ASTM B788/B788M-00

(Practice)Standard Practice for Installing Factory-Made Corrugated Aluminum Culverts and Storm Sewer Pipe

Standard Practice for Installing Factory-Made Corrugated Aluminum Culverts and Storm Sewer Pipe

SCOPE

1.1 This practice describes procedures, soils, and soil placement for the proper installation of corrugated aluminum culverts and storm sewers in either trench or projection installations. A typical trench installation is shown in Fig. 1, and a typical embankment (projection) installation is shown in Fig. 2. The pipes described in this practice are manufactured in a factory and furnished to the job in lengths ordinarily from 10 to 30 ft [3 to 9 m], with 20 ft [6m] being common, for field joining.

1.2 This practice is applicable to either inch-pound units as B788 or to SI units as B788M. Inch-pound units are not necessary equivalent to SI units. SI units are shown in the text in brackets, and they are the applicable values for metric installation.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B 788/B 788M – 00

Standard Practice for

Installing Factory-Made Corrugated Aluminum Culverts and

Storm Sewer Pipe

This standard is issued under the fixed designation B 788/B 788M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope *

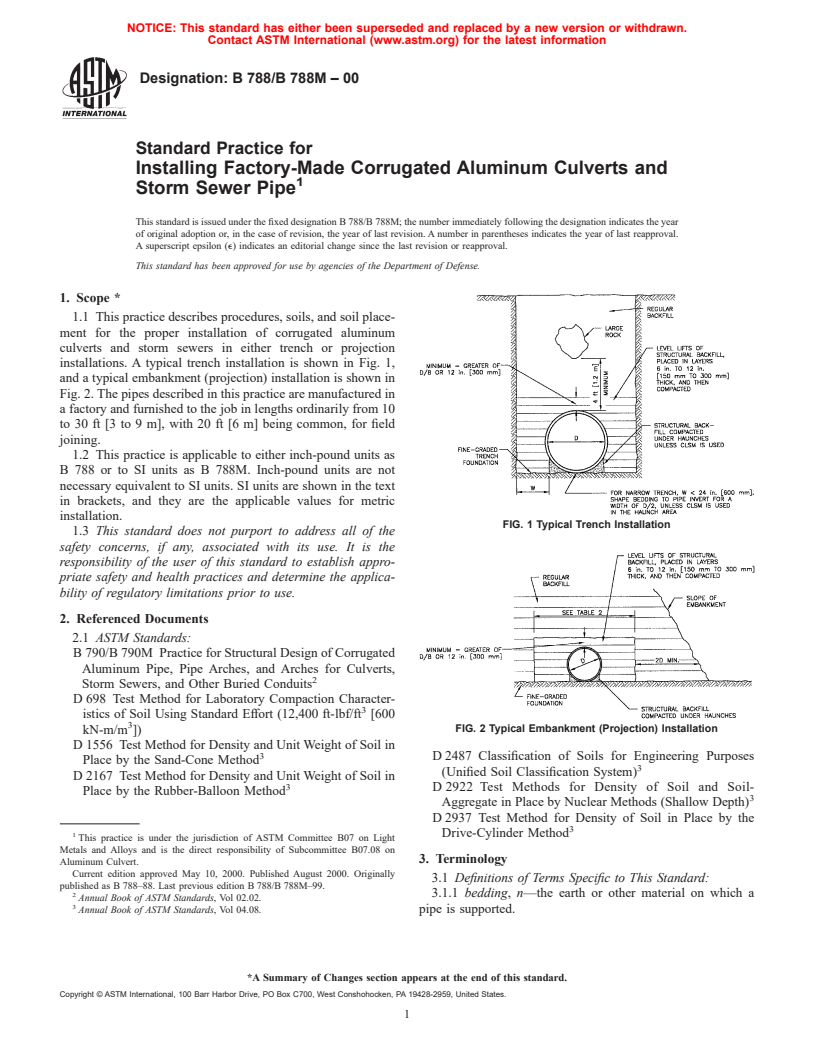

1.1 This practice describes procedures, soils, and soil place-

ment for the proper installation of corrugated aluminum

culverts and storm sewers in either trench or projection

installations. A typical trench installation is shown in Fig. 1,

and a typical embankment (projection) installation is shown in

Fig. 2. The pipes described in this practice are manufactured in

a factory and furnished to the job in lengths ordinarily from 10

to 30 ft [3 to 9 m], with 20 ft [6 m] being common, for field

joining.

1.2 This practice is applicable to either inch-pound units as

B 788 or to SI units as B 788M. Inch-pound units are not

necessary equivalent to SI units. SI units are shown in the text

in brackets, and they are the applicable values for metric

installation.

FIG. 1 Typical Trench Installation

1.3 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

B 790/B 790M Practice for Structural Design of Corrugated

Aluminum Pipe, Pipe Arches, and Arches for Culverts,

Storm Sewers, and Other Buried Conduits

D 698 Test Method for Laboratory Compaction Character-

istics of Soil Using Standard Effort (12,400 ft-lbf/ft [600

FIG. 2 Typical Embankment (Projection) Installation

kN-m/m ])

D 1556 Test Method for Density and Unit Weight of Soil in

D 2487 Classification of Soils for Engineering Purposes

Place by the Sand-Cone Method

(Unified Soil Classification System)

D 2167 Test Method for Density and Unit Weight of Soil in

D 2922 Test Methods for Density of Soil and Soil-

Place by the Rubber-Balloon Method

Aggregate in Place by Nuclear Methods (Shallow Depth)

D 2937 Test Method for Density of Soil in Place by the

1 Drive-Cylinder Method

This practice is under the jurisdiction of ASTM Committee B07 on Light

Metals and Alloys and is the direct responsibility of Subcommittee B07.08 on

3. Terminology

Aluminum Culvert.

Current edition approved May 10, 2000. Published August 2000. Originally

3.1 Definitions of Terms Specific to This Standard:

published as B 788–88. Last previous edition B 788/B 788M–99.

3.1.1 bedding, n—the earth or other material on which a

Annual Book of ASTM Standards, Vol 02.02.

Annual Book of ASTM Standards, Vol 04.08. pipe is supported.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

B 788/B 788M

3.1.2 haunch, n—the portion of the pipe cross section

between the maximum horizontal dimension and the top of the

bedding.

3.1.3 invert, n—the lowest point on the pipe cross section;

also, the bottom portion of a pipe.

3.1.4 pipe, n—a conduit having full circular shape; also, in

a general context, all structure shapes covered by this practice.

3.1.5 pipe–arch, n—a pipe with an approximate semicircu-

lar crown, small-radius corners, and large-radius invert.

4. Significance and Use

4.1 Corrugated aluminum pipe functions structurally as a

flexible ring which is supported by and interacts with the

compacted surrounding soil. The soil constructed around the

pipe is thus an integral part of the structural system. It is

therefore important to ensure that the soil structure or backfill

is made up of acceptable material and is well-constructed.

Field verification of soil structure acceptability using Test

Methods D 1556, D 2167, D 2922, or D 2937, as applicable,

and comparing the results with Test Method D 698 in accor-

d = ⁄2 in./ft [40 mm/m] of fill over pipe, with a 24-in. [600-mm] maximum.

dance with the specifications for each project, is the most

NOTE 1—Section B-B is applicable to all continuous rock foundations.

reliable basis for installation of an acceptable structure. The

FIG. 3 Foundation Transition Zones and Rock Foundations

required density and method of measurement are not specified

by this practice, but they must be established in the specifica-

tions for each project.

5. Trench Excavation

5.1 To obtain anticipated structural performance of corru-

gated aluminum pipe it is not necessary to control trench width

beyond the minimum required for proper installation of pipe

and backfill. However, the soil on each side beyond the

excavated trench must be able to support anticipated loads.

When a construction situation calls for a relatively wide trench,

it may be made as wide as required, for its full depth if so

desired. However, trench excavation must be in compliance

with any local, state, and federal codes and safety regulations.

6. Foundation

6.1 The supporting soil beneath the pipe must provide a

reasonably uniform resistance to the imposed load, both

FIG. 4 Soft Foundation Treatment

longitudinally and laterally. Sharp variations in the foundation

must be avoided. When rock is encountered, it must be

densely compacted than the soil alongside, beneath the struc-

excavated and replaced with soil. If the pipe runs along a

ture. This creates favorable relative movement between pipe

continuous rock foundation, it is necessary to provide a

and the soil on each side. It is of particular importance on

suitable soil bedding under the pipe. See Fig. 3.

pipe-arches.

6.2 Lateral changes in foundation should never be such that

6.4 Pipe-Arches—All pipe-arch structures must have excel-

the pipe is firmly supported while the backfill alongside is not.

lent soil support at their corners by both the in-situ foundation

When soft material is encountered during construction and

and the structural backfill. See Fig. 4 and Fig. 5. They do not

must be removed in order to provide an adequate foundation,

require the same degree of support under their large-radius

remove the soft material for a distance of three pipe widths,

inverts.

unless the engineer has set another limit. See Fig. 4.

6.5 The engineer is encouraged to develop details specific to

6.3 Performance of buried pipe is enhanced by allowing the

the site based on the general principles for foundation condi-

pipe to settle slightly under load compared to the columns of

tions given in 6.1 through 6.4.

soil alongside. Thus, for larger pipes it can be beneficial to

purposely create a foundation under the pipe itself which will

7. Bedding

yield under load more than will the foundation under the

columns of soil to each side. It can usually be obtained by 7.1 Corrugated aluminum pipe may be placed directly on

placing a layer of compressible soil of a suitable thickness, less the fine-graded foundation for the pipe line. Material in contact

B 788/B 788M

8.2.1.5 Other equally effective types of field joints may be

used with the approval of the engineer.

8.2.2 Joint Types—Applications may require either standard

or special joints. Standard joints are for pipe not subject to

large soil movements or disjointing forces. These joints are

satisfactory for ordinary installations, where simple slip-type

joints are typically used. Special joints are for more adverse

requirements such as the need to withstand soil movements or

resist disjointing forces. Stab joints are for pipes subject to

minimal settlement or disjointing forces. Special designs must

be considered for unusual conditions such as in poor founda-

tion conditions.

NOTE 1—Examples of stab joints are bell and spigot, and tongue and

groove.

8.2.3 Soil Conditions:

8.2.3.1 The requirements of the joints are dependent upon

the soil conditions at the construction site. Pipe backfill that is

not subject to piping action is classified as nonerodible. Such

backfill typically includes granular soil (with grain sizes

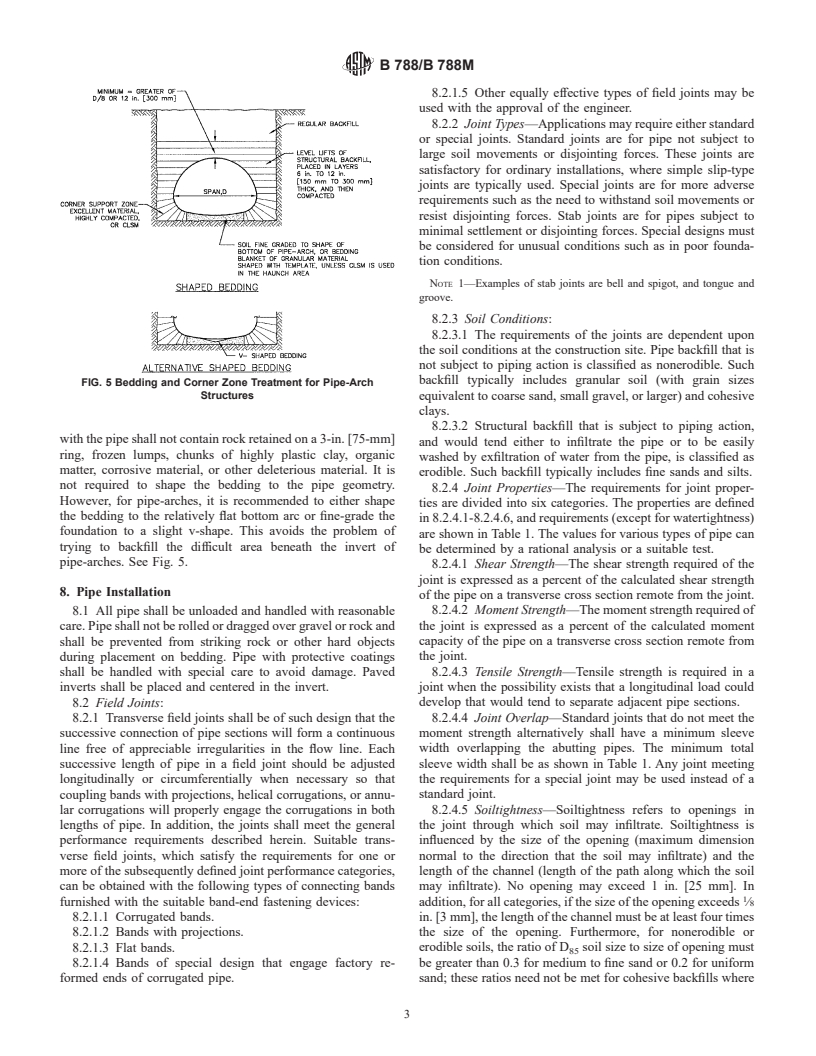

FIG. 5 Bedding and Corner Zone Treatment for Pipe-Arch

Structures equivalent to coarse sand, small gravel, or larger) and cohesive

clays.

8.2.3.2 Structural backfill that is subject to piping action,

with the pipe shall not contain rock retained on a 3-in. [75-mm]

and would tend either to infiltrate the pipe or to be easily

ring, frozen lumps, chunks of highly plastic clay, organic

washed by exfiltration of water from the pipe, is classified as

matter, corrosive material, or other deleterious material. It is

erodible. Such backfill typically includes fine sands and silts.

not required to shape the bedding to the pipe geometry.

8.2.4 Joint Properties—The requirements for joint proper-

However, for pipe-arches, it is recommended to either shape

ties are divided into six categories. The properties are defined

the bedding to the relatively flat bottom arc or fine-grade the

in 8.2.4.1-8.2.4.6, and requirements (except for watertightness)

foundation to a slight v-shape. This avoids the problem of

are shown in Table 1. The values for various types of pipe can

trying to backfill the difficult area beneath the invert of

be determined by a rational analysis or a suitable test.

pipe-arches. See Fig. 5.

8.2.4.1 Shear Strength—The shear strength required of the

joint is expressed as a percent of the calculated shear strength

8. Pipe Installation

of the pipe on a transverse cross section remote from the joint.

8.2.4.2 Moment Strength—The moment strength required of

8.1 All pipe shall be unloaded and handled with reasonable

care. Pipe shall not be rolled or dragged over gravel or rock and the joint is expressed as a percent of the calculated moment

capacity of the pipe on a transverse cross section remote from

shall be prevented from striking rock or other hard objects

during placement on bedding. Pipe with protective coatings the joint.

8.2.4.3 Tensile Strength—Tensile strength is required in a

shall be handled with special care to avoid damage. Paved

inverts shall be placed and centered in the invert. joint when the possibility exists that a longitudinal load could

develop that would tend to separate adjacent pipe sections.

8.2 Field Joints:

8.2.1 Transverse field joints shall be of such design that the 8.2.4.4 Joint Overlap—Standard joints that do not meet the

moment strength alternatively shall have a minimum sleeve

successive connection of pipe sections will form a continuous

line free of appreciable irregularities in the flow line. Each width overlapping the abutting pipes. The minimum total

successive length of pipe in a field joint should be adjusted sleeve width shall be as shown in Table 1. Any joint meeting

longitudinally or circumferentially when necessary so that the requirements for a special joint may be used instead of a

coupling bands with projections, helical corrugations, or annu- standard joint.

lar corrugations will properly engage the corrugations in both 8.2.4.5 Soiltightness—Soiltightness refers to openings in

lengths of pipe. In addition, the joints shall meet the general the joint through which soil may infiltrate. Soiltightness is

performance requirements described herein. Suitable trans- influenced by the size of the opening (maximum dimension

verse field joints, which satisfy the requirements for one or normal to the direction that the soil may infiltrate) and the

more of the subsequently defined joint performance categories, length of the channel (length of the path along which the soil

can be obtained with the following types of connecting bands may infiltrate). No opening may exceed 1 in. [25 mm]. In

furnished with the suitable band-end fastening devices: addition, for all categories, if the size of the opening exceeds ⁄8

8.2.1.1 Corrugated bands. in. [3 mm], the length of the channel must be at least four times

8.2.1.2 Bands with projections. the size of the opening. Furthermore, for nonerodible or

8.2.1.3 Flat bands. erodible soils, the ratio of D soil size to size of opening must

8.2.1.4 Bands of special design that engage factory re- be greater than 0.3 for medium to fine sand or 0.2 for uniform

formed ends of corrugated pipe. sand; these ratios need not be met for cohesive backfills where

B 788/B 788M

TABLE 1 Categories of Pipe Joints

Soil Condition

Joint Properties Nonerodible Joint Type Erodible Joint Type

A A

Stab Standard Special Stab Standard Special

Shear strength, % 225225

B

Moment strength,% 05 15 05 15

Tensile strength, min, lbf [kN]:

0 to 42-in. [0 to 1050-mm] diameter or span 0 0 5000 [22] 0 0 5000 [22]

>42 -in. [1050-mm] diameter or span 10 000 [45] 10 000 [45]

C

1 1

Joint overlap, min, in. [mm] 3 [75] 10 ⁄2 [265] NA 3 [75] 10 ⁄2 [265] NA

D

Soiltightness NA NA NA 0.3 or 0.2 0.3 or 0.2 0.3 or 0.2

A

Stab joint for maximum 42 in. [1050 mm] diameter.

B

See 8.2.4.2.

C

Alternative requirement. See 8.2.4.4.

D

Minimum ratio of D soil size to size of opening 0.3 for medium to fine sand and 0.2 for uniform sand.

A,B

TABLE 2 Structural Backfill Width Requirements

the plasticity index exceeds 12. (D is the soil diameter at

Adjacent Material Required Structural Backfill Width

which 85 % if the soil weight is finer.) As a general guideline,

Normal highway embankment As needed to establish pipe bedding and

a backfill material containing a high percentage of fine grained

compacted to minimum of to fill and compact the backfill in the

90 % Test Method D 698 haunch area and beside the pipe. Where

soils requires investigation for the specific type of joint to be

density, or equivalent trench backfill materials that do not require

used to guard against soil infiltration. Alternatively, if a joint

wall. compaction are used, such as cement

demonstrates its ability to pass a 2 psi [14 kPa] hydrostatic test

slurry or controlled low strength material

(CLSM), a minimum of 3 in. [75 mm] on

without leakage, it will be considered soiltight.

each side of the pipe is required.

8.2.4.6 Watertightness—Watertightness may be specified

Embankment or trench wall of Increase backfill width as necessary to

for joints of any category where needed to satisfy other criteria.

lesser quality. reduce horizontal pressure from pipe to

a level compatible with bearing capacity

The leakage rate shall be measured with the pipe in place or at

of adjacent materials.

an approved test facility.

A

For pipe arches and other multiple radius structures, as well as for al

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.