ASTM F1048-87(1999)

(Test Method)Standard Test Method for Measuring the Effective Surface Roughness of Optical Components by Total Integrated Scattering (Withdrawn 2003)

Standard Test Method for Measuring the Effective Surface Roughness of Optical Components by Total Integrated Scattering (Withdrawn 2003)

SCOPE

This standard was transferred to SEMI (www.semi.org) May 2003

1.1 This test method covers the measurement of the effective surface roughness of an opaque reflecting surface as determined by the total integrated light scattering (TIS).

1.2 Applications:

1.2.1 This test method is particularly applicable to metal mirrors or smooth dielectrics covered with an opaque reflecting surface.

1.2.2 This test method is applicable to specimens ranging in size from 5 mm in diameter to as large as the supporting components will accommodate. The sampling area is approximately 1 mm in diameter.

1.3 Limitations -This test method is limited to specimens with optical surfaces that are flat or that are spherical with a radius of curvature greater than 10 m.

1.4 This test method determines the integrated scattering from an angle approximately 2.5° from the surface normal to an angle approximately 70° from the surface normal.

1.5 The test method is performed with a helium-neon laser operating at the wavelength 632.8 nm.

1.6 Repeated use of this test method on different areas of the specimen permits mapping of the surface TIS.

1.7 This test method is nondestructive.

1.8 The maintenance of a control chart to monitor the stability of the measurement process is discussed in Annex A1.

1.9 This standard may involve hazardous materials, operations, and equipment. This standard does not purport to address all of the safety problems associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific hazard statements see Section 8.

General Information

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: F 1048 – 87 (Reapproved 1999)

Standard Test Method for

Measuring the Effective Surface Roughness of Optical

Components by Total Integrated Scattering

This standard is issued under the fixed designation F 1048; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 2.2 ANSI Standard:

Z136.1 Safe Use of Lasers

1.1 This test method covers the measurement of the effec-

tive surface roughness of an opaque reflecting surface as

3. Terminology

determined by the total integrated light scattering (TIS).

3.1 Definitions of Terms Specific to This Standard:

1.2 Applications:

3.1.1 microroughness, h —the root mean square of the

rms

1.2.1 This test method is particularly applicable to metal

short-range deviations of a surface above and below its mean

mirrors or smooth dielectrics covered with an opaque reflecting

position.

surface.

3.1.2 surface flaws—defects such as scratches or pits which

1.2.2 This test method is applicable to specimens ranging in

are not typical of the surface finish.

size from 5 mm in diameter to as large as the supporting

3.1.3 total integrated scatter, TIS—for the purposes of this

components will accommodate. The sampling area is approxi-

test method, the radiation scattered by an opaque reflecting

mately 1 mm in diameter.

surface into a 2p solid angle.

1.3 Limitations—This test method is limited to specimens

with optical surfaces that are flat or that are spherical with a

4. Summary of Test Method

radius of curvature greater than 10 m.

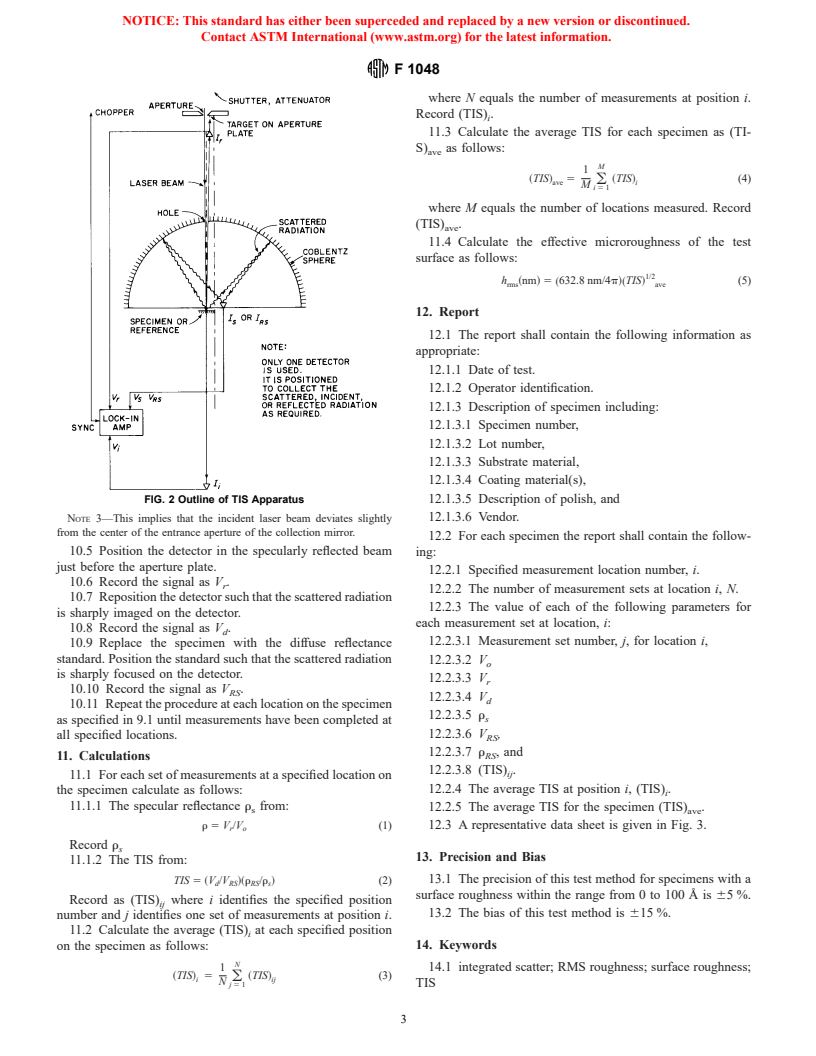

4.1 A beam of radiation from a helium-neon laser is made to

1.4 This test method determines the integrated scattering

impinge on the surface of the specimen. First, the specular

from an angle approximately 2.5° from the surface normal to

reflectance is measured. Next, the power of the radiation

an angle approximately 70° from the surface normal.

scattered by the specimen is measured by focussing the

1.5 The test method is performed with a helium-neon laser

scattered radiation onto a Si photovoltaic detector by means of

operating at the wavelength 632.8 nm.

a hemispherical mirror. The specimen is then replaced by a

1.6 Repeated use of this test method on different areas of the

diffuse reflectance standard and the measurement of the scat-

specimen permits mapping of the surface TIS.

tered power is repeated. The effective surface roughness is

1.7 This test method is nondestructive.

computed from the two scattered radiation measurements, the

1.8 The maintenance of a control chart to monitor the

specular reflectance of the specimen, and the total reflectance

stability of the measurement process is discussed in Annex A1.

of the standard. A control chart is established and maintained to

1.9 This standard does not purport to address all of the

monitor the stability of the measurement process over an

safety concerns, if any, associated with its use. It is the

extended period of time.

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

5. Significance and Use

bility of regulatory limitations prior to use. For specific hazard

5.1 The performance of optical components is affected by

statements see Section 8.

the degree to which these components scatter optical radiation.

5.2 The effective microroughness, h , may be computed

2. Referenced Documents

rms

from the TIS.

2.1 ASTM Standards:

5.3 This test method may be used in manufacture, quality

E 691 Practice for Conducting an Interlaboratory Test Pro-

2 control, and research.

gram to Determine the Precision of Test Methods

6. Interferences

6.1 Variations in detector response as a function of the angle

This test method is under the jurisdiction of ASTM Committee F01 on

Electronics, and is the direct responsibility of Subcommittee F01.06 on Silicon

Materials and Process Control.

Current edition approved May 29, 1987. Published August 1987. Available from the American National Standards Institute, Inc., 1430 Broad-

Annual Book of ASTM Standards, Vol 14.02. way, New York, NY 10018.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

F 1048

of incidence can affect the precision of the measurement. with a range of gain settings appropriate for accommodating

6.2 Flaws or contaminants on the surface can produce the range of signals originating from the detector. The

scattering which is not characteristic of the microroughness of amplifier-detector combination shall have a linear response

the surface. within 610 % and reproducibility of 65 % over the required

6.3 Stray background radiation will affect the precision of range of measurement.

measurement. 7.8 Diffuse Reflectance Standard—A diffuse reflector of

6.4 Detector offset voltages will affect the precision of known total reflectance, r .

RS

measurement.

NOTE 1—Commonly used diffuse reflectance standards are fabri-cated

6.5 Degradation of the diffuse reflectance standard will

from barium sulfate or polytetrafluoroethylene powders. The total reflec-

degrade the precision of measurement.

tance of reflectors freshly prepared from these materials is typically

6.6 Degradation of the specular reflectance standard can greater than 0.98; therefore, a reflectance value of 0.98 for such reflectors

is adequate for the purposes of this test method.

cause the control chart to indicate lack of experimental control.

7.9 Polished Reflectance Standard—An optically polished

7. Apparatus

metallic mirror to be maintained in a protected environment to

7.1 Laser—He-Ne type, operating in the TEM mode at

prevent degradation of polish.

wavelength 632.8 nm, having a beam diameter of 1 mm or less,

NOTE 2—A polished stainless steel mirror preserved in a covered glass

a beam divergence of 5 mr or less and an output power of

petri dish would be adequate for this test method.

approximately 2 m W.

7.2 Detector—Silicon photovoltaic type having a dynamic

8. Hazards

5 2

range of 10 , with a sensitive area of 2 mm or greater, and in

8.1 Warning: Lasers with an output power on the order of

a housing less than 10 mm in diameter. The detector shall be

1 mW or greater can cause injury to personnel. The provisions

equipped with a diffuser or other means to minimize variation

of ANSI Z136.1 should be followed.

of signal with the position of the image on the detector, with

8.2 Warning: Do not let the unexpanded laser beam im-

angle of incidence, and with polarization of the radiation.

pinge on the skin. In no case should the laser beam be viewed

7.3 Filters—Attenuation type to prevent detector saturation.

directly. Avoid looking directly into the beam or into a

7.4 Mirror—Spherical type having a radius of curvature 10

specularly reflected beam.

cm or greater and having an aperture at the center that shall

subtend an angle of 5° or less at the specimen. The outer 9. Sampling

diameter of the mirror shall allow for a collecting angle of 70°

9.1 The location of all measurement positions on the speci-

or greater relative to the specimen normal. The optical quality

men and the number of measurements to be performed at each

of the mirror shall be such that the irradiated portion of the

of these positions shall be agreed to by the parties to the test.

specimen is imaged fully within the detector area.

9.2 The number of test specimens and their manner of

7.5 Aperture Plate—Opaque type approximately 10 by 10

selection from a given lot shall be agreed to by the parties to

cm containing an aperture 3 mm in diameter and a target

the test.

symbol located 10 mm from the aperture center. See Fig. 1 for

10. Procedure

schematic of aperture plate.

10.1 Align laser beam, aperture pla

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.