ASTM F1636-95e1

(Specification)Specification for Bores and Cones for Modular Femoral Heads (Withdrawn 2001)

Specification for Bores and Cones for Modular Femoral Heads (Withdrawn 2001)

SCOPE

1.1 This specification covers the functional dimensions and tolerances for tapered cones of proximal femoral stems and the bores of mating ceramic and metal heads.

1.2 This specification does not cover the dimensions of proximal femoral stems other than the cone portion, nor does it cover the dimensions of the ceramic/metal femoral heads, other than the inside tapers.

1.3 The dimensions stated in SI units are to be regarded as the standard.

1.4 The purpose of this specification is to codify matching bore and cone combinations for easy identification. Nonetheless, components from different manufacturers should not be mixed because the combinations of tolerances within the family, surface finish, and configuration from the different manufacturers may not have been validated through axial load strengths or fatigue strength.

1.5 The codification described in this specification represents the most current state of the art at the time of balloting. Future additions can be made but because of the time required to revise the specification, it is recommended that the manufacturer of new combinations label their components with at least the angles until such time that new code letters can be established in accordance with future revisions of this specification.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

e1

Designation: F 1636 – 95

Standard Specification for

Bores and Cones for Modular Femoral Heads

This standard is issued under the fixed designation F 1636; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

e NOTE—Editorial changes were made throughout in December 1996.

1. Scope Surgical Implants (Special Quality)

F 562 Specification for Wrought Cobalt-Nickel-Chromium-

1.1 This specification covers the functional dimensions and

Molybdenum Alloy for Surgical Implant Applications

tolerances for tapered cones of proximal femoral stems and the

F 563 Specification for Wrought Cobalt-Nickel-Chromium-

bores of mating ceramic and metal heads.

Molybdenum-Tungsten-Iron Alloy for Surgical Implant

1.2 This specification does not cover the dimensions of

Applications

proximal femoral stems other than the cone portion, nor does it

F 603 Specification for High-Purity Dense Aluminum Ox-

cover the dimensions of the ceramic/metal femoral heads, other

ide for Surgical Implant Application

than the inside tapers.

F 620 Specification for Titanium 6Al, 4V ELI Alloy Forg-

1.3 The dimensions stated in SI units are to be regarded as

ings for Surgical Implants

the standard.

F 621 Specification for Stainless Steel Forgings for Surgical

1.4 The purpose of this specification is to codify matching

Implants

bore and cone combinations for easy identification. Nonethe-

F 799 Specification for Thermomechanically Processed

less, components from different manufacturers should not be

Cobalt-Chromium-Molybdenum Alloy Forgings for Surgi-

mixed because the combinations of tolerances within the

cal Applications

family, surface finish, and configuration from the different

F 961 Specification for Cobalt-Nickel-Chromium-

manufacturers may not have been validated through axial load

Molybdenum Alloy Forgings for Surgical Implant Appli-

strengths or fatigue strength. Information supplied by the

cations

manufacturer with the implants should include a precaution

F 1108 Specification for Ti-6Al, 4V Alloy Castings for

statement that informs the user (surgeon) that bores and cones

Surgical Implants

with the same code letter from different manufacturers should

not be used without first consulting the supplier of the femoral

3. Terminology

components.

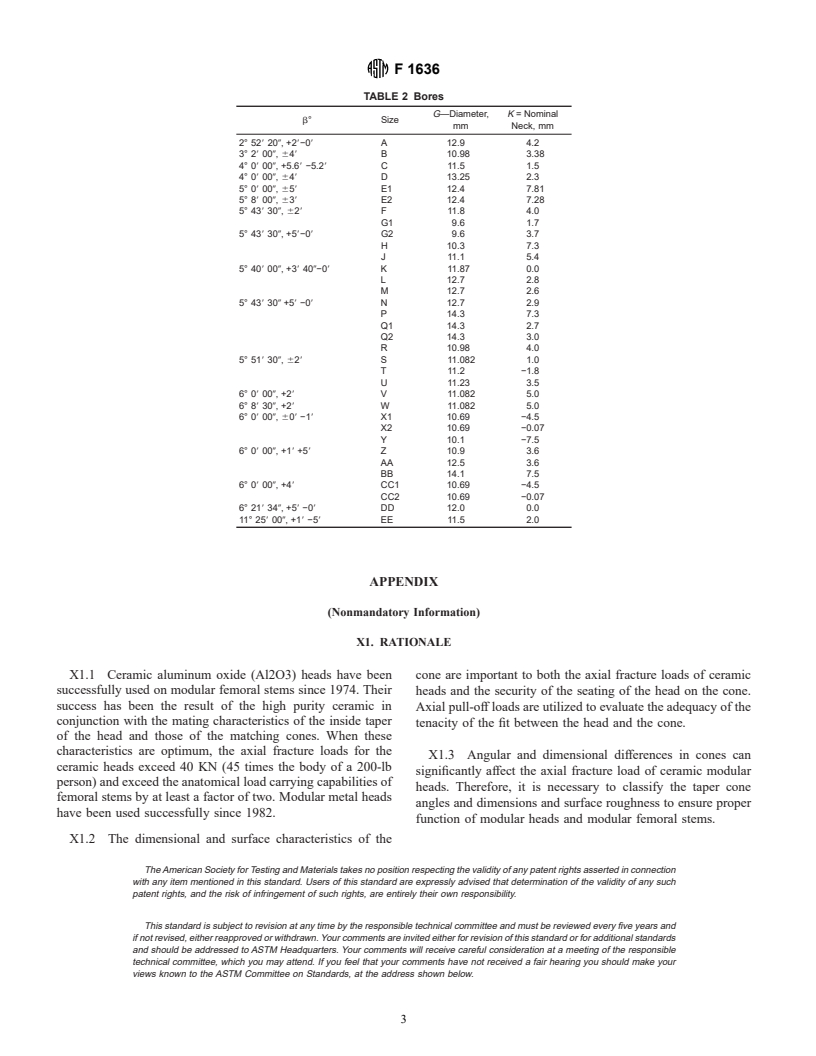

3.1 Definitions:

1.5 The codification described in this specification repre-

3.1.1 nominal neck length—the distance, K, parallel to the

sents the most current state of the art at the time of balloting.

taper axis, between the theoretical gage point and the horizon-

Future additions can be made but because of the time required

tal plane through the center of the head; this distance does not

to revise the specification, it is recommended that the manu-

include standard variants used to adjust for resection level, leg

facturer of new combinations label their components with at

length, and so forth. The K dimension may be plus or minus

least the angles until such time that new code letters can be

(proximal or distal to the location of the theoretical gage Point

established in accordance with future revisions of this specifi-

G).

cation.

3.1.2 residual or free length—the distance, A, parallel to the

2. Referenced Documents cone axis, between the end of the cone and the theoretical gage

point.

2.1 ASTM Standards:

3.1.3 theoretical gage point—the diameter, G, at nominal

F 75 Specification for Cast-Cobalt-ChromiumMolybdenum

tolerance, where the stem cone (external taper) theoretically

Alloy for Surgical Implant Applications

engages the femoral head bore (internal taper).

F 136 Specification for Wrought Titanium 6A1, 4V ELI

Alloy for Surgical Implant Applications

4. Materials

F 138 Specification for Stainless Steel Bar and Wire for

4.1 The cones may be made from any of the implantable

grade materials used for femoral stems including: Specifica-

This specification is under the jurisdiction of ASTM Committee F-4 on Medical

tions F 75, F 136, F 138, F 562, F 563, F 620, F 621, F 799,

and Surgical Materials and Devices and is under the direct responsibility of

F 961, and F 1108.

Subcommittee F04.22 on Arthroplasty.

4.2 The ceramic heads may be made from Specification

Current edition approved Dec. 10, 1995. Published June 1996.

F 603 or a material determined to be substantially equivalent or

Annual Book of ASTM Standards, Vol 13.01.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

F 1636

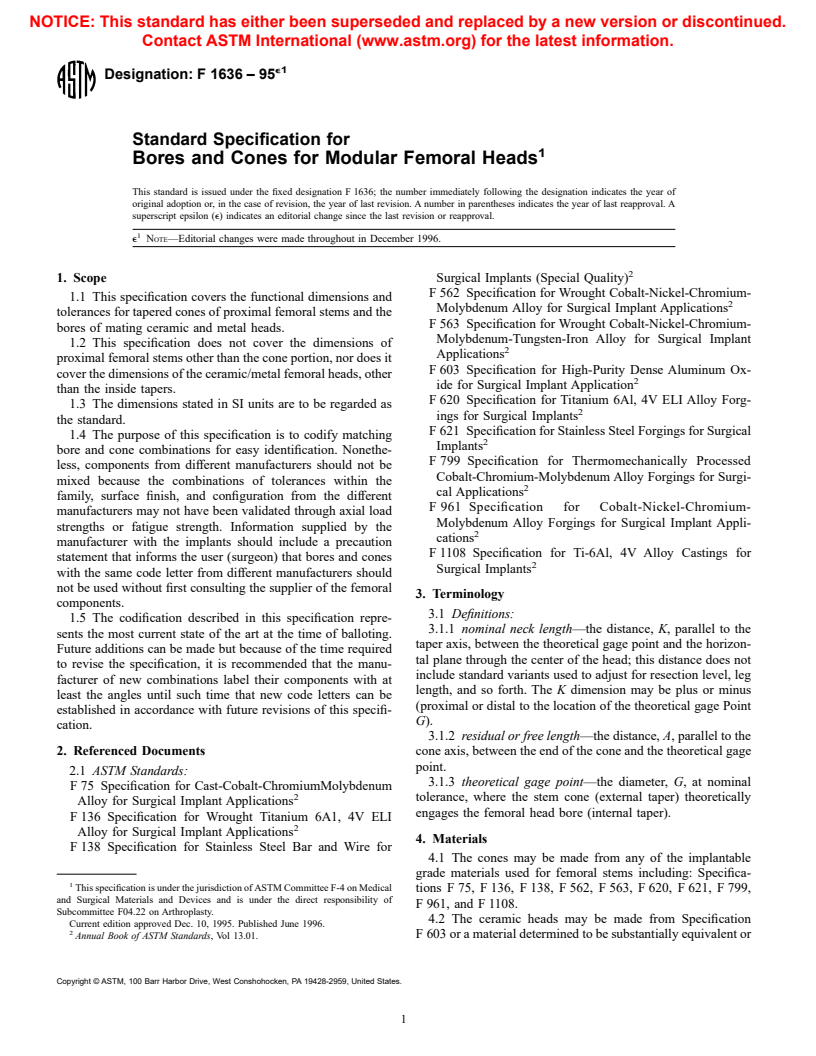

TABLE 1 Cones

superior in mechanical strength, wear properties, and biocom-

patibility. The metal heads may be made from any of the G—Diameter, A—Dimension,

a° Size

mm mm

recognized materials used for femoral stems including:

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.