ASTM D4974-04(2011)

(Test Method)Standard Test Method for Hot Air Thermal Shrinkage of Yarn and Cord Using a Thermal Shrinkage Oven

Standard Test Method for Hot Air Thermal Shrinkage of Yarn and Cord Using a Thermal Shrinkage Oven

SIGNIFICANCE AND USE

This test method may be used for the acceptance testing of commercial shipments of yarns and cords. Caution is advised because yarn and cord may contract in length over a period of time due to room temperature retraction. Thermal shrinkage values are reduced proportionately by the amount of room temperature retraction.

Note 1—Experience, especially with nylon, shows that yarn retraction, which may be observed directly as shortening of length (or indirectly as denier increase), will occur in unrestrained yarn or cord that is not at equilibrium (equilibrium in this case being defined as essentially zero thermal shrinkage yarn or fully relaxed yarn). Normally, retractive forces are present in most wound packages of yarn and cord; thus, unrestrained yarn near the surface is likely, with time, to undergo some retraction. After retraction, such yarns exhibit lower thermal shrinkage values than yarn or cord deeper within the package. The opposite condition of yarn on the surface exists with yarn or cord wound against or near a rigid package core, such as a metal or hardwood wind-up spool. Such core yarn or cord cannot move against this restraint, and thus, will exhibit thermal shrinkage values even several weeks later near to those which were measured immediately from the surface of the freshly wound package. Elevated humidity will accelerate retraction of unrestrained yarn, but moisture content in itself will have little influence on thermal shrinkage. Exposure of untensioned skeins of yarn or cord to 95 to 100 % relative humidity at room temperature for two days and reconditioning under standard laboratory conditions will cause most of the room temperature retraction that is possible within a sample to occur.

In case of differences of practical significance in reported test results from two or more laboratories conduct comparative tests to determine if there is a statistical bias between them. Competent statistical assistance is recommended for the investigation of ...

SCOPE

1.1 This test method covers the measurement of shrinkage of yarns and cords when exposed in a thermal shrinkage oven.

1.2 This test method is applicable to yarns and cords made of nylon, polyester, and other polymers not detrimentally affected by the temperature used and with linear densities in the range from 20 to 700 tex (180 to 6300 denier).

1.2.1 Yarns or cords for testing may be taken from yarn or cord packages or from fabrics.

1.3 This test method shows values in both SI and inch-pound units. SI is the technically correct name for the system of units known as the International System of Units. Inch-pound units is the technically correct name for the customary units used in the United States. The values stated in either acceptable metric units or other units shall be regarded separately as standard. The values expressed in each system may not be exact equivalents; therefore, each system must be used independently of each other, without combining values in any way. Referee decisions are to use SI units.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific hazard statements are given in Section 8.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D4974 − 04(Reapproved 2011)

Standard Test Method for

Hot Air Thermal Shrinkage of Yarn and Cord Using a

Thermal Shrinkage Oven

This standard is issued under the fixed designation D4974; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D1776 Practice for Conditioning and Testing Textiles

D6477 Terminology Relating to Tire Cord, Bead Wire, Hose

1.1 This test method covers the measurement of shrinkage

Reinforcing Wire, and Fabrics

of yarns and cords when exposed in a thermal shrinkage oven.

1.2 This test method is applicable to yarns and cords made

3. Terminology

of nylon, polyester, and other polymers not detrimentally

3.1 Definitions:

affectedbythetemperatureusedandwithlineardensitiesinthe

3.2 For definitions of terms relating to tire cord, bead wire,

range from 20 to 700 tex (180 to 6300 denier).

1.2.1 Yarns or cords for testing may be taken from yarn or hose wire, and tire cord fabrics, refer to Terminology D6477.

3.2.1 The following terms are relevant to this standard:

cord packages or from fabrics.

greige cord, in tire cords, standard atmosphere for testing

1.3 This test method shows values in both SI and inch-

textiles, thermal shrinkage, tire cord.

pound units. SI is the technically correct name for the system

of units known as the International System of Units. Inch- 3.3 For definitions of other terms related to textiles, refer to

Terminology D123.

pound units is the technically correct name for the customary

units used in the United States. The values stated in either 3.3.1 The following terms are relevant to this standard:

yarn.

acceptable metric units or other units shall be regarded

separately as standard. The values expressed in each system

4. Summary of Test Method

may not be exact equivalents; therefore, each system must be

used independently of each other, without combining values in

4.1 A relaxed, conditioned specimen of yarn or cord is

any way. Referee decisions are to use SI units.

subjected to dry heat for a specified time while under a

1.4 This standard does not purport to address all of the specified tension. The percent shrinkage is read directly from a

safety concerns, if any, associated with its use. It is the scale or display on the instrument while the specimen is still

responsibility of the user of this standard to establish appro- under tension and exposed to heat.

priate safety and health practices and determine the applica-

5. Significance and Use

bility of regulatory limitations prior to use. Specific hazard

statements are given in Section 8.

5.1 This test method may be used for the acceptance testing

of commercial shipments of yarns and cords. Caution is

2. Referenced Documents

advised because yarn and cord may contract in length over a

2.1 ASTM Standards:

period of time due to room temperature retraction. Thermal

D123 Terminology Relating to Textiles

shrinkage values are reduced proportionately by the amount of

D885 Test Methods for Tire Cords, Tire Cord Fabrics, and

room temperature retraction.

Industrial Filament Yarns Made from Manufactured

NOTE 1—Experience, especially with nylon, shows that yarn retraction,

Organic-Base Fibers

which may be observed directly as shortening of length (or indirectly as

denier increase), will occur in unrestrained yarn or cord that is not at

equilibrium (equilibrium in this case being defined as essentially zero

This test method is under the jurisdiction ofASTM Committee D13 on Textiles

thermal shrinkage yarn or fully relaxed yarn). Normally, retractive forces

and is the direct responsibility of Subcommittee D13.19 on Industrial Fibers and

are present in most wound packages of yarn and cord; thus, unrestrained

Metallic Reinforcements.

yarnnearthesurfaceislikely,withtime,toundergosomeretraction.After

Current edition approved Jan. 1, 2011. Published March 2011. Originally

retraction, such yarns exhibit lower thermal shrinkage values than yarn or

approved in 1999. Last previous edition approved in 2004 as D4974–04. DOI:

cord deeper within the package. The opposite condition of yarn on the

10.1520/D4974-04R11.

surface exists with yarn or cord wound against or near a rigid package

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

core, such as a metal or hardwood wind-up spool. Such core yarn or cord

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on cannotmoveagainstthisrestraint,andthus,willexhibitthermalshrinkage

the ASTM website. values even several weeks later near to those which were measured

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D4974 − 04 (2011)

immediately from the surface of the freshly wound package. Elevated

bias or determine the proper set point to give the specified

humidity will accelerate retraction of unrestrained yarn, but moisture

specimen temperature.

content in itself will have little influence on thermal shrinkage. Exposure

6.3 The degree of room temperature length retraction, (for

of untensioned skeins of yarn or cord to 95 to 100 % relative humidity at

room temperature for two days and reconditioning under standard

example, that which occurs in unrestrained skeins of yarn over

laboratory conditions will cause most of the room temperature retraction

time in the testing laboratory), of the laboratory sample or

that is possible within a sample to occur.

specimen affects the measurement of thermal shrinkage. Un-

5.1.1 In case of differences of practical significance in

relaxed nylon, for example, shrinks much more than relaxed

reported test results from two or more laboratories conduct

nylon. The amount of relaxation (retraction) occurring prior to

comparative tests to determine if there is a statistical bias

testing of thermal shrinkage can affect the result.

between them. Competent statistical assistance is recom-

6.4 Frictional forces against the pulley/indicator assembly

mendedfortheinvestigationofbias.Asaminimum,theparties

cause measurement errors. Ensure that the indicator needle

should take a group of test specimens that are as homogeneous

does not rub against the scale. Maintain the pulley bearings in

as possible and that are from a lot of material of the type in

good condition. The pulley wheel must be centered in the

question.Thetestspecimensthenshouldbeassignedrandomly

bearings. A force of 10 mN or less, applied to the tip of the

in equal numbers to each laboratory for testing. The average

indicatorneedle,shouldcausepulleyrotationwhenthetesteris

results from the two laboratories should be compared using

in proper operating condition.

Student’s t-testforunpaireddataandaprobabilitylevelchosen

6.5 Thermal shrinkage increases as the exposure time in-

by the parties before the testing is begun. If a bias is found,

creases. Check the exposure time with a stopwatch. Some

either its cause must be found and corrected, or future test

thermalovenmodelshaveatimerinstalled.Comparethistimer

results must be adjusted in consideration of the known bias.

to a stopwatch and calibrate as necessary.

5.2 Thermal shrinkage of nylon, polyester, and other fibers

6.6 Center the threadline between the heating plates of the

is related to the polymer of origin and its manipulation in

oven to obtain a correct measurement.

processing. Thermal shrinkage measurement can be used to

control product uniformity.

6.7 Specimens that are spun, textured, or crimped (as those

removed from a fabric) may allow filaments to come in contact

5.3 The level of thermal shrinkage is critical in the user’s

with interior surfaces of the thermal shrinkage oven. Such

subsequent operations. For example it can affect the drumset

physical contact will cause inaccurate readings of thermal

(original length of cord) required in tire building to produce a

shrinkage.

finished, final tire of a particular size.

6.8 Yarn or cords that are sufficiently sticky or tacky to

5.4 Thermal shrinkage is critical to final shape and size of

prevent their free release from the pulley surface as it rotates

fiberreinforcedarticles.Forexample,thermalshrinkageaffects

will cause inaccurate readings of thermal shrinkage.

final size of V-belts and their ability to maintain tension while

running.

7. Apparatus

5.5 This test method is similar to the procedures of Methods

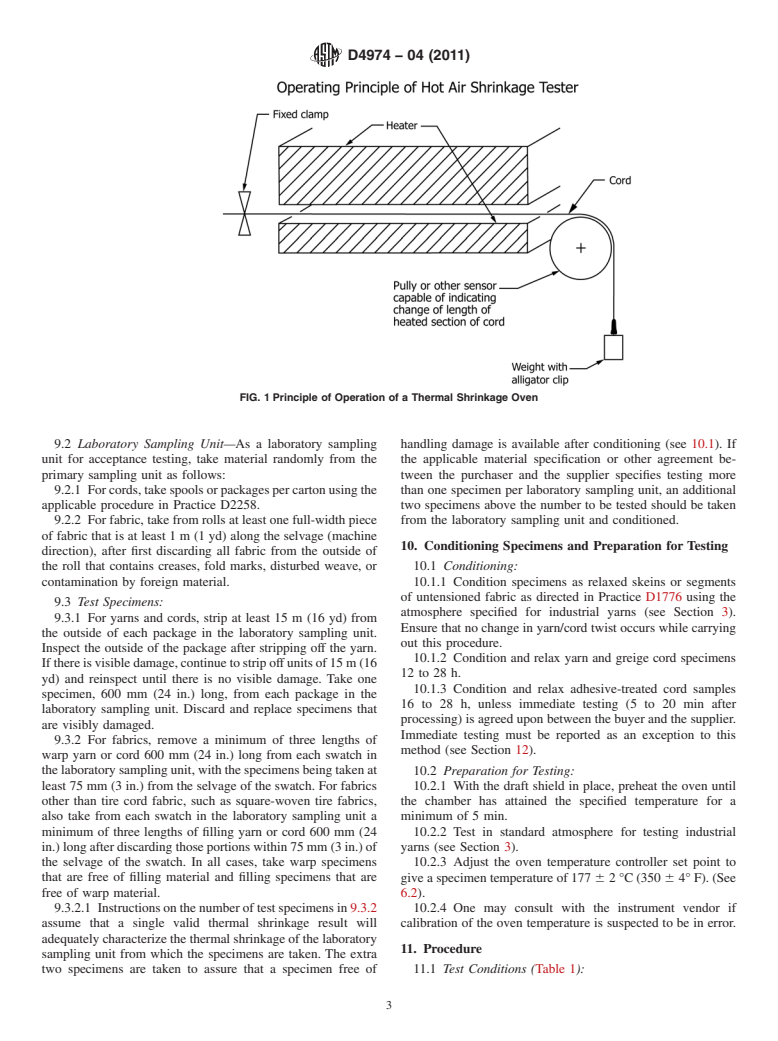

7.1 Thermal Shrinkage Oven , consisting of a specimen

D885 for the determination of thermal shrinkage of yarns and

heatingcavitycapableofheatingupto250°C(480°F),ameans

cords. Shrinkage is measured while the specimen is within an

of accurately controlling the temperature of the cavity 6 2°C

oven and tensioned as specified in Methods D885;D885

(6 4°F), and a means for measuring and displaying the amount

however, there are enough vagaries among different units of

of specimen shrinkage to the nearest 0.1 %. Fig. 1 shows the

apparatusformeasurementofthermalshrinkagethatnumerical

principle of operation of commercial thermal shrinkage ovens.

equivalence between units of different design should not be

assumed, even under the same nominal conditions.

7.2 Stopwatch or Timer.

7.3 Clip-On Masses.

6. Interferences

7.4 Draft Shield, if the oven does not have one provided.

6.1 An effective draft shield on the thermal oven is critical.

Because the chamber in which the specimen is heated is open

8. Safety Hazards

on three sides, air drafts can effectively shorten the length of

specimen experiencing the prescribed temperature environ-

8.1 The oven portion of the tester can reach temperatures

ment. Results obtained without a shield generally are lower

over 200°C (390° F). Do not touch the oven.

than with a shield.

8.2 Do not leave oven unattended if a specimen is installed.

6.2 The accurate control of temperature at any prescribed

9. Sampling and Test Specimens

setting is of utmost importance. Bias between the set point

temperature and the temperature that the specimen sees is a

9.1 Primary Sampling Unit—Consider shipping containers

major cause of instrument bias. The temperature that the

of cords or rolls of fabric to be the primary sampling unit, as

specimen sees may be checked by attaching a small calibrated

applicable.

thermocouple to a piece of cord and suspending it in the

specimen position such that the tip of the thermocouple is in

the center of the oven cavity.The thermocouple must not touch

Commercial thermal shrinkage ovens are available. Clip-on masses also are

the oven walls. Either correct any set point/sample temperature available from the manufacturer.

D4974 − 04 (2011)

FIG. 1 Principle of Operation of a Thermal Shrinkage Oven

9.2 Laboratory Sampling Unit—As a laboratory sampling handling damage is available after conditioning (see 10.1). If

unit for acceptance testing, take material randomly from the the applicable material specification or other agreement be-

primary sampling unit as follows: tween the purchaser and the supplier specifies testing more

9.2.1 Forcords,takespoolsorpackagespercartonusingthe than one specimen per laboratory sampling unit, an additional

applicable procedure in Practice D2258. two specimens above the number to be tested should be taken

9.2.2 For fabric, take from rolls at least one full-width piece from the laboratory sampling unit and conditioned.

of fabric that is at least1m(1yd) along the selvage (machine

10. Conditioning Specimens and Preparation for Testing

direction), after first discarding all fabric from the outside of

the roll that contains creases, fold marks, disturbed weave, or 10.1 Conditioning:

contamination by foreign material. 10.1.1 Condition specimens as relaxed skeins or segments

of untensioned fabric as directed in Practice D1776 using the

9.3 Test Specimens:

atmosphere specified for industrial yarns (see Section 3).

9.3.1 For yarns and cords, strip at least 15 m (16 yd) from

Ensure that no change in yarn/cord twist occurs while carrying

the outside of each package in the laboratory sampling unit.

out this procedure.

Inspect the outside of the package after stripping off the yarn.

10.1.2 Condition and relax yarn and greige cord specimens

Ifthereisvisibledamage,continuetostripoffunitsof15m(16

12 to 28 h.

yd) and reinspect until there is no visible damage. Take one

10.1.3 Condition and relax adhesive-treated cord samples

specimen, 600 mm (24 in.) long, from each package in the

16 to 28 h, unless immediate testing (5 to 20 min after

laboratory sampling unit. Discard and replace specimens that

processing) is agreed upon between the buyer and the supplier.

are visibly damaged.

Immediate testing must be reported as an exception to this

9.3.2 For fabrics, remove a minimum of three lengths of

method (see Section 12).

warp yarn or cord 600 mm (24 in.) long from each swatch in

thelaboratorysamplingunit,withthespecimensbeingtakenat 10.2 Preparation for Testing:

least 75 mm (3 in.) from the selvage of the swatch. For fabrics

10.2.1 With the draft shield in place, preheat the oven until

other than tire cord fabric, such as square-woven tire fabrics, the chamber has attained the specified temperature for a

also take from each swatch in the laboratory sampling unit a minimum of 5 min.

minimum of three lengths of filling yarn or cord 600 mm (24 10.2.2 Test in standard atmosphere for testing industrial

in.)longafterdiscardingthoseportionswithin75mm(3in.)of yarns (see Section 3).

the selvage of the swatch. In all cases, take warp specimens 10.2.3 Adjust the oven temperature controller set point to

that are free of filling material and filling specimens that are give a specimen temperature of 177 6 2 °C (350 6 4° F). (See

free of warp material. 6.2).

9.3.2.1 Instructionsonthenumberoftestspecimensin9.3.2 10.2.4 One may consult with the instrument vendor if

assume that a single valid thermal shrinkage result will calibration of the oven temperature is suspected to be in error.

adequately characterize the thermal shrinkage of the laboratory

11. Procedure

sampling unit from which the specimens are taken. The extra

two specimens are taken to assure that a specimen free of 11.1 Test Conditions (Table 1):

D4974 − 04 (2011)

TABLE 1 Test Conditions indicator to a shrinkage level in 11.4 sufficient to prevent the indicator

from going below zero. Record positive shrinkage as the interval between

Time, s

the lowest and highest reading of the indicator during the test of that

Specimen with Linear Specimen with Linear

Temperature Tension

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.