ASTM C1129-17

(Practice)Standard Practice for Estimation of Heat Savings by Adding Thermal Insulation to Bare Valves and Flanges

Standard Practice for Estimation of Heat Savings by Adding Thermal Insulation to Bare Valves and Flanges

SIGNIFICANCE AND USE

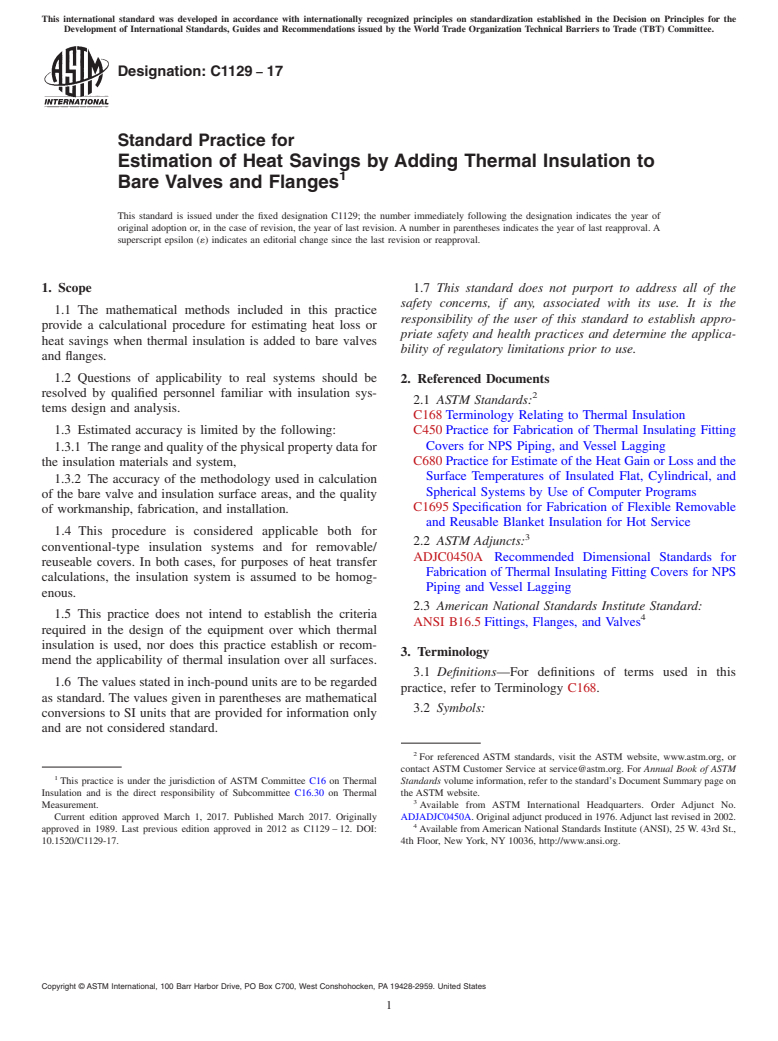

5.1 Manufacturers of thermal insulation for valves typically express the performance of their products in charts and tables showing heat loss per valve. These data are presented for both bare and insulated valves of different pipe sizes, ANSI classes, insulation types, insulation thicknesses, and service temperatures. Additional information on effects of wind velocity, jacket emittance, bare valve emittance, and ambient conditions are also required to properly select an insulation system. Due to the infinite combination of pipe sizes, ANSI classes, insulation types and thicknesses, service temperatures, insulation cover geometries, surface emittance values, and ambient conditions, it is not possible to publish data for each possible case.

5.2 Users of thermal insulation for piping systems faced with the problem of designing large systems of insulated piping, encounter substantial engineering costs to obtain the required thermal information. This cost can be substantially reduced by both the use of accurate engineering data tables, or by the use of available computer analysis tools, or both.

5.3 The use of this practice by the manufacturer, contractor, and users of thermal insulation for valves and flanges will provide standardized engineering data of sufficient accuracy and consistency for predicting the savings in heating energy use by insulating bare valves and flanges.

5.4 Computers are now readily available to most producers and consumers of thermal insulation to permit use of this practice.

5.5 The computer program in Practice C680 has been developed to calculate the heat loss per unit length, or per unit surface area, of both bare and insulated pipe. With values for bare valve or flange surface areas, heat loss can be estimated. By estimating the outer insulation surface area from an insulation manufacturer's or contractor's drawings, the heat loss from the insulation surface can likewise be calculated by taking the product of heat loss per unit ar...

SCOPE

1.1 The mathematical methods included in this practice provide a calculational procedure for estimating heat loss or heat savings when thermal insulation is added to bare valves and flanges.

1.2 Questions of applicability to real systems should be resolved by qualified personnel familiar with insulation systems design and analysis.

1.3 Estimated accuracy is limited by the following:

1.3.1 The range and quality of the physical property data for the insulation materials and system,

1.3.2 The accuracy of the methodology used in calculation of the bare valve and insulation surface areas, and the quality of workmanship, fabrication, and installation.

1.4 This procedure is considered applicable both for conventional-type insulation systems and for removable/reuseable covers. In both cases, for purposes of heat transfer calculations, the insulation system is assumed to be homogenous.

1.5 This practice does not intend to establish the criteria required in the design of the equipment over which thermal insulation is used, nor does this practice establish or recommend the applicability of thermal insulation over all surfaces.

1.6 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: C1129 − 17

Standard Practice for

Estimation of Heat Savings by Adding Thermal Insulation to

1

Bare Valves and Flanges

This standard is issued under the fixed designation C1129; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 1.7 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

1.1 The mathematical methods included in this practice

responsibility of the user of this standard to establish appro-

provide a calculational procedure for estimating heat loss or

priate safety and health practices and determine the applica-

heat savings when thermal insulation is added to bare valves

bility of regulatory limitations prior to use.

and flanges.

1.2 Questions of applicability to real systems should be

2. Referenced Documents

resolved by qualified personnel familiar with insulation sys-

2

2.1 ASTM Standards:

tems design and analysis.

C168Terminology Relating to Thermal Insulation

1.3 Estimated accuracy is limited by the following: C450Practice for Fabrication of Thermal Insulating Fitting

Covers for NPS Piping, and Vessel Lagging

1.3.1 Therangeandqualityofthephysicalpropertydatafor

C680Practice for Estimate of the Heat Gain or Loss and the

the insulation materials and system,

Surface Temperatures of Insulated Flat, Cylindrical, and

1.3.2 The accuracy of the methodology used in calculation

Spherical Systems by Use of Computer Programs

of the bare valve and insulation surface areas, and the quality

C1695Specification for Fabrication of Flexible Removable

of workmanship, fabrication, and installation.

and Reusable Blanket Insulation for Hot Service

1.4 This procedure is considered applicable both for

3

2.2 ASTM Adjuncts:

conventional-type insulation systems and for removable/

ADJC0450A Recommended Dimensional Standards for

reuseable covers. In both cases, for purposes of heat transfer

Fabrication of Thermal Insulating Fitting Covers for NPS

calculations, the insulation system is assumed to be homog-

Piping and Vessel Lagging

enous.

2.3 American National Standards Institute Standard:

1.5 This practice does not intend to establish the criteria

4

ANSI B16.5Fittings, Flanges, and Valves

required in the design of the equipment over which thermal

insulation is used, nor does this practice establish or recom-

3. Terminology

mend the applicability of thermal insulation over all surfaces.

3.1 Definitions—For definitions of terms used in this

1.6 Thevaluesstatedininch-poundunitsaretoberegarded

practice, refer to Terminology C168.

as standard. The values given in parentheses are mathematical

3.2 Symbols:

conversions to SI units that are provided for information only

and are not considered standard.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

1

This practice is under the jurisdiction of ASTM Committee C16 on Thermal Standards volume information, refer to the standard’s Document Summary page on

Insulation and is the direct responsibility of Subcommittee C16.30 on Thermal the ASTM website.

3

Measurement. Available from ASTM International Headquarters. Order Adjunct No.

Current edition approved March 1, 2017. Published March 2017. Originally ADJADJC0450A. Original adjunct produced in 1976.Adjunct last revised in 2002.

4

approved in 1989. Last previous edition approved in 2012 as C1129–12. DOI: Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

10.1520/C1129-17. 4th Floor, New York, NY 10036, http://www.ansi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C1129 − 17

4. Summary of Practice

4.1 The procedures for estimating heat loss used in this

practice are based upon standard steady-state heat transfer

theoryasoutlinedinPracticeC680(orprogramsconformingto

5

it such as 3E Plus ). Practice C680 and 3E plus are used to

estimate the heat loss per unit surface area for the particular

conditions and for all configurations, both bare and insulated.

4.2 The procedures for estimating surface areas used in this

practicearebasedonstandardgeometriclogic:forabarevalve

or flange, the contours of the metal surface are considered. For

aninsulatedvalveorflange,thefabricatedshapeofthefinished

insulation system is considered.

4.3 Data Input:

4.3.1 Total bare surf

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: C1129 − 12 C1129 − 17

Standard Practice for

Estimation of Heat Savings by Adding Thermal Insulation to

1

Bare Valves and Flanges

This standard is issued under the fixed designation C1129; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 The mathematical methods included in this practice provide a calculational procedure for estimating heat loss or heat

savings when thermal insulation is added to bare valves and flanges.

1.2 Questions of applicability to real systems should be resolved by qualified personnel familiar with insulation systems design

and analysis.

1.3 Estimated accuracy is limited by the following:

1.3.1 The range and quality of the physical property data for the insulation materials and system,

1.3.2 The accuracy of the methodology used in calculation of the bare valve and insulation surface areas, and the quality of

workmanship, fabrication, and installation.

1.4 This procedure is considered applicable both for conventional-type insulation systems and for removable/reuseable covers.

In both cases, for purposes of heat transfer calculations, the insulation system is assumed to be homogenous.

1.5 This practice does not intend to establish the criteria required in the design of the equipment over which thermal insulation

is used, nor does this practice establish or recommend the applicability of thermal insulation over all surfaces.

1.6 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

C168 Terminology Relating to Thermal Insulation

C450 Practice for Fabrication of Thermal Insulating Fitting Covers for NPS Piping, and Vessel Lagging

C680 Practice for Estimate of the Heat Gain or Loss and the Surface Temperatures of Insulated Flat, Cylindrical, and Spherical

Systems by Use of Computer Programs

C1695 Specification for Fabrication of Flexible Removable and Reusable Blanket Insulation for Hot Service

3

2.2 ASTM Adjuncts:

ADJC0450A Recommended Dimensional Standards for Fabrication of Thermal Insulating Fitting Covers for NPS Piping and

Vessel Lagging

2.3 American National Standards Institute Standard:

4

ANSI B16.5 Fittings, Flanges, and Valves

3. Terminology

3.1 Definitions—For definitions of terms used in this practice, refer to Terminology C168.

3.2 Symbols:

1

This practice is under the jurisdiction of ASTM Committee C16 on Thermal Insulation and is the direct responsibility of Subcommittee C16.30 on Thermal Measurement.

Current edition approved May 1, 2012March 1, 2017. Published July 2012March 2017. Originally approved in 1989. Last previous edition approved in 20082012 as

C1129–89C1129 – 12. (2008). DOI: 10.1520/C1129-12. 10.1520/C1129-17.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from ASTM International Headquarters. Order Adjunct No. ADJADJC0450A. Original adjunct produced in 1976. Adjunct last revised in 2002.

4

Available from American National Standards Institute (ANSI), 25 W. 43rd St., 4th Floor, New York, NY 10036, http://www.ansi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C1129 − 17

3.2.1 The following symbols are used in the development of the equations for this practice. Other symbols will be introduced

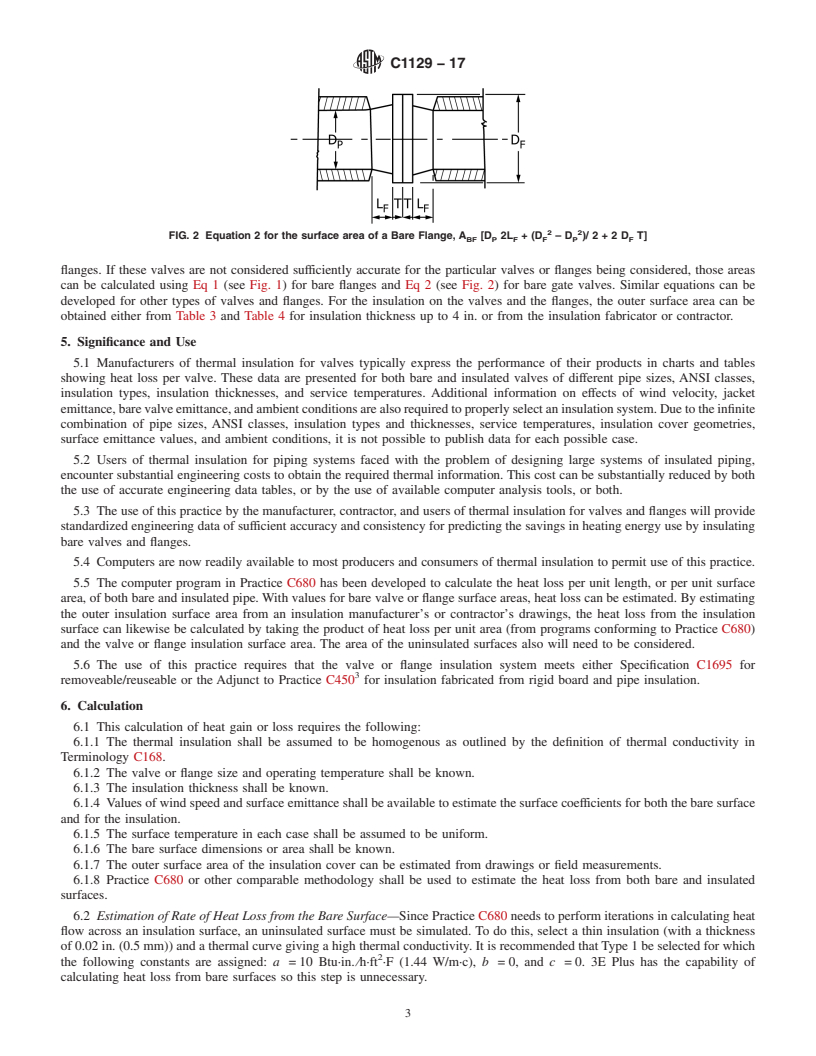

and defined in the detailed description of the development. See Fig. 1 and Fig. 2.

2 2

A = outer surface area of the bare valve or flange (does not include the wheel and stem of the valve), ft (m ).

B

2 2

A = surface area of the insulation cover over the valve or flange, ft (m ).

I

C = distance from the center-line axis of the pipe (to which the valve is

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.