prevent metal from the surrounding flange being localized through thickness neck (localized necking) is ob-

pulled into the die cavity. served, if possible, or as soon as the specimen fractures.

3.10.1 Discussion—The LDH test was designed to give a 4.1.7 Removing the specimen from the testing machine

repeatable measure of punch movement among specimens of a grips and then proceeding with another, different width, blank

specific metal sheet sample, thus the only measured value in the test series of the same material.

would be the punch height at incipient fracture. Problems with 4.1.8 Measuring and recording the (e ) and the (e ) strains

1 2

maintaining a secure clamp result in variation of the measured of the grid pattern on the surface area near the neck of all the

LDH value.Amodification of the LDH test using a strip in the test specimens for the series.

range of 200 mm (4 in.) wide was found to give (e ) values 4.1.8.1 These measurements can include good (no localized

near 0% (e ), when the surface strains were measured using a necking), marginal (localized necking), and fracture areas.

grid pattern. On this basis, a test was developed to use a 4.1.8.2 If other than good (no localized necking) locations

sheared strip of metal sheet 200 mm (4 in.) wide and are included, each measured point shall be visually evaluated

sufficientlylongtobesecurelyclampedintheLDHtestfixture. and noted as illustrated in Fig. 2.

The height at incipient fracture was to correlate with FLD . 4.1.9 Plotting the measured strain combinations on a FLD.

o

The test was not sufficiently repeatable to be employed for See Fig. 2.

evaluation of metal sheet samples. The equipment is used to 4.1.10 Establishing the forming limit curve (FLC) be con-

stretchspecimens,withgridpatterns,thathavebeenshearedto necting the uppermost good (no localized necking) (e ) strains

various widths and is one method to obtain a range of (e ) and over the associated (e ) strain range used in the study.

2 2

associated (e ) values for plotting a FLC on a FLD. 4.1.10.1 For practical purposes, the specimens that have

been strained to a localized neck-down, or through thickness

4. Summary of Test Method

fracture, condition can be measured at a location on the

4.1 The procedure for determining a forming limit curve

oppositesideofthehemisphericalbulgefromthefracture,ina

(FLC) involves the following:

good (no localized necking) location, to obtain values to

4.1.1 Using a hemispherical punch testing machine (LDH

establish the FLC.

tester).Sometimescalledabulgetester.TheLDHtestemploys

4.1.10.2 Another acceptable procedure is to measure the

a 100 mm (4 in.) diameter machined surface punch.

grid near the necked, or fracture, location and identify these

4.1.1.1 A universal testing machine for tension load appli-

data points in determining the forming limit curve. This

cation and a sub-press for against the metal sheet surface

procedure was used in locating the FLC of Fig. 2.

loading with a ball punch of 75 mm (3 in.), 100 mm (4 in.), or

4.1.10.3 Establishing the FLC depends on judgement. Note

larger diameter can be used in place of the LDH test equip-

thatinFig.2thereareseveralgood(nolocalizednecking)data

ment.

points above the FLC and two marginal points below the FLC.

4.1.2 Preparing a series of grid pattern blanks with different

4.1.10.4 The FLC curve shall not include an area where

widths and a common length suitable for being securely

there is a preponderance of marginal data points at an (e )

gripped in the test apparatus.

strain level below the measured good (no localized necking)

4.1.2.1 All specimens for a series shall have their long

data points.

dimension in the same orientation, relative to the original

5. Significance and Use

process rolling direction of the sample and that direction noted

i

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.