ASTM F2405-04(2011)

(Test Method)Standard Test Method for Trace Metallic Impurities in High Purity Copper by High-Mass-Resolution Glow Discharge Mass Spectrometer (Withdrawn 2020)

Standard Test Method for Trace Metallic Impurities in High Purity Copper by High-Mass-Resolution Glow Discharge Mass Spectrometer (Withdrawn 2020)

SIGNIFICANCE AND USE

This test method is intended for application in the semiconductor industry for evaluating the purity of materials (for example, sputtering targets, evaporation sources) used in thin film metallization processes. This test method may be useful in additional applications, not envisioned by the responsible technical committee, as agreed upon between the parties concerned.

This test method is intended for use by GDMS analysts in various laboratories for unifying the protocol and parameters for determining trace impurities in copper. The objective is to improve laboratory-to-laboratory agreement of analysis data. This test method is also directed to the users of GDMS analyses as an aid to understanding the determination method, and the significance and reliability of reported GDMS data.

For most metallic species, the detection limit for routine analysis is on the order of 0.01 wt. ppm. With special precautions, detection limits to sub-ppb levels are possible.

This test method may be used as a referee method for producers and users of electronic-grade copper materials.

SCOPE

1.1 This test method covers the concentrations of trace metallic impurities in high purity (99.95 wt. % pure, or purer, with respect to metallic trace impurities) electronic grade copper.

1.2 This test method pertains to analysis by magnetic-sector glow discharge mass spectrometer (GDMS).

1.3 This test method does not include all the information needed to complete GDMS analyses. Sophisticated computer-controlled laboratory equipment, skillfully used by an experienced operator, is required to achieve the required sensitivity. This test method does cover the particular factors (for example, specimen preparation, setting of relative sensitivity factors, determination of detection limits, and the like) known by the responsible technical committee to effect the reliability of high purity copper analyses.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

WITHDRAWN RATIONALE

This test method covers the concentration of trace metallic impurities in high purity (99.05 wt. % pure, or purer, with respect to metallic trace impurities) electronic grade copper.

Formerly under the jurisdiction of Committee F01 on Electronics, this test method was withdrawn in January 2020 in accordance with section 10.6.3 of the Regulations Governing ASTM Technical Committees, which requires that standards shall be updated by the end of the eighth year since the last approval date.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F2405 − 04 (Reapproved 2011)

Standard Test Method for

Trace Metallic Impurities in High Purity Copper by High-

Mass-Resolution Glow Discharge Mass Spectrometer

This standard is issued under the fixed designation F2405; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Methods for Analysis and Testing of Industrial and Spe-

cialty Chemicals (Withdrawn 2009)

1.1 This test method covers the concentrations of trace

E691 Practice for Conducting an Interlaboratory Study to

metallic impurities in high purity (99.95 wt. % pure, or purer,

Determine the Precision of a Test Method

with respect to metallic trace impurities) electronic grade

E876 Practice for Use of Statistics in the Evaluation of

copper.

Spectrometric Data (Withdrawn 2003)

1.2 This test method pertains to analysis by magnetic-sector

F1593 Test Method for Trace Metallic Impurities in Elec-

glow discharge mass spectrometer (GDMS).

tronic Grade Aluminum by High Mass-Resolution Glow-

1.3 This test method does not include all the information Discharge Mass Spectrometer

needed to complete GDMS analyses. Sophisticated computer-

3. Terminology

controlled laboratory equipment, skillfully used by an experi-

enced operator, is required to achieve the required sensitivity.

3.1 Terminology in this test method is consistent with

Thistestmethoddoescovertheparticularfactors(forexample,

Terminology E135. Required terminology specific to this test

specimen preparation, setting of relative sensitivity factors,

method, not covered in Terminology E135, is indicated in 3.2.

determination of detection limits, and the like) known by the

3.2 Definitions:

responsible technical committee to effect the reliability of high

3.2.1 campaign—a test procedure to determine the accuracy

purity copper analyses.

of the instrument, which was normally performed at the

1.4 This standard does not purport to address all of the

beginning of the day or after the instrument modification, or

safety concerns, if any, associated with its use. It is the

both.

responsibility of the user of this standard to establish appro-

3.2.2 reference sample—material accepted as suitable for

priate safety and health practices and determine the applica-

use as a calibration/sensitivity reference standard by all parties

bility of regulatory limitations prior to use.

concerned with the analyses.

3.2.3 specimen—a suitably sized piece cut from a reference

2. Referenced Documents

or test sample, prepared for installation in the GDMS ion

2.1 ASTM Standards:

source, and analyzed.

E135 Terminology Relating to Analytical Chemistry for

3.2.4 test sample—material(copper)tobeanalyzedfortrace

Metals, Ores, and Related Materials

metallic impurities by this GDMS method.

E173 Practice for Conducting Interlaboratory Studies of

3.2.4.1 Discussion—Generally the test sample is extracted

Methods for Chemical Analysis of Metals (Withdrawn

from a larger batch (lot, casting) of product and is intended to

1998)

be representative of the batch.

E180 Practice for Determining the Precision of ASTM

4. Summary of Test Method

This test method is under the jurisdiction of ASTM Committee F01 on

4.1 A specimen is mounted in a plasma discharge cell.

Electronics and is the direct responsibility of Subcommittee F01.17 on Sputter

Atoms subsequently sputtered from the specimen surface are

Metallization.

ionized, and then focused as an ion beam through a double-

Current edition approved June 1, 2011. Published June 2011. Originally

approved in 2004. Last previous edition approved in 2004 as F2405–04. DOI:

focusing magnetic-sector mass separation apparatus. The mass

10.1520/F2405-04R11.

spectrum (the ion current) is collected as magnetic field or

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

acceleration voltage, or both, and is scanned.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

4.2 The ion current of an isotope at mass M is the total

i

the ASTM website.

measured current, less contributions from all other interfering

The last approved version of this historical standard is referenced on

www.astm.org. sources. Portions of the measured current may originate from

Copyright ©ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA19428-2959. United States

F2405 − 04 (2011)

the ion detector alone (detector noise). Portions may be due to 5.3 For most metallic species, the detection limit for routine

incompletelymassresolvedionsofanisotopeormoleculewith analysis is on the order of 0.01 wt. ppm. With special

mass close to, but not identical with M. In all such instances precautions, detection limits to sub-ppb levels are possible.

i

the interfering contributions must be estimated and subtracted

5.4 This test method may be used as a referee method for

from the measured signal.

producers and users of electronic-grade copper materials.

4.2.1 If the source of interfering contributions to the mea-

sured ion current at M cannot be determined unambiguously,

i 6. Apparatus

the measured current less the interfering contributions from

6.1 Glow Discharge Mass Spectrometer, with mass resolu-

identified sources constitutes an upper bound of the detection

tion greater than 3500, and associated equipment and supplies.

limit for the current due to the isotope.

6.2 Machining Apparatus, capable of preparing specimens

4.3 The composition of the test specimen is calculated from

andreferencesamplesinthedesiredgeometryandwithsmooth

the mass spectrum by applying a relative sensitivity factor

surfaces.

(RSF(X/M)) for each contaminant element, X, compared to the

matrix element, M . RSF’s are determined in a separate

7. Reagents and Materials

analysis of a reference material performed under the same

7.1 Reagents—Reagent and high purity grade reagents as

analytical conditions, source configuration, and operating pro-

required (MeOH, HNO , and HF).

tocol as for the test specimen. 3

7.2 Demineralized Water.

4.4 The relative concentrations of elements X and Y are

calculated from the relative isotopic ion currentsI(X) and I

7.3 Tantalum Reference Sample.

i

(Y) in the mass spectrum, adjusted for the appropriate isotopic

j

7.4 Copper Reference Sample:

abundance factors (A (X),A(Y) and RSF’s.I(X) andI(Y)

i j i j

7.4.1 To the extent available, copper reference materials

refer to the measured ion current from isotopes X and Y,

i j

shall be used to produce the GDMS relative sensitivity factors

respectively, of atomic species X and Y as follows:

for the various elements being determined (see Table 1).

~X! RSF~X/M! A~Y ! I~X !

7.4.1.1 As necessary, non-copper reference materials may

j i

5 3 3

Y RSF Y/M A X I Y

~ ! ~ ! ~ ! ~ ! be used to produce the GDMS relative sensitivity factors for

i j

the various elements being determined.

where (X)/(Y) is the concentration ratio of atomic species X

7.4.2 Reference materials should be homogeneous (see

to species Y. If species Y is taken to be the copper matrix (RSF

11.1) and free of cracks or porosity.

(M/M) = 1.0), (X) is (with only very small error for pure metal

7.4.3 At least two reference materials are required to estab-

matrices) the absolute impurity concentration of X.

lish the relative sensitivity factors, including a 99.9999 % pure

copper metal to establish the background contribution in

5. Significance and Use

analyses.

5.1 This test method is intended for application in the

7.4.4 The concentration of each analyte for relative sensi-

semiconductor industry for evaluating the purity of materials

tivity factor determination should be at a factor of 100 greater

(for example, sputtering targets, evaporation sources) used in

than the detection limit determined using a 99.9999 % pure

thin film metallization processes. This test method may be

copper specimen, but less than 100 ppmw.

useful in additional applications, not envisioned by the respon-

7.4.5 To meet expected analysis precision, it is necessary

sible technical committee, as agreed upon between the parties

that specimens of reference and test material present the same

concerned.

size and configuration (shape and exposed length) in the glow

discharge ion source, with a tolerance of 0.2 mm in diameter

5.2 This test method is intended for use by GDMS analysts

and 0.5 mm in the distance of sample to cell ion exit slit.

invariouslaboratoriesforunifyingtheprotocolandparameters

for determining trace impurities in copper. The objective is to

8. Preparation of Reference Standards and Test

improve laboratory-to-laboratory agreement of analysis data.

Specimens

This test method is also directed to the users of GDMS

analyses as an aid to understanding the determination method, 8.1 The surface of the parent material must not be included

and the significance and reliability of reported GDMS data. in the specimen.

A

TABLE 1 Suite of Impurity Elements to Be Analyzed

NOTE 1—Establish RSFs for the following suite of elements:

Aluminum Antimony Arsenic Beryllium Bismuth Boron Calcium Carbon

Chromium Cobalt Germanium Gold Iron Lead Lithium Magnesium

Manganese Molybdenum Nickel Niobium Nitrogen Oxygen Phosphorous Potassium

Selenium Silicon Silver Sodium Sulfur Tellurium Thorium Tin

Titanium Uranium Vanadium Zinc Zirconium

A

Additional species may be determined and reported, as agreed upon between all parties concerned with the analyses.

F2405 − 04 (2011)

A

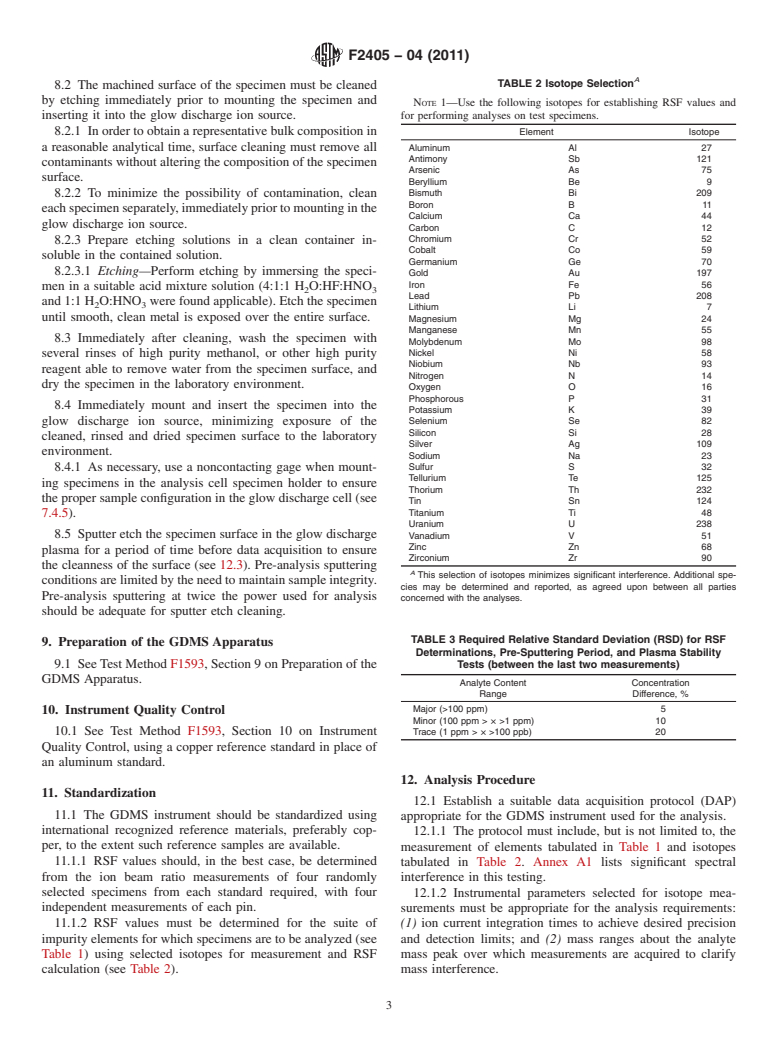

TABLE 2 Isotope Selection

8.2 The machined surface of the specimen must be cleaned

by etching immediately prior to mounting the specimen and

NOTE 1—Use the following isotopes for establishing RSF values and

inserting it into the glow discharge ion source. for performing analyses on test specimens.

8.2.1 In order to obtain a representative bulk composition in Element Isotope

a reasonable analytical time, surface cleaning must remove all Aluminum Al 27

Antimony Sb 121

contaminants without altering the composition of the specimen

Arsenic As 75

surface.

Beryllium Be 9

Bismuth Bi 209

8.2.2 To minimize the possibility of contamination, clean

Boron B 11

eachspecimenseparately,immediatelypriortomountinginthe

Calcium Ca 44

glow discharge ion source.

Carbon C 12

Chromium Cr 52

8.2.3 Prepare etching solutions in a clean container in-

Cobalt Co 59

soluble in the contained solution.

Germanium Ge 70

8.2.3.1 Etching—Perform etching by immersing the speci-

Gold Au 197

Iron Fe 56

men in a suitable acid mixture solution (4:1:1 H O:HF:HNO

2 3

Lead Pb 208

and 1:1 H O:HNO were found applicable). Etch the specimen

2 3

Lithium Li 7

until smooth, clean metal is exposed over the entire surface.

Magnesium Mg 24

Manganese Mn 55

8.3 Immediately after cleaning, wash the specimen with

Molybdenum Mo 98

Nickel Ni 58

several rinses of high purity methanol, or other high purity

Niobium Nb 93

reagent able to remove water from the specimen surface, and

Nitrogen N 14

dry the specimen in the laboratory environment.

Oxygen O 16

Phosphorous P 31

8.4 Immediately mount and insert the specimen into the

Potassium K 39

glow discharge ion source, minimizing exposure of the Selenium Se 82

Silicon Si 28

cleaned, rinsed and dried specimen surface to the laboratory

Silver Ag 109

environment.

Sodium Na 23

8.4.1 As necessary, use a noncontacting gage when mount- Sulfur S 32

Tellurium Te 125

ing specimens in the analysis cell specimen holder to ensure

Thorium Th 232

the proper sample configuration in the glow discharge cell (see

Tin Sn 124

Titanium Ti 48

7.4.5).

Uranium U 238

8.5 Sputter etch the specimen surface in the glow discharge Vanadium V 51

Zinc Zn 68

plasma for a period of time before data acquisition to ensure

Zirconium Zr 90

the cleanness of the surface (see 12.3). Pre-analysis sputtering

A

This selection of isotopes minimizes significant interference. Additional spe-

conditions are limited by the need to maintain sample integrity.

cies may be determined and reported, as agreed upon between all parties

Pre-analysis sputtering at twice the power used for analysis

concerned with the analyses.

should be adequate for sputter etch cleaning.

TABLE 3 Required Relative Standard Deviation (RSD) for RSF

9. Preparation of the GDMS Apparatus

Determinations, Pre-Sputtering Period, and Plasma Stability

9.1 See Test Method F1593, Section 9 on Preparation of the Tests (between the last two measurements)

GDMS Apparatus.

Analyte Content Concentration

Range Difference, %

Major (>100 ppm) 5

10. Instrument Quality Control

Minor(100ppm>×>1 ppm) 10

Trace (1 ppm > × >100 ppb) 20

10.1 See Test Method F1593, Section 10 on Instrument

Quality Control, using a copper reference standard in place of

an aluminum standard.

12. Analysis Procedure

11. Standardization

12.1 Establish a suitable data acquisition protocol (DAP)

11.1 The GDMS instrument should be standardized using

appropriate for the GDMS instrument used for the analysis.

international recognized reference materials, preferably cop-

12.1.1 The protocol must include, but is not limited to, the

per, to the extent such reference samples are available.

measurement of elements tabulated in Table 1 and isotopes

11.1.1 RSF values should, in the best case, be determined

tabulated in Table 2. Annex A1 lists significant spectral

from the ion beam ratio measurements of four randomly interference in this testing.

selected specimens from each standard required, with four

12.1.2 Instrumental parameters selected for isotope mea-

independent measurements of each pin. surements must be appropriate for the analysis requirements:

11.1.2 RSF values must be determined for the suite of (1) ion current integration times to achieve desired precision

impurity elements for which specimens are to be analyzed (see and detection limits; and (2) mass ranges about the analyte

Table 1) using selected isotopes for measurement and RSF mass peak over which measurements are acquired to clarify

calculation (see Table 2). mass interference.

F2405 − 04 (2011)

TABLE 4 Summary of Copper Round Robin Test Results Providing Precision and Bias on Interlaboratory GDMS Analysis

A

of High Purity Copper

All entries are wt. ppm

Material CuA (6N + 10) CuB (6N + 1) CuC (6N)

Element Avg Sr SR r R Avg Sr SR r R Avg Sr SR r R

Li 0.007 0.003 0.012 0.433 1.746 0.010 0.011 0.017 1.119 1.693 0.001 0.001 0.003 1.000 3.000

Be 7.86 0.94 2.82 0.12 0.36 0.73 0.08 0.25 0.11 0.35 0.010 0.003 0.004 0.300 0.400

B 10.12 1.02 2.86 0.10 0.28 1.16 0.09 0.36 0.07 0.31 0.278 1.215 1.286 4.371 4.62

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.