ASTM D4974-04

(Test Method)Standard Test Method for Hot Air Thermal Shrinkage of Yarn and Cord Using a Thermal Shrinkage Oven

Standard Test Method for Hot Air Thermal Shrinkage of Yarn and Cord Using a Thermal Shrinkage Oven

SCOPE

1.1 This test method covers the measurement of shrinkage of yarns and cords when exposed in a thermal shrinkage oven.

1.2 This test method is applicable to yarns and cords made of nylon, polyester, and other polymers not detrimentally affected by the temperature used and with linear densities in the range from 20 to 700 tex (180 to 6300 denier).

1.2.1 Yarns or cords for testing may be taken from yarn or cord packages or from fabrics.

1.3 This test method shows values in both SI and inch-pound units. SI is the technically correct name for the system of units known as the International System of Units. Inch-pound units is the technically correct name for the customary units used in the United States. The values stated in either acceptable metric units or other units shall be regarded separately as standard. The values expressed in each system may not be exact equivalents; therefore, each system must be used independently of each other, without combining values in any way. Referee decisions are to use SI units.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific hazard statements are given in Section .

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D4974–04

Standard Test Method for

Hot Air Thermal Shrinkage of Yarn and Cord Using a

1

Thermal Shrinkage Oven

This standard is issued under the fixed designation D4974; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D6477 Terminology Relating to Tire Cord, Bead Wire,

Hose Reinforcing Wire, and Fabrics

1.1 This test method covers the measurement of shrinkage

of yarns and cords when exposed in a thermal shrinkage oven.

3. Terminology

1.2 This test method is applicable to yarns and cords made

3.1 Definitions:

of nylon, polyester, and other polymers not detrimentally

3.2 For definitions of terms relating to tire cord, bead wire,

affectedbythetemperatureusedandwithlineardensitiesinthe

hose wire, and tire cord fabrics, refer to Terminology D6477.

range from 20 to 700 tex (180 to 6300 denier).

3.2.1 The following terms are relevant to this standard:

1.2.1 Yarns or cords for testing may be taken from yarn or

greige cord, in tire cords, standard atmosphere for testing

cord packages or from fabrics.

textiles, thermal shrinkage, tire cord.

1.3 This test method shows values in both SI and inch-

3.3 For definitions of other terms related to textiles, refer to

pound units. SI is the technically correct name for the system

Terminology D123.

of units known as the International System of Units. Inch-

3.3.1 The following terms are relevant to this standard:

pound units is the technically correct name for the customary

yarn.

units used in the United States. The values stated in either

acceptable metric units or other units shall be regarded

4. Summary of Test Method

separately as standard. The values expressed in each system

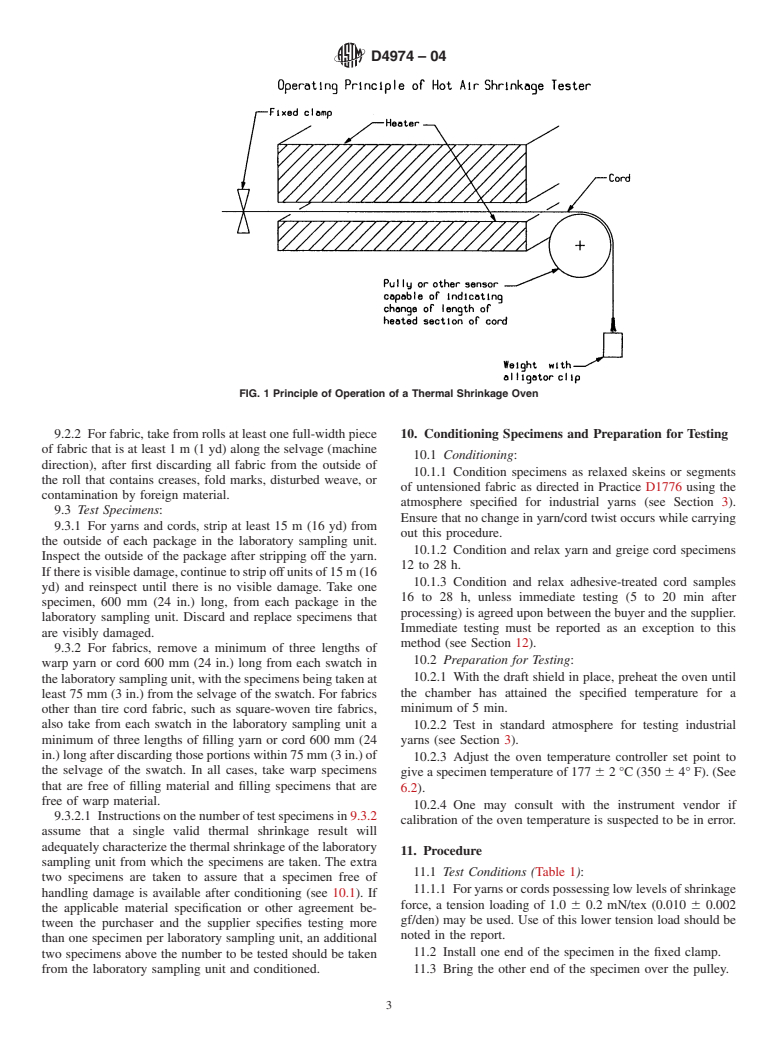

4.1 A relaxed, conditioned specimen of yarn or cord is

may not be exact equivalents; therefore, each system must be

subjected to dry heat for a specified time while under a

used independently of each other, without combining values in

specified tension. The percent shrinkage is read directly from a

any way. Referee decisions are to use SI units.

scale or display on the instrument while the specimen is still

1.4 This standard does not purport to address all of the

under tension and exposed to heat.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

5. Significance and Use

priate safety and health practices and determine the applica-

5.1 This test method may be used for the acceptance testing

bility of regulatory limitations prior to use. Specific hazard

of commercial shipments of yarns and cords. Caution is

statements are given in Section 8.

advised because yarn and cord may contract in length over a

period of time due to room temperature retraction. Thermal

2. Referenced Documents

shrinkage values are reduced proportionately by the amount of

2

2.1 ASTM Standards:

room temperature retraction.

D123 Terminology Relating to Textiles

D885 Test Methods for Tire Cords, Tire Cord Fabrics, and

NOTE 1—Experience, especially with nylon, shows that yarn retraction,

which may be observed directly as shortening of length (or indirectly as

Industrial Filament Yarns Made from Manufactured

denier increase), will occur in unrestrained yarn or cord that is not at

Organic-Base Fibers

equilibrium (equilibrium in this case being defined as essentially zero

D1776 Practice for Conditioning and Testing Textiles

thermal shrinkage yarn or fully relaxed yarn). Normally, retractive forces

are present in most wound packages of yarn and cord; thus, unrestrained

yarnnearthesurfaceislikely,withtime,toundergosomeretraction.After

1

This test method is under the jurisdiction ofASTM Committee D13 onTextiles

retraction, such yarns exhibit lower thermal shrinkage values than yarn or

and is the direct responsibility of Subcommittee D13.19 on Tire Cord and Fabrics.

cord deeper within the package. The opposite condition of yarn on the

Current edition approved Oct. 1, 2004. Published October 2004. Originally

surface exists with yarn or cord wound against or near a rigid package

approved in 1999. Last previous edition approved in 2002 as D4974–02. DOI:

core, such as a metal or hardwood wind-up spool. Such core yarn or cord

10.1520/D4974-04.

2 cannotmoveagainstthisrestraint,andthus,willexhibitthermalshrinkage

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

values even several weeks later near to those which were measured

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

immediately from the surface of the freshly wound package. Elevated

Standards volume information, refer to the standard’s Document Summary

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.