ASTM C305-11

(Practice)Standard Practice for Mechanical Mixing of Hydraulic Cement Pastes and Mortars of Plastic Consistency

Standard Practice for Mechanical Mixing of Hydraulic Cement Pastes and Mortars of Plastic Consistency

SIGNIFICANCE AND USE

This practice is intended for use in the mechanical mixing of pastes and mortars for the testing of hydraulic cements.

SCOPE

1.1 This practice covers the mechanical mixing of hydraulic cement pastes and mortars of plastic consistency.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

American Association State

Designation:C305–11 Highway and Transportation Officials Standard

AASHTO No.: T162

Standard Practice for

Mechanical Mixing of Hydraulic Cement Pastes and Mortars

1

of Plastic Consistency

This standard is issued under the fixed designation C305; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* clearance adjustment bracket such as the one shown in Fig. 1

(Note 1) to provide clearance between the lower end of the

1.1 This practice covers the mechanical mixing of hydraulic

paddle and the bottom of the bowl that is not greater than 2.5

cement pastes and mortars of plastic consistency.

mm but not less than 0.8 mm (Note 2) when the bowl is in the

1.2 This standard does not purport to address all of the

mixing position.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

NOTE 1—When the bracket is in the proper position beneath the motor

priate safety and health practices and determine the applica- housing, the lugs are to the front and facing upward and the heads of the

adjustment screws are to the rear and facing downward in the path of the

bility of regulatory limitations prior to use.

sliding frame that holds the bowl. It is intended that the bracket be

fastened at the front housing connection by inserting replacement screws

2. Referenced Documents

onanappropriatesizeupwardthroughtheopeningineachlugandintothe

2

2.1 ASTM Standards:

existing threaded holes in the bottom of the motor housing. The original

C511 Specification for Mixing Rooms, Moist Cabinets,

stops for the sliding frame are to be filed down if they prevent the frame

Moist Rooms, and Water Storage Tanks Used in the

from coming in contact with the adjustment screws.

Testing of Hydraulic Cements and Concretes NOTE 2—This is the approximate diameter of a grain of 20-30 sand as

described in Specification C778.

C778 Specification for Sand

4.2 Paddle—The paddle shall be readily removable, made

3. Significance and Use

of stainless steel, and shall conform to the basic design shown

3.1 This practice is intended for use in the mechanical

in Fig. 2.The dimensions of the paddle shall be such that when

mixing of pastes and mortars for the testing of hydraulic

in the mixing position the paddle outline conforms to the

cements.

contour of the bowl used with the mixer, and the clearance

betweencorrespondingpointsontheedgeofthepaddleandthe

4. Apparatus

side of the bowl in the position of closest approach shall be

4.1 Mixer—The mixer shall be an electrically driven me-

approximately 4.0 mm but not less than 0.8 mm.

chanical mixer of the epicyclic type, which imparts both a

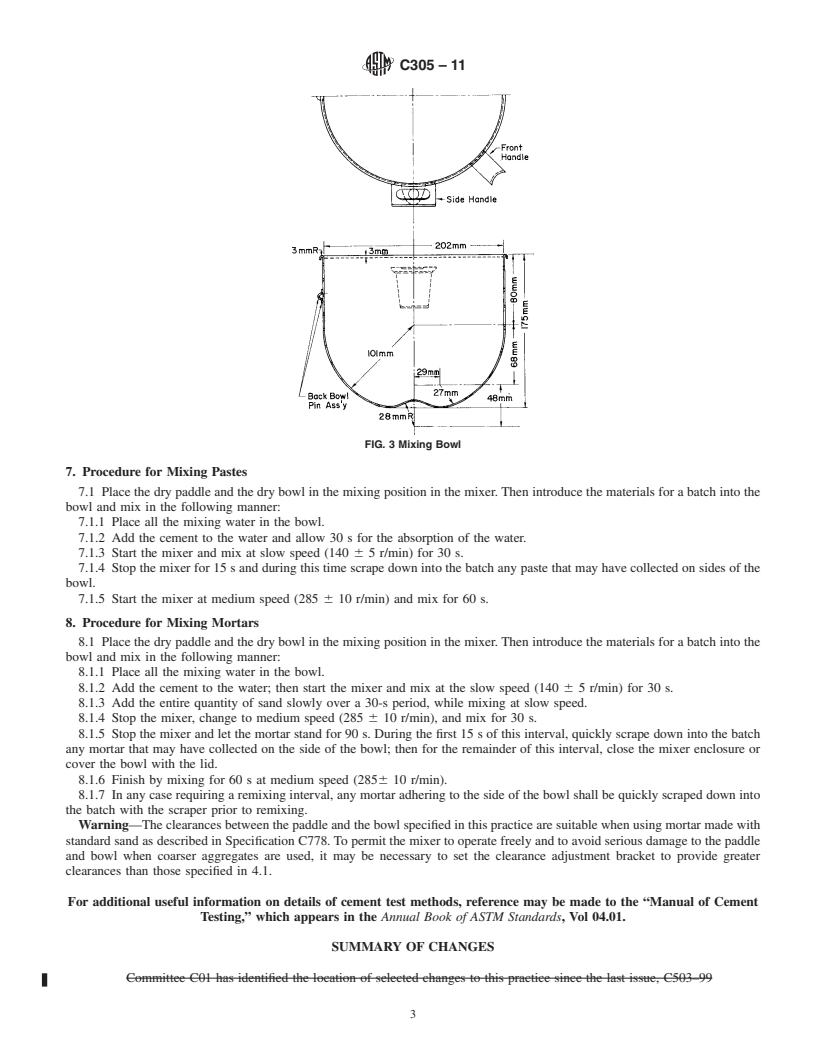

4.3 Mixing Bowl—The removable mixing bowl shall have a

planetary and a revolving motion to the mixer paddle. The

nominal capacity of 4.73 L, shall be of the general shape and

mixer shall have a minimum of two speeds, controlled by

comply with the limiting dimensions shown in Fig. 3, and shall

definite mechanical means. (Rheostat adjustment of speed will

be made of stainless steel. The bowl shall be so equipped that

not be acceptable.) The first, or slow speed shall revolve the

it will be positively held in the mixing apparatus in a fixed

paddle at a rate of 140 6 5 r/min, with a planetary motion of

position during the mixing procedure. There shall be provided

approximately 62 r/min. The second speed shall revolve the

a lid, made of a nonabsorbing material not attacked by the

paddle at a rate of 285 6 10 r/min, with a planetary motion of

cement.

approximately 125 r/min. The electric motor shall be at least

4.4 Scraper—Thescrapershallconsistofasemirigidrubber

1

124 W ( ⁄6 hp). The mixer shall be equipped with either an

blade attached to a handle about 150 mm long. The blade shall

adjustment screw which is an integral part of the mixer or a

be about 75 mm long, 50 mm wide, and tapered to a thin edge

about 2 mm thick.

1

This practice is under the jurisdiction ofASTM Committee C01 on Cement and

NOTE 3—Akitchen tool known as a plate and bowl scraper conforms to

is the direct responsibility of Subcommittee C01.22 on Workability.

these requirements.

Current edition approved April 1, 2011. Published May 2011. Originally

approved in 1953. Last previous edition approved in 2006 as C305 – 06. DOI:

4.5 Supplementary Apparatus—The balances, weights,

10.1520/C0305-11.

glass graduates, and any other supplementary apparatus used in

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

measuring and preparing the mortar materials prior to mixing

contact ASTM Customer Service at service@astm

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

American Association State

Designation:C305–06 Designation:C305–11 Highway and Transportation Officials Standard

AASHTO No.: T162

Standard Practice for

Mechanical Mixing of Hydraulic Cement Pastes and Mortars

1

of Plastic Consistency

This standard is issued under the fixed designation C305; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This practice covers the mechanical mixing of hydraulic cement pastes and mortars of plastic consistency.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards: ASTM Standards:

C511 Specification for Mixing Rooms, Moist Cabinets, Moist Rooms, and Water Storage Tanks Used in the Testing of

Hydraulic Cements and Concretes

C778 Specification for Sand

3. Significance and Use

3.1 This practice is intended for use in the mechanical mixing of pastes and mortars for the testing of hydraulic cements.

4. Apparatus

4.1 Mixer—The mixer shall be an electrically driven mechanical mixer of the epicyclic type, which imparts both a planetary

and a revolving motion to the mixer paddle. The mixer shall have a minimum of two speeds, controlled by definite mechanical

means. (Rheostat adjustment of speed will not be acceptable.) The first, or slow speed shall revolve the paddle at a rate of 140 6

5 r/min, with a planetary motion of approximately 62 r/min.The second speed shall revolve the paddle at a rate of 285 6 10 r/min,

1

withaplanetarymotionofapproximately125r/min.Theelectricmotorshallbeatleast124W( ⁄6hp).Themixershallbeequipped

with either an adjustment screw which is an integral part of the mixer or a clearance adjustment bracket such as the one shown

in Fig. 1 (Note 1) to provide clearance between the lower end of the paddle and the bottom of the bowl that is not greater than

2.5 mm but not less than 0.8 mm (Note 2) when the bowl is in the mixing position.

NOTE 1—When the bracket is in the proper position beneath the motor housing, the lugs are to the front and facing upward and the heads of the

adjustment screws are to the rear and facing downward in the path of the sliding frame that holds the bowl. It is intended that the bracket be fastened

at the front housing connection by inserting replacement screws on an appropriate size upward through the opening in each lug and into the existing

threaded holes in the bottom of the motor housing. The original stops for the sliding frame are to be filed down if they prevent the frame from coming

in contact with the adjustment screws.

NOTE 2—This is the approximate diameter of a grain of 20-30 sand as described in Specification C778.

4.2 Paddle—The paddle shall be readily removable, made of stainless steel, and shall conform to the basic design shown in Fig.

2. The dimensions of the paddle shall be such that when in the mixing position the paddle outline conforms to the contour of the

bowl used with the mixer, and the clearance between corresponding points on the edge of the paddle and the side of the bowl in

the position of closest approach shall be approximately 4.0 mm but not less than 0.8 mm.

4.3 Mixing Bowl—The removable mixing bowl shall have a nominal capacity of 4.73 L, shall be of the general shape and

comply with the limiting dimensions shown in Fig. 3, and shall be made of stainless steel. The bowl shall be so equipped that it

will be positively held in the mixing apparatus in a fixed position during the mixing procedure.There shall be provided a lid, made

of a nonabsorbing material not attacked by the cement.

1

This practice is under the jurisdiction of ASTM Committee C01 on Cement and is the direct responsibility of Subcommittee C01.22 on Workability .

´1

Current edition approved Aug. 1, 2006. Published August 2006. Originally approved in 1953. Last previous edition approved in 1999 as C305–99 . DOI:

10.1520/C0305-06.

Current edition approvedApril 1, 2011. Published May 2011. Originally approved in 1953. Last previous edition approved in 2006 as C305 – 06. DOI: 10.1520/C0305-11.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Ser

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.