ASTM D3886-99(2007)e1

(Test Method)Standard Test Method for Abrasion Resistance of Textile Fabrics (Inflated Diaphragm Apparatus)

Standard Test Method for Abrasion Resistance of Textile Fabrics (Inflated Diaphragm Apparatus)

SCOPE

1.1 This test method covers the determination of the resistance to abrasion of woven and knitted textile fabrics, both conditioned and wet, using the inflated diaphragm tester. This procedure is not applicable to floor coverings. Note 1 - Other procedures for measuring the abrasion resistance of textile fabrics are given in Test Methods D 3884, D 3885, D 1175, and AATCC Test Method 93.

1.2 The values stated in SI units are to be regarded as standard; the values in English units are provided as information only and are not exact equivalents.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation: D3886 – 99 (Reapproved 2007)

Standard Test Method for

Abrasion Resistance of Textile Fabrics (Inflated Diaphragm

Apparatus)

This standard is issued under the fixed designation D3886; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

´ NOTE—Editorial changes were made in August 2007.

1. Scope D2906 Practice for Statements on Precision and Bias for

2 Textiles

1.1 This test method covers the determination of the

D3884 Test Method for Abrasion Resistance of Textile

resistance to abrasion of woven and knitted textile fabrics, both

Fabrics (Rotary Platform, Double-Head Method)

conditioned and wet, using the inflated diaphragm tester. This

D3885 Test Method for Abrasion Resistance of Textile

procedure is not applicable to floor coverings.

Fabrics (Flexing and Abrasion Method)

NOTE 1—Other procedures for measuring the abrasion resistance of

2.2 AATCC Standard:

textile fabrics are given in Test Methods D3884, D3885, D1175 and

TestMethod 93 AbrasionResistanceofFabrics:Accelerator

AATCC Test Method 93.

Method

1.2 The values stated in SI units are to be regarded as

3. Terminology

standard; the values in English units are provided as informa-

tion only and are not exact equivalents.

3.1 Definitions:

1.3 This standard does not purport to address all of the

3.1.1 abrasion, n—the wearing away of any part of a

safety concerns, if any, associated with its use. It is the

material by rubbing against another surface.

responsibility of the user of this standard to establish appro-

3.1.2 For definitions of other textile terms used in this test

priate safety and health practices and determine the applica-

method, refer to Terminology D123.

bility of regulatory limitations prior to use.

4. Summary of Test Method

2. Referenced Documents

4.1 A specimen is abraded by rubbing either unidirection-

2.1 ASTM Standards:

ally or multidirectionally against an abradant having specified

D123 Terminology Relating to Textiles

surface characteristics. A specimen is held in a fixed position

D1175 Discontinued 1982; Method of Test for Abrasion

and supported by an inflated rubber diaphragm which is held

Resistance of Textile Fabrics (Oscillatory Cylinder and

under constant pressure. A specimen is abraded by rubbing

Uniform Abrasion); Replaced by D 4157, D 4158

eitherunidirectionallyormultidirectionallyagainstanabradant

D1776 Practice for Conditioning and Testing Textiles

having specified surface characteristics. The resistance to

D2904 Practice for Interlaboratory Testing of a Textile Test

abrasion is determined using Option 1, the number of cycles to

Method that Produces Normally Distributed Data

wear a hole in the specimen, or Option 2, visual assessment of

the specimen surface after a specified number of cycles.

This test method is under the jurisdiction ofASTM Committee D13 onTextiles

5. Significance and Use

and is the direct responsibility of Subcommittee D13.60 on Fabric Test Methods,

Specific.

5.1 The measurement of the resistance to abrasion of textile

Current edition approved July 1, 2007. Published August 2007. Originally

and other materials is very complex.The resistance to abrasion

approved in 1980. Last previous edition approved in 2006 as D3886 – 99(2006).

is affected by many factors, such as the inherent mechanical

DOI: 10.1520/D3886-99R07E01.

properties of the fibers; the dimensions of the fibers; the

This test method is based upon the development described by R. G. Stoll, in

“Improved MultipurposeAbrasion Test and ItsApplication for the Wear Resistance

structure of the yarns; the construction of the fabrics; and the

of Textiles,” Textile Research Journal , July 1949, p. 394.

type,kind,andamountoffinishingmaterialaddedtothefibers,

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

yarns, or fabric.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

4 5

Withdrawn. The last approved version of this historical standard is referenced Available from American Association of Textile Chemists and Colorists, P.O.

on www.astm.org. Box 12215, Research Triangle Park, NC 27709.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

´1

D3886 – 99 (2007)

5.2 The resistance to abrasion is also greatly affected by the tance of various materials is large, but they should not be relied

conditions of the tests, such as the nature of abradant, variable upon where differences in laboratory test findings are small. In

action of the abradant over the area of specimen abraded, the general, they should not be relied upon for prediction of actual

tension of the specimen, the pressure between the specimen wear-life in specific end uses unless there are data showing the

and abradant, and the dimensional changes in the specimens. specific relationship between laboratory abrasion tests and

5.3 Abrasion tests are all subject to variation due to changes actual wear in the intended end-use.

in the abradant during specific tests. The abradant must 5.5 These general observations apply to all types of fabrics,

accordingly be discarded at frequent intervals or checked including woven, nonwoven, and knit apparel fabrics, house-

periodically against a standard. With disposable abradants, the hold fabrics, industrial fabrics, and floor coverings. It is not

abradant is used only once or discarded after limited use. With surprising, therefore, to find that there are many different types

permanent abradants that use hardened metal or equivalent of abrasion testing machines, abradants, testing conditions,

surfaces, it is assumed that the abradant will not change testing procedures, methods of evaluation of abrasion resis-

appreciably in a specific series of tests. Similar abradants used tance and interpretation of results.

in different laboratories will not change at the same rate, due to 5.6 All the test methods and instruments so far developed

differencesinusage.Permanentabradantsmayalsochangedue for measuring abrasion resistance may show a high degree of

to pick up of finishing or other material from test fabrics and variability in results obtained by different operators and in

must accordingly be cleaned at frequent intervals. The mea- different laboratories; however, they represent the test methods

surement of the relative amount of abrasion may also be now most widely in use.

affected by the method of evaluation and may be influenced by 5.7 Because there is a definite need for measuring the

the judgment of the operator. relative resistance to abrasion, standardized test methods are

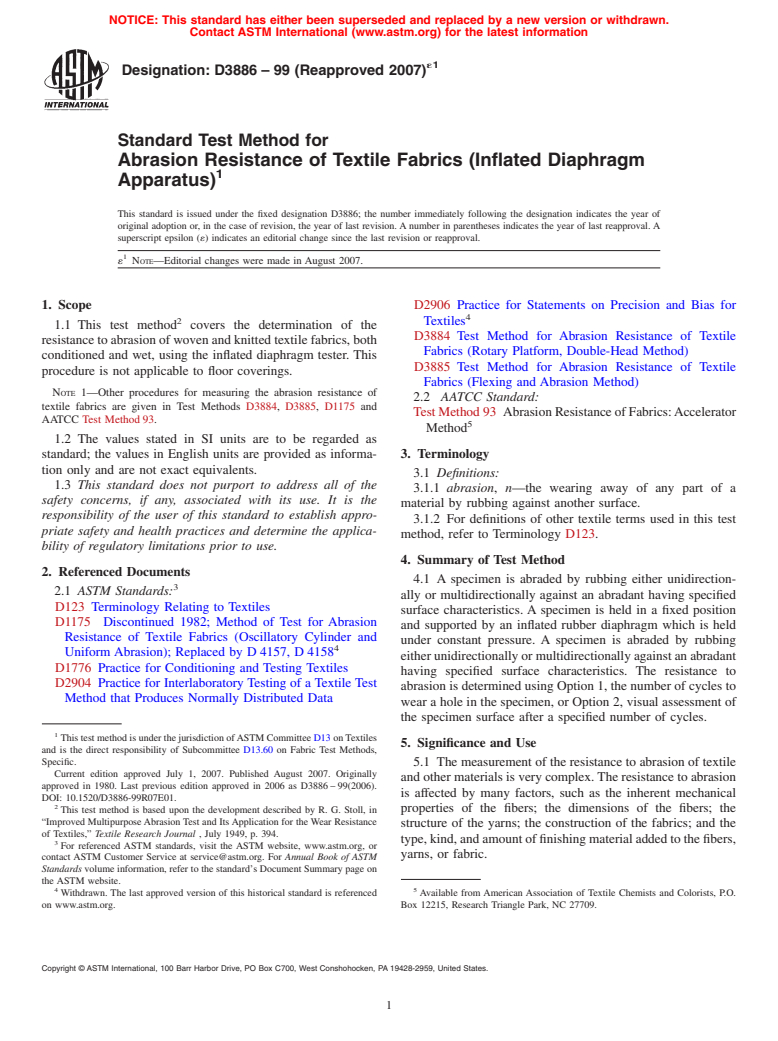

FIG. 1 Schematic Diagram of Inflated Diaphragm Abrasion Tester

5.4 The resistance of textile materials to abrasion as mea- needed and useful and may clarify the problem and lessen the

sured on a testing machine in the laboratory is generally only confusion.

one of several factors contributing to wear performance or 5.8 Because of the conditions mentioned above, technicians

durability as experienced in the actual use of the material. frequently fail to get good agreement between results obtained

While “abrasion resistance” (often stated in terms of the onthesametypeoftestinginstrumentbothwithinandbetween

number of cycles on a specified machine, using a specified laboratories, and the precision of these test methods is uncer-

technique to produce a specified degree or amount of abrasion) tain.

and “durability” (defined as the ability to withstand deteriora- 5.9 Test Method D3886 is not recommended for acceptance

tion or wearing out in use, including the effects of abrasion) are testing of commercial shipment because of the poor between-

frequently related, the relationship varies with different end laboratory precision.

uses, and different factors may be necessary in any calculation 5.9.1 In cases of a dispute arising from differences in

of predicted durability from specific abrasion data. Laboratory reported test results when using this test method for acceptance

tests may be reliable as an indication of relative end-use testing of commercial shipments, the purchaser and the sup-

performance in cases where the difference in abrasion resis- plier should conduct comparative tests to determine if there is

´1

D3886 – 99 (2007)

a statistical bias between their laboratories. Competent statis- specimen and leakage of air pressure during the test. Means

tical assistance is recommended for the investigation of bias. shouldbeprovidedforsupplyingairpressuretothebodyofthe

As a minimum, the two parties should take a group of test clamp so that the pressure under the diaphragm can be

specimens which are as homogeneous as possible and which controlled between 0 and 41 kPa (0 and 6 psi) with an accuracy

are from a lot of material of the type in question. The test

of 65 % of range.

specimens should then be randomly assigned in equal numbers

6.1.2 Diaphragm—The rubber diaphragm should be 1.40 6

to each laboratory for testing.The average results from the two

0.25 mm (0.055 6 0.010 in.) in thickness. A metallic contact

laboratories should be compared using appropriate statistical 1

pin 3.2 mm ( ⁄8 in.) in diameter is sealed into the center of the

analysis for unpaired data and an acceptable probability level

diaphragm flush with the diaphragm surface. Provision should

chosen by the two parties before the testing begins. If a bias is

be made for a flexible electrical connection from this contact

found, either its cause must be found and corrected or the

pin to the ground of the machine. The strain distribution on the

purchaser and the supplier must agree to interpret future test

diaphragm must be uniform so that when inflated without the

results in the light of the known bias.

specimen, it assumes the shape of a section of a sphere.

Pressure can be controlled from 0 to 41 kPa (0 to 6 psi).

6. Apparatus

6.1.3 Driving Mechanism—The design of the driving

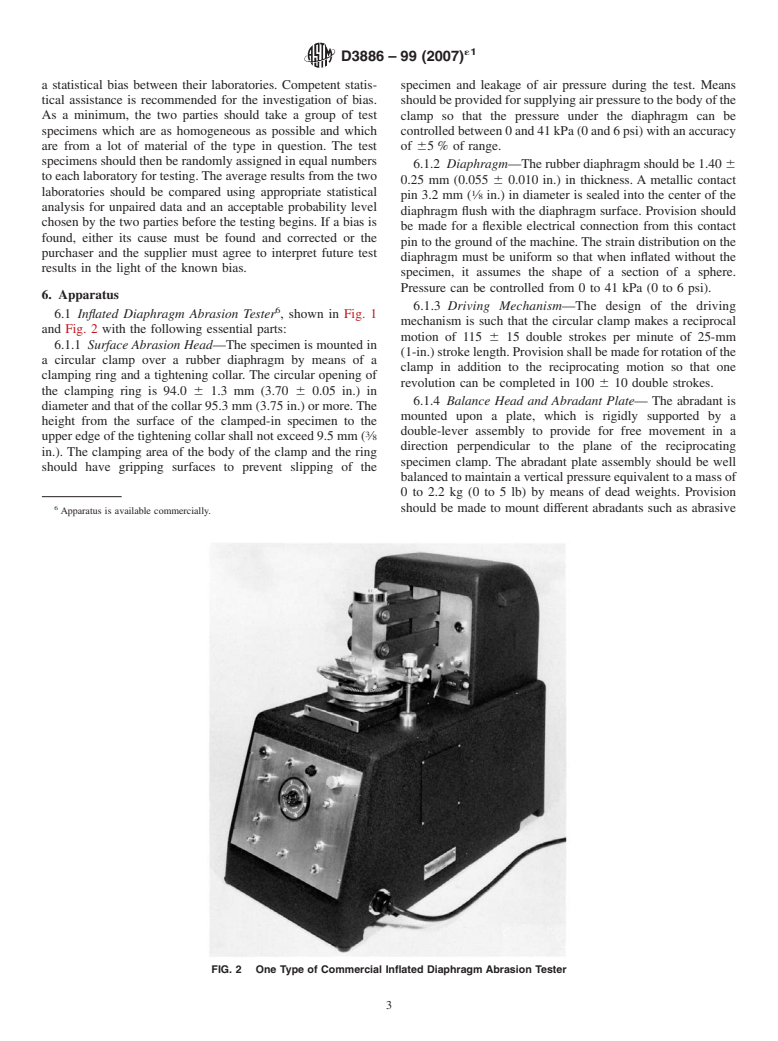

6.1 Inflated Diaphragm Abrasion Tester , shown in Fig. 1

mechanism is such that the circular clamp makes a reciprocal

and Fig. 2 with the following essential parts:

motion of 115 6 15 double strokes per minute of 25-mm

6.1.1 Surface Abrasion Head—The specimen is mounted in

(1-in.)strokelength.Provisionshallbemadeforrotationofthe

a circular clamp over a rubber diaphragm by means of a

clamp in addition to the reciprocating motion so that one

clamping ring and a tightening collar. The circular opening of

revolution can be completed in 100 6 10 double strokes.

the clamping ring is 94.0 6 1.3 mm (3.70 6 0.05 in.) in

6.1.4 Balance Head and Abradant Plate— The abradant is

diameter and that of the collar 95.3 mm (3.75 in.) or more.The

mounted upon a plate, which is rigidly supported by a

height from the surface of the clamped-in specimen to the

double-lever assembly to provide for free movement in a

upper edge of the tightening collar shall not exceed 9.5 mm ( ⁄8

direction perpendicular to the plane of the reciprocating

in.). The clamping area of the body of the clamp and the ring

specimen clamp. The abradant plate assembly should be well

should have gripping surfaces to prevent slipping of the

balanced to maintain a vertical pressure equivalent to a mass of

0 to 2.2 kg (0 to 5 lb) by means of dead weights. Provision

should be made to mount different abradants such as abrasive

Apparatus is available commercially.

FIG. 2 One Type of Commercial Inflated Diaphragm Abrasion Tester

´1

D3886 – 99 (2007)

paper, fabrics, etc., on this plate, and to stretch them into an 9.3 Place the abrasive paper or other abradant on the

even position. An electrically insulated contact pin, adjustable abradant plate under sufficient tension to be held smooth and in

tothethicknessoftheabradantismountedintothisplateonthe such a position that the contact pin, reaching through a hole in

length axis at one of the turning points of the center of the the abradant, is even with the surface of the abradant. No. 0

clamp. emery polishing paper is the standard abradant. The method

6.1.5 Some testers can also be equipped with a continuous may be modified to use other abradants but this information

changing abradant head which is optional. should be included in the final report.

NOTE 4—If the continuous changing abradant head is used, it should be

NOTE 2—Themachinemanufacturerdoesnotprovideadequateinstruc-

noted that, although the weight of the head is counter-balanced, the

tions for the use of the continuous changing abradant head. Work is being

balance changes during use as the paper passes from the back roll to the

done with the manufacturer to write a set of instructions.

front roll unless the continuous changing abradant head is used.

6.1.6 Machine Stopping Mechanism—Contact between the

NOTE 5—Unless the continuous changing abradant head is used, it is

adjustable pin on the lower side of the abradant plate and the

recommended that the abradant paper be changed at some regular

contact pin inserted into the center of the diaphragm closes a frequency,suchasevery100to300cycles.Asthisfrequencyisdependent

upon the type of fabric being tested, the task group is working on devising

low-voltage circuit and stops the machine.

a more extensive system.

6.1.7 Indicators—Means should be provided for indicating

9.4 Set the air pressure under the diaphragm and force on

the diaphragm pressure, and the number of abrasion cycles (1

the abradant plate. The air pressure should be 28 kPa (4 psi)

cycle = 1 double stroke).

and the load on the abradant should be 454 g (1 lb). Be sure

6.1.8 Fig. 2 shows a commercially available machine that

that the air pressure control and contact between inflated

conforms to the requirements of this method.

specimen and loaded abradant is in a state of equilibrium

before abrasion is started. To ensure consistent inflation of the

7. Sampling

diaphragm, inflate to a higher air pressure (25 %) and then

7.1 Lot Sample—As a lot sample for acceptance testing,

reduce to testing pressure.

take at random the number of rolls of fabric directed in an

9.5 Direction of Abrasion:

applicable material specification or other agreement between

9.5.1 Standard Multidirection—Engage the rotation mecha-

thepurchaserandthesupplier.Considerrollsoffabrictobethe

nism of the specimen clamp.

primary sampling unit.

9.5.2 Unidirection—When this is used, disengage the rota-

NOTE 3—An adequate specification or other agreement between the

tion mechanism of

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.