ASTM D6794-02

(Test Method)Standard Test Method for Measuring the Effect on Filterability of Engine Oils After Treatment with Various Amounts of Water and a Long (6-h) Heating Time

Standard Test Method for Measuring the Effect on Filterability of Engine Oils After Treatment with Various Amounts of Water and a Long (6-h) Heating Time

SCOPE

1.1 This test method covers the determination of the tendency of an oil to form a precipitate that can plug an oil filter. It simulates a problem that may be encountered in a new engine run for a short period of time, followed by a long period of storage with some water in the oil.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

An American National Standard

Designation: D 6794 – 02

Standard Test Method for

Measuring the Effect on Filterability of Engine Oils After

Treatment with Various Amounts of Water and a Long (6-h)

1

Heating Time

This standard is issued under the fixed designation D 6794; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

Any properly equipped laboratory, without outside assistance, can use the procedure described in

2

this test method. However, the ASTM Test Monitoring Center (TMC) provides reference oils and an

assessment of the test results obtained on those oils by the laboratory (see Annex A1). By these means,

the laboratory will know whether their use of the test method gives results statistically similar to those

obtained by other laboratories. Furthermore, various agencies require that a laboratory utilize the TMC

services in seeking qualification of oils against specifications. For example, the U.S. Army imposes

such a requirement in connection with several Army engine lubricating oil specifications.

Accordingly, this test method is written for use by laboratories that utilize the TMC services.

Laboratories that choose not to use those services may simply ignore those portions of the test method

that refer to the TMC.

This test method may be modified by means of information letters issued by the TMC. In addition,

the TMC may issue supplementary memoranda related to the test method (see Annex A1).

3

For other information, refer to the research report of this test method.

5

1. Scope Petroleum Products

5

D 4485 Specification for Performance of Engine Oils

1.1 This test method covers the determination of the ten-

D 5844 Test Method for Evaluation of Automotive Engine

dency of an oil to form a precipitate that can plug an oil filter.

6

Oils for Inhibition of Rusting (Sequence IID)

It simulates a problem that may be encountered in a new engine

D 5862 Test Method for Evaluation of Engine Oils in

run for a short period of time, followed by a long period of

Two-Stroke Cycle Turbo-Supercharged 6V92TA Diesel

storage with some water in the oil.

6

Engine

1.2 This standard does not purport to address all of the

E 344 Terminology Relating to Thermometry and Hydrom-

safety concerns, if any, associated with its use. It is the

7

etry

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

3. Terminology

bility of regulatory limitations prior to use.

3.1 Definitions:

2. Referenced Documents 3.1.1 calibrate, v—to determine the indication or output of

a measuring device with respect to that of a standard. E 344

2.1 ASTM Standards:

4

3.1.2 calibration test, n—a test, using a coded oil, con-

D 1193 Specification for Reagent Water

ducted as specified in the test method.

D 4057 Practice for Manual Sampling of Petroleum and

3.1.2.1 Discussion—The test result is used to determine the

suitability of the testing facility/laboratory to conduct such

1

This test method is under the jurisdiction of ASTM Committee D02 on

tests on non-reference oils.

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

3.1.3 candidate oil, n—an oil that is intended to have the

D02.B0 on Automotive Lubricants.

Current edition approved April 10, 2002. Published September 2002. performance characteristics necessary to satisfy a specification

2

ASTM Test Monitoring Center, 6555 Penn Ave., Pittsburgh, PA 152006-4489.

and is tested against that specification. D 5844

This test method is supplemented by Information Letters and Memoranda issued by

the ASTM Test Monitoring Center. Users of this test method can contact the ASTM

Test Monitoring Center to obtain the most recent of these.

3 5

Supporting data have been filed at ASTM International Headquarters and may Annual Book of ASTM Standards, Vol 05.02.

6

be obtained by requesting Research Report RR: D02–1492. Annual Book of ASTM Standards, Vol 05.03.

4 7

Annual Book of ASTM Standards, Vol 11.01. Annual Book of ASTM Standards, Vol 14.03.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D6794–02

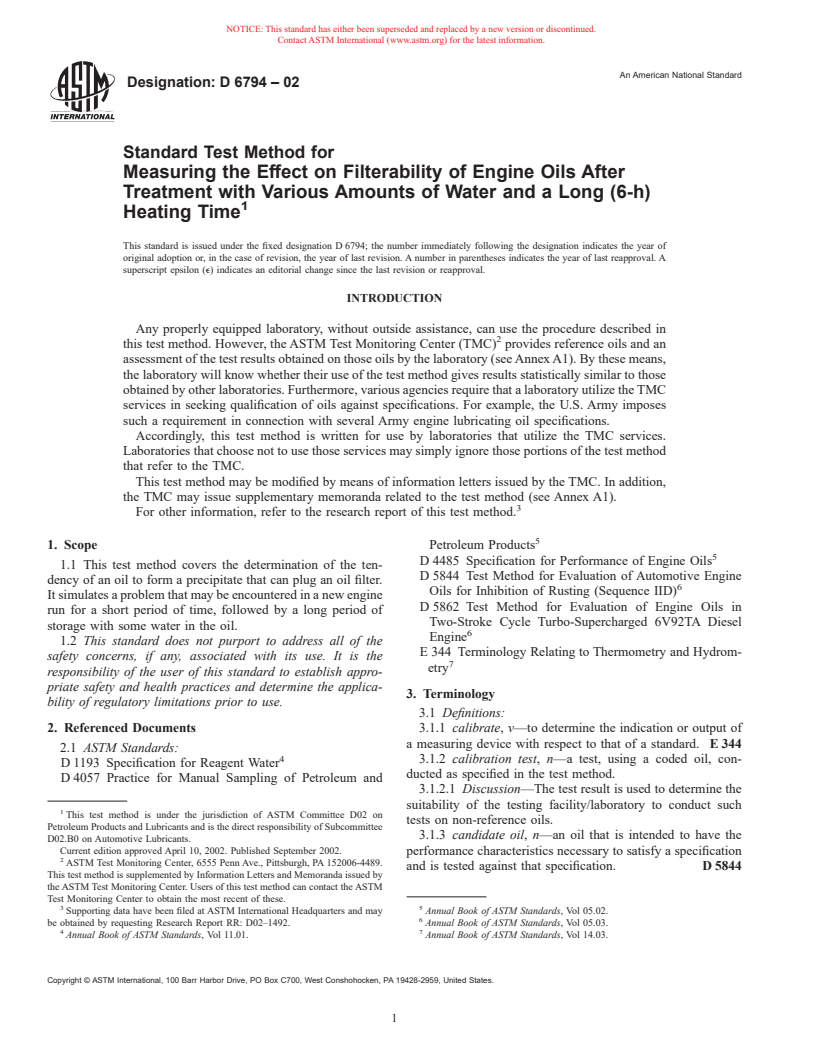

3.1.4 engine oil, n—a liquid that reduces friction or wear, or with 25-μm automotive oil filter paper, and a source of 69 6 2

both, between the moving parts within an engine; removes kPa (10 6 0.3 psi) air pressure. Discs of filter paper are cut to

heat, particularly from the underside of pistons; and serves as fit the holder and installed (see Fig. 1).

a combustion gas sealant for the piston rings. 6.1.1 Burette (glass or plastic), 25 mL, with polytetrafluo-

3.1.4.1 Discussion—It may contain additives to enhance roethylene (PTFE) stopcock and 1.8 6 0.1

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.