ASTM F2971-13

(Practice)Standard Practice for Reporting Data for Test Specimens Prepared by Additive Manufacturing

Standard Practice for Reporting Data for Test Specimens Prepared by Additive Manufacturing

SIGNIFICANCE AND USE

4.1 Due to variables unique to each AM process and piece of equipment, it is critical to standardize descriptions used to report the preparation, processing, and post processing of specimens produced for tests or evaluation. The intent of this practice is to consistently document the materials and processing history associated with specimens undergoing test or evaluation. The level of detail for the documentation will match the application.

4.2 This practice establishes minimum data element requirements for reporting of material and process data for the purpose of:

4.2.1 Standardizing test specimen descriptions and test reports,

4.2.2 Assisting designers by standardizing AM materials databases,

4.2.3 Aiding material traceability through testing and evaluation,

4.2.4 Capturing property-parameter-performance relationships of AM specimens to enable predictive modeling and other computational approaches.

SCOPE

1.1 This practice describes a standard procedure for reporting results by testing or evaluation of specimens produced by additive manufacturing (AM). This practice provides a common format for presenting data for AM specimens, for two purposes: (1) to establish further data reporting requirements, and (2) to provide information for the design of material property databases.

1.2 The values stated in SI units are required for all additive manufacturing related standards. However, when this standard is used in combination with any test method or equipment specified in inch-pound units the results should be reported with mathematical conversions to SI units immediately following in parentheses. The conversions shall be provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F2971 − 13

Standard Practice for

Reporting Data for Test Specimens Prepared by Additive

1

Manufacturing

This standard is issued under the fixed designation F2971; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

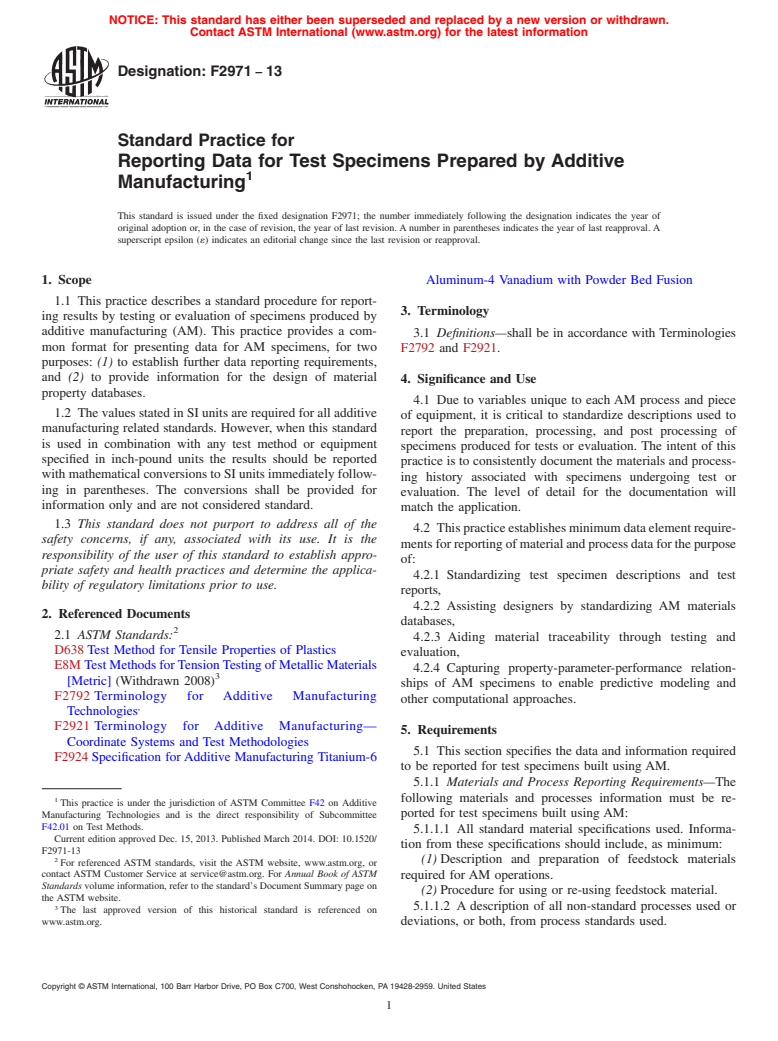

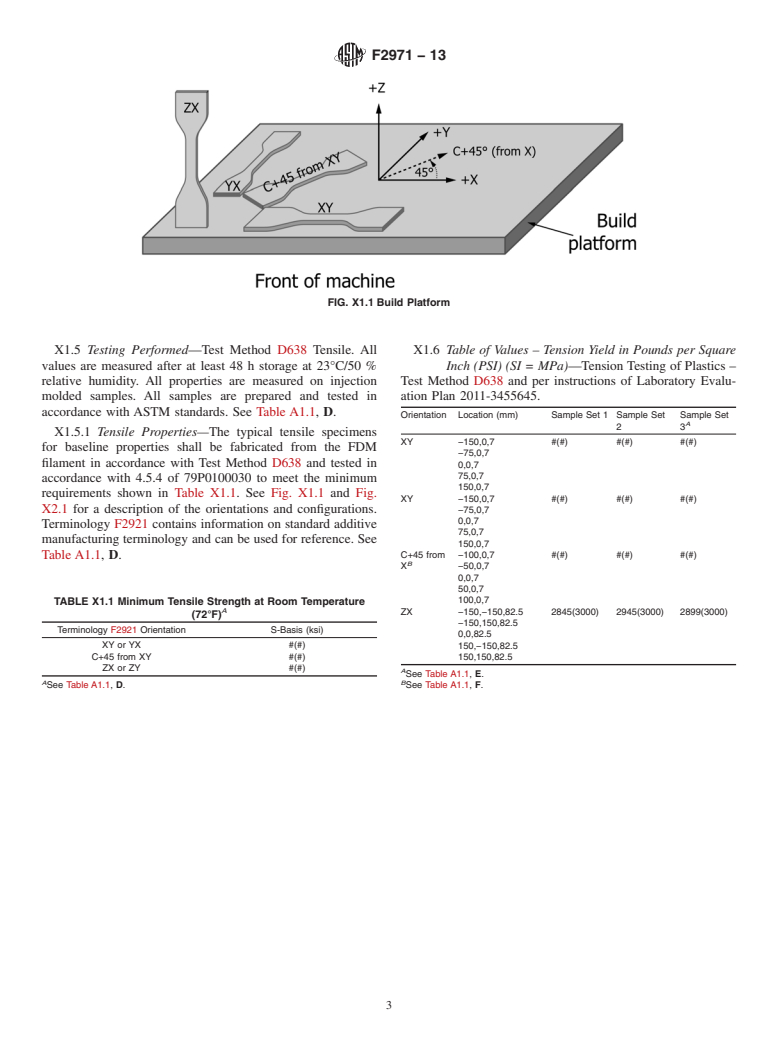

1. Scope Aluminum-4 Vanadium with Powder Bed Fusion

1.1 This practice describes a standard procedure for report-

3. Terminology

ing results by testing or evaluation of specimens produced by

additive manufacturing (AM). This practice provides a com-

3.1 Definitions—shall be in accordance with Terminologies

mon format for presenting data for AM specimens, for two

F2792 and F2921.

purposes: (1) to establish further data reporting requirements,

and (2) to provide information for the design of material

4. Significance and Use

property databases.

4.1 Due to variables unique to each AM process and piece

1.2 The values stated in SI units are required for all additive

of equipment, it is critical to standardize descriptions used to

manufacturing related standards. However, when this standard

report the preparation, processing, and post processing of

is used in combination with any test method or equipment

specimens produced for tests or evaluation. The intent of this

specified in inch-pound units the results should be reported

practice is to consistently document the materials and process-

with mathematical conversions to SI units immediately follow-

ing history associated with specimens undergoing test or

ing in parentheses. The conversions shall be provided for

evaluation. The level of detail for the documentation will

information only and are not considered standard.

match the application.

1.3 This standard does not purport to address all of the

4.2 Thispracticeestablishesminimumdataelementrequire-

safety concerns, if any, associated with its use. It is the

mentsforreportingofmaterialandprocessdataforthepurpose

responsibility of the user of this standard to establish appro-

of:

priate safety and health practices and determine the applica-

4.2.1 Standardizing test specimen descriptions and test

bility of regulatory limitations prior to use.

reports,

4.2.2 Assisting designers by standardizing AM materials

2. Referenced Documents

databases,

2

2.1 ASTM Standards:

4.2.3 Aiding material traceability through testing and

D638 Test Method for Tensile Properties of Plastics

evaluation,

E8M Test Methods forTensionTesting of Metallic Materials

4.2.4 Capturing property-parameter-performance relation-

3

[Metric] (Withdrawn 2008)

ships of AM specimens to enable predictive modeling and

F2792 Terminology for Additive Manufacturing

other computational approaches.

,

Technologies

F2921 Terminology for Additive Manufacturing—

5. Requirements

Coordinate Systems and Test Methodologies

5.1 This section specifies the data and information required

F2924 Specification for Additive Manufacturing Titanium-6

to be reported for test specimens built using AM.

5.1.1 Materials and Process Reporting Requirements—The

following materials and processes information must be re-

1

This practice is under the jurisdiction of ASTM Committee F42 on Additive

Manufacturing Technologies and is the direct responsibility of Subcommittee ported for test specimens built using AM:

F42.01 on Test Methods.

5.1.1.1 All standard material specifications used. Informa-

Current edition approved Dec. 15, 2013. Published March 2014. DOI: 10.1520/

tion from these specifications should include, as minimum:

F2971-13

2

(1) Description and preparation of feedstock materials

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

required for AM operations.

Standards volume information, refer to the standard’s Document Summary page on

(2) Procedure for using or re-using feedstock material.

the ASTM website.

3

5.1.1.2 A description of all non-standard processes used or

The last approved version of this historical standard is referenced on

www.astm.org. deviations, or both, from process standards used.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F2971 − 13

5.1.1.3 All standard process specifications used. Informa- (2) The test plan. Note: this can be incorporated in the

tion form these specifications should include, as a minimum: materials and process specifications.

(1) All processes used to produce the specimen from (3) Test procedures.

feedstock material. (4) Non-destructive inspection procedures and results.

(2) Placement and orientation of

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.