ASTM E468-90(1998)

(Practice)Standard Practice for Presentation of Constant Amplitude Fatigue Test Results for Metallic Materials

Standard Practice for Presentation of Constant Amplitude Fatigue Test Results for Metallic Materials

SCOPE

1.1 This practice establishes the desirable and minimum information to be communicated between the originator and the user of data derived from constant-force amplitude axial, bending, or torsion fatigue test of metallic materials tested in air and at room temperature.

Note 1-Practice E 466, although not directly referenced in the text, is considered important enough to be listed in this standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E 468 – 90 (Reapproved 1998)

Standard Practice for

Presentation of Constant Amplitude Fatigue Test Results for

Metallic Materials

This standard is issued under the fixed designation E 468; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3.2 criterion of failure—complete separation, or the pres-

ence of a crack of specified length visible at a specified

1.1 This practice establishes the desirable and minimum

magnification. Other criteria may be used but should be clearly

information to be communicated between the originator and

defined.

the user of data derived from constant-force amplitude axial,

3.3 run-out—no failure at a specified number of load cycles.

bending, or torsion fatigue tests of metallic materials tested in

air and at room temperature.

4. Significance and Use

NOTE 1—Practice E 466, although not directly referenced in the text, is

4.1 Fatigue test results may be significantly influenced by

considered important enough to be listed in this standard:

the properties and history of the parent material, the operations

performed during the preparation of the fatigue specimens, and

2. Referenced Documents

the testing machine and test procedures used during the

2.1 ASTM Standards:

generation of the data. The presentation of fatigue test results

E 6 Terminology Relating to Methods of Mechanical Test-

should include citation of basic information on the material,

ing

specimens, and testing to increase the utility of the results and

E 8 Test Methods for Testing of Metallic Materials

to reduce to a minimum the possibility of misinterpretation or

E 206 Definitions of Terms Relating to Fatigue Testing and

improper application of those results.

the Statistical Analysis of Fatigue Data

E 466 Practice for Conducting Force Controlled Constant

5. Listing of Basic Information About Fatigue Test

Amplitude Axial Fatigue Tests of Metallic Materials

Specimen

E 467 Practice for Verification of Constant Amplitude

5.1 Specification and Properties of Material:

Dynamic Loads on Displacements in an Axial Load

5.1.1 Material Prior to Fatigue Test Specimen

Fatigue Testing System

Preparation—The minimum information to be presented

2.2 Special Technical Publications:

should include the designation or specification (for example, A

STP 91 A Guide for Fatigue Testing and the Statistical

441, SAE 1070, and so forth) or proprietary grade; form of

Analysis of Fatigue Data

product (for example, plate, bar, casting, and so forth); heat

STP 588 Manual on Statistical Planning and Analysis

number; melting practice; last mechanical working and last

heat treatment that produced the material in the “as-received”

3. Terminology Definitions and Nomenclature

condition (for example, cold-worked and aged, annealed and

3.1 The terms and abbreviations used in this practice are

rolled, and so forth); chemical composition; and surface

defined in Terminology E 6 and in Definitions E 206. In

condition (for example, rolled and descaled, ground, and so

addition, the following nomenclature is used:

forth).

5.1.1.1 It is desirable but not required (unless by mutual

consent of the originator and user of the data) to list the raw

material production sequence, billet preparation, results of

This practice is under the jurisdiction of ASTM Committee E-8 on Fatigue and

Fracture and is the direct responsibility of Subcommitee E08.05 on Cyclic cleanliness analysis, or a combination thereof, when appli-

Deformation and Fatigue Crack Formation.

cable.

Current edition approved April 27, 1990. Published June 1990. Originally

5.1.2 Material in the Fatigue Test Specimen:

published as E 468 – 72 T. Last previous edition E468 — 82.

5.1.2.1 Mechanical Properties—The minimum data on the

Annual Book of ASTM Standards, Vol 03.01.

Discontinued, See 1986 Annual Book of ASTM Standards, Vol 03.01.

mechanical properties of the material in a condition identical to

A Guide for Fatigue Testing and the Statistical Analysis of Fatigue Data, ASTM

that of the fatigue test specimen should include the tensile

STP 91 A, ASTM, 1963. Out of print; available from University Micro- films, Inc.,

strength, yield point or yield strength at a specified onset;

300 N. Zeeb Rd., Ann Arbor, MI 48106.

Manual on Statistical Planning and Analysis, ASTM STP 588, ASTM, 1975. elongation in a specified gage length; reduction of area when

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

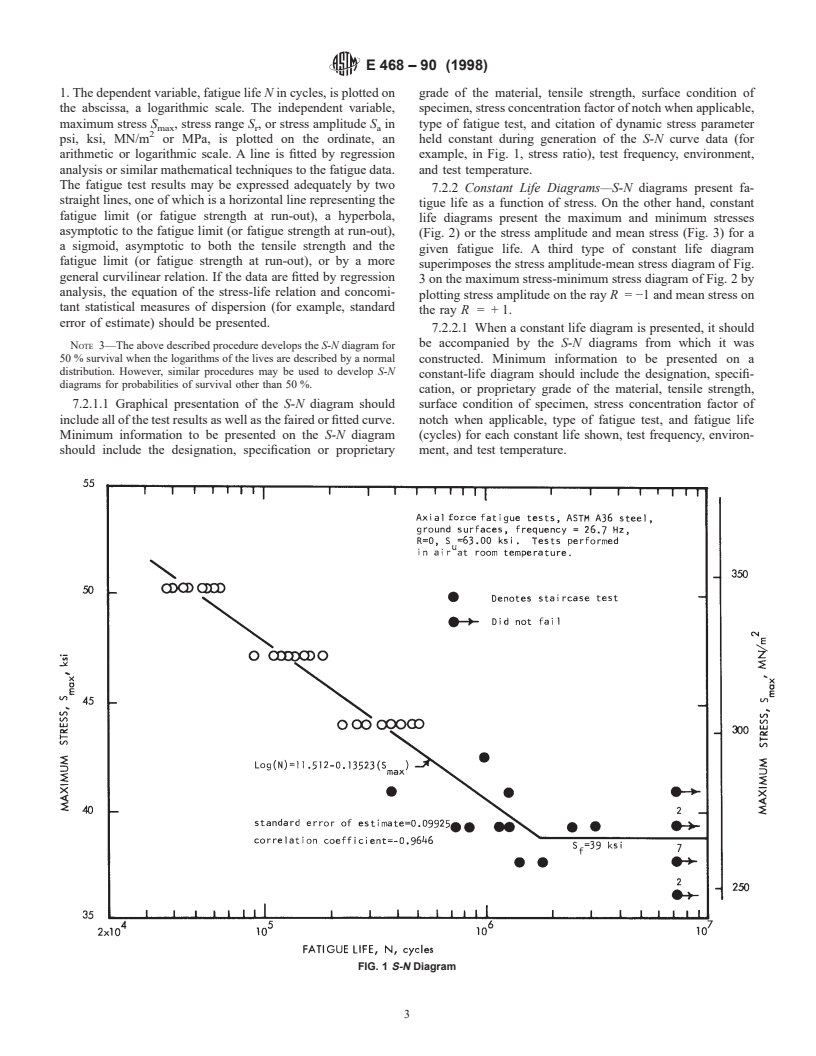

E 468 – 90 (1998)

applicable; and the designation of the test used to procure the used to accommodate expected or observed heterogeneities

mechanical properties (for example, ASTM Methods E 8, should be presented. Statistical techniques are described in

4 5

Tension Testing of Metallic Materials, and so forth). If notched ASTM STP 91 and STP 588 .

fatigue tests were conducted, the notched tensile strength also 6.2 Fatigue Testing Machine:

should be listed. 6.2.1 Minimum information to be presented should include

5.1.2.2 Metallography—It is desirable but not required the type of testing machine, the functional characteristic (for

(unless by mutual consent of the originator and user of the example, electrohydraulic, crank and lever, rotating mass, etc.),

data) to list the grain size (when applicable), phases and frequency of force application, and forcing function (for

dispersions characteristic of the fatigue test specimen in the example, sine, square, etc.). If tests were performed on more

“ready-to-test” condition. than one machine, the number of testing machines used should

5.1.2.3 It is desirable but not required (unless by mutual be listed.

consent of the originator and user of the data) to show the 6.2.2 Minimum information should include the method of

locations, in the parent material, from which the specimens dynamic force verification and force monitoring procedures.

were taken.

NOTE 2—For guidance on axial load machines, refer to Practice E 467.

5.2 Minimum Information to Be Presented on Design of

6.3 Fatigue Test:

Fatigue Test Specimen in the “Ready-To-Test” Conditions:

6.3.1 Minimum information to be presented should include

5.2.1 Shape, Size, and Dimensions—A drawing showing

the type of test (axial, rotary bending, plane bending, or

shape, size, and dimensions of the fatigue test specimen should

torsion), the derivation (or method of computation) of the test

be presented including details on test section, grip section,

section dynamic stresses, and, when applicable, the experimen-

fillets, radii, swaged portions, holes, and orientation of the

tal stress analysis techniques (for example, electric resistance

fatigue test specimen with respect to the direction of maximum

strain gages, photoelastic coating, etc.) used. The failure

working of the material. When reporting the test results of

criterion and number of cycles to run-out used in the test

notched fatigue specimens, the geometry of the notch, its

program should be presented.

dimensions and stress concentration factor, the method of

6.3.1.1 It is desirable but not required (unless by mutual

derivation of the stress concentration factor, and whether the

consent of the originator and user of the data) to include the

stress concentration factor is based on the gross or net area of

procedure for mounting the specimen in the testing machine,

the test section should be presented.

grip details, and precautions taken to ensure that stresses

5.3 Listing of Information on Specimen Preparation:

induced by vibration, friction, eccentricity, etc., were negli-

5.3.1 The minimum information to be presented should list,

gible.

in chronological order, the operations performed on the fatigue

6.4 Ambient Conditions During the Fatigue Test—Mini-

test specimen, including the type of process used to form the

mum information to be presented should include the average

specimen (for example, milling, turning, grinding, etc.), ther-

value and ranges of both temperature and relative humidity that

mal treatment (for example, stress relieving, aging, etc.), and

were observed in the laboratory during the test program.

surface treatment (for example, shot-peening, nitriding, coat-

6.5 Results of Post-Test Examination—Minimum informa-

ing, etc.). If the final specimen surface treatment is polishing,

tion to be presented for each fatigue test specimen should

the polishing sequence and direction should be listed. If

include the reason for test termination, either achievement of

deterioration of the specimen surface is observed during

the failure criterion or run-out, and, if applicable, a description

storage, after preparation but prior to testing, the procedures

of the failure surface appearance and location of the crack

that were used to eliminate the defects and changes, if any, in

origin.

shape, dimensions, or mechanical properties should be listed.

5.3.1.1 It is desirable but not required (unless by mutual

7. Presentation of Fatigue Test Results

consent of the originator and user of the data) to include details

7.1 Tabular Presentation—It is desirable but not required

of the operations performed (for example, feed, speed, depth of

(unless by mutual consent of the originator and user of the

cut and coolants, thermal cycles, etc.), and the surface residual

data) that the fatigue test results be reported in tabular form.

stresses of the specimen, if measured.

When used, the tabular presentation should inc

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.