ASTM E779-99

(Test Method)Standard Test Method for Determining Air Leakage Rate by Fan Pressurization

Standard Test Method for Determining Air Leakage Rate by Fan Pressurization

SCOPE

1.1 This test method describes a standardized technique for measuring air-leakage rates through a building envelope under controlled pressurization and de-pressurization.

1.2 This test method is applicable to small temperature differentials and low-wind pressure conditions. For tests conducted in the field, it must be recognized that field conditions may be less than ideal. Nevertheless, strong winds and large indoor-outdoor temperature differentials should be avoided.

1.3 The proper use of this test method requires a knowledge of the principles of air flow and pressure measurements.

1.4 This test method is intended to produce a measure of air tightness of a building envelope. Because of differences between natural load and test conditions, however, such measurements cannot be interpreted as direct measurements of air change rates that would occur under natural conditions.

1.5 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific hazard statements see Section 7.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: E 779 – 99

Standard Test Method for

Determining Air Leakage Rate by Fan Pressurization

This standard is issued under the fixed designation E 779; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.2 air-leakage graph, n—the graph that shows the rela-

tionship of measured airflow rates to the corresponding mea-

1.1 This test method describes a standardized technique for

sured pressure differences, usually plotted on a log-log scale.

measuring air-leakage rates through a building envelope under

3.1.3 air-leakage rate, n—the volume of air movement/unit

controlled pressurization and de-pressurization.

time across the building envelope.

1.2 This test method is applicable to small temperature

3.1.3.1 Discussion—This movement includes flow through

differentials and low-wind pressure conditions. For tests con-

joints, cracks, and porous surfaces, or a combination thereof.

ducted in the field, it must be recognized that field conditions

The driving force for such an air leakage, in service can be

may be less than ideal. Nevertheless, strong winds and large

either mechanical pressurization and de-pressurization, natural

indoor-outdoor temperature differentials should be avoided.

wind pressures, or air temperature differentials between the

1.3 This test method is intended to produce a measure of air

building interior and the outdoors, or a combination thereof.

tightness of a building envelope. This test method does not

3.1.4 building envelope, n—the boundary or barrier sepa-

measure air leakage rates under normal conditions of weather

rating the interior volume of a building from the outside

and building operation. To measure air-change rate directly, use

environment.

the tracer gas dilution method (see Test Method E 741).

3.1.4.1 Discussion—For the purpose of this test method, the

1.4 This test method is intended for the measurement of the

interior volume is the deliberately conditioned space within a

airtightness of building envelopes of single-zone buildings. For

building, generally not including attics, basements, and at-

the purpose of this test method, many multi-zone buildings can

tached structures, for example, garages, unless such spaces are

be treated as single-zone buildings by opening interior doors or

connected to the heating and air conditioning system, such as

by inducing equal pressures in adjacent zones.

a crawl space plenum.

1.5 This standard does not purport to address all of the

3.1.5 single zone, n—a space in which the pressure differ-

safety concerns, if any, associated with its use. It is the

ences between any two places, differ by no more than 5 % of

responsibility of the user of this standard to establish appro-

the inside to outside pressure difference.

priate safety and health practices and determine the applica-

3.1.5.1 Discussion—A multi-room space that is intercon-

bility of regulatory limitations prior to use. For specific hazard

nected within itself with door-sized openings through any

statements see Section 7.

partitions or floors is likely to satisfy this criterion if the fan

3 3 3

2. Referenced Documents

airflow rate is less than 3 m /s 6 3 10 ft /min).

3.1.6 test pressure difference, n—the measured pressure

2.1 ASTM Standards:

difference across the building envelope, expressed in Pascals

E 741 Test Method for Determining Air Change in a Single

(in. of water or pounds-force/ft or in. of mercury).

Zone by Means of Tracer Gas Dilution.

3.2 Symbols and Units—See Table 1.

E 1258 Test Method for Airflow Calibration of Fan Pressur-

ization Devices

4. Summary of Test Method

3. Terminology 4.1 This test method consists of mechanical pressurization

or de-pressurization of a building and measurements of the

3.1 Definitions of Terms Specific to This Standard:

resulting airflow rates at given indoor-outdoor static pressure

3.1.1 air-change rate, n—air-leakage rate in volume units/h

differences. From the relationship between the airflow rates

divided by the building space volume with identical volume

and pressure differences, the air leakage characteristics of a

units, normally expressed as air changes/h, ACT–.

building envelope can be evaluated.

5. Significance and Use

This test method is under the jurisdiction of ASTM Committee E-6 on

5.1 Air leakage accounts for a significant portion of the

Performance of Buildings and is the direct responsibility of Subcommittee E06.41

on Air Leakage and Ventilation. thermal space conditioning load. In addition, it can affect

Current edition approved June 10, 1999. Published November 1999. Originally

occupant comfort and indoor air quality.

E1

published as E 779–81. Last previous edition E 779–87 (1992) .

5.2 In most commercial or industrial buildings, outdoor air

Annual Book of ASTM Standards, Vol 04.11.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

E 779

TABLE 1 Symbols and Units

practical. List the height above ground at which wind speed is

Symbol Quantity Unit measured.

E Elevation above sea level m [ft]

3 7. Hazards

Q Measured airflow rate m / s [cfm]

Q Air leakage rate m / s [cfm]

o

7.1 Eye Protection—Glass should not break at the building

3 n n

C Air leakage coefficient m /(s·Pa ) [cfm/ Pa ]

3 3 pressure differences normally applied to the test structure:

r Air density kg / m [lb/ ft ]

T Temperature ° C [°F]

however, for added safety, adequate precautions, such as the

n Pressure exponent . . .

use of eye protection should be taken to protect the personnel.

P Pressure Pa [lb/ft ]

2 7.2 Safety Clothing—Use safety equipment required for

dP Induced pressure difference Pa [lb/ ft ]

dP Reference pressure difference Pa [lb / ft ]

general field work, including safety shoes, and hard hats.

r

μ Dynamic air viscosity kg/(m·s) [lb / (ft·h)]

7.3 Equipment Guards—The air-moving equipment shall

2 2

A Area m [ft ]

have a proper guard or cage to house the fan or blower and to

prevent accidental access to any moving parts of the equip-

ment.

often is introduced by design; however, air leakage can be a

7.4 Noise Protection—Make hearing protection available

significant addition to the designed outdoor airflow. In most

for personnel who must be close to the noise that may be

residential buildings, indoor-outdoor air exchange is attribut-

generated by the fan.

able primarily to air leakage through cracks and construction

7.5 Debris and Fumes—The blower or fan forces a large

joints and can be induced by pressure differences due to

volume of air into or out of a building while operation.

temperature differences, wind, operation of auxiliary fans, for

Exercise care not to damage plants, pets, occupants, or internal

example, kitchen and bathroom exhausts, and the operation of

furnishings due to influx of cold or warm air. Exercise similar

combustion equipment in the building.

cautions against sucking debris or exhaust gases from fire-

5.3 The fan-pressurization method is simpler than tracer gas

places and flues into the interior of the building. Active

measurements and is intended to characterize the air tightness

combustion devices require a properly trained technician to

of the building envelope. It can be used to compare the relative

shut them off or to determine the safety of conducting the test.

air tightness of several similar buildings, to identify the leakage

8. Procedure

sources and rates of leakage from different components of the

same building envelope, and to determine the air leakage

8.1 To create a single zone for this test procedure, all

reduction for individual retrofit measures applied incrementally

interconnecting doors, except for closets, which should be

to an existing building, and to determine ventilation rates when

closed, in the conditioned space should be opened such that a

combined with weather and leak location information.

uniform pressure will be maintained within the conditioned

space to within 610 % of the measured inside/outside pressure

6. Apparatus

difference. Verify this condition by differential pressure mea-

6.1 The following is a general description of the required surements at the highest pressure used in the test. Make these

apparatus. Any arrangement of equipment using the same measurements at the highest and lowest level of the building

principles and capable of performing the test procedure within and on the windward and leeward sides.

the allowable tolerances is permitted. 8.2 HVAC balancing dampers and registers should not be

6.2 Major Components: adjusted. Fireplace and other operable dampers should be

6.2.1 Air-Moving Equipment—A fan, blower, or blower closed unless they are used to pass air to pressurize or

door assembly that is capable of moving air into and out of the de-pressurize the building.

conditioned space at required flow rates under a range of test 8.3 Make general observations of the condition of the

pressure differences. The system shall provide constant airflow building. Take notes on the windows, doors, opaque walls,

at each incremental pressure difference at fixed pressure for the roof, and floor.

period required to obtain readings of airflow rate. Where 8.4 Measure and record the indoor and outdoor tempera-

applicable, the HVAC system of the building may be used in tures at the beginning and the end of the test so that their

place of the fan or blower. average values can be estimated. If the product of the absolute

6.2.2 Pressure-Measuring Device—A manometer or pres- value of the indoor/outdoor air temperature difference multi-

sure indicator to measure pressure difference with an accuracy plied by the building height, gives a result greater than 200

of 65 % of measured pressure.

m°C (1180 ft°F), do not perform the test, because the pressure

6.2.3 Airflow Measuring System—A device to measure difference induced by the stack effect is too large to allow

airflow with an accuracy of 65 % of the measured flow. The

accurate interpretation of the results.

airflow measuring system shall be calibrated in accordance 8.5 If the wind speed is to be part of the measurement

with Test Method E 1258 record, use a wind-measuring device or obtain readings from a

6.2.4 Temperature-Measuring Device—An instrument to nearby weather bureau. Preferred test conditions are wind

measure temperature with an accuracy of 61°C (2°F). speed of 0 to 2 m/s (0 to 4 mph) and an outside temperature

6.2.5 Wind Speed-Measuring Device (Optional)—A device from 5 to 35°C (41 to 95°F).

to give an accuracy within 60.25 m/s (0.56 mph) at 2.5 m/s 8.6 Connect the air duct or blower door assembly to the

(5.6 mph). Perform wind speed measurements at a distance building envelope, using a window, door, or vent opening. Seal

three to five building heights away from the buildings, where or tape openings to avoid leakage at these points.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

E 779

8.7 If a damper is used to control airflow, it should be in a 8.12 At each pressure difference, measure the airflow rate

fully closed position for the zero flow pressure measurements. and the pressure differences across the envelope. After the fan

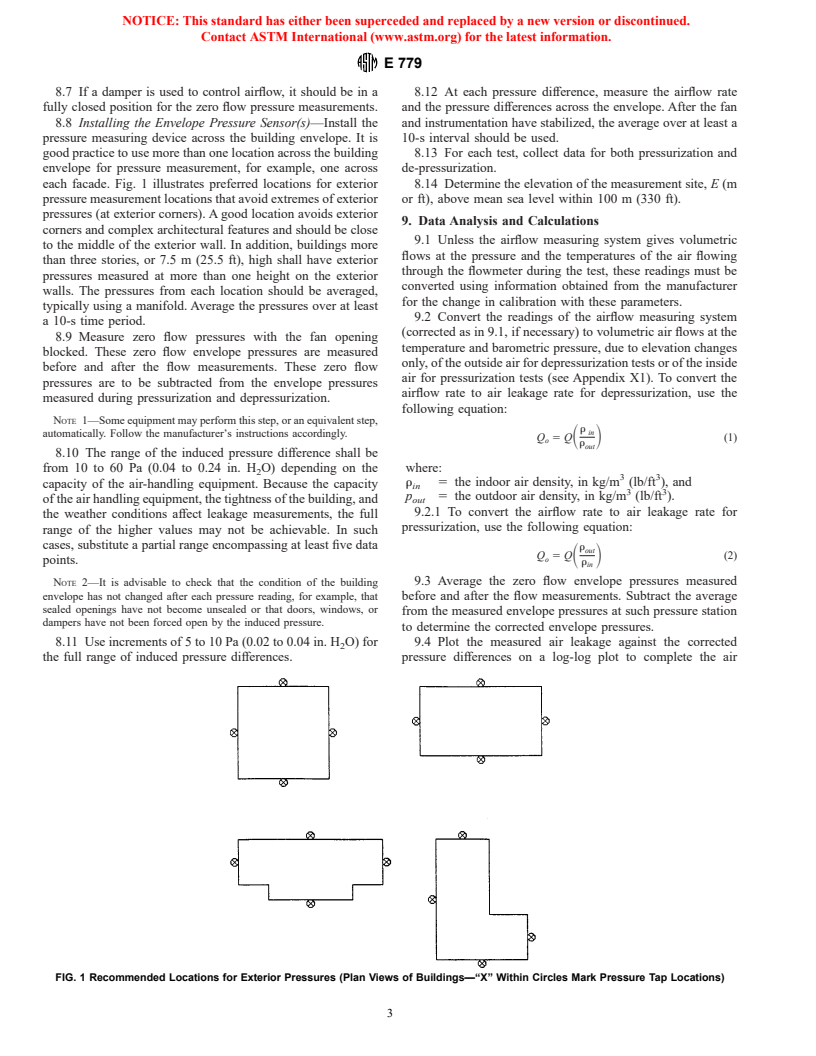

8.8 Installing the Envelope Pressure Sensor(s)—Install the and instrumentation have stabilized, the average over at least a

pressure measuring device across the building envelope. It is 10-s interval should be used.

good practice to use more than one location across the building 8.13 For each test, collect data for both pressurization and

envelope for pressure measurement, for example, one across de-pressurization.

each facade. Fig. 1 illustrates preferred locations for exterior 8.14 Determine the elevation of the measurement site, E (m

pressure measurement locations that avoid extremes of exterior or ft), above mean sea level within 100 m (330 ft).

pressures (at exterior corners). A good location avoids exterior

9. Data Analysis and Calculations

corners and complex architectural features and should be close

9.1 Unless the airflow measuring system gives volumetric

to the middle of the exterior wall. In addition, buildings more

flows at the pressure and the temperatures of the air flowing

than three stories, or 7.5 m (25.5 ft), high shall have exterior

through the flowmeter during the test, these readings must be

pressures measured at more than one height on the exterior

converted using information obtained from the manufacturer

walls. The pressures from each location should be averaged,

for the change in calibration with these parameters.

typically using a manifold. Average the pressures over at least

9.2 Convert the readings of the airflow measuring system

a 10-s time period.

(corrected as in 9.1, if necessary) to volumetric air flows at the

8.9 Measure zero flow pressures with the fan opening

temperature and barometric pressure, due to elevation changes

blocked. These zero flow envelope pressures are measured

only, of the outside air for depressurization tests or of the inside

before and after the flow measurements. These zero flow

air for pressurization tests (see Appendix X1). To convert the

pressures are to be subtracted from the envelope pressures

airflow rate to air leakage rate for depressurization, use the

measured during pressurization and depressurization.

following equation:

NOTE 1—Some equipment may perform this step, or an equivalent step,

r

in

automatically. Follow the manufacturer’s instructions accordingly.

Q 5 Q (1)

S D

o

r

out

8.10 The range of the induced pressure difference shall be

where:

from 10 to 60 Pa (0.04 to 0.24 in. H O) depending on the

3 3

r 5 the indoor air density, in kg/m (lb/ft ), and

capacity of the air-handling equipment. Because the capacity

in

3 3

p 5 the outdoor air density, in kg/m (lb/ft ).

of the air handling equipment, the tightness of the building, and out

9.2.1 To convert the airflow rate to air leakage rate for

the weather conditions affect leakage measurements, the full

pressurization, use the following equation:

range of the higher values may not be achievable. In such

cases, substitute a partial range encompassing at least five data

r

out

Q 5 Q (2)

S D

o

points. r

in

9.3 Average the zero flow envelope pressures measured

NOTE 2—It is advisable to check that the condition of the building

envelope has not changed after each pressure reading, f

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.