ASTM D5034-95(2001)

(Test Method)Standard Test Method for Breaking Strength and Elongation of Textile Fabrics (Grab Test)

Standard Test Method for Breaking Strength and Elongation of Textile Fabrics (Grab Test)

SCOPE

1.1 This test method covers the grab and modified grab test procedures for determining the breaking strength and elongation of most textile fabrics. Provisions are made for wet testing.

1.1.1 The grab test procedure is applicable to woven, nonwoven, and felted fabrics, while the modified grab test procedure is used primarily for woven fabrics.

1.2 This test method is not recommended for glass fabrics, or for knitted fabrics and other textile fabrics which have high stretch (more than 11 %).

Note 1—For the determination of the breaking force and elongation of textile fabrics using the raveled strip test procedure and the cut strip test procedure, refer to Test Method D 5035.

1.3 This test method provides the values in both inch-pound units and SI units. Inch-pound units is the technically correct name for the customary units used in the United States. SI units is the technically correct name for the system of metric units known as the International System of Units. The values stated in either acceptable metric units or in other units shall be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system must be used independently of the other, without combining in any way.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 5034 – 95 (Reapproved 2001)

Standard Test Method for

Breaking Strength and Elongation of Textile Fabrics (Grab

1

Test)

This standard is issued under the fixed designation D 5034; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

2

1. Scope D 629 Test Methods for Quantitative Analysis of Textiles

D 1059 Test Method for Yarn Number on Short-Length

1.1 This test method covers the grab and modified grab test

2

Specimens

procedures for determining the breaking strength and elonga-

2

D 1776 Practice for Conditioning Textiles for Testing

tionofmosttextilefabrics.Provisionsaremadeforwettesting.

D 5035 Test Method for Breaking Force and Elongation of

1.1.1 The grab test procedure is applicable to woven,

3

Textile Fabrics (Strip Force)

nonwoven, and felted fabrics, while the modified grab test

procedure is used primarily for woven fabrics.

3. Terminology

1.2 This test method is not recommended for glass fabrics,

3.1 Definitions:

or for knitted fabrics and other textile fabrics which have high

3.1.1 breaking force, n—the maximum force applied to a

stretch (more than 11 %).

material carried to rupture. (Compare breaking point, breaking

NOTE 1—For the determination of the breaking force and elongation of

strength. Syn. force-at-break.)

textile fabrics using the raveled strip test procedure and the cut strip test

3.1.1.1 Discussion—Materials that are brittle usually rup-

procedure, refer to Test Method D 5035.

ture at the maximum force. Materials that are ductile usually

1.3 This test method provides the values in both inch-pound

experience a maximum force before rupturing.

units and SI units. Inch-pound units is the technically correct

3.1.2 breaking load, n—deprecated term. Use breaking

nameforthecustomaryunitsusedintheUnitedStates.SIunits

force.

is the technically correct name for the system of metric units

3.1.3 constant-rate-of-extension (CRE) tensile testing

known as the International System of Units. The values stated

machine—a testing machine in which the rate of increase of

in either acceptable metric units or in other units shall be

specimen length is uniform with time.

regarded separately as standard. The values stated in each

3.1.4 constant-rate-of-load (CRL) tensile testing

system may not be exact equivalents; therefore, each system

machine—atestingmachineinwhichtherateofincreaseofthe

must be used independently of the other, without combining in

load being applied to the specimen is uniform with time after

any way.

the first 3 s.

1.4 This standard does not purport to address all of the

3.1.5 constant-rate-of-traverse (CRT) tensile testing

safety concerns, if any, associated with its use. It is the

machine—a testing machine in which the pulling clamp moves

responsibility of the user of this standard to establish appro-

at a uniform rate and the load is applied through the other

priate safety and health practices and determine the applica-

clamp which moves appreciably to actuate a weighing mecha-

bility of regulatory limitations prior to use.

nism, so that the rate of increase of load or elongation is

dependent upon the extension characteristics of the specimen.

2. Referenced Documents

3.1.6 elongation, n—the ratio of the extension of a material

2.1 ASTM Standards:

to the length of the material prior to stretching, expressed as a

D76 Specification for Tensile Testing Machines for Tex-

percent.

2

tiles

3.1.7 extension, n—thechangeinlengthofamaterialdueto

2

D 123 Terminology Relating to Textiles

stretching. (Compare elongation.)

3.1.8 grab test, n—in fabric testing, a tensile test in which

the central part of the width of the specimen is gripped in the

1

This test method is under the jurisdiction ofASTM Committee D13 onTextiles

clamps.

and is the direct responsibility of Subcommittee D13.60 on Fabric Test Methods,

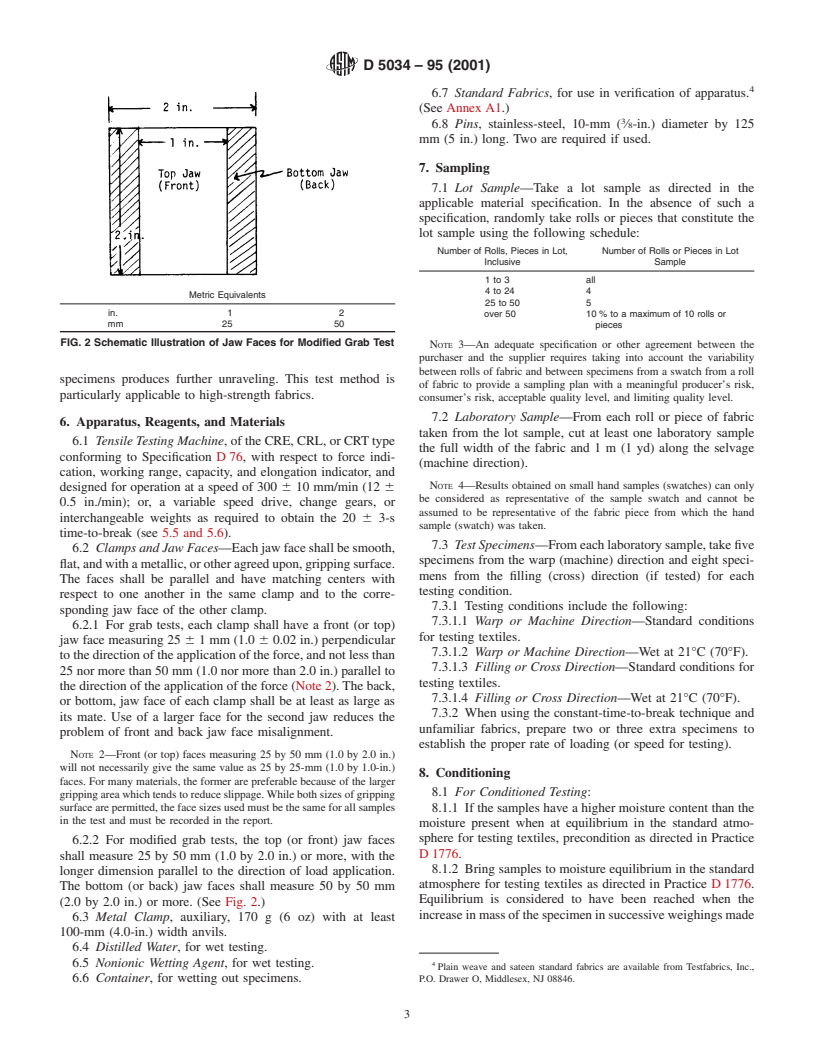

3.1.8.1 Discussion—For example, if the specimen width is

Specific.

Current edition approved Sept. 10, 2001. Published May 2002. Originally 100 mm (4.0 in.), and the width of the jaw faces 25 mm (1.0

approved in 1990. Last previous edition approved in 1995 as D 5034 – 95. Replaces

Grab Testing sections of Test Method D 1682 – 90.

2 3

Annual Book of ASTM Standards, Vol 07.01. Annual Book of ASTM Standards, Vol 07.02.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D 5034 – 95 (2001)

in.), the specimen is gripped in the clamp with approximately 5. Significance and Use

37.5 mm (1.5 i

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.