ASTM G18-07(2020)

(Test Method)Standard Test Method for Joints, Fittings, and Patches in Coated Pipelines

Standard Test Method for Joints, Fittings, and Patches in Coated Pipelines

SIGNIFICANCE AND USE

4.1 The exposed metal surfaces at joints, fittings, and damaged areas in an otherwise coated pipeline will be subjected to corrosion if allowed to come in contact with the soil environment. The performance of joint and patching materials designed to function as protective coverings will depend upon such factors as the ability of the material to bond to both the pipe coating and exposed metal surfaces, the integrity of the moisture seal at lapped joints, and the water absorption characteristics of the joint material.

4.2 The existence of substantial leakage current through the coating joint, patch, or fitting is reliable evidence that the material has suffered a significant decrease in its performance as a protective barrier. In a similar manner, measured changes in joint capacitance and dissipation factor are useful because they are related to the water absorption rate of the joint material. Water permeating an insulating barrier increases its capacitance and its progress can be measured through the use of a suitable impedance bridge.

SCOPE

1.1 This test method describes determination of the comparative corrosion preventative characteristics of materials used for applications to joints, couplings, irregular fittings, and patched areas in coated pipelines. The test method is applicable to materials whose principal function is to act as barriers between the pipe surface and surrounding soil environment.

1.2 The test method described employs measurements of leakage current, capacitance, and dissipation factor to indicate changes in the insulating effectiveness of joint and patching materials.

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 The values stated in SI units to three significant decimals are to be regarded as the standard. The values given in parentheses are for information only.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: G18 − 07 (Reapproved 2020)

Standard Test Method for

Joints, Fittings, and Patches in Coated Pipelines

ThisstandardisissuedunderthefixeddesignationG18;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Thickness of Pipeline Coatings on Steel (Withdrawn

2013)

1.1 This test method describes determination of the com-

parative corrosion preventative characteristics of materials

3. Summary of Test Method

used for applications to joints, couplings, irregular fittings, and

patchedareasincoatedpipelines.Thetestmethodisapplicable

3.1 The test method consists of an immersion test where

to materials whose principal function is to act as barriers

coated pipe specimens, each containing a simulated joint, tee,

between the pipe surface and surrounding soil environment.

or patched area, are suspended in an electrolyte and placed

under cathodic protection by connecting the specimens to the

1.2 The test method described employs measurements of

negative (−) terminal of a 6-V d-c power supply (see Fig. 1).

leakage current, capacitance, and dissipation factor to indicate

An anode, also immersed in the electrolyte and connected to

changes in the insulating effectiveness of joint and patching

the positive (+) terminal of the power supply, completes the

materials.

test circuit. Joint or patch performance is followed through

1.3 The values stated in SI units are to be regarded as the

periodicdeterminationsofleakagecurrentmeasuredasvoltage

standard. The values given in parentheses are for information

drops across a calibrated resistor in the anode-to-cathode

only.

circuit.

1.4 The values stated in SI units to three significant deci-

3.2 Capacitance and dissipation factor measurements are

mals are to be regarded as the standard. The values given in

used to supplement the periodic leakage current determina-

parentheses are for information only.

tions.

1.5 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

4. Significance and Use

responsibility of the user of this standard to establish appro-

4.1 The exposed metal surfaces at joints, fittings, and

priate safety, health, and environmental practices and deter-

mine the applicability of regulatory limitations prior to use. damaged areas in an otherwise coated pipeline will be sub-

1.6 This international standard was developed in accor- jected to corrosion if allowed to come in contact with the soil

dance with internationally recognized principles on standard- environment. The performance of joint and patching materials

ization established in the Decision on Principles for the designed to function as protective coverings will depend upon

Development of International Standards, Guides and Recom- such factors as the ability of the material to bond to both the

mendations issued by the World Trade Organization Technical pipe coating and exposed metal surfaces, the integrity of the

Barriers to Trade (TBT) Committee. moisture seal at lapped joints, and the water absorption

characteristics of the joint material.

2. Referenced Documents

4.2 The existence of substantial leakage current through the

2.1 ASTM Standards:

coating joint, patch, or fitting is reliable evidence that the

G12Test Method for Nondestructive Measurement of Film

material has suffered a significant decrease in its performance

as a protective barrier. In a similar manner, measured changes

in joint capacitance and dissipation factor are useful because

they are related to the water absorption rate of the joint

This test method is under the jurisdiction of ASTM Committee D01 on Paint

and Related Coatings, Materials, andApplications and is the direct responsibility of

material. Water permeating an insulating barrier increases its

Subcommittee D01.48 on Durability of Pipeline Coating and Linings.

capacitance and its progress can be measured through the use

Current edition approved Aug. 1, 2020. Published August 2020. Originally

of a suitable impedance bridge.

approvedin1971.Lastpreviouseditionapprovedin2013asG18–07(2013).DOI:

10.1520/G0018-07R20.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on The last approved version of this historical standard is referenced on

the ASTM website. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

G18 − 07 (2020)

NOTE 1—A commercially available, 42 L (11-gal) waste container of

high-density polyethylene can be conveniently used as a test vessel and

will accommodate up to six test specimens of a size indicated in 7.2.

5.2 Support Plate, fabricated from a nonconductive

material, to suspend the specimens in the test vessel. The

support plate shall contain an access hole for the reference

electrode. A typical test cell is illustrated in Fig. 3.

5.3 Anode, fabricated from 9.525 mm (0.375-in.) diameter

300seriesstainlesssteelrod,609.6mm(24.00in.)long.Other

inert anodes such as carbon or platinum may be used.

5.4 D-C Voltmeter, to serve the dual purpose of (1)

measuringleakagecurrentasapotentialdropacrossa1,000-Ω

shunt in the measuring circuit and (2) measuring the potential

of the test specimen with reference to a Cu-CuSO half cell.

The instrument characteristics for these functions shall be:

5.4.1 Voltage Range—50 µV full scale to 10 V full scale in

overlapping 1× and 3× ranges.

5.4.2 Accuracy—63 percent of full scale on all ranges.

5.4.3 Input Resistance—Greater than 10 MΩ on all ranges.

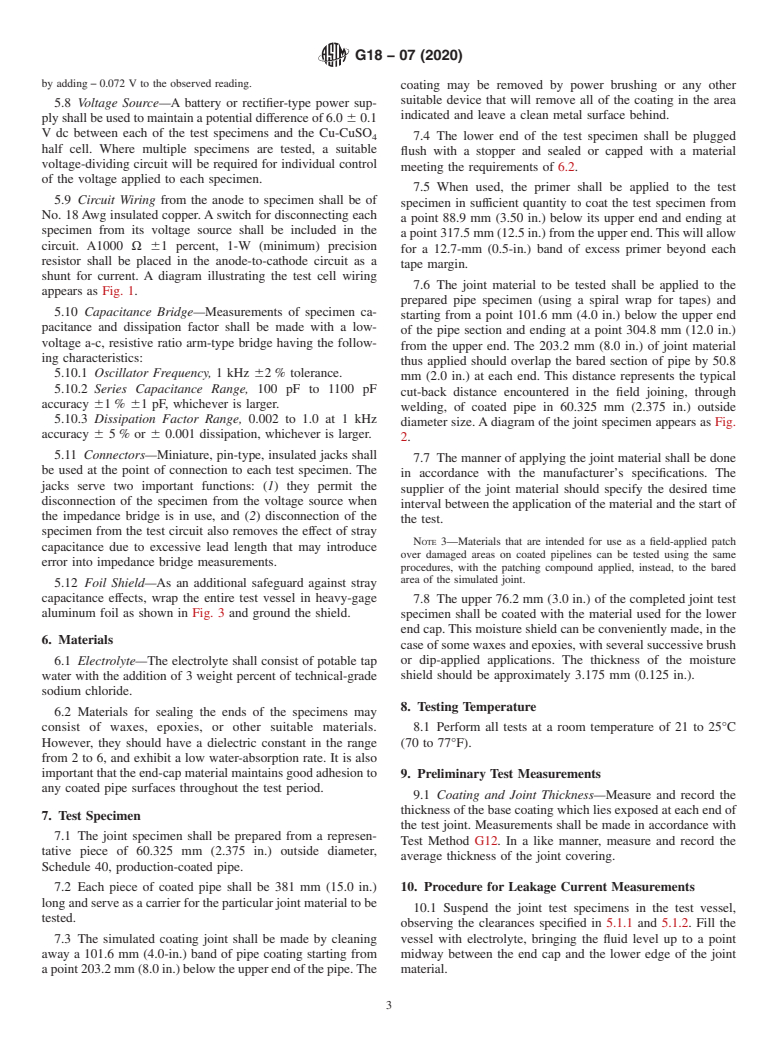

FIG. 1 Test Circuits

5.5 Thickness Gage—Measurements of coating thickness

will be required for this test. Any instrument suitable for use

5. Apparatus with Test Method G12 can be used. However, the choice of

measuring gage shall be compatible with the joint coating

5.1 Test Vessel, nonconducting, shall be used to contain the

thickness that will be encountered in the test.

test specimens. Dimensions of the vessel shall permit the

following requirements:

5.6 Ohmmeter—Measurements for end-cap integrity shall

5.1.1 The test vessel shall be large enough to allow for be made with a suitable ohmmeter capable of reading resis-

suspension of the specimens in a vertical position and equidis-

tance to an upper limit of 1000 MΩ 65%.

tant from a centrally located anode. The specimens shall not

5.7 Reference Electrode—ACu-CuSO half cell of conven-

touch either each other, the walls, or bottom of the test vessel.

tional glass or plastic tube with porous plug construction, but

5.1.2 The test vessel shall be deep enough to allow for

preferably not over 19.05 mm ( ⁄4 in.) in diameter, having a

immersionofthespecimensintheelectrolytetotheloweredge

potential of−0.316 V with respect to the standard hydrogen

of the upper moisture shield (see Fig. 2).

electrode.

NOTE 2—Asaturated calomel half cell may be used, but measurements

made with it shall be converted to the Cu-CuSO reference for reporting

NOTE 1—All dimensions are in millimetres with inches in parentheses.

FIG. 2 Joint Test Specimen FIG. 3 Joint Test Cell

G18 − 07 (2020)

by adding−0.072 V to the observed reading.

coating may be removed by power brushing or any other

suitable device that will remove all of the coating in the area

5.8 Voltage Source—A battery or rectifier-type power sup-

indicated and leave a clean metal surface behind.

plyshallbeusedtomaintainapotentialdifferenceof6.0 60.1

V dc between each of the test specimens and the Cu-CuSO

4 7.4 The lower end of the test specimen shall be plugged

half cell. Where multiple specimens are tested, a suitable

flush with a stopper and sealed or capped with a material

voltage-dividing circuit will be required for individual control

meeting the requirements of 6.2.

of the voltage applied to each specimen.

7.5 When used, the primer shall be applied to the test

5.9 Circuit Wiring from the anode to specimen shall be of

specimen in sufficient quantity to coat the test specimen from

No. 18Awg insulated copper.Aswitch for disconnecting each

a point 88.9 mm (3.50 in.) below its upper end and ending at

specimen from its voltage source shall be included in the

apoint317.5mm(12.5in.)fromtheupperend.Thiswillallow

circuit. A1000 Ω 61 percent, 1-W (minimum) precision

for a 12.7-mm (0.5-in.) band of excess primer beyond each

resistor shall be placed in the anode-to-cathode circuit as a

tape margin.

shunt for current. A diagram illustrating the test cell wiring

7.6 The joint material to be tested shall be applied to the

appears as Fig. 1.

prepared pipe specimen (using a spiral wrap for tapes) and

5.10 Capacitance Bridge—Measurements of specimen ca-

starting from a point 101.6 mm (4.0 in.) below the upper end

pacitance and dissipation factor shall be made with a low-

of the pipe section and ending at a point 304.8 mm (12.0 in.)

voltage a-c, resistive ratio arm-type bridge having the follow-

from the upper end. The 203.2 mm (8.0 in.) of joint material

ing characteristics:

thus applied should overlap the bared section of pipe by 50.8

5.10.1 Oscillator Frequency, 1 kHz 62% tolerance.

mm (2.0 in.) at each end. This distance represents the typical

5.10.2 Series Capacitance Range, 100 pF to 1100 pF

cut-back distance encountered in the field joining, through

accuracy 61% 61 pF, whichever is larger.

welding, of coated pipe in 60.325 mm (2.375 in.) outside

5.10.3 Dissipation Factor Range, 0.002 to 1.0 at 1 kHz

diameter size.Adiagram of the joint specimen appears as Fig.

accuracy 65%or 6 0.001 dissipation, whichever is larger.

2.

5.11 Connectors—Miniature, pin-type, insulated jacks shall

7.7 The manner of applying the joint material shall be done

be used at the point of connection to each test specimen. The

in accordance with the manufacturer’s specifications. The

jacks serve two important functions: (1) they permit the

supplier of the joint material should specify the desired time

disconnection of the specimen from the voltage source when

interval between the application of the material and the start of

the impedance bridge is in use, and (2) disconnection of the

the test.

specimen from the test circuit also removes the effect of stray

NOTE 3—Materials that are intended for use as a field-applied patch

capacitance due to excessive lead length tha

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.