ASTM F1774-99

(Specification)Standard Specification for Climbing and Mountaineering Carabiners

Standard Specification for Climbing and Mountaineering Carabiners

SCOPE

1.1 This specification covers six mechanical tests and the minimum performance requirements for carabiners designed specifically for the sports of climbing and mountaineering.

1.2 Two different types of carabiners are defined in this standard, non-locking carabiners and locking carabiners.

1.3 The values stated in SI units are to be regarded as the standard.

1.4 Tests contained herein are destructive in nature. Carabiners subjected to any of these tests shall not be used in any way after testing except in evaluating the results of such testing.

1.5 this specification does not imply approval of any method of use of climbing and mountaineering carabiners. In addition, the test load values contained herein are not to be interpreted as the forces which a climbing and mountaineering carabiner may be subjected to, or expected to sustain in actual field use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation: F 1774 – 99

Standard Specification for

Climbing and Mountaineering Carabiners

This standard is issued under the fixed designation F 1774; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.2 failure, n—an arbitrary point beyond which a material

or product ceases to be functionally capable of its intended use.

1.1 This specification covers six mechanical tests and the

In this application, the point at which some part of the

minimum performance requirements for carabiners designed

carabiner physically breaks or distorts to an extent that the test

specifically for the sports of climbing and mountaineering.

members are released.

1.2 Two different types of carabiners are defined in this

3.1.3 locking carabiner, n—a carabiner with a mechanism

standard, non-locking carabiners and locking carabiners.

that reduces the possibility of a gate being opened inadvert-

1.3 The values stated in SI units are to be regarded as the

ently. A locking mechanism requires at least two different

standard.

consecutive manual actions to open the gate.

1.4 Tests contained herein are destructive in nature. Cara-

3.1.4 nonlocking carabiner, n—any carabiner that does not

biners subjected to any of these tests shall not be used in any

have a mechanism that reduces the possibility of a gate being

way after testing except in evaluating the results of such

opened inadvertently.

testing.

3.1.5 normal body weight, n—a standardized weight that

1.5 This specification does not imply approval of any

representsatypicalclimber,definedasFunctionTestForceNo.

method of use of climbing and mountaineering carabiners. In

1.

addition, the test load values contained herein are not to be

3.1.6 ultimate strength, n—the maximum force sustained by

interpreted as the forces which a climbing and mountaineering

a carabiner during an ultimate force test, prior to its failure.

carabiner may be subjected to, or expected to sustain in actual

field use.

4. Significance and Use

1.6 This specification is limited to carabiners made of steel

4.1 Gate Function During Body Weight Test—This test

or aluminum alloys only.

simulates a climber’s body weight of Function Test Force No.

2. Referenced Documents 1 and verifies that the gate functions as intended under body

weight force.

2.1 ASTM Standards:

4.2 Major Axis Gate Closed 70 % Force Test—This test

E 4 Practices for Load Verification of Testing Machines

verifies that the gate functions as originally intended after

F 1772 Terminology Relating to Climbing and Mountain-

Function Test Force No. 2 has been applied and released.

eering Practices

4.3 Locking Mechanism Test—This test verifies that the

F 1775 Specification for Labeling of Climbing and Moun-

locking mechanism keeps the gate in the locked position

taineering Equipment

between forces of 0 kN and Function Force Test No. 3.

2.2 Other Standard:

4.4 Major Axis Gate Closed Ultimate Strength Test—This

EN 566:1994 Slings [preliminary]

test is intended to show the force required to physically fail the

3. Terminology carabiner.

4.5 MajorAxis Gate Open Ultimate Strength Test—Thistest

3.1 Definitions of Terms Specific to This Standard:

simulates a potential inadvertent use of a carabiner. It is

3.1.1 carabiner, n—a self-closing gated, load-bearing, con-

intended to show the force required to physically fail the

nective device. Some carabiner models may have cocking or

carabiner.

blocking devices, that when activated, override the self-closing

4.6 Minor Axis Gate Closed Ultimate Strength Test—This

features.

test simulates a potential inadvertent use of a carabiner. It is

intended to show the force required to fail physically the

This specification is under the jurisdiction of ASTM Committee F-8 on Sports

carabiner along the minor axis.

Equipment, Surfaces, and Facilitiesand is the direct responsibility of Subcommittee

F08.21on Climbing and Mountaineering.

Current edition approved Feb. 10, 1999. Published April 1999. Originally

published as F 1774–97. Last previous edition F 1774–97.

Annual Book of ASTM Standards, Vol 03.02.

Annual Book of ASTM Standards, Vol 15.07.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F 1774

5. Responsibility for Quality Assurance 7. Hazards

7.1 Carabiners may disengage or eject parts from the test

5.1 Quality control is solely the responsibility of the manu-

fixture. Use a safety screen and wear safety glasses while

facturer or purchaser, or both, and is not addressed by this

testing. Do not perform this test alone.

specification.

8. Sampling

6. Apparatus and Condition

8.1 Number of Tests—The number of samples for testing

6.1 Tensile Tester, capable of calibration in accordance with

will be specified by the manufacturer’s quality assurance

Practices E 4 to the ultimate strength of all carabiners tested.

program.Aminimum of five will be used, in sequence, for the

6.2 Test Fixtures and Supplies:

gate function during body weight, major axis gate closed 70 %,

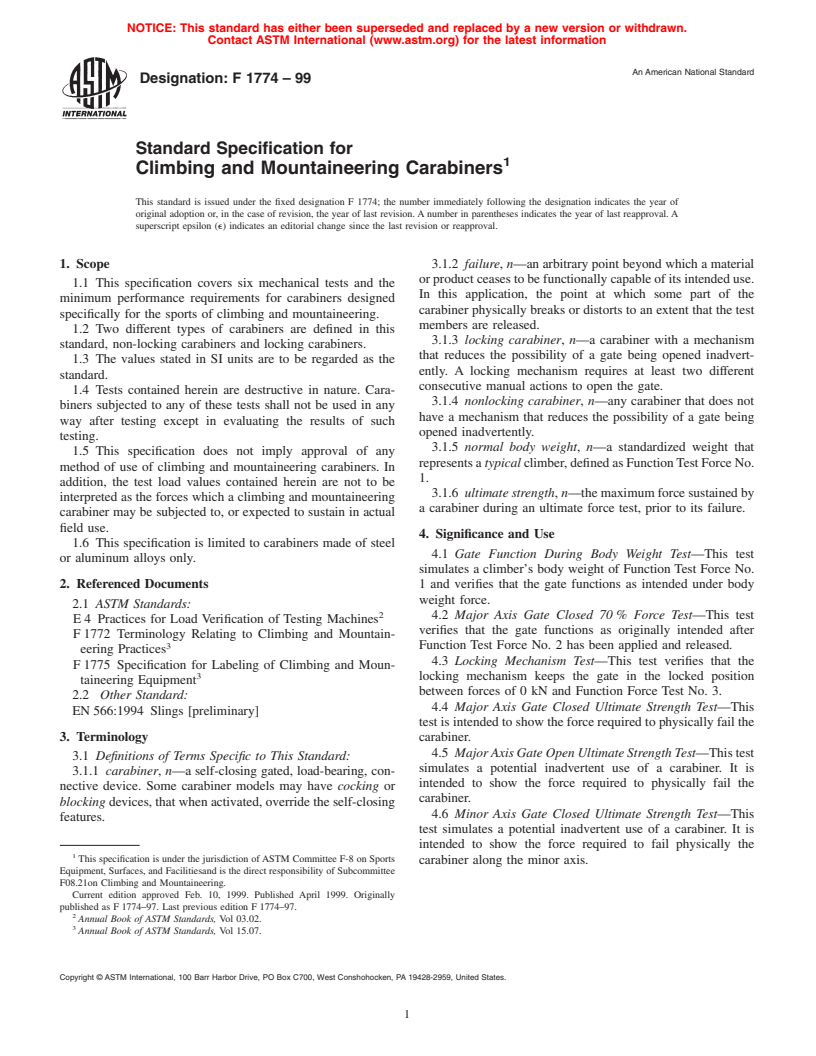

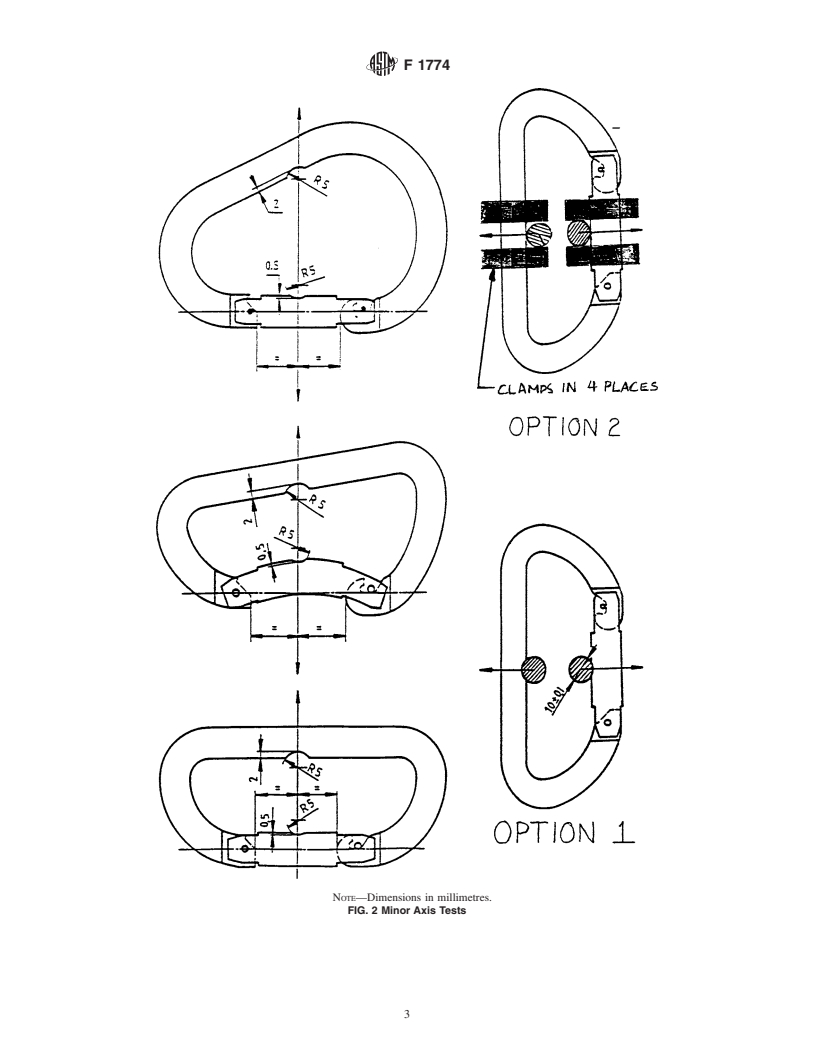

6.2.1 There are four total test pins required, two pins with

and major axis gate closed ultimate strength tests.Aminimum

6 6 0.05-mm radius and two pins with 5 6 0.05-mm radius.

of five will be used for the major axis gage open ultimate

Pinsmustbealloysteelandheat-treatedtominimumRockwell

strengthtest.Aminimumoffivewillbeusedfortheminoraxis

hardness,Cscale60.Themeansurfaceroughness,R ,mustnot

a gate closed ultimate strength test.

exceed 0.8 µm and the peak to valley height, R , must not

max

exceed 6.3 µm. The fixture should be designed in such a way

9. Performance Specifications

thatthepinsdonotrotateandthatthecarabinerisfreetolocate

9.1 Gate Function During Body Weight Test:

itself on the pins when the force is applied. See Figs. 1 and 2.

9.1.1 Function Test Force No. 1 will be used for this test.

6.2.2 Molybdenum-Based Grease.

Each of the carabiners subjected to the body weight test shall

6.3 Test Conditions—The ambient temperature shall be show no evidence of distortion that impairs the designed

function.

between 15 and 23°C.

FIG. 1 Major Axis Test Set-Up

F 1774

NOTE—Dimensions in millimetres.

FIG. 2 Minor Axis Tests

F 1774

9.1.2 While the body weight force is applied, the carabiner 10. Procedure

gateshallopenandcloseasdesignedandwiththesamequality

10.1 Gate Function During Body Weight Test:

and performance as before the test.

10.1.1 Grease the test pins where the carabiner comes in

9.1.3 When a locking carabiner is locked while the body

contact with the pins.

weight force is applied, the locking mechanism must be able to

10.1.2 Positionthecarabineronthe6-mmradiustestpinsas

be rotated to its unlocked position by hand after the force is

shown in Fig. 1. Position the test pins against the spine of the

removed.

carabiner. If the carabiner has a captive sling that is intended to

9.2 Major Axis Gate Closed 70 Force Test—Function Test

be loaded directly, apply the test force directly to the sling by

Force No. 2 will be used for this test. Each of the carabiners

one of the 5-mm radius test pins in accordance with prEN 566.

subjected to the 70 % force test shall show no evidence of

If the carabiner has provision for a semicaptive sling, apply the

distortion that impairs the designed function after the test is

test force to a short sling by one of the 5-mm radius test pins.

conducted.Thelockingmechanismofalockingcarabinershall

10.1.3 Loadthecarabinertowithin2 %oftheFunctionTest

openandcloseasoriginallyintendedandwiththesamequality

Force No. 1, without going above it, at a rate of 10 6 5

and performance as before the test.

mm/min.

9.3 Locking Mechanism Test—Function Test Force No. 3

10.1.4 Nonlocking Test—While maintaining the force, open

will be used for this test. With the locking mechanism in the

and close the gate and check that gate functions as originally

locked position and an inward force of 50 N applied to the

intended. On the report, record whether gate opens or closes as

center of the gate, the gate must not open as Function Test

intended and the actual tensile force applied.

Force No. 3 is applied to the major axis of the carabiner. When

10.1.5 Locking Test—While maintaining the force with the

the load is released, the gate and locking mechanism must be

locking mechanism unlocked, open and close the gate and

fully functional.

check that the gate functions as originally intended. On the

9.4 Major Axis Gate Closed Ultimate Strength Test:

report, record whether gate opens or closes as intended and the

9.4.1 Each of the nonlocking carabiners subjected to this

actual force applied. Engage the locking mechanism to its

test shall have an ultimate strength equal to or greater than the

locked posit

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.