ASTM C1053-00(2015)

(Specification)Standard Specification for Borosilicate Glass Pipe and Fittings for Drain, Waste, and Vent (DWV) Applications (Withdrawn 2019)

Standard Specification for Borosilicate Glass Pipe and Fittings for Drain, Waste, and Vent (DWV) Applications (Withdrawn 2019)

ABSTRACT

This specification covers chemically resistant, low expansion, Type I, borosilicate glass, Class A, used to manufacture corrosion-resistant pipe and fittings for drain, waste, and vent service. The pipe and fittings covered by the specification are intended for chemical resistant service above and below grade under gravity flow or vacuum conditions. The pipe and fittings shall have beaded or plain ends. The chemical and physical requirements shall conform to the requirements specified.

SCOPE

1.1 This specification covers chemically resistant, low expansion, Type I, borosilicate glass, Class A (see Specification E438), used to manufacture corrosion-resistant pipe and fittings for drain, waste, and vent service.

1.2 The pipe and fittings covered by the specification are intended for chemical resistant service above and below grade under gravity flow or vacuum conditions.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.4 The pipe and fittings shall have beaded or plain ends.

WITHDRAWN RATIONALE

This specification covers chemically resistant, low expansion, Type I, borosilicate glass, Class A (see Specification E438), used to manufacture corrosion-resistant pipe and fittings for drain, waste, and vent service.

Formerly under the jurisdiction of Committee C14 on Glass and Glass Products, this test method was withdrawn in November 2019. This standard is being withdrawn without replacement due to its limited use by industry.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:C1053 −00 (Reapproved 2015)

Standard Specification for

Borosilicate Glass Pipe and Fittings for Drain, Waste, and

Vent (DWV) Applications

This standard is issued under the fixed designation C1053; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.6 Accessory items such as couplings, drains, adapters,

and cutters.

1.1 This specification covers chemically resistant, low

expansion,TypeI,borosilicateglass,ClassA(seeSpecification

4. Materials and Manufacture

E438), used to manufacture corrosion-resistant pipe and fit-

tings for drain, waste, and vent service.

4.1 The glass components shall represent good workman-

ship as consistent with standard glass process capabilities.

1.2 The pipe and fittings covered by the specification are

intended for chemical resistant service above and below grade

5. Chemical Requirements

under gravity flow or vacuum conditions.

1.3 The values stated in inch-pound units are to be regarded

5.1 The chemical requirements shall be as described in

as standard. The values given in parentheses are mathematical

Specification E438.

conversions to SI units that are provided for information only

and are not considered standard.

6. Physical Requirements

1.4 The pipe and fittings shall have beaded or plain ends.

6.1 The physical requirements shall be as described in

Specification E438.

2. Referenced Documents

6.2 Refer also to AnnexA1 for additional physical require-

2.1 ASTM Standards:

ments.

C600Test Method of Thermal Shock Test on Glass Pipe

C623Test Method for Young’s Modulus, Shear Modulus,

7. Operating Temperatures

and Poisson’s Ratio for Glass and Glass-Ceramics by

Resonance

7.1 Minimum Operating Temperature—The minimum rated

C693Test Method for Density of Glass by Buoyancy

operating temperature for all sizes shall be −40°F (−40°C)

E438Specification for Glasses in Laboratory Apparatus

provided the material being conveyed is fluid.

7.2 Maximum Operating Temperature—The maximum

3. Ordering Information

rated continuous operating temperature shall be 212°F

3.1 The minimum ordering information for material under

(100°C).

this specification shall include the following information:

7.3 Thermal Shock Resistance—The maximum allowable

3.1.1 ASTM designation and date of issue,

temperature differential for installed systems shall be in accor-

3.1.2 Manufacturer’s catalog number or parts identification,

dance with Table 1 for the various pipe sizes. Maximum

3.1.3 Quantity ordered,

temperature differential refers to an almost instantaneous

3.1.4 Special test or certification requirements,

temperature change, such as low-pressure steam followed

3.1.5 Special packaging or marking, if required, and

directly by a flush of ice cold water, or the reverse. Maximum

temperaturedifferentialpertainstoeitherinsideoroutsidepipe

surfaces.

This specification is under the jurisdiction ofASTM Committee C14 on Glass

and Glass Products and is the direct responsibility of Subcommittee C14.05 on

7.3.1 Thermal shock resistance is not ordinarily tested. If

Glass Pipe.

thermal shock resistance may be questioned, it shall be tested

Current edition approved Nov. 1, 2015. Published November 2015. Originally

in accordance with Method C600. If all pieces tested pass the

approved in 1985. Last previous edition approved in 2010 as C1053–00(2010).

DOI: 10.1520/C1053-00R15.

allowable temperature differential, the lot shall be accepted. If

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

one or more failures occur, a retest shall be made using a

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

sample size twice that of the first test. If any failures occur on

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. the retest, the entire shipment shall be retested.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

C1053−00 (2015)

TABLE 1 Maximum Temperature Differential for Thermal Shock

any difference between the remaining flange face and the other

Pipe Size, in. (mm) Sudden Temperature Difference, Max surface plate shall be measured with Feller gages. Differences

°F (°C)

shallnotexceedtheamountshowninTable2fortherespective

1 ⁄2 –3 (38–76) 200 (93)

fitting size.

4 (102) 175 (78)

6 (152) 160 (71) 9.1.3 Flange Dimensions and Specifications—Beaded

flange dimensions shall be as required by the manufacturer for

the system.

8. Pressure Rating

9.2 Bow:

9.2.1 Bow for All Pipe Diameters—Bow shall be measured

8.1 DWVpipingsystemsaredesignedforgravityflowonly.

by supporting the pipe in “V” blocks approximately 2 in. from

8.2 All pipe sizes are suitable for vacuum service.

each end with a dial gage at midlength, rotating the pipe full

360°.Thetotaldialdeflectiondividedbytwoisthemeasureof

9. Dimensions and Permissible Variations

bow, which shall not exceed 0.25% of the pipe length.

9.1 Beaded Flanges:

9.3 Dimensions of All Pipe and Fittings:

9.1.1 Flange Face Flatness—Maximum permissible devia-

9.3.1 Dimensional specifications for pipe and common fit-

tion from a flat plane across the face of a flange on all sizes

tingsshallbeasshowninthemanufacturer’sliterature.Typical

shall be ⁄16 in. (1.6 mm).

configurations are as illustrated in Figs. 1-45.

9.1.2 Flange Face Squareness—Flange faces of both pipe

and fittings shall be square to the pipe centerline within the

10. Inspection

limits prescribed in Table 2.

10.1 Inspection of the material shall be made at the point of

9.1.2.1 Squareness of straight pipe lengths shall be mea-

deliveryunlessotherwiseagreeduponbythepurchaserandthe

sured by placing the pipe on rollers, located approximately 2

seller.

in. (51 mm) from each end, and butting one end against a flat

plate perpendicular to the axis of the rollers. The pipe shall be

11. Packaging

rotated and length variation read with a suitable mechanism,

11.1 Pipe, fittings, and hardware shall be so packaged as to

suchasadialindicator.Themaximumreadingshallnotexceed

prevent damage during transportation and handling. Those

that shown in Table 2 for the respective pipe size.

items packed in containers conforming to all construction

9.1.2.2 Pipe fittings shall be measured for flange squareness

requirements of consolidated freight classification as to burst-

byagagehavingflatplatesconstructedattheanglerequiredby

ingtests,sizelimit,andgrossmassshallbeconsideredasbeing

that fitting. One flange shall be firmly placed on one plate, and

properly packed.

11.2 All hardware items shall be packed in such a way as to

TABLE 2 Flange Face Squareness

preventcontactwithglasscomponents.Sometypicalhardware

Nominal Pipe Size, in. Squareness Measurement, Max, in

1 1

items are shown in Appendix X1.

1 ⁄2 to 2 ⁄32

3 ⁄64

4 ⁄16

12. Keywords

6 ⁄64

12.1 borosilicate; components; fittings; glass; pipe

C1053−00 (2015)

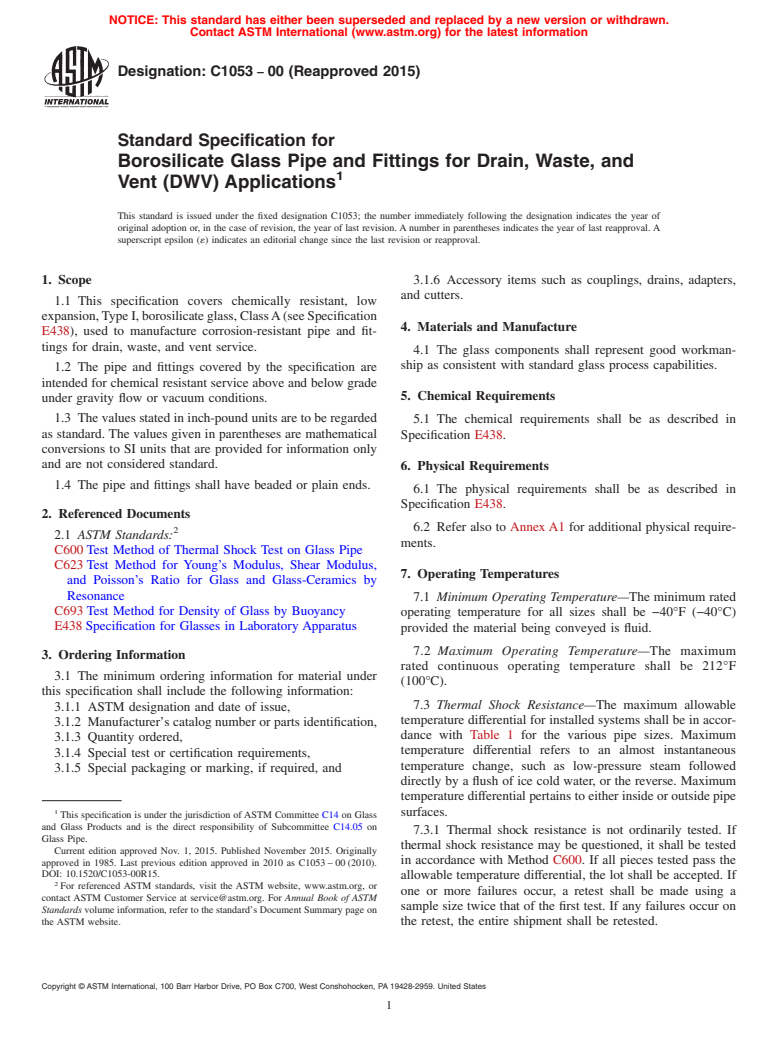

Wall

A (OD) B (OD)

A

Size, in. Thickness, Length, ft

Diameter, in. Diameter, in.

in.

1 ⁄2 2.06 1.84 0.17 5 and 10

2 2.58 2.34 0.17 5 and 10

3 3.69 3.41 0.20 5 and 10

4 4.84 4.53 0.27 5 and 10

6 7.12 6.66 0.33 5 and 10

A

Length includes coupling allowance.

A

Nominal OD Over EPS

1 13

1 ⁄2 in. 2 ⁄16

2in. 3 ⁄16

3in. 5

4in. 6 ⁄4

6in. 8 ⁄16

A

Pipe with EPS (expanded polystyrene) covering for underground service; lengths

of 5 ft only.

FIG. 1 Standard Specifications for Straight Lengths of Pipe

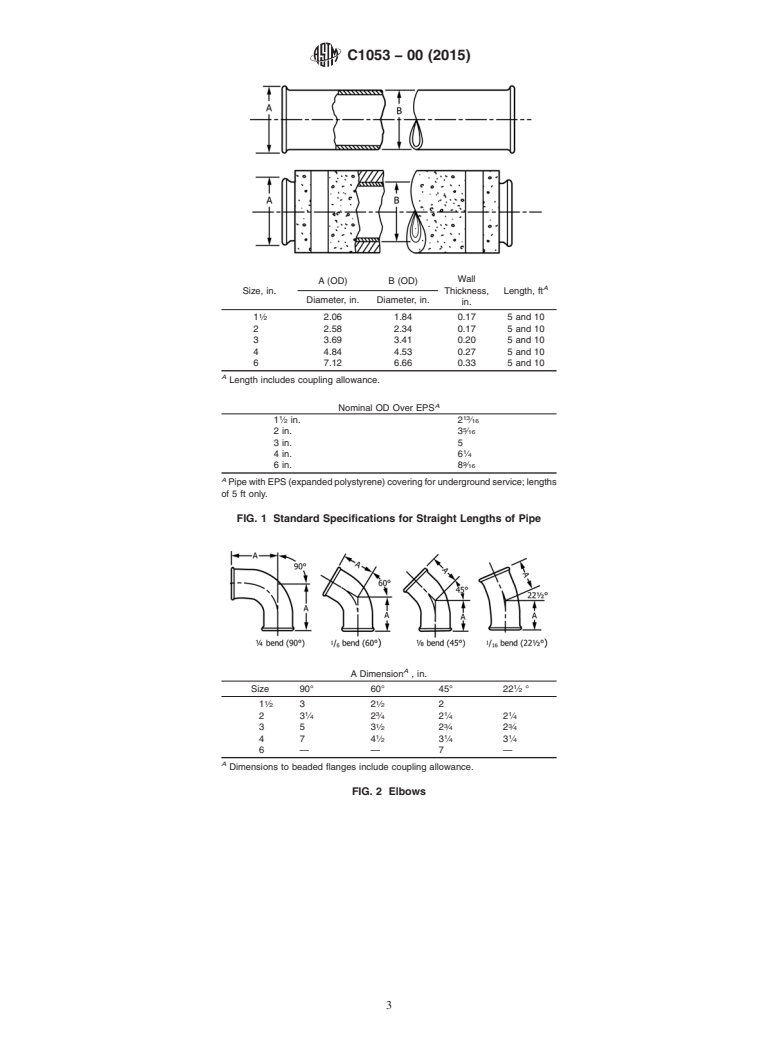

A

A Dimension ,in.

Size 90° 60° 45° 22 ⁄2 °

1 1

1 ⁄232 ⁄2 2

1 3 1 1

23 ⁄4 2 ⁄4 2 ⁄4 2 ⁄4

1 3 3

35 3 ⁄2 2 ⁄4 2 ⁄4

1 1 1

47 4 ⁄2 3 ⁄4 3 ⁄4

6— — 7 —

A

Dimensions to beaded flanges include coupling allowance.

FIG. 2 Elbows

C1053−00 (2015)

FIG. 3Elbow

A

A Dimensions ,in.

Size 90° 60° 45° 22 ⁄2 °

1 1 1 1 1

1 ⁄2 4 ⁄2 4 ⁄2 4 ⁄2 4 ⁄2

25 5 5 5

1 1 1 1

36 ⁄2 6 ⁄2 6 ⁄2 6 ⁄2

49 9 9 9

612 12 12 12

A

Dimensions to beaded flanges include coupling allowance.

FIG. 4 Sweep Elbows

A

Dimensions ,in.

Size A B (min)

A 1 3

2by1 ⁄2 41 ⁄4

Dimensions

1 1

3by1 ⁄2 52 ⁄4

Size A B

1 1 3by2 5 2 ⁄4

2by1 ⁄2 43 ⁄2

1 4by1 ⁄2 73

3by1 ⁄2 54

4by2 7 3

3by2 5 4 ⁄2

1 1 4by3 7 3

4by1 ⁄2 74 ⁄2

6by1 ⁄2 94

4by2 7 5

1 6by2 9 4

4by3 7 5 ⁄2

1 1

6by3 9 4

6by1 ⁄2 95 ⁄2

6by4 9 4

6by2 9 6

6by3 9 6 ⁄2 A

Dimensions to beaded flanges include coupling allowance.

6by4 9 8

A

Dimensions to beaded flanges include coupling allowance. FIG. 6 Straight Reducers and Eccentric Reducers

FIG. 5 Quarter Bend Reducer

C1053−00 (2015)

A

Dimensions ,in.

Size A B C

1 1

1 ⁄2 by 1 ⁄263 3

1 1

2by1 ⁄2 83 ⁄4 4

2by2 8 4 4

1 1

3by1 ⁄2 12 4 ⁄2 6

3by2 12 4 ⁄2 6

3by3 12 6 6

4by1 ⁄2 14 5 7

4by2 14 5 7

4by3 14 6 ⁄2 7

4by4 14 8 7

6by3 20 7 ⁄4 10

6by4 20 9 10

6 by 6 20 10 10

A

Dimensions to beaded flanges include cou

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.