ASTM D4048-19

(Test Method)Standard Test Method for Detection of Copper Corrosion from Lubricating Grease

Standard Test Method for Detection of Copper Corrosion from Lubricating Grease

SIGNIFICANCE AND USE

5.1 This test method measures the tendency of lubricating grease to corrode copper under specific static conditions. It may be of some value in predicting possible chemical attack on lubricated parts, such as bearings that contain copper or copper alloys. Such corrosion, for example, can cause premature bearing failures. However, no correlations with actual field service, most of which are under dynamic conditions, have been established. It does not measure either the ability of the lubricant to inhibit copper corrosion caused by factors other than the lubricant itself nor does it measure the stability of the grease in the presence of copper.

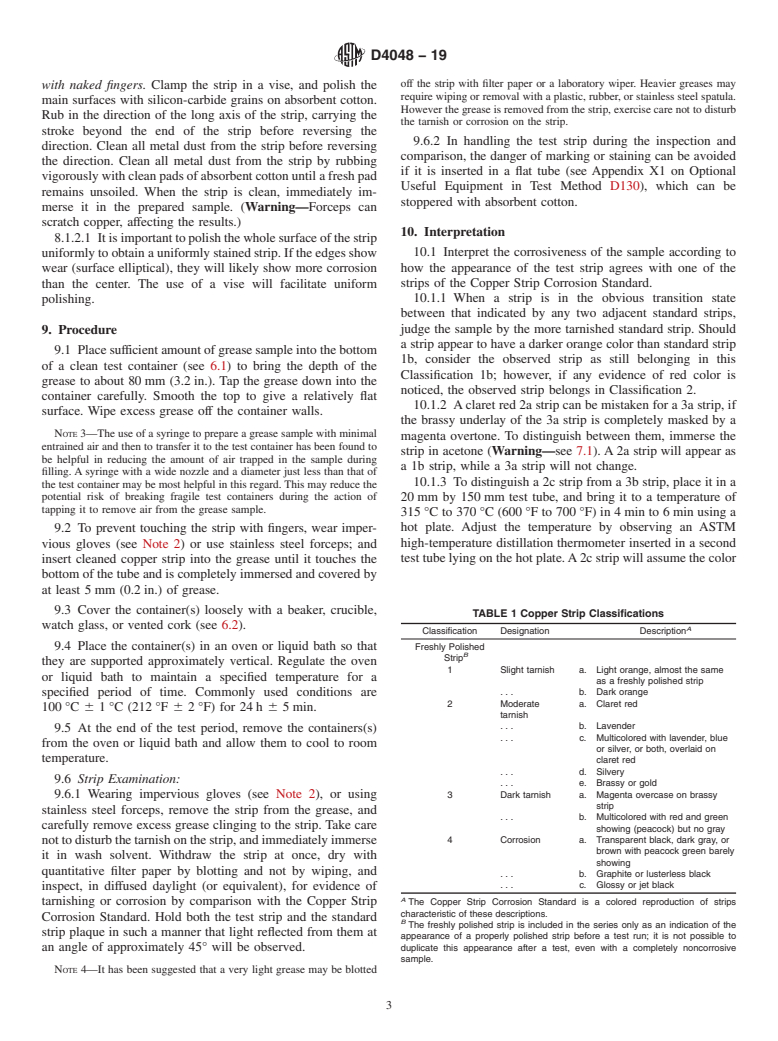

Note 1: Because this test method requires the ability to determine subtle differences in color of copper strips, persons with certain types of color blindness may find it difficult to accurately compare a test strip to the Copper Strip Corrosion Standard.

SCOPE

1.1 This test method covers the detection of the corrosiveness to copper of lubricating grease.

1.2 The values stated in SI units are to be regarded as the standard.

1.2.1 Exception—The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. For specific warning statements, see Sections 7, 8, and 10.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D4048 − 19

Standard Test Method for

1

Detection of Copper Corrosion from Lubricating Grease

This standard is issued under the fixed designation D4048; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope* 3. Terminology

1.1 This test method covers the detection of the corrosive- 3.1 Definitions—See Terminology D4175.

ness to copper of lubricating grease.

3.2 copper corrosion, n—effect of a chemical attack on

coppermetalbyalubricantcausingvariouslevelsoftarnishing

1.2 The values stated in SI units are to be regarded as the

and change in appearance.

standard.

3.2.1 Discussion—Acidic and other aggressive species, of-

1.2.1 Exception—The values given in parentheses are for

ten sulfur-based, in a lubricant can attack copper or copper

information only.

alloys present in bearings or other lubricated surfaces. The

1.3 This standard does not purport to address all of the

presence of this antagonistic interaction is often apparent in a

safety concerns, if any, associated with its use. It is the

well-defined series of color changes.

responsibility of the user of this standard to establish appro-

3.3 lubricant, n—any material interposed between two sur-

priate safety, health, and environmental practices and deter-

faces that reduces the friction or wear between them.

mine the applicability of regulatory limitations prior to use.

For specific warning statements, see Sections 7, 8, and 10.

3.4 lubricating grease, n—a semi-fluid to solid product of a

1.4 This international standard was developed in accor-

dispersion of a thickener in a liquid lubricant.

dance with internationally recognized principles on standard-

3.4.1 Discussion—The dispersion of the thickener forms a

ization established in the Decision on Principles for the

two-phase system and immobilizes the liquid lubricant by

Development of International Standards, Guides and Recom-

surface tension and other physical forces. Other ingredients are

mendations issued by the World Trade Organization Technical

commonly included to impart special properties.

Barriers to Trade (TBT) Committee.

4. Summary of Test Method

2. Referenced Documents

4.1 Aprepared copper strip is totally immersed in a sample

2

2.1 ASTM Standards:

of grease and heated in an oven or liquid bath at a specified

D97 Test Method for Pour Point of Petroleum Products

temperature for a definite period of time. Commonly used

D130 Test Method for Corrosiveness to Copper from Petro-

conditions are 100 °C 6 1 °C (212 °F 6 2 °F) for 24 h 6

leum Products by Copper Strip Test

5 min. At the end of this heating period, the strip is removed,

D2500 Test Method for Cloud Point of Petroleum Products

washed, and compared with the Copper Strip Corrosion Stan-

and Liquid Fuels

dard.

D4175 Terminology Relating to Petroleum Products, Liquid

Fuels, and Lubricants

5. Significance and Use

2.2 ASTM Adjuncts:

5.1 This test method measures the tendency of lubricating

3

Copper Strip Corrosion Standard

grease to corrode copper under specific static conditions. It

maybeofsomevalueinpredictingpossiblechemicalattackon

1

This test method is under the jurisdiction of ASTM Committee D02 on

lubricated parts, such as bearings that contain copper or copper

Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of

alloys. Such corrosion, for example, can cause premature

Subcommittee D02.G0.01 on Chemical and General Laboratory Tests.

bearing failures. However, no correlations with actual field

Current edition approved June 1, 2019. Published September 2019. Originally

ɛ1

published in 1981. Last previous edition approved in 2016 as D4048 – 16 . DOI:

service, most of which are under dynamic conditions, have

10.1520/D4048-19.

been established. It does not measure either the ability of the

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

lubricant to inhibit copper corrosion caused by factors other

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

than the lubricant itself nor does it measure the stability of the

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

grease in the presence of copper.

3

Available from ASTM International Headquarters. Order Adjunct No.

ADJD0130. Originally produced in 1973. NOTE 1—Because this test method requires the ability to determine

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation: D4048 − 16 D4048 − 19

Standard Test Method for

1

Detection of Copper Corrosion from Lubricating Grease

This standard is issued under the fixed designation D4048; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1

ε NOTE—Subsections 8.1.1 and 8.1.2 were corrected editorially in October 2017.

1. Scope*

1.1 This test method covers the detection of the corrosiveness to copper of lubricating grease.

1.2 The values stated in SI units are to be regarded as the standard.

1.2.1 Exception—The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of

regulatory limitations prior to use. For specific warning statements, see Sections 7, 8, and 10.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

D97 Test Method for Pour Point of Petroleum Products

D130 Test Method for Corrosiveness to Copper from Petroleum Products by Copper Strip Test

D2500 Test Method for Cloud Point of Petroleum Products and Liquid Fuels

D4175 Terminology Relating to Petroleum Products, Liquid Fuels, and Lubricants

2.2 ASTM Adjuncts:

3

Copper Strip Corrosion Standard

3. Terminology

3.1 Definitions—See Terminology D4175.

3.2 copper corrosion, n—effect of a chemical attack on copper metal by a lubricant causing various levels of tarnishing and

change in appearance.

3.2.1 Discussion—

Acidic and other aggressive species, often sulfur-based, in a lubricant can attack copper or copper alloys present in bearings or

other lubricated surfaces. The presence of this antagonistic interaction is often apparent in a well-defined series of color changes.

3.3 lubricant, n—any material interposed between two surfaces that reduces the friction or wear between them.

3.4 lubricating grease, n—a semi-fluid to solid product of a dispersion of a thickener in a liquid lubricant.

3.4.1 Discussion—

1

This test method is under the jurisdiction of ASTM Committee D02 on Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of Subcommittee

D02.G0.01 on Chemical and General Laboratory Tests.

Current edition approved Dec. 1, 2016June 1, 2019. Published January 2017September 2019. Originally published in 1981. Last previous edition approved in 20102016

ɛ1

as D4048 – 10.D4048 – 16 . DOI: 10.1520/D4048-16E01.10.1520/D4048-19.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from ASTM International Headquarters. Order Adjunct No. ADJD0130. Originally produced in 1973.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D4048 − 19

The dispersion of the thickener forms a two-phase system and immobilizes the liquid lubricant by surface tension and other

physical forces. Other ingredients are commonly included to impart special properties.

4. Summary of Test Method

4.1 A prepared copper strip is totally immersed in a sample of grease and heated in an oven or liquid bath at a specified

temperature for a definite period of time. Commonly used conditions are 100 °C 6 1 °C (212 °F 6 2 °F) for 24 h 6 5 min. At the

end of this heating period, the strip is removed, washed, and compared with the Copper Strip Corrosion Standard.

5. Significance and Use

5.1 This test method measures the tendency of lubricating grease to corrode copper under specific static conditions. It may be

of some value in predicting possible chemical attack on lub

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.