ASTM A878/A878M-05(2011)

(Specification)Standard Specification for Steel Wire, Modified Chromium Vanadium Valve Spring Quality

Standard Specification for Steel Wire, Modified Chromium Vanadium Valve Spring Quality

ABSTRACT

This specification covers the highest quality of round modified chromium vanadium alloy steel valve spring wires, uniform in quality and temper, intended for the manufacture of valve springs and other springs requiring high-fatigue properties when used at moderately elevated temperatures. This wire shall either be in the annealed and cold-drawn or oil-tempered condition. The steel shall be subjected to continuous casting and be free from detrimental pipe and undue segregation. Heat and product analysis shall conform to the chemical requirements for carbon, manganese, phosphorus, sulfur, silicon, chromium, and vanadium. Mechanical properties shall be determined by the following: annealing and cold-drawing, oil tempering, wrap testing, and special surface inspection. In the oil-tempered condition, steel shall conform to the tensile requirements for different wire diameters. Metallurgical characterization shall include surface condition, decarburization, and inclusion content. The wire or wire rod shall conform to the maximum inclusion content requirements for the surface and core zones.

SCOPE

1.1 This specification covers the highest quality of round modified chromium vanadium alloy steel valve spring wire, uniform in quality and temper, intended for the manufacture of valve springs and other springs requiring high-fatigue properties when used at moderately elevated temperatures. This wire shall be either in the annealed and cold-drawn or oil-tempered condition as specified by purchaser.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. Within the text, the inch-pound units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system must be used independent of the other.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:A878/A878M −05 (Reapproved 2011)

Standard Specification for

Steel Wire, Modified Chromium Vanadium Valve Spring

Quality

This standard is issued under the fixed designationA878/A878M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 2.4 AIAG Standard:

AIAG B-502.00 Primary Metals IdentificationTagApplica-

1.1 This specification covers the highest quality of round

tion Standard

modified chromium vanadium alloy steel valve spring wire,

uniform in quality and temper, intended for the manufacture of

3. Ordering Information

valve springs and other springs requiring high-fatigue proper-

3.1 Ordersformaterialunderthisspecificationshallinclude

ties when used at moderately elevated temperatures. This wire

the following information for each ordered item:

shall be either in the annealed and cold-drawn or oil-tempered

3.1.1 Quantity (mass),

condition as specified by purchaser.

3.1.2 Name of material (modified chromium vanadium

1.2 The values stated in either SI units or inch-pound units

alloy steel valve spring quality wire),

are to be regarded separately as standard. Within the text, the

3.1.3 Dimensions (Table 1 and Section 8),

inch-pound units are shown in brackets. The values stated in

3.1.4 Condition (Section 6),

each system are not exact equivalents; therefore, each system

3.1.5 Packaging (Section 14),

must be used independent of the other.

3.1.6 Heat analysis report, if requested (5.2),

3.1.7 Certification or test report, or both, if specified (Sec-

2. Referenced Documents

tion 13), and

2.1 ASTM Standards:

3.1.8 ASTM designation and year of issue.

A370Test Methods and Definitions for Mechanical Testing

NOTE 1—A typical ordering description is as follows: 20 000-kg

of Steel Products

oil-tempered modified chromium vanadium alloy steel valve spring

A700Guide for Packaging, Marking, and Loading Methods

qualitywire,size6.00mmin150-kgcoilstoASTM___dated___,orfor

for Steel Products for Shipment

inch-pound, 40 000-lb oil-tempered modified chromium vanadium alloy

A751Test Methods, Practices, and Terminology for Chemi-

steelvalvespringqualitywire,size0.250in.in350-lbcoilstoASTM___

dated ___.

cal Analysis of Steel Products

E29Practice for Using Significant Digits in Test Data to

4. Materials and Manufacture

Determine Conformance with Specifications

E45Test Methods for Determining the Inclusion Content of 4.1 The steel may be made by any commercially accepted

steel making process. The steel shall be continuously cast.

Steel

2.2 Federal Standard:

4.2 The finished wire shall be free from detrimental pipe

Fed. Std. No. 123Marking for Shipment (Civil Agencies)

and undue segregation.

2.3 Military Standard:

MIL-STD-163Steel Mill Products, Preparation for Ship- 5. Chemical Composition

ment and Storage

5.1 Thesteelshallconformtotherequirementsforchemical

composition specified in Table 2.

This specification is under the jurisdiction ofASTM Committee A01 on Steel,

5.2 Heat Analysis—Each heat of steel shall be analyzed by

Stainless Steel and Related Alloysand is the direct responsibility of Subcommittee

the manufacturer to determine the percentage of elements

A01.03 on Steel Rod and Wire.

prescribed in Table 2. This analysis shall be made from a test

Current edition approved Nov. 1, 2011. Published November 2011. Originally

approved in 1987. Last previous edition approved in 2005 as A878/A878M–05.

specimen preferably taken during the pouring of the heat.

DOI: 10.1520/A0878_A0878M-05R11.

When requested, this shall be reported to the purchaser and

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

shall conform to the requirements of Table 2.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

3 4

Available from Standardization Documents Order Desk, DODSSP, Bldg. 4, Available fromAutomotive IndustryAction Group (AIAG), 26200 Lahser Rd.,

Section D, 700 Robbins Ave., Philadelphia, PA 19111-5098 Suite 200, Southfield, MI 48034.

*A Summary of Changes section appears at the end of this standard

Copyright ©ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA19428-2959. United States

A878/A878M−05 (2011)

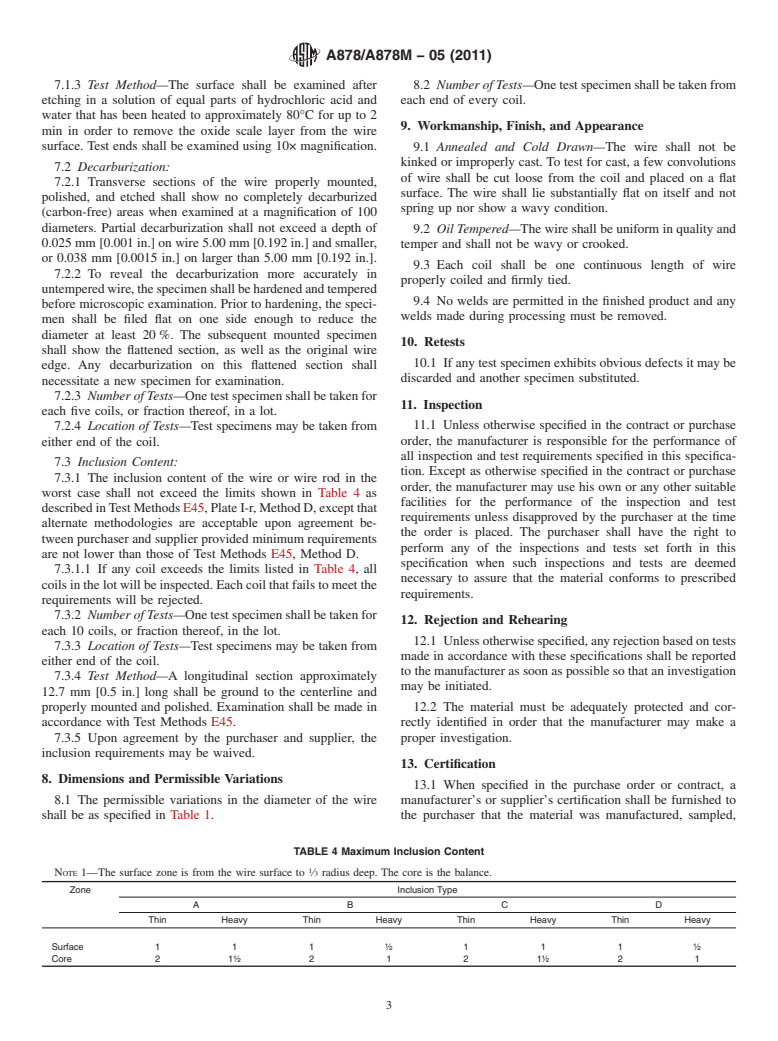

A A

TABLE 1 Permissible Variations in Wire Diameter TABLE 3 Tensile Requirements

SI Units SI Units

B

Permissible Permissible Diameter, mm MPa, min MPa, max Min % R.A.

Diameter, mm Variations, Out-of Round,

±mm mm

0.5 2000 2170 β

1.0 1930 2100 β

0.5 to 2.0, incl 0.02 0.02 1.5 1830 2000 β

Over 2.0 to 4.0, incl 0.03 0.03 2.0 1760 1900 45

Over 4.0 to 9.5, incl 0.04 0.04 3.0 1660 1800 45

Inch-Pound Units 3.75 1620 1760 40

Permissible Permissible 4.5 1590 1730 40

Diameter, in. Variations, Out-of Round, 5.0 1550 1690 40

±in. in. 5.7 1520 1660 40

6.3 1480 1620 40

0.020 to 0.075, incl 0.0008 0.0008

7.9 1450 1590 40

Over 0.075 to 0.148, incl 0.001 0.001 9.5 1410 1550 40

Over 0.148 to 0.375, incl 0.0015 0.0015

Inch-Pound Units

A

For purposes of determining conformance with this specification, all specified

B

Diameter, in. ksi, min ksi, max Min % R.A.

limits are absolute as defined in Recommended Practice E29.

0.020 290 315 β

0.040 280 305 β

0.060 265 290 β

TABLE 2 Chemical Requirements

0.080 255 275 45

Analysis,% ProductAnalysis

0.120 240 260 45

Tolerance,%

0.148 235 255 40

0.177 230 250 40

Carbon 0.60–0.75 ±0.02 0.200 225 245 40

Manganese 0.50–0.90 ±0.03 0.225 220 240 40

Phosphorus 0.025 max +0.005 0.250 215 235 40

Sulfur 0.025 max +0.005 0.312 210 230 40

Silicon 0.15–0.30 ±0.02 0.375 205 225 40

Chromium 0.35–0.60 ±0.05

A

Tensile strength valves for intermediate diameters may be interpolated.

Vanadium 0.10–0.25 ±0.01

B

β is not applicable to wire diameters under .080 in. (2.0 mm).

5.3 Product Analysis—An analysis may be made by the

purchaser from finished wire representing each heat of steel.

6.3.1 Oil-tempered or cold-drawn wire 4.00 mm [0.162 in.]

The average of all the separate determinations made shall be

andsmallerindiametershallwindonitselfasanarborwithout

within the limits specified in the analysis column. Individual

breakage. Larger diameter wire up to and including 8.00 mm

determinations may vary to the extent shown in the product

[0.312 in.] in diameter shall wrap without breakage on a

analysis tolerance column, except that the several determina-

mandrel twice the wire diameter. The wrap test is not appli-

tions of a single element in any one heat shall not vary both

cable to wire over 8.00 mm [0.312 in.] in diameter.

above and below the specified range.

6.3.2 NumberofTests—Onetestspecimenshallbetakenfor

5.4 For referee purposes, Test Methods, Practices, and

eachfivecoils,orfractionthereof,inalot.Eachheatinagiven

Terminology A751 shall be used.

lot shall be tested.

6.3.3 LocationofTests—Test specimens shall be taken from

6. Mechanical Properties

either end of the coil.

6.1 Annealed and Cold Drawn—When purchased in the

6.3.4 Test Method—The wrap test shall be made in accor-

annealed and cold-drawn condition, the wire shall have been dance with Test Methods and Definitions A370.

given a sufficient amount of cold working to meet the purchas-

6.4 Special Surface Inspection—When specified, the entire

er’scoilingrequirementsandshallbeinasuitableconditionto

lengthofeverycoilshallbeinspectedforsurfaceimperfections

respond properly to heat treatment. In special cases the

with a magnetic or eddy current defect analyzer, or both, or

hardness, if desired, shall be stated in the purchase order.

equivalent. The defect depth of this surface inspection shall be

6.2 Oil Tempered—When purchased in the oil-tempered

agreed upon between the manufacturer and the purchaser. All

condition, the tensile strength and % R.A. shall conform to the detected defects shall be properly marked so the purchaser has

requirements prescribed in Table 3.

the ability to identify and discard that length of wire.

6.2.1 NumberofTests—Onetestspecimenshallbetakenfor

eachfivecoils,orfractionthereof,inalot.Eachheatinagiven 7. Metallurgical Requirements

lot shall be tested.

7.1 Surface Condition:

6.2.2 LocationofTests—Test specimens shall be taken from

7.1.1 The surface of the wire as received shall be free of

either end of the coil.

imperfections such as pits, die marks, scratches, seams, and

6.2.3 Test Method—The t

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.