ASTM F2045-00(2018)e1

(Specification)Standard Specification for Indicators, Sight, Liquid Level, Direct and Indirect Reading, Tubular Glass/Plastic

Standard Specification for Indicators, Sight, Liquid Level, Direct and Indirect Reading, Tubular Glass/Plastic

ABSTRACT

This specification covers the requirements for direct and indirect reading sight liquid level indicators for general applications. General applications for indirect reading sight glasses are water and fuel service at working pressures 2.07 MPa (300 lb/in.2) and below, temperatures of 149°C (300°F) and below. Direct reading sight glass indicators may consist of glass or plastic tubes with fittings including shutoff valves. Glass tubes may be used for low shock direct reading sight glass indicators in which the fluid is not compatible with plastic. Indirect reading indicators may consist of a sealed chamber with a magnetic float or flag indicator. Indicator designs are classified as either direct reading or indirect reading. Qualification testing and quality conformance testing shall be performed to meet the requirements prescribed.

SCOPE

1.1 This specification covers the requirements for direct and indirect reading sight liquid level indicators for general applications. General applications for indirect reading sight glasses are water and fuel service at working pressures 2.07 MPa (300 lb/in.2) and below, temperatures of 149°C (300°F) and below. General applications for direct reading sight glasses are applications in which the temperature does not exceed 66°C (150°F).

1.2 Direct reading sight glass indicators may consist of glass or plastic tubes with fittings including shutoff valves. Glass tubes may be used for low shock direct reading sight glass indicators in which the fluid is not compatible with plastic.

1.3 Indirect reading indicators may consist of a sealed chamber with a magnetic float or flag indicator.

1.4 Special requirements for naval shipboard applications are included in the supplement to this standard.

1.5 The values stated in SI units are to be regarded as standard. The values given in parentheses are mathematical conversions to inch-pound units that are provided for information only and are not considered standard.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

´1

Designation: F2045 −00 (Reapproved 2018) An American National Standard

Standard Specification for

Indicators, Sight, Liquid Level, Direct and Indirect Reading,

Tubular Glass/Plastic

This standard is issued under the fixed designation F2045; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

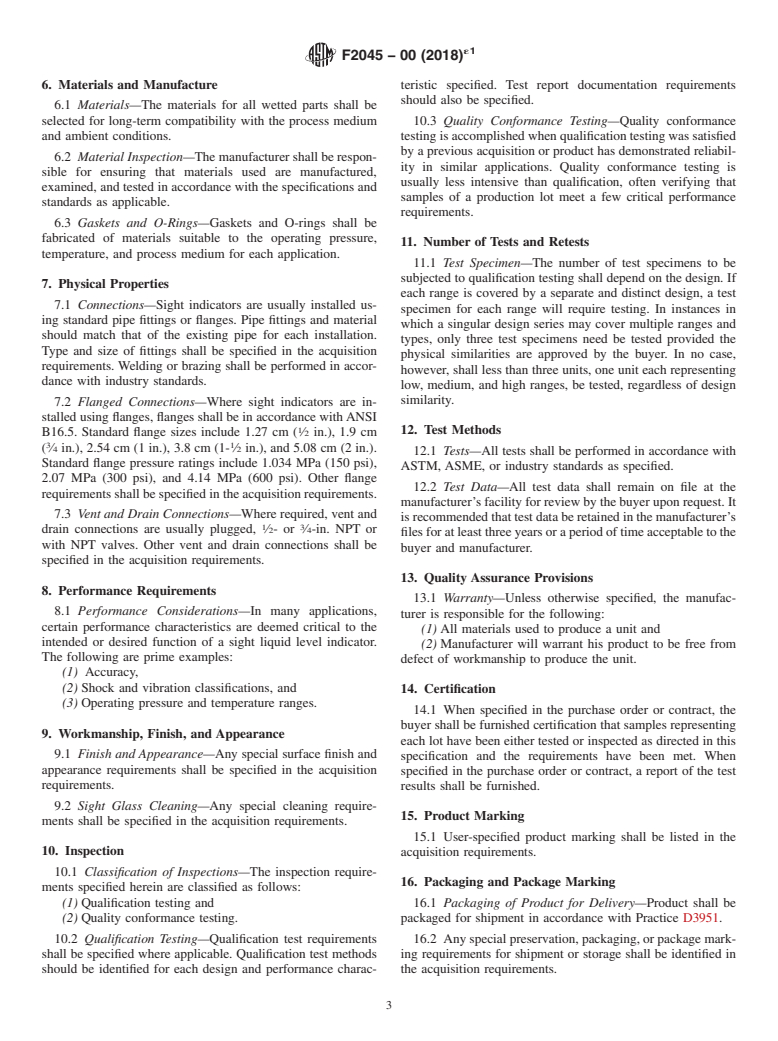

ε NOTE—A key was editorially added to Fig. 1 in January 2018.

1. Scope 2. Referenced Documents

1.1 This specification covers the requirements for direct and 2.1 ASTM Standards:

indirect reading sight liquid level indicators for general appli- D3951 Practice for Commercial Packaging

cations. General applications for indirect reading sight glasses

2.2 ANSI Standards:

are water and fuel service at working pressures 2.07 MPa (300 B16.5 Pipe Flanges and Flanged Fittings (DoD adopted)

lb/in. ) and below, temperatures of 149°C (300°F) and below.

3. Terminology

General applications for direct reading sight glasses are appli-

cations in which the temperature does not exceed 66°C

3.1 Definitions:

(150°F).

3.1.1 SI (Le Systeme International d’Unites) Units—units of

measurement recognized by the CIPM (Comite’ International

1.2 Directreadingsightglassindicatorsmayconsistofglass

des Poids et Mesures).

or plastic tubes with fittings including shutoff valves. Glass

tubes may be used for low shock direct reading sight glass

4. Design Classification

indicators in which the fluid is not compatible with plastic.

4.1 Types—Indicator designs are classified as either direct

1.3 Indirect reading indicators may consist of a sealed

reading or indirect reading. Both types are depicted in Fig. 1,

chamber with a magnetic float or flag indicator.

complete with dimensions that facilitate ordering.

1.4 Special requirements for naval shipboard applications

4.2 Special Considerations—Special considerations that

are included in the supplement to this standard.

may affect selection and installation are listed below. This is

1.5 The values stated in SI units are to be regarded as

not to be construed as a complete listing.

standard. The values given in parentheses are mathematical

(1) Type of indicator,

conversions to inch-pound units that are provided for informa-

(2) Manual or automatic shutoff valves,

tion only and are not considered standard.

(3) Indication length of liquid level range,

(4) Method of connection,

1.6 This international standard was developed in accor-

(5) Location of indicator relative to vibrating equipment,

dance with internationally recognized principles on standard-

(6) Protection of the instrumentation,

ization established in the Decision on Principles for the

(7) Application of each indicator,

Development of International Standards, Guides and Recom-

(8) Cleaning procedure or reference to the cleaning proce-

mendations issued by the World Trade Organization Technical

dure being used, and

Barriers to Trade (TBT) Committee.

1 2

This specification is under the jurisdiction of ASTM Committee F25 on Ships For referenced ASTM standards, visit the ASTM website, www.astm.org, or

and Marine Technology and is the direct responsibility of Subcommittee F25.10 on contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Electrical. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved Jan. 1, 2018. Published January 2018. Originally the ASTM website.

approved in 2000. Last previous edition approved in 2011 as F2045 – 00 (2011). Available from American National Standards Institute (ANSI), 25 W. 43rd St.,

DOI: 10.1520/F2045-00R18E01. 4th Floor, New York, NY 10036, http://www.ansi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

F2045 − 00 (2018)

Dimensions (mm)

A Distance between center of top attachment flange face and top of indicator tube

B Distance between center of bottom attachment flange face and bottom of indicator tube

C Length of piping between outer tube wall and connection to tank attachment flange

D Distance between outer tube wall and outer edge of tank attachment flange

L Distance between center of attachment flange faces

FIG. 1 Indicator Design Types

(9) Selection of indicator for compatibility with materials, (5) Final disposition of qualification test samples;

temperature, pressure, ambient environment, and with the

(6) Environmental requirements;

parameter being measured.

(7) Operating media;

(8) Viscosity and specific gravity of fluid for indirect

5. Ordering Information

indicators;

5.1 The buyer shall provide the manufacturer with all of the

(9) Materials;

pertinent application data outlined in the acquisition require-

(10) Indication length;

ments.

(11) Size and type of connections;

(12) Shutoff valve requirements;

5.2 Acquisition Requirements—Acquisitiondocumentsshall

(13) Cleaning requirements;

specify the following:

(14) When certification is required;

(1) Title, number, and date of this specification;

(15) Marking requirements;

(2) Type and quantity of indicators required;

(16) Unique packaging requirements; and

(3) Manufacturer’s part number;

(4) When qualification testing is required; (17) Unique preservation requirements.

´1

F2045 − 00 (2018)

6. Materials and Manufacture teristic specified. Test report documentation requirements

should also be specified.

6.1 Materials—The materials for all wetted parts shall be

selected for long-term compatibility with the process medium 10.3 Quality Conformance Testing—Quality conformance

and ambient conditions. testing is accomplished when qualification testing was satisfied

by a previous acquisition or product has demonstrated reliabil-

6.2 Material Inspection—The manufacturer shall be respon-

ity in similar applications. Quality conformance testing is

sible for ensuring that materials used are manufactured,

usually less intensive than qualification, often verifying that

examined, and tested in accordance with the specifications and

samples of a production lot meet a few critical performance

standards as applicable.

requirements.

6.3 Gaskets and O-Rings—Gaskets and O-rings shall be

fabricated of materials suitable to the operating pressure,

11. Number of Tests and Retests

temperature, and process medium for each application.

11.1 Test Specimen—The number of test specimens to be

subjected to qualification testing shall depend on the design. If

7. Physical Properties

each range is covered by a separate and distinct design, a test

7.1 Connections—Sight indicators are usually installed us-

specimen for each range will require testing. In instances in

ing standard pipe fittings or flanges. Pipe fittings and material

which a singular design series may cover multiple ranges and

should match that of the existing pipe for each installation.

types, only three test specimens need be tested provided the

Type and size of fittings shall be specified in the acquisition

physical similarities are approved by the buyer. In no case,

requirements. Welding or brazing shall be performed in accor-

however, shall less than three units, one unit each representing

dance with industry standards.

low, medium, and high ranges, be tested, regardless of design

similarity.

7.2 Flanged Connections—Where sight indicators are in-

stalled using flanges, flanges shall be in accordance withANSI

12. Test Methods

B16.5. Standard flange sizes include 1.27 cm ( ⁄2 in.), 1.9 cm

3 1

( ⁄4 in.), 2.54 cm (1 in.), 3.8 cm (1- ⁄2 in.), and 5.08 cm (2 in.).

12.1 Tests—All tests shall be performed in accordance with

Standard flange pressure ratings include 1.034 MPa (150 psi),

ASTM, ASME, or industry standards as specified.

2.07 MPa (300 psi), and 4.14 MPa (600 psi). Other flange

12.2 Test Data—All test data shall remain on file at the

requirements shall be specified in the acquisition requirements.

manufacturer’s facility for review by the buyer upon request. It

7.3 Vent and Drain Connections—Where required, vent and

isrecommendedthattestdataberetainedinthemanufacturer’s

1 3

drain connections are usually plugged, ⁄2-or ⁄4-in. NPT or

filesforatleastthreeyearsoraperiodoftimeacceptabletothe

with NPT valves. Other vent and drain connections shall be

buyer and manufacturer.

specified in the acquisition requirements.

13. Quality Assurance Provisions

8. Performance Requirements

13.1 Warranty—Unless otherwise specified, the manufac-

8.1 Performance Considerations—In many applications,

turer is responsible for the following:

certain performance characteristics are deemed critical to the

(1) All materials used to produce a unit and

intended or desired function of a sight liquid level indicator.

(2) Manufacturer will warrant his product to be free from

The following are prime examples:

defect of workmanship to produce the unit.

(1) Accuracy,

(2) Shock and vibration classifications, and

14. Certification

(3) Operating pressure and temperature ranges.

14.1 When specified in the purchase order or contract, the

buyer shall be furnished certification that samples representing

9. Workmanship, Finish, and Appearance

each lot have been either tested or inspected as directed in this

9.1 Finish and Appearance—Any special surface finish and

specification and the requirements have been met. When

appearance requirements shall be specified in the acquisition

specified in the purchase order or contract, a report of the test

requirements.

results shall be furnished.

9.2 Sight Glass Cleaning—Any special cleaning require-

15. Product Marking

ments shall be specified in the acquisition requirements.

15.1 User-specified product marking shall be listed in the

10. Inspection acquisition requirements.

10.1 Classification of Inspections—The inspection require-

16. Packaging and Package Marking

ments specified herein are classified as follows:

(1) Qualification testing and 16.1 Packaging of Product for Delivery—Product shall be

(2) Quality conformance testing. packaged for shipment in accordance with Practice D3951.

10.2 Qualification Testing—Qualification test requirements 16.2 Any special preservation, packaging, or package mark-

shall be specified where applicable. Qualification test methods ing requirements for shipment or storage shall be identified in

should be identified for each design and performance charac- the acquisition requirements.

´1

F2045 − 00 (2018)

17. Keywords

17.1 direct level indicator; indirect level indicator; liquid

level indicator; sight glass

SUPPLEMENTARY REQUIREMENTS

The following supplementary requirements established for U.S. Naval shipboard application shall

apply when specified in the contract or purchase order. When there is conflict between the standard

(Specification F2045) and this supplement, the requirements of this supplement shall take precedence

forequipmentacquiredbythissupplement.ThisdocumentsupersedesMIL-I-20037,Indicators,Sight,

Liquid Level, Direct/Indirect Reading, Tubular Glass/Plastic, for new ship construction.

INDICATORS, SIGHT, LIQUID LEVEL, DIRECT AND INDIRECT READING, TUBULAR GLASS/PLASTIC

(NAVAL SHIPBOARD USE)

S1. Scope ASTM D1784 Specification for Rigid Poly Vinyl Chloride

PVC Compounds and Chlorinated Poly Vinyl Chloride CPVC

S1.1 This supplement covers sight liquid level indicators of

Compounds (DoD adopted)

the direct and indirect reading type having tubular glass, clear

ASTM D3935 Specification for Polycarbonate (PC) Unfilled

polycarbonate, or rigid polyvinyl chloride (PVC).

and Reinforced Material

S1.2 Direct reading sight glass indicators may consist of

ASTM D3951 Practice for Commercial Packaging

glass or plastic tubes with fittings including shutoff valves.

MSS-SP-72 Ball Valves with Flanged or Butt-Welding Ends

Indirect reading indicators may consist of a sealed chamber

for General Service

with a magnetic float or flag indicator.

MSS-SP-110 Ball Valves, Threaded Socket-Welding, Solder

S1.3 Indirect indicators are intended for use in water and 4

Joint, Grooved and Flared Ends

fuel service at working pressures of 2.07 MPa (300 lb/in. ) and

S2.2 Government Documents:

below, temperatures of 149°C (300°F) and below, and for

S2.2.1 Military Standards:

hi-shock applications. Direct indicators are intended for use in

MIL-STD-167-1 Mechanical Vibrations of Shipboard

hi-shock applications and shall use plastic sight tubes where

Equipment (Type I - Environmental and Type II - Internally

the fluid is compatible and temperatures do not exceed 66°C

Excited)

(150°F). Glass tubes shall only be used for low shock appli-

S2.2.2 Military Specifications:

cationsandwherethefluidisnotcompatiblewithplastictubes.

MIL-S-901 Shock Tests, H.I. (High Impact); Shipboard

S1.4 Only direct-type indicators with glass tube material

Machinery, Equipment and Systems, Requirements for

less than 92 cm (36 in.) in length or indirect type indicators

S2.2.3 Other Government Documents: Drawings and

shall be used for hydrocarbons and flammable fluid applica-

publications, Naval Sea Systems Command (NAVSEA)

tions. 5

803-5184222 Gage Glass Ball Valve

S8700-1385802 Level Indicator Shield

S2. Referenced Documents

S9074-AR-GIB-010/278 Requirements for Fabrication

Welding and Inspection and Casting Inspection and Repair for

S2.1 Commercial Documents:

Machinery, Piping and Pressure Vessels

ANSI B16.5 Pipe Flanges and Flanged Fittings (DoD ad-

opted)

S3. Terminology

ANSI/ASQC Q9001-1994 Quality Systems—Model for

Quality Assurance in Design, Development, Production, S3.1 Definitions:

Installation, Inspection, Testing and Servicing S3.1.1 directindication—thetankfluidlevelisvisibleinthe

glass or tube.

ASTM A312/A312M Specification for Seamless and

S3.1.2 indirect indication—the tank fluid level is contained

Welded Austenitic Stainless Steel Pipes (DoD adopted)

inasealedchamberandindicatedbysomeothermeanssuchas

ASTM B61 Specification for Steam or Valve Bronze Cast-

a float or flag actuated by a magnet contained in a float in the

ings (DoD adopted)

fluid chamber.

ASTM B62 Specification for Composition Bronze or Ounce

Metal Castings (DoD adopted)

ASTM B117 Practice for Operating Salt Spray (Fog) Appa-

AvailablefromManufacturersStandardizationSocietyoftheValveandFittings

ratus

Industry (MSS), 127 Park St., NE,Vienna,VA22180-4602, http://www.mss-hq.org.

ASTMB283SpecificationforCopperandCopper-AlloyDie

Available from DLA Document Services, B

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.