ASTM E986-04(2017)

(Practice)Standard Practice for Scanning Electron Microscope Beam Size Characterization

Standard Practice for Scanning Electron Microscope Beam Size Characterization

SIGNIFICANCE AND USE

4.1 The traditional resolution test of the SEM requires, as a first step, a photomicrograph of a fine particulate sample taken at a high magnification. The operator is required to measure a distance on the photomicrograph between two adjacent, but separate edges. These edges are usually less than one millimetre apart. Their image quality is often less than optimum limited by the S/N ratio of a beam with such a small diameter and low current. Operator judgment is dependent on the individual acuity of the person making the measurement and can vary significantly.

4.2 Use of this practice results in SEM electron beam size characterization which is significantly more reproducible than the traditional resolution test using a fine particulate sample.

SCOPE

1.1 This practice provides a reproducible means by which one aspect of the performance of a scanning electron microscope (SEM) may be characterized. The resolution of an SEM depends on many factors, some of which are electron beam voltage and current, lens aberrations, contrast in the specimen, and operator-instrument-material interaction. However, the resolution for any set of conditions is limited by the size of the electron beam. This size can be quantified through the measurement of an effective apparent edge sharpness for a number of materials, two of which are suggested. This practice requires an SEM with the capability to perform line-scan traces, for example, Y-deflection waveform generation, for the suggested materials. The range of SEM magnification at which this practice is of utility is from 1000 to 50 000 × . Higher magnifications may be attempted, but difficulty in making precise measurements can be expected.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.3 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: E986 − 04 (Reapproved 2017)

Standard Practice for

Scanning Electron Microscope Beam Size Characterization

This standard is issued under the fixed designation E986; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Terminology

1.1 This practice provides a reproducible means by which 3.1 Definitions: For definitions of terms used in this

one aspect of the performance of a scanning electron micro- practice, see Terminology E7.

scope (SEM) may be characterized. The resolution of an SEM

3.2 Definitions of Terms Specific to This Standard:

depends on many factors, some of which are electron beam

3.2.1 Y-deflection waveform—the trace on a CRT resulting

voltage and current, lens aberrations, contrast in the specimen,

from modulating the CRT with the output of the electron

and operator-instrument-material interaction. However, the

detector. Contrast in the electron signal is displayed as a

resolution for any set of conditions is limited by the size of the

changein Y(vertical)ratherthanbrightnessonthescreen.This

electron beam. This size can be quantified through the mea-

operating method is often called Y-modulation.

surement of an effective apparent edge sharpness for a number

ofmaterials,twoofwhicharesuggested.Thispracticerequires 4. Significance and Use

an SEM with the capability to perform line-scan traces, for

4.1 The traditional resolution test of the SEM requires, as a

example, Y-deflection waveform generation, for the suggested

first step, a photomicrograph of a fine particulate sample taken

materials. The range of SEM magnification at which this

at a high magnification. The operator is required to measure a

practice is of utility is from 1000 to 50000×. Higher

distance on the photomicrograph between two adjacent, but

magnifications may be attempted, but difficulty in making

separate edges. These edges are usually less than one millime-

precise measurements can be expected.

tre apart. Their image quality is often less than optimum

1.2 This standard does not purport to address all of the

limited by the S/N ratio of a beam with such a small diameter

safety concerns, if any, associated with its use. It is the

and low current. Operator judgment is dependent on the

responsibility of the user of this standard to establish appro-

individual acuity of the person making the measurement and

priate safety and health practices and determine the applica-

can vary significantly.

bility of regulatory limitations prior to use.

4.2 Use of this practice results in SEM electron beam size

1.3 This international standard was developed in accor-

characterization which is significantly more reproducible than

dance with internationally recognized principles on standard-

the traditional resolution test using a fine particulate sample.

ization established in the Decision on Principles for the

Development of International Standards, Guides and Recom-

5. Suggested Materials

mendations issued by the World Trade Organization Technical

5.1 SEM resolution performance as measured using the

Barriers to Trade (TBT) Committee.

procedurespecifiedinthispracticewilldependonthematerial

used; hence, only comparisons using the same material have

2. Referenced Documents

meaning. There are a number of criteria for a suitable material

2.1 ASTM Standards:

to be used in this practice. Through an evaluation of these

E7Terminology Relating to Metallography

criteria, two samples have been suggested. These samples are

E766Practice for Calibrating the Magnification of a Scan-

nonmagnetic; no surface preparation or coating is required;

ning Electron Microscope

thus, the samples have long-term structural stability. The

sample-electron beam interaction should produce a sharply

rising signal without inflections as the beam scans across the

This practice is under the jurisdiction of ASTM Committee E04 on Metallog-

raphy and is the direct responsibility of Subcommittee E04.11 on X-Ray and

edge. Two such samples are:

Electron Metallography. 3

5.1.1 Carbon fibers, NIST—SRM 2069B.

Current edition approved June 1, 2017. Published June 2017. Originally

5.1.2 Fracture edge of a thin silicon wafer, cleaved on a

approvedin1984.Lastpreviouseditionapprovedin2010asE986–04(2010).DOI:

10.1520/E0986-04R17. (111) plane.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on Available from National Institute of Standards and Technology (NIST), 100

the ASTM website. Bureau Dr., Stop 1070, Gaithersburg, MD 20899-1070, http://www.nist.gov.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E986 − 04 (2017)

6. Procedure

6.1 Inspect the specimen for cleanliness. If the specimen

appears contaminated, a new sample is recommended as any

cleaningmayadverselyaffectthequalityofthespecimenedge.

6.2 Ensure good electrical contact with the specimen by

using a conductive cement to hold the specimen on a SEM

stub, or by clamping the specimen on the stage of the SEM.

MountthespecimenrigidlyintheSEMtominimizeanyimage

degradation caused by vibration.

6.3 Verify magnification calibration for both X and Y direc-

tions. This can be accomplished by using Practice E766.

−2 −4

6.4 Use a clean vacuum of 1.33 by 10 Pa (10 mm Hg)

or better to minimize specimen contamination resulting from

electron beam and residual hydrocarbons interacting during

examination. The presence of a contamination layer has a

deleterious effect on image-edge quality.

6.5 Allow a minimum of 30 min for stabilization of elec-

tronic components, vacuum stability, and thermal equilibrium

fortheelectrongunandlenses.TheselectionofoptimumSEM

parameters is at the discretion of the operator. For measuring

the ultimate resolution, these will typically be: high kV

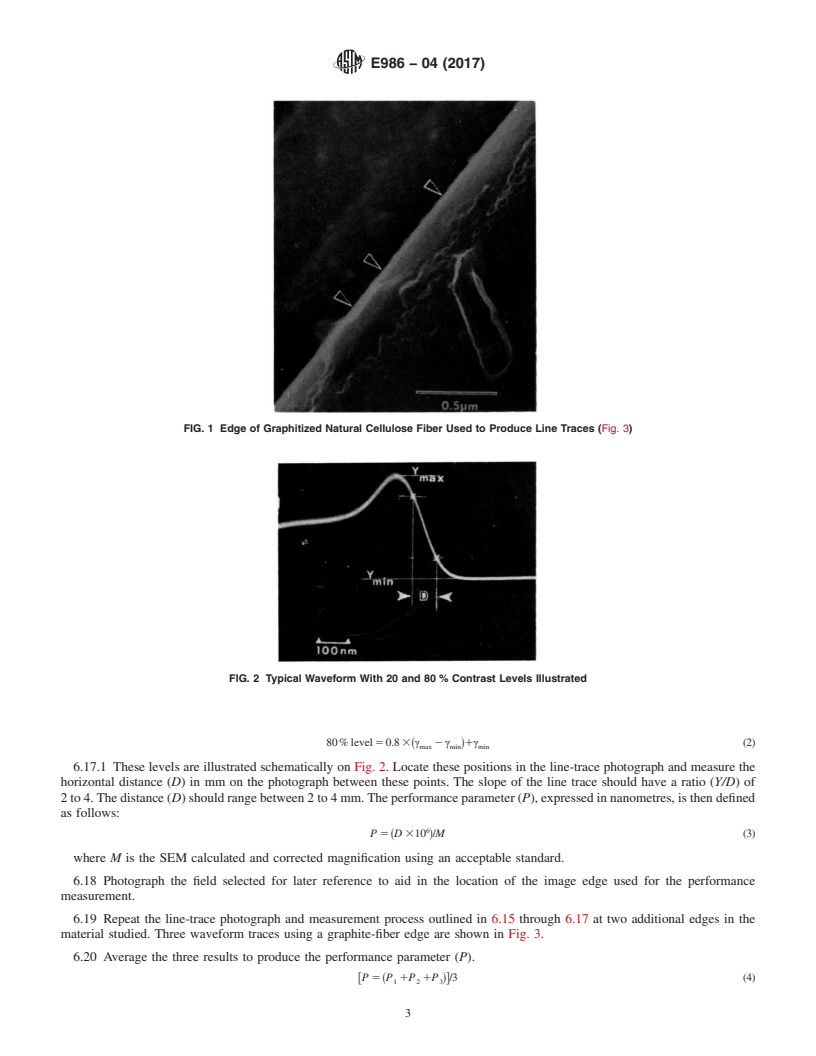

FIG. 1 Edge of Graphitized Natural Cellulose Fiber Used to Pro-

duce Line Traces (Fig. 3)

(~30max.), short working

...

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E986 − 04 (Reapproved 2017)

Standard Practice for

Scanning Electron Microscope Beam Size Characterization

This standard is issued under the fixed designation E986; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Terminology

1.1 This practice provides a reproducible means by which 3.1 Definitions: For definitions of terms used in this

one aspect of the performance of a scanning electron micro- practice, see Terminology E7.

scope (SEM) may be characterized. The resolution of an SEM

3.2 Definitions of Terms Specific to This Standard:

depends on many factors, some of which are electron beam

3.2.1 Y-deflection waveform—the trace on a CRT resulting

voltage and current, lens aberrations, contrast in the specimen,

from modulating the CRT with the output of the electron

and operator-instrument-material interaction. However, the

detector. Contrast in the electron signal is displayed as a

resolution for any set of conditions is limited by the size of the

change in Y (vertical) rather than brightness on the screen. This

electron beam. This size can be quantified through the mea-

operating method is often called Y-modulation.

surement of an effective apparent edge sharpness for a number

of materials, two of which are suggested. This practice requires

4. Significance and Use

an SEM with the capability to perform line-scan traces, for

4.1 The traditional resolution test of the SEM requires, as a

example, Y-deflection waveform generation, for the suggested

first step, a photomicrograph of a fine particulate sample taken

materials. The range of SEM magnification at which this

at a high magnification. The operator is required to measure a

practice is of utility is from 1000 to 50 000 × . Higher

distance on the photomicrograph between two adjacent, but

magnifications may be attempted, but difficulty in making

separate edges. These edges are usually less than one millime-

precise measurements can be expected.

tre apart. Their image quality is often less than optimum

1.2 This standard does not purport to address all of the

limited by the S/N ratio of a beam with such a small diameter

safety concerns, if any, associated with its use. It is the

and low current. Operator judgment is dependent on the

responsibility of the user of this standard to establish appro-

individual acuity of the person making the measurement and

priate safety and health practices and determine the applica-

can vary significantly.

bility of regulatory limitations prior to use.

4.2 Use of this practice results in SEM electron beam size

1.3 This international standard was developed in accor-

characterization which is significantly more reproducible than

dance with internationally recognized principles on standard-

the traditional resolution test using a fine particulate sample.

ization established in the Decision on Principles for the

Development of International Standards, Guides and Recom-

5. Suggested Materials

mendations issued by the World Trade Organization Technical

5.1 SEM resolution performance as measured using the

Barriers to Trade (TBT) Committee.

procedure specified in this practice will depend on the material

used; hence, only comparisons using the same material have

2. Referenced Documents

meaning. There are a number of criteria for a suitable material

2.1 ASTM Standards:

to be used in this practice. Through an evaluation of these

E7 Terminology Relating to Metallography

criteria, two samples have been suggested. These samples are

E766 Practice for Calibrating the Magnification of a Scan-

nonmagnetic; no surface preparation or coating is required;

ning Electron Microscope

thus, the samples have long-term structural stability. The

sample-electron beam interaction should produce a sharply

rising signal without inflections as the beam scans across the

This practice is under the jurisdiction of ASTM Committee E04 on Metallog-

raphy and is the direct responsibility of Subcommittee E04.11 on X-Ray and

edge. Two such samples are:

Electron Metallography.

5.1.1 Carbon fibers, NIST—SRM 2069B.

Current edition approved June 1, 2017. Published June 2017. Originally

5.1.2 Fracture edge of a thin silicon wafer, cleaved on a

approved in 1984. Last previous edition approved in 2010 as E986 – 04(2010). DOI:

(111) plane.

10.1520/E0986-04R17.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on Available from National Institute of Standards and Technology (NIST), 100

the ASTM website. Bureau Dr., Stop 1070, Gaithersburg, MD 20899-1070, http://www.nist.gov.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E986 − 04 (2017)

6. Procedure

6.1 Inspect the specimen for cleanliness. If the specimen

appears contaminated, a new sample is recommended as any

cleaning may adversely affect the quality of the specimen edge.

6.2 Ensure good electrical contact with the specimen by

using a conductive cement to hold the specimen on a SEM

stub, or by clamping the specimen on the stage of the SEM.

Mount the specimen rigidly in the SEM to minimize any image

degradation caused by vibration.

6.3 Verify magnification calibration for both X and Y direc-

tions. This can be accomplished by using Practice E766.

− 2 − 4

6.4 Use a clean vacuum of 1.33 by 10 Pa (10 mm Hg)

or better to minimize specimen contamination resulting from

electron beam and residual hydrocarbons interacting during

examination. The presence of a contamination layer has a

deleterious effect on image-edge quality.

6.5 Allow a minimum of 30 min for stabilization of elec-

tronic components, vacuum stability, and thermal equilibrium

for the electron gun and lenses. The selection of optimum SEM

parameters is at the discretion of the operator. For measuring

the ultimate resolution, these will typically be: high kV

FIG. 1 Edge of Graphitized Natural Cellulose Fiber Used to Pro-

duce Line Traces (Fig. 3)

(~30max.), short working distance (5 to 10 mm), smallest spot

size, and long scan time.

6.6 Any alternative set

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: E986 − 04 (Reapproved 2010) E986 − 04 (Reapproved 2017)

Standard Practice for

Scanning Electron Microscope Beam Size Characterization

This standard is issued under the fixed designation E986; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This practice provides a reproducible means by which one aspect of the performance of a scanning electron microscope

(SEM) may be characterized. The resolution of an SEM depends on many factors, some of which are electron beam voltage and

current, lens aberrations, contrast in the specimen, and operator-instrument-material interaction. However, the resolution for any

set of conditions is limited by the size of the electron beam. This size can be quantified through the measurement of an effective

apparent edge sharpness for a number of materials, two of which are suggested. This practice requires an SEM with the capability

to perform line-scan traces, for example, Y-deflection waveform generation, for the suggested materials. The range of SEM

magnification at which this practice is of utility is from 1000 to 50 000 × . Higher magnifications may be attempted, but difficulty

in making precise measurements can be expected.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

1.3 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2.1 ASTM Standards:

E7 Terminology Relating to Metallography

E766 Practice for Calibrating the Magnification of a Scanning Electron Microscope

3. Terminology

3.1 Definitions: For definitions of terms used in this practice, see Terminology E7.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 Y-deflection waveform—the trace on a CRT resulting from modulating the CRT with the output of the electron detector.

Contrast in the electron signal is displayed as a change in Y (vertical) rather than brightness on the screen. This operating method

is often called Y-modulation.

4. Significance and Use

4.1 The traditional resolution test of the SEM requires, as a first step, a photomicrograph of a fine particulate sample taken at

a high magnification. The operator is required to measure a distance on the photomicrograph between two adjacent, but separate

edges. These edges are usually less than one millimetre apart. Their image quality is often less than optimum limited by the S/N

ratio of a beam with such a small diameter and low current. Operator judgment is dependent on the individual acuity of the person

making the measurement and can vary significantly.

4.2 Use of this practice results in SEM electron beam size characterization which is significantly more reproducible than the

traditional resolution test using a fine particulate sample.

This practice is under the jurisdiction of ASTM Committee E04 on Metallography and is the direct responsibility of Subcommittee E04.11 on X-Ray and Electron

Metallography.

Current edition approved April 1, 2010June 1, 2017. Published May 2010 June 2017. Originally approved in 1984. Last previous edition approved in 20042010 as

E986 – 04.E986 – 04(2010). DOI: 10.1520/E0986-04R10.10.1520/E0986-04R17.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E986 − 04 (2017)

5. Suggested Materials

5.1 SEM resolution performance as measured using the procedure specified in this practice will depend on the material used;

hence, only comparisons using the same material have meaning. There are a number of criteria for a suitable material to be used

in this practice. Through an evaluation of these criteria, two samples have been suggested. These samples are nonmagnetic; no

surface preparation or coating is required; thus, the samples have long-term structural stability. The sample-electron beam

interaction should produce a sharply rising signal without inflections as the beam scans across the edge. Two such samples are:

5.1.1 Carbon fibers, NIST—SRM 2069B.

5.1.2 Fracture edge of a thin silicon wafer, cleaved on a (111) plane.

6. Procedure

6.1 Inspect the specimen for cleanliness. If the specimen appears contaminated, a new sample is recommended as any cleaning

may adversely affect the quality of the specimen edge.

6.2 Ensure good electrical contact with the specimen by using a conductive cement to hold the specimen on a SEM stub, or by

clamping the specimen on the stage of the SEM. Mount the specimen rigidly in the SEM to minimize any image degradation

caused by vibration.

6.3 Verify magnification calibration for both X and Y directions. This can be accomplished by using Practice E766.

− 2 − 4

6.4 Use a clean vacuum of 1.33 by 10 Pa (10 mm Hg) or better to minimize specimen contamination resulting from electron

beam and residual hydrocarbons interacting during examination. The presence of a contamination layer has a deleterious effect on

image-edge quality.

6.5 Allow a minimum of 30 min for stabilization of electronic components, vacuum stability, and thermal equilibrium for the

electron gun and lenses. The selection of optimum SEM parameters is at the discretion of the operator. For measuring the ultimate

resolution, these will typically be: high kV (~30max.), short working distance (5 to 10 mm), smallest spot size, and long scan time.

6.6 Any alternative set of conditions can be used to measure probe size, but they will measure beam diameter under those

specific

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.