ASTM D6042-96

(Test Method)Standard Test Method for Determination of Phenolic Antioxidants and Erucamide Slip Additives in Polypropylene Homopolymer Formulations Using Liquid Chromatography (LC)

Standard Test Method for Determination of Phenolic Antioxidants and Erucamide Slip Additives in Polypropylene Homopolymer Formulations Using Liquid Chromatography (LC)

SCOPE

1.1 This test method covers a liquid-chromatographic procedure for the separation of some additives currently used in polypropylene. These additives are extracted with a cyclohexane:methylene chloride mixture using either reflux or ultrasonic bath prior to liquid-chromatographic separation. The ultraviolet absorbence (200 nm) of the compound(s) is measured, and quantitation is performed using the internal standard method.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific precautionary statements are given in Section 9.

Note 1- There is no similar or equivalent ISO standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 6042 – 96

Standard Test Method for

Determination of Phenolic Antioxidants and Erucamide Slip

Additives in Polypropylene Homopolymer Formulations

Using Liquid Chromatography (LC)

This standard is issued under the fixed designation D 6042; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

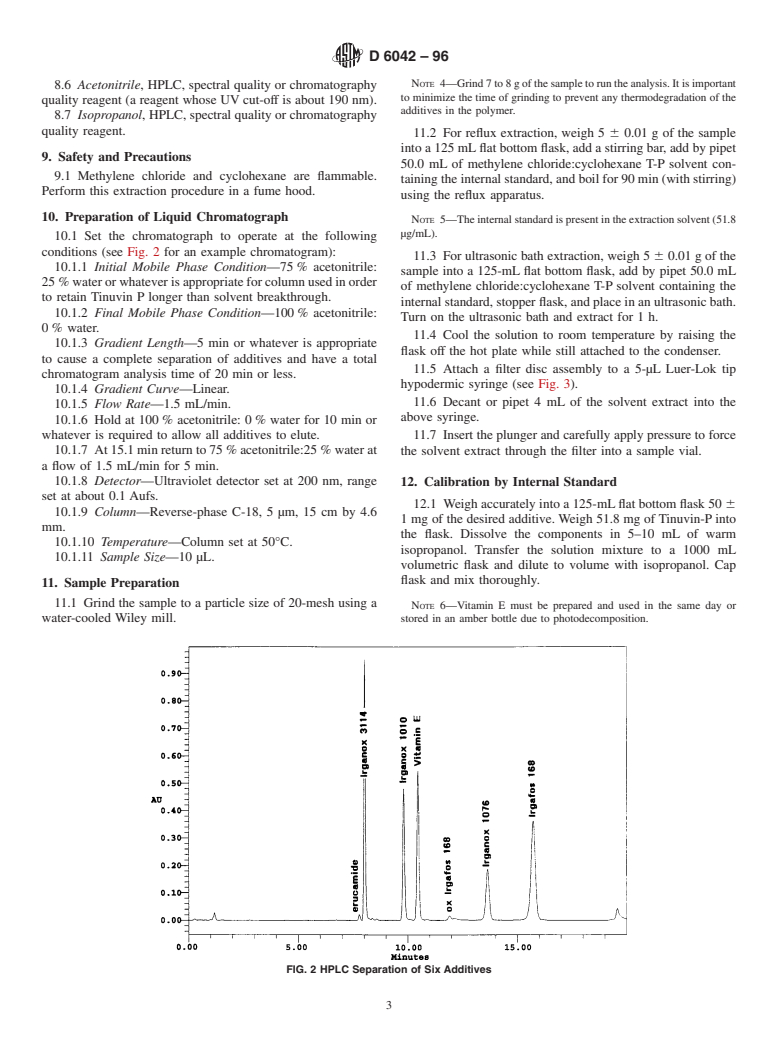

1. Scope 3.3.1 LC—liquid chromatography.

3.3.2 PP—polypropylene.

1.1 This test method covers a liquid-chromatographic pro-

3.4 Trade Names:

cedure for the separation of some additives currently used in

3.5 Vitamin E—a-Tocopherol, or 3,4-dihydro-2,5,7,8-

polypropylene. These additives are extracted with a cyclohex-

tetramethyl-2-(4,8,12-trimethyltridecyl)-2H-1-benzopyran-6-

ane:methylene chloride mixture using either reflux or ultra-

ol.

sonic bath prior to liquid-chromatographic separation. The

3.6 Irgafos 168—Tris(2,4 di-tert-butylphenyl) phosphite.

ultraviolet absorbence (200 nm) of the compound(s) is mea-

3.7 Irganox 3114—Tris(3,5-di-t-butyl-4-hydroxybenzyl)

sured, and quantitation is performed using the internal standard

isocyanurate.

method.

3.8 Kemamide-E—cis-13-docosenamide or erucamide.

1.2 This standard does not purport to address all of the

3.9 Irganox 1010—tetrakis[methylene(3,5-di-t-butyl-4-

safety concerns, if any, associated with its use. It is the

hydroxy hydrocinnamate)]methane.

responsibility of the user of this standard to establish appro-

3.10 Irganox 1076—octadecyl-3,5-di-t-butyl-4-hydroxy hy-

priate safety and health practices and determine the applica-

drocinnamate.

bility of regulatory limitations prior to use. Specific precau-

3.11 Tinuvin P—2(28-hydroxy-58-methyl phenyl)benzotria-

tionary statements are given in Section 9.

zole.

NOTE 1—There is no similar or equivalent ISO standard.

4. Summary of Test Method

2. Referenced Documents

4.1 The PPsample is ground to a 20-mesh particle size (850

2.1 ASTM Standards:

microns) and extracted by refluxing with a mixture of 75:25

D 883 Terminology Relating to Plastics

methylene chloride:cyclohexane or placing in an ultrasonic

D 1600 Terminology for Abbreviated Terms Relating to

bath with the same mixture.

Plastics

4.2 The solvent extract is examined by liquid chromatogra-

E 131 Terminology Relating to Molecular Spectroscopy

phy.

E 380 Practice for Use of the International System of Units

4.3 Additive concentrations are determined relative to an

(SI) (the Modernized Metric System)

internalstandard(containedinthesolvent)usingreverse-phase

E 691 Practice for Conducting an Interlaboratory Study to

chromatography(C-18column)withultraviolet(UV)detection

Determine the Precision of a Test Method

at 200 nm.

3. Terminology

5. Significance and Use

3.1 For definitions of plastic terms used in this test method,

5.1 Separation and identification of stabilizers used in the

see Terminologies D 883 and D 1600.

manufactureofpolypropyleneisnecessaryinordertocorrelate

3.2 For the units, symbols, and abbreviations used in this

performance properties with polymer composition. This test

test method, refer to Terminology E 131 or Practice E 380.

method provides a means to determine erucamide slip,Vitamin

3.3 Abbreviations:Abbreviations:

E, Irgafos 168, Irganox 3114, Irganox 1010, and Irganox 1076

levels in polypropylene samples. This test method should be

applicable for the determination of other antioxidants, such as

ThistestmethodisunderthejurisdictionofASTMCommitteeD-20onPlastics

and is the direct responsibility of Subcommittee D20.70 on Analytical Methods.

Ultranox 626, Ethanox 330, Santanox R, and BHT, but the

Current edition approved Nov. 10, 1996. Published April 1997.

applicability of this test method has not been investigated for

Annual Book of ASTM Standards, Vol 08.01.

these antioxidants.

Annual Book of ASTM Standards, Vol 03.06.

Annual Book of ASTM Standards, Vol 14.02.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D6042–96

5.2 The additive-extraction procedure is made effective by

the insolubility of the polymer sample in solvents generally

used for liquid chromatographic analysis.

5.3 Under optimum conditions, the lowest level of detection

for a phenolic antioxidant is approximately 2 ppm.

NOTE 2—Other methods that have been used successfully to remove

additivesfromtheplasticsmatrixincludethinfilm,microwave,ultrasonic,

and supercritical fluid extractions. Other methods have been used success-

fully to separate additives including SFC and capillary GC.

5.4 Irgafos 168 is a phosphite antioxidant. Phosphites are

known to undergo both oxidation and hydrolysis reactions.

Less Irgafos 168 may be seen in the polymer than originally

added to the polymer due to oxidation during processing. The

HPLC separation is capable of separating the phosphite,

phosphate (oxidation product), and hydrolysis product. If

standards are obtained, then the reaction products also can be

quantified. No significant breakdown of the phosphite antioxi-

dant has been seen due to either extraction technique or the

separation presented in this standard.

6. Interferences

6.1 Any material eluting at or near the same retention time

as the additive can cause erroneous results.Apolymer-solvent-

extract solution containing no internal standard should be

examined to minimize the possibility of interferences.

6.2 A major source of interferences can be from solvent

impurities. For this reason, the solvents should be examined

prior to use by injecting a sample of solvent on the HPLC

system and analyzing as in Section 10.

6.3 The oxidation product of Irgafos 168 can overlap with

other additives with retention times of components that elute

between Irganox 1010 and Irgafos 168. Standards should be

run to ensure that components of interest do not coelute with

the oxidation product of Irgafos 168.

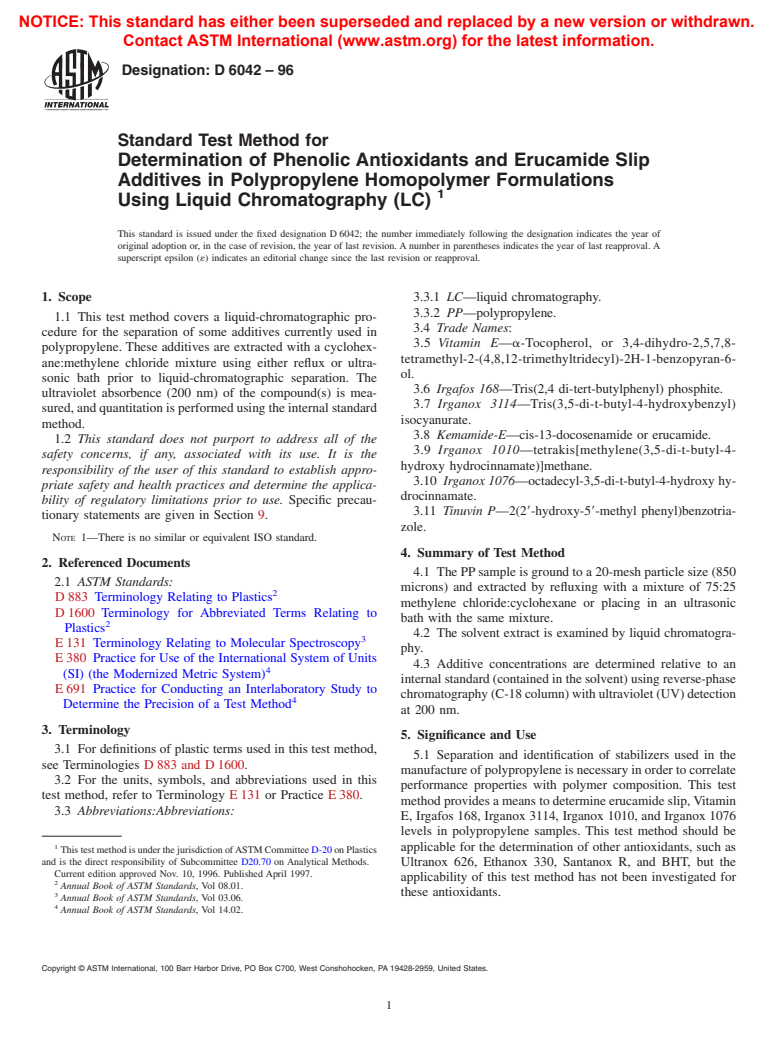

FIG. 1 Sample Extraction

7. Apparatus

7.1 Liquid Chromatograph, equipped with a variable-

7.7 Ultrasonic Bath Apparatus, consisting of the ultrasonic

wavelength ultraviolet detector, heated column, and gradient-

bath, a flat bottom 125-mL flask having a 24/40 ground-glass

elution capabilities. The liquid chromatograph should be

joint, and a 24/40 ground-glass stopper.

equipped with a means for a 10-µL-sample-solution injection,

7.8 Filter System (Teflon) for nonaqueous solutions (pore

such as a sample loop.

size of 0.22 µm) equipped with a glass 5-cm syringe.

7.2 Chromatographic Column, RP-18, 5-µm particle size,

7.9 Analytical Balance, capable of weighing to 60.0001 g.

15 cm by 4.6 mm.

8. Reagents and Materials

NOTE 3—A Zorbax RX C-18 Column, MAC MOD Analytical, Inc.,

was used for this test method. The gradient described in 10.1 provides

8.1 Tinuvin-P, 2(28 hydroxy-58-methyl phenyl) benzotriaz-

complete separation of antioxidants using this C-18 column.

ole.

8.2 Methylene Chloride, HPLC grade, spectral quality or

7.3 Computer System or Integrator, coupled with the chro-

chromatography quality reagent.

matograph is recommended to measure peak area.

8.3 Cyclohexane, HPLC grade, spectral quality or chroma-

7.4 Wiley Mill, equipped with a 20-mesh screen and water-

tography quality reagent.

cooled jacket to prevent thermodegradation of antioxidants.

8.4 75:25 Methylene Chloride:Cyclohexane T-P, mixture

7.5 Recorder, mV scale dependent upon the output of the

with 51.8 mg/L Tinuvin-P added as an internal standard.

detector.

8.5 Water, HPLC or UV quality reagent, degassed by

7.6 Reflux Extraction Apparatus, consisting of a condenser

spargingwithhighpurityheliumorbyfiltrationundervacuum.

(24/40 ground-glass joint), a flat bottom 125 mL flask having

a24/40ground-glassjoint,andahotplatewithmagneticstirrer

(see Fig. 1). Registered trademark of DuPont.

D6042–96

NOTE 4—Grind7to8gofthesampletoruntheanalysis.Itisimportant

8.6 Acetonitrile, HPLC, spectral quality or chromatography

to minimize the time of grinding to prevent any thermodegradation of the

quality reagent (a reagent whose UV cut-off is about 190 nm).

additives in the polymer.

8.7 Isopropanol, HPLC, spectral quality or chromatography

quality reagent.

11.2 For reflux extraction, weigh 5 6 0.01 g of the sample

into a 125 mLflat bottom flask, add a stirring bar, add by pipet

9. Safety and Precautions

50.0 mL of methylene chloride:cyclohexane T-P solve

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.