ASTM E1303-95

(Practice)Practice for Refractive Index Detectors Used in Liquid Chromatography

Practice for Refractive Index Detectors Used in Liquid Chromatography

SCOPE

1.1 This practice is intended to describe tests used to evaluate the performance and to list certain descriptive specifications of a refractive index (RI) detector used as the detection component of a liquid chromatographic (LC) system.

1.2 This practice is intended to describe the performance of the detector both independent of the chromatographic system (static conditions, without flowing solvent) and with flowing solvent (dynamic conditions).

1.3 The values stated in SI units are to be regarded as the standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: E 1303 – 95

Practice for

Refractive Index Detectors Used in Liquid Chromatography

This standard is issued under the fixed designation E 1303; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope may be adapted for use at whatever conditions may be chosen

for other reasons.

1.1 This practice is intended to describe tests used to

evaluate the performance and to list certain descriptive speci-

4. Noise, Drift, and Flow Sensitivity

fications of a refractive index (RI) detector used as the

4.1 Descriptions of Terms Specific to This Standard:

detection component of a liquid chromatographic (LC) system.

4.1.1 short term noise—This noise is the mean amplitude in

1.2 This practice is intended to describe the performance of

refractive index units (RIU) for random variations of the

the detector both independent of the chromatographic system

detector signal having a frequency of one or more cycles per

(static conditions, without flowing solvent) and with flowing

min. Short term noise limits the smallest signal detectable by

solvent (dynamic conditions).

an RI detector, limits the precision attainable and sets the lower

1.3 The values stated in SI units are to be regarded as the

limit on the dynamic range. This noise corresponds to observed

standard.

noise of the RI detector only. (The actual noise of the LC

1.4 This standard does not purport to address all of the

system may be larger or smaller than the observed value,

safety concerns, if any, associated with its use. It is the

depending upon the method of data collection, or signal

responsibility of the user of this standard to establish appro-

monitoring of the detector, since observed noise is a function of

priate safety and health practices and determine the applica-

the frequency, speed of response and the band width of the

bility of regulatory limitations prior to use.

recorder or other electronic circuit measuring the detector

2. Referenced Documents signal.)

4.1.2 long term noise—this noise is the maximum ampli-

2.1 ASTM Standards:

tude in RIU for random variations of the detector signal with

E 386 Practice for Data Presentation Relating to High-

frequencies between 6 and 60 cycles per h (0.1 and 1.0 cycles

Resolution Nuclear Magnetic Resonance (NMR) Spectros-

per min). It represents noise that may be mistaken for a

copy

late-eluting peak. This noise corresponds to the observed noise

3. Significance and Use

only and may not always be present.

4.1.3 drift—the average slope of the long term noise enve-

3.1 Although it is possible to observe and measure each of

lope expressed in RIU per hour as measured over a period of

several characteristics of a detector under different and unique

1h.

conditions, it is the intent of this practice that a complete set of

4.1.4 static—refers to the noise and drift measured under

detector test results should be obtained under the same oper-

conditions of no flow.

ating conditions. It should also be noted that to specify

4.1.5 dynamic—refers to the noise and drift measured at a

completely a detector’s capability, its performance should be

flow rate of 1.0 mL/min.

measured at several sets of conditions within the useful range

4.1.6 flow sensitivity—the rate of change of signal displace-

of the detector.

ment (in RIU) vs flow rate (in mL per min) resulting from step

3.2 The objective of this practice is to test the detector under

changes in flow rate calculated at 1 mL per min as described in

specified conditions and in a configuration without an LC

4.3.12.

column. This is a separation independent test. In certain

4.2 Test Conditions:

circumstances it might also be necessary to test the detector in

4.2.1 The same test solvent must be used in both sample and

the separation mode with an LC column in the system, and the

reference cells. The test solvent used and its purity should be

appropriate concerns are also mentioned. The terms and tests

specified. Water equilibrated with the laboratory atmosphere

described in this practice are sufficiently general so that they

containing minimum impurities is the preferred test solvent for

measuring noise and drift. Water for this purpose (preferably

This practice is under the jurisdiction of ASTM Committee E13 on Molecular

purified by distillation, deionization or reverse osmosis) should

Spectoscopy and is the direct responsibility of Subcommittee E13.19 on Chroma-

tography. be drawn, filtered through a 0.45 μm filter and allowed to stand

Current edition approved May 15, 1995. Published July 1995. Originally

in a loosely covered container for several hours at ambient

published as E 1303 – 89. Last previous edition E 1303 – 89.

temperature in the laboratory in which testing is to be carried

Annual Book of ASTM Standards, Vol 03.06.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

E 1303

out. This will ensure complete equilibration of the water with should be obtained to determine if they can be decoupled for

the gases in the laboratory atmosphere. testing. Set the recorder zero to near mid-scale. Record at least

1 h of baseline under these static conditions, during which time

NOTE 1—It is essentially impossible to maintain a constant RI value of

the ambient temperature should not change by more than 2°C.

de-gassed water and of very dilute samples in de-gassed water. This is due

to the fact that the difference in refractive index between completely

NOTE 2—RI detectors will have one or more controls labeled attenua-

−6 3

de-gassed water and atmosphere-equilibrated water is 1.5 3 10 RIU.

tion, range, sensitivity, and scale factor. All are used to set the full scale

Thus, small differences in the concentration of dissolved gases between

range (in RIU) of an output display device such as a strip chart recorder.

sample and the trapped reference can lead to significant errors in

4.3.5 Draw pairs of parallel lines, each between ⁄2to 1 min

measurement of solutions where the expected difference in RI due to

−6

solute is of the order of 10 RIU or less. Therefore, in order to minimize in length, to form an envelope of all observed random

error in determining samples with small RIU differences between them,

variations over any 15 min period (Fig. 1). Draw the parallel

atmosphere-equilibrated water (5.2.1) is recommended as the solvent for

lines in such a way as to minimize the distance between them.

determining linearity and minimum detectability (Section 5).

Measure the distance perpendicular to the time axis between

4.2.2 The detector should be located at the test site and

the parallel lines. Convert this value to RIU (4.2.9). Calculate

switched on at least 24 h prior to the start of testing. Some the mean value over all the segments; this value is the static

detectors provide an oven to thermostat the optics assembly.

short term noise.

The oven should be set at a suitable temperature, following the 4.3.6 Now mark the center (center of gravity) of each

manufacturer’s recommendations, and this temperature should

segment over the 15 min period of the short term noise

be noted and maintained throughout the test procedures. measurement. Draw a series of parallel lines to these centers,

4.2.3 Linearity and speed of response of the recorder or

each 10 min in length (Fig. 1), and choose that pair of lines

other data acquisition device used should be such that it does

whose distance apart perpendicular to the time axis is greatest.

not distort or otherwise interfere with the performance of the This distance is the static long term noise.

detector. If additional amplifiers are used between the detector

4.3.7 Draw the pair of parallel lines, over the1hof

and the final readout device, their characteristics should also measurement, that minimizes the distance perpendicular to the

first be established.

time axis between the parallel lines. The slope of either line,

4.3 Methods of Measurement:

4.3.1 Connecta1m (39.37 in.) length of clean, dry,

stainless steel tubing of 0.25 mm (0.009 to 0.01 in.) inside

diameter in place of the analytical column. The tubing can be

straight, or coiled to minimize the space requirement. The

tubing should terminate in standard low dead volume fittings to

connect with the detector and to the pump. Commercial

chromatographs may already contain some capillary tubing to

connect the pump to the injection device. If this is of a similar

diameter to that specified, it should be included in the 1.0 m

length; if significantly wider, it should be replaced for this test.

4.3.2 Repeatedly rinse the reservoir and chromatographic

system, including the detector, with the test solvent prepared as

described in 4.2.1, until all previous solvent is removed from

the system. Fill the reservoir with the test solvent.

4.3.3 Thoroughly flush the reference cell with the same

solvent; keep the reference cell static.

4.3.3.1 It may be necessary to flush both sample and

reference cells with an intermediate solvent (such as methanol

or acetone), if the solvent previously used in the system is

immiscible with the test solvent.

4.3.4 Allow the chromatographic system to stabilize for at

least 60 min without flow. The detector range, Note 2, should

be set such that the amplitude of short term noise may be easily

measured. Ideally, the output should contain no filtering of the

signal. If the filtering cannot be turned off, the minimum time

constant should be set and noted in the evaluation. Manuals or

manufacturers should be consulted to determine if time con-

stant and detector range controls are coupled, and information

Munk, M. N., Liquid Chromatography Detectors, (T. M. Vickrey, Ed.), Marcel

Dekker, New York and Basel, 1983, pp. 165–204.

Bonsall, R. B., “The Chromatography Slave—The Recorder,” Journal of Gas FIG. 1 Examples for the Measurement of Short Term Noise, Long

Chromatography, Vol 2, 1964, pp. 277–284. Term Noise and Drift

E 1303

measured in RIU/h, is the static drift.

4.3.8 Set the solvent delivery system to a flow rate that has

previously been shown to deliver 1.0 mL per min under the

same conditions of capillary tubing, solvent, and temperature.

Allow at least 15 min to stabilize. Set the recorder zero near

mid-scale. Record at least1hof baseline under these flowing

conditions, during which time the ambient temperature should

not change by more than 2°C.

4.3.9 Draw pairs of parallel lines, measure the perpendicular

distances and calculate the dynamic short term noise, in the

manner described in 4.3.5 for the static short term noise.

4.3.10 Make the measurement for the dynamic long term

noise following the procedure outlined in 4.3.6.

4.3.11 Draw the pair of parallel lines as directed in 4.3.7.

The slope of this line is the dynamic drift.

4.3.12 Stop the chromatographic flow. Allow at least 15 min

for re-equilibration. Set the recorder at about 5 % of full scale

and leave the detector range setting at the value used for the

noise measurements. Set the solvent delivery system at a flow

FIG. 3 Example of Plot for Calculation of Flow Sensitivity

rate of 0.5 mL per min. Run for 15 min, or more if necessary

for re-equilibration, at a slow recorder speed. Increase the flow

rate to 1.0 mL per min and record for 15 min or more. Run at

twice the static short-term noise.

2.0, 4.0 and 8.0 mL per min if the pressure flow limit of the

5.1.1.1 Discussion—The static short-term noise is a mea-

chromatographic system is not exceeded. If necessary, adjust

surement of peak-to-peak noise. A statistical approach to noise

the detector range to maintain an on-scale response.

suggests that a value of three times the rms (root-mean-square)

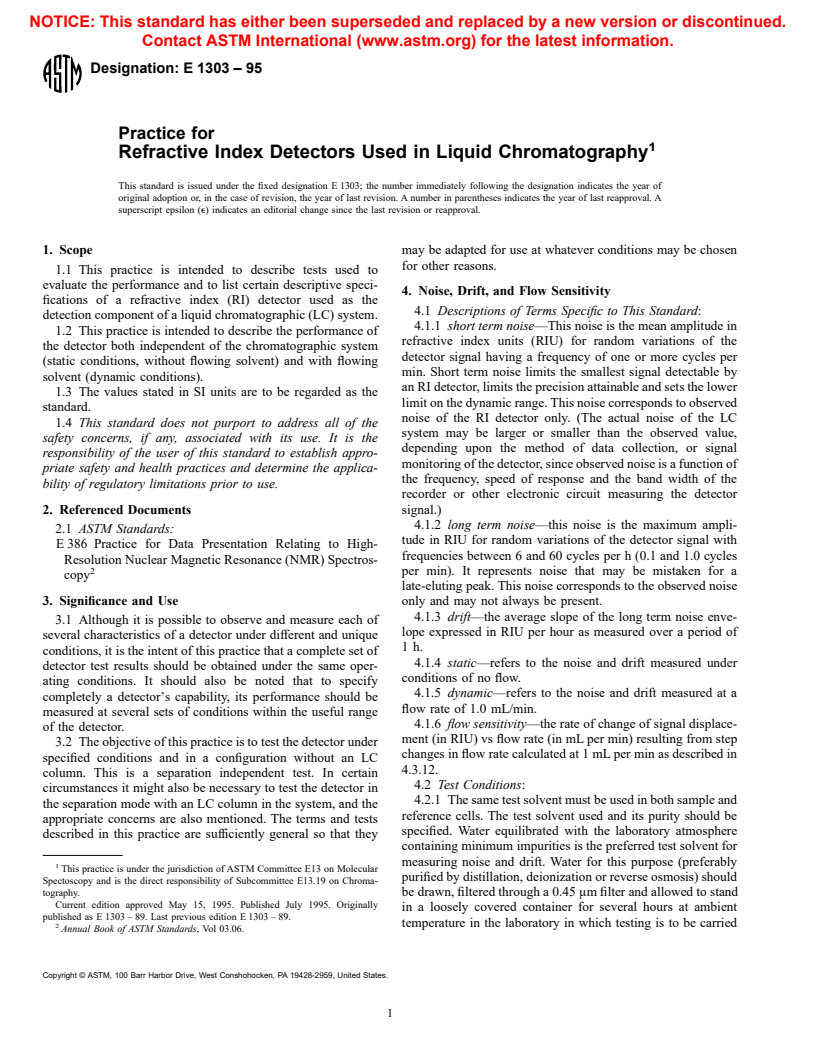

4.3.13 Draw a horizontal line through the plateau produced

noise would insure that any value outside this range would not

at each flow rate, after a steady state is reached (Fig. 2).

be noise with a confidence level of greater than 99 %. Since

Measure the vertical displacement between these lines, and

peak-to-peak noise is approximately five times the rms

,

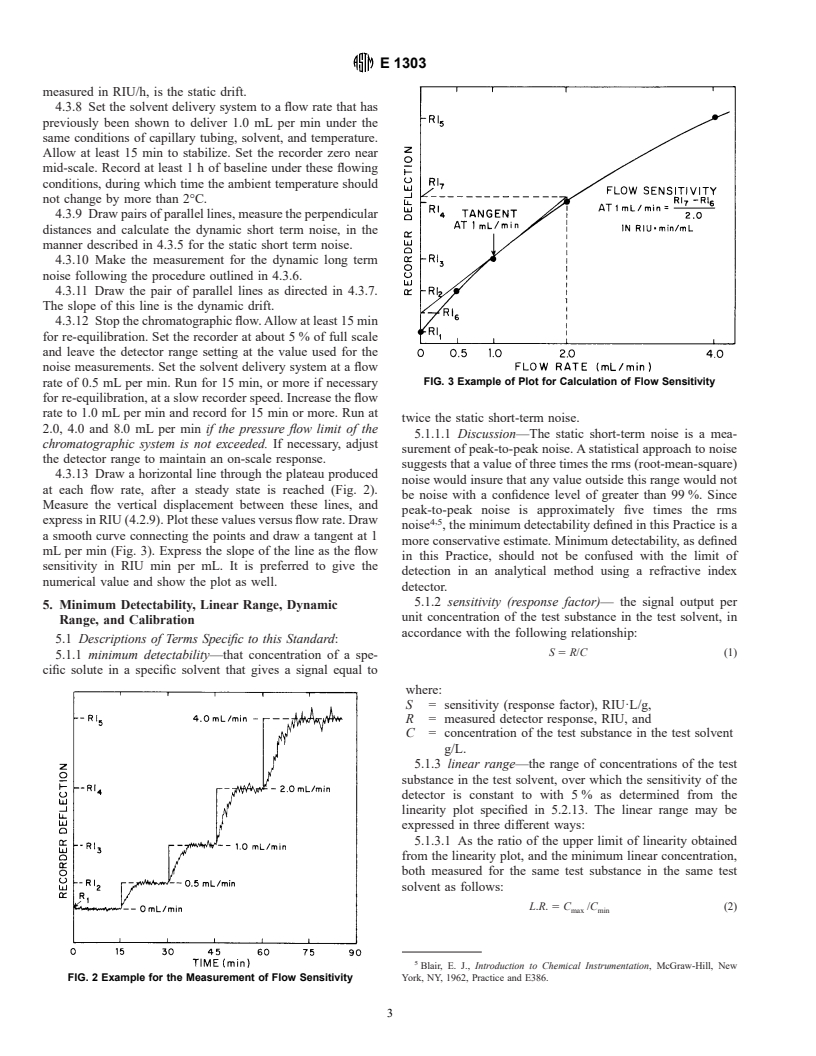

express in RIU (4.2.9). Plot these values versus flow rate. Draw 4 5

noise , the minimum detectability defined in this Practice is a

a smooth curve connecting the points and draw a tangent at 1

more conservative estimate. Minimum detectability, as defined

mL per min (Fig. 3). Express the slope of the line as the flow

in this Practice, should not be confused with the limit of

sensitivity in RIU min per mL. It is preferred to give the

detection in an analytical method using a refractive index

numerical value and show the plot as well.

detector.

5.1.2 sensitivity (response factor)— the signal output per

5. Minimum Detectability, Linear Range, Dynamic

unit concentration of the test substance in the test solvent, in

Range, and Calibration

accordance with the following relationship:

5.1 Descriptions of Terms Specific to this Standard:

S 5 R/C (1)

5.1.1 minimum detectability—that concentration of a spe-

cific solute in a specific solvent that gives a signal equal to

where:

S = sensitivity (response factor), RIU·L/g,

R = measured detector response, RIU, and

C = concentration of the test substance in the test solvent

g/L.

5.1.3 linear range—the range of concentrations of the test

substance in the test solvent, over which the sensitivity of the

detector is constant to with 5 % as determined from the

linearity plot specified in 5.2.13. The linear range may be

expressed in three different ways:

5.1.3.1 As the ratio of the upper limit of linearity obtained

from the linearity plot, and the minimum linear concentration,

both measured for the same test substance in the same test

solvent as follows:

L.R. 5 C /C (2)

max min

Blair, E. J., Introduction to Chemical Instrumentation, McGraw-Hill, New

FIG. 2 Example for the Measurement of Flow Sensitivity York, NY, 1962, Practice and E386.

E 1303

TABLE 1 Concentrations of Test Solutions

where:

Relative Actual Concentration Theoretical RI

L.R. = linear range of the detector,

Concentration (g/L) Difference (RIU)

C = upper limit of linearity obtained from the linearity

max

−3

50.0 43.6 5 3 10

plot, g/L, and

−3

20.0 17.4 2 3 10

C = minimum linear concentration g/L, as defined in

min −3

10.0 8.72 1 3 10

−4

5.2.13.1, the minimum linear concentration should

5.0 4.36 5 3 10

−4

2.0 1.74 2 3 10

also be stated.

−1 −4

1.0 8.72 3 10 1 3 10

5.1.3.2 By giving the minimum linear concentration and the

−1 −5

0.5 4.36 3 10 5 3 10

−3

−1 −5

upper limit of linearity (for example, from 8.72 3 10 g/L to

0.2 1.74 3 10 2 3 10

−1 −5

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.