ASTM F1630-00

(Test Method)Standard Test Method for Low Temperature FT-IR Analysis of Single Crystal Silicon for III-V Impurities (Withdrawn 2003)

Standard Test Method for Low Temperature FT-IR Analysis of Single Crystal Silicon for III-V Impurities (Withdrawn 2003)

SCOPE

This standard was transferred to SEMI (www.semi.org) May 2003

1.1 This test method covers the determination of electrically active boron, phosphorus, arsenic, aluminum, antimony, and gallium concentration in single crystal silicon.

1.2 This test method can be used for silicon in which the impurity/dopant concentrations are between 0.01 ppba and 5.0 ppba for each of the electrically active elements.

1.3 The concentration for each impurity/dopant can be obtained by application of Beer's Law. Calibration factors are given for each element.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: F 1630 – 00

Standard Test Method for

Low Temperature FT-IR Analysis of Single Crystal Silicon

for III-V Impurities

This standard is issued under the fixed designation F 1630; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Terminology

1.1 This test method covers the determination of electrically 3.1 Many of the terms associated with this test method can

active boron, phosphorus, arsenic, aluminum, antimony, and be found in Terminology E 131.

gallium concentration in single crystal silicon. 3.2 Definitions for terms related to silicon materials tech-

1.2 This test method can be used for silicon in which the nology are found in Terminology F 1241.

impurity/dopant concentrations are between 0.01 ppba and 5.0 3.3 Definitions:

ppba for each of the electrically active elements. 3.3.1 electrically active elements,, n—dopants or impurities

1.3 The concentration for each impurity/dopant can be in silicon that are members of either Group III (boron,

obtained by application of Beer’s Law. Calibration factors are aluminum, gallium, and indium) or Group V (phosphorus,

given for each element. arsenic, antimony and bismuth) of the periodic table.

1.4 This standard does not purport to address all of the 3.4 Definitions of Terms Specific to This Standard:

safety concerns, if any, associated with its use. It is the 3.4.1 background spectrum—a spectrum obtained without

responsibility of the user of this standard to establish appro- any sample specimen in the IR beam.

priate safety and health practices and determine the applica- 3.4.2 baseline—a straight line interpolation between points

bility of regulatory limitations prior to use. on either side of the absorption peak in the absorbance

spectrum.

2. Referenced Documents

3.4.3 FT-IR—acronym for Fourier transform infrared (spec-

2.1 ASTM Standards: trometer).

E 131 Terminology Relating to Molecular Spectroscopy

3.4.4 FWHM—acronym for the full width of an absorption

−1

E 168 Practices for General Techniques of Infrared Quan- peak expressed in cm at half its absorbance magnitude as

titative Analysis

measured from the baseline.

E 177 Practices for Use of the Terms Precision and Bias in 3.4.5 LTFT-IR—acronym for low temperature, Fourier

ASTM Test Methods

transform infrared (spectrometer).

E 275 Practice for Describing and Measuring the Perfor- 3.4.6 sample spectrum—the ratio of a spectrum obtained

mance of Ultraviolet, Visible, and Near-Infrared Spectro-

with the test specimen in the IR beam to a background

photometers spectrum.

F 723 Practice for Conversion Between Resistivity and

4. Summary of Test Method

Dopant Density for Boron-Doped and Phosphorus-Doped

Silicon 4.1 A sample specimen of single crystal silicon is cooled to

F 1241 Terminology of Semiconductor Technology less than 15 K. Under these conditions the number of free

F 1391 Test Method for Substitutional Atomic Carbon carriers becomes negligibly small and the IR spectrum of the

Content of Silicon by Infrared Absorption sample exhibits a series of absorption bands that are charac-

F 1723 Practice for Evaluation of Polycrystalline Silicone teristic for each shallow impurity species (1).

Rods by Float-Zone Crystal Growth and Spectroscopy 4.2 The sample specimen is illuminated with an incident

white light source to flood the silicon with photons of greater

energy than the silicon band gap to allow neutralization of

compensated impurities (2).

This test method is under the jurisdiction of ASTM Committee F01 on

4.3 An infrared beam is directed through the sample speci-

Electronics and is the direct responsibility of Subcommittee F01.06 on Silicon

men and a transmitted spectrum is collected. The spectrum is

Materials and Process Control.

ratioed to the background spectrum and then converted to an

Current edition approved Dec. 10, 2000. Published January 2001. Originally

published as F 1630-95. Last previous edition F 1630-95.

absorbance spectrum.

Annual Book of ASTM Standards, Vol 03.06.

Annual Book of ASTM Standards, Vol 14.02.

Annual Book of ASTM Standards, Vol 10.05.

The boldface numbers in parentheses refer to the list of references at the end of

this test method.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

F 1630

4.4 Baselines are constructed at one of the characteristic annealing the sample specimen.

absorption bands for each impurity/dopant to be measured. 6.5 Multiple internal reflections can produce a secondary

4.5 The areas of the absorption bands are measured. interferogram and baseline oscillations. Changing the sample

4.6 Concentrations of each impurity/dopant are calculated specimen thickness, the surface preparation, or the resolution

in accordance with Bouguer-Beer’s Law with factors given in can eliminate the secondary interferogram and the baseline

this test method. oscillation.

−1

6.6 High antimony levels interfere with the 320 cm boron

5. Significance and Use

absorption line. Antimony’s strongest absorption line is 293

−1 −1

5.1 LTFT-IR spectroscopy identifies and quantitates boron,

cm , but a secondary absorption line occurs at 320 cm .

phosphorus, aluminum, arsenic, indium, antimony, and gal-

7. Apparatus and Materials

lium.

5.2 LTFT-IR spectroscopy can be applied to FZ, CZ,or

7.1 Cryostat, which maintains the sample specimen tem-

other single crystal silicon (either doped or undoped) up to the

perature below 15 K is required. This cryostat may be liquid

concentration limits given in 1.2.

helium immersion, exchange gas, or closed cycle refrigeration.

5.3 The measurement of carbon in silicon at low tempera-

7.2 Sample Specimen Holder, constructed of high heat

ture can be accomplished concurrently in accordance with Test

conductivity metal with an aperture(s) to block any of the

Method F 1391. The carbon can be measured at lower concen-

infrared beam except that passing through the sample.

trations at <15 K than is possible at room temperature because

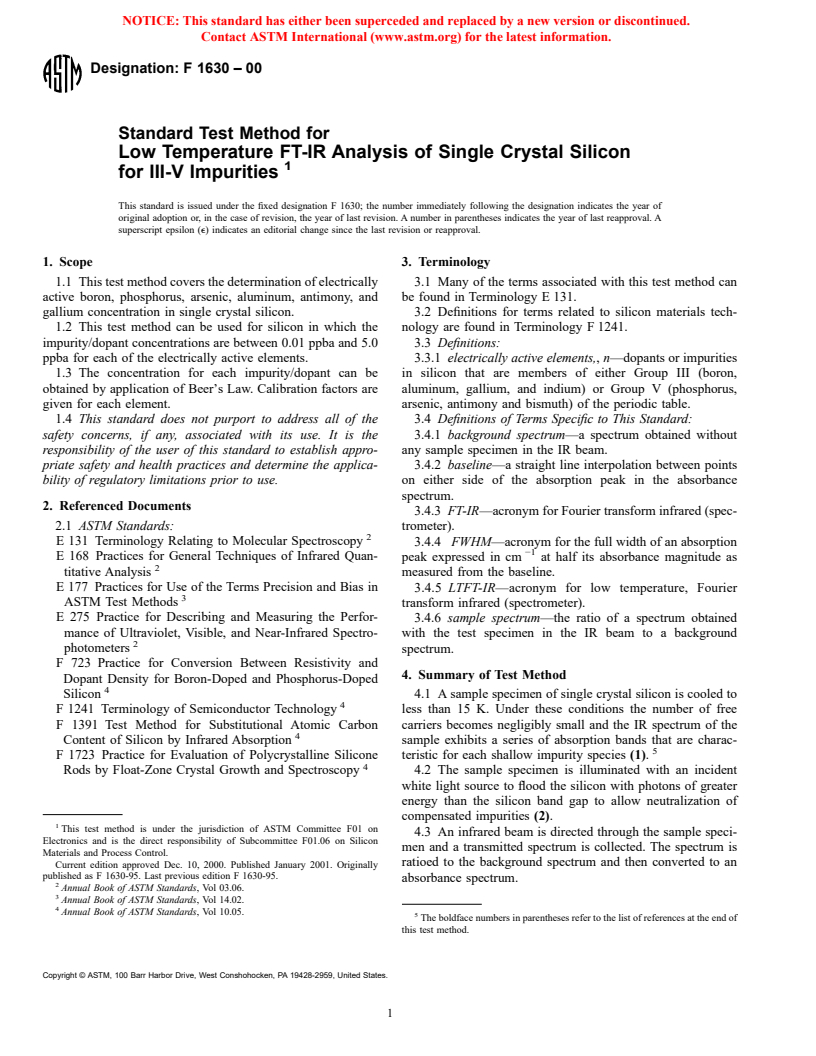

7.3 White-light Source, (see Fig. 1).

the two-phonon band transmission is increased by a factor of

7.4 Fourier Transform Infrared Spectrometer (FT-IR), must

two allowing greater throughput to the detector that results in

be equipped with suitable optics and detector for use in the

−1 −1

an increased signal to noise ratio. Also the carbon adsorption

region from 250 cm to 1300 cm .

−1

−1

band narrows from a FWHM of 5 to 6 cm to a FWHM of 2.5

7.4.1 The spectrometer must be capable of at least 1.0 cm

−1

to 3.0 cm at these temperatures.

resolution. The resolution shall be sufficient so that after

5.4 Electronic grade polysilicon producers and users rely on

zero-filling, apodization, and Fourier transformation the phos-

−1

LTFT-IR spectroscopy to evaluate polysilicon for quality

phorus adsorption band at 315.9 cm will have a FWHM not

−1

assurance and research purposes.

to exceed 1.1 cm .

7.4.2 The detector shall be sufficiently sensitive to provide a

6. Interferences

reasonable signal to noise response in the desired spectral

6.1 The sample specimen must be colder than 15 K for

region. A room temperature DTGS with a CsI window will

measurement of electrically active species. If the sample

suffice for the higher concentrations of elements in this test

specimen is mounted on a cold finger, care must be taken to

method. However, a zinc-doped germanium Ge:Zn detector

obtain good contact between the sample specimen and the cold

operated at 4.4 to 10.0 K is preferred to give a signal to noise

finger for efficient heat transfer. The oxygen absorption lines at

ratio sufficient to properly determine the elements at the lower

−1 −1

1136 cm and 1128 cm are sensitive to temperature and can

concentrations and for improved precision.

be used to determine the specimen temperature (3). When the

7.5 Calcium Fluoride Crystal (CaF ), cut to nominal

sample specimen is less than 15 K the net absorbance at 1136

thickness of 5 mm.

−1

cm is three times larger than the net absorbance at 1128

−1

cm . A ratio of greater than three is obtained for temperatures

8. Sample Preparation

below 15 K.

8.1 If the samples are from polysilicon, they must first be

6.2 Without sufficient incident white light the compensated

converted to single crystal in accordance with Practice F 1723

donors and acceptors will not absorb. Therefore, the white light

or other established means.

intensity must be great enough to completely neutralize all the

compensated donors and acceptors. The intensity of the white

light necessary must be determined for each system. The user

should increase the intensity of the white light until further

increase in intensity no longer affects the area/height of the

electrically active impurity/dopant peaks.

6.3 Water vapor absorption interferes with the measurement

of several peaks. Consequently, the background spectrum

should be collected at least daily. The entire light path,

including the sample chamber, must be purged to remove

moisture. Special care should be taken whenever a sample

specimen is changed so that the moisture level in the sample

chamber or elsewhere in the light path is not affected.

6.4 Oxygen level in Czochralski silicon can be high enough

to exhibit thermal donor absorption lines. These lines fall

−1 −1

between 400 cm and 550 cm and can interfere with

−1 −1

aluminum (473 cm ), gallium (548 cm ), and occasionally

FIG. 1 Sample Holder and Optics Suitable for Illumination with

−1

arsenic (382 cm ). Thermal donors can be removed by White-light via Fiber-optics

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

F 1630

8.2 Sample specimen must be cut and polished to fit the the sample specimen is fully illuminated with white light and

sample specimen holder. The surface may be mechanically or properly aligned relative to the IR beam (see Fig. 1).

chemically polished. Each sample specimen should have a 11.6 Collect a minimum of 300 scans of the sample.

thickness variation of less than 1 % of overall thickness. Zero-fill, apodize, and transform the interferogram into a

8.3 For measurement of electrically active impurities, the spectrum and then ratio to the background spectrum. Covert to

sample specimens should be 3 to 5-mm thick with high purity an absorbance spectrum and use as the sample specimen

silicon (>2000 V -cm) to allow for lower detection limits. spectrum. Store this spectrum and subsequent ones for further

Sample thicknesses between 5 and 20 mm may be used in cases manipulation and measurement of the peak areas.

where impurity levels to be measured are below 0.01 ppba. The 11.7 Make sure that the first specimen is a reference

sample specimens should be 1 to 2-mm thick for heavily doped specimen which serves as an audit to ensure that the entire

silicon (<10 V-cm) to allow greater transmission of the instrument is performing correctly.

infrared radiation. 11.8 Repeat 11.4 through 11.6 for each sample specimen.

12. Data Reduction

9. Reference Specimens

12.1 This test procedure requires the measurement of the

9.1 One or more silicon samples that contains impurities in

areas of the absorption bands before calculation of the concen-

the range of the samples to be tested should be classified as

tration of each element. The absorption bands are very sharp,

reference specimens. These reference specimens should be

especially for the Group V elements, and therefore peak height

analyzed repeatedly and periodically according to this test

measurements are difficult to reproduce from instrument to

method. Compare the results obtained to previous data to

instrument. Use of peak areas greatly reduces this variability.

establish that the measurement process is in control.

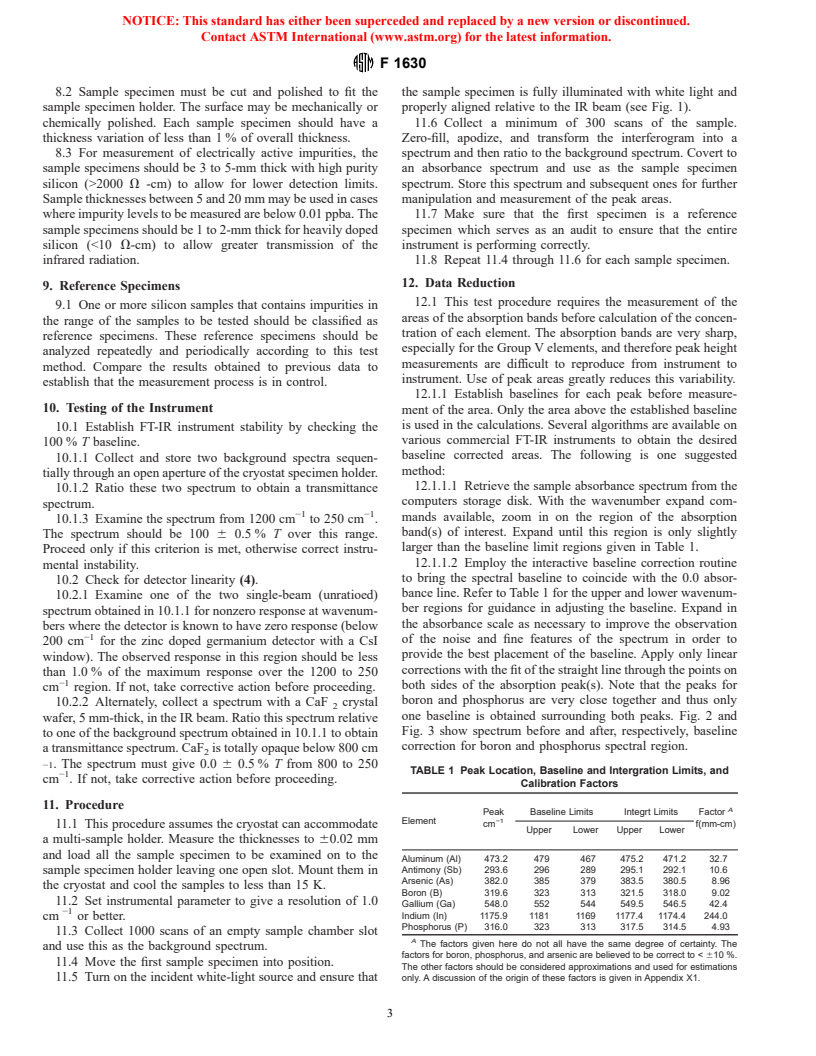

12.1.1 Establish baselines for each peak before measure-

10. Testing of the Instrument

ment of the area. Only the area above the established baseline

is used in the calculations. Several algorithms are available on

10.1 Establish FT-IR instrument stability by checking the

various commercial FT-IR instruments to obtain the desired

100 % T baseline.

baseline corrected areas. The following is one suggested

10.1.1 Collect and store two background spectra sequen-

method:

tially through an open aperture of the cryostat specimen holder.

12.1.1.1 Retrieve the sample absorbance spectrum from the

10.1.2 Ratio these two spectrum to obtain a transmittance

computers storage disk. With the wavenumber expand com-

spectrum.

−1 −1

mands available, zoom in on the region of the absorption

10.1.3 Examine the spectrum from 1200 cm to 250 cm .

band(s) of interest. Expand until this region is only slightly

The spectrum should be 100 6 0.5 % T over this range.

larger than the baseline limit regions given in Table 1.

Proceed only if this criterion is met, otherwise correct instru-

12.1.1.2 Employ the interactive baseline correction routine

mental instability.

to bring the spectral baseline to coincide with the 0.0 absor-

10.2 Check for detector linearity (4).

bance line. Refer to Table 1 for the upper and lower wavenum-

10.2.1 Examine one of the two single-beam (unratioed)

ber regions for guidance in adjusting the baseline. Expand in

spectrum obtained in 10.1.1 for nonzero response at wavenum-

the absorbance scale as necessary to improve the observation

bers where the detector is known to have zero response (below

−1

of the noise and fine features of the spectrum in order to

200 cm for the zinc doped germanium detector with a CsI

provide the best placement of the baseline. Apply only linear

window). The observed response in this region should be less

corrections with the fit of the straight line through the points on

than 1.0 % of the maximum response over the 1200 to 250

−1

both sides of the absorption peak(s). Note that the peaks for

cm region. If not, take corrective action before proceeding.

boron and phosphorus are very close together and thus only

10.2.2 Alternately, collect a spectrum with a CaF crystal

one baseline is obtained surrounding both peaks. Fig. 2 and

wafer, 5 mm-thick, in the IR beam. Ratio this spectrum relative

Fig. 3 show spectrum before and after, respectively, baseline

to one of the background spectrum obtained in 10.1.1 to obtain

correction for boron and phosphorus spectral region.

a transmittance spectrum. CaF is tot

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.